Impact of Isocyanates on Global Environmental Goals

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Technology Evolution and Objectives

Isocyanates have played a pivotal role in the chemical industry since their discovery in the early 20th century. The evolution of isocyanate technology has been driven by the increasing demand for polyurethane products across various sectors, including construction, automotive, and consumer goods. This technological progression has been marked by significant milestones, from the initial synthesis of isocyanates to the development of more efficient and environmentally friendly production methods.

The primary objective of isocyanate technology has been to enhance the performance and versatility of polyurethane materials while addressing environmental concerns. Over the years, researchers and industry professionals have focused on improving the reactivity, stability, and functionality of isocyanates to meet evolving market demands and regulatory requirements. This has led to the creation of a diverse range of isocyanate compounds, each tailored for specific applications and performance characteristics.

In recent decades, the isocyanate industry has faced increasing scrutiny due to the potential environmental and health impacts associated with these chemicals. As a result, a significant shift in technological objectives has occurred, with a greater emphasis on developing sustainable alternatives and minimizing the ecological footprint of isocyanate production and use. This has spurred innovation in areas such as bio-based isocyanates, low-emission formulations, and improved end-of-life recyclability for polyurethane products.

The global push towards environmental sustainability has further shaped the trajectory of isocyanate technology. Current research and development efforts are largely focused on aligning isocyanate production and application with international environmental goals, such as reducing greenhouse gas emissions, minimizing waste, and promoting circular economy principles. This has led to the exploration of novel synthesis routes, the optimization of production processes to reduce energy consumption, and the development of isocyanate-free alternatives for certain applications.

As we look towards the future, the objectives of isocyanate technology are increasingly intertwined with broader environmental and societal goals. The industry is striving to balance the continued demand for high-performance polyurethane materials with the imperative to mitigate environmental impacts. This includes efforts to enhance the biodegradability of polyurethane products, improve recycling technologies, and develop isocyanates from renewable feedstocks. The ultimate aim is to position isocyanate technology as a contributor to, rather than a detractor from, global sustainability efforts.

The primary objective of isocyanate technology has been to enhance the performance and versatility of polyurethane materials while addressing environmental concerns. Over the years, researchers and industry professionals have focused on improving the reactivity, stability, and functionality of isocyanates to meet evolving market demands and regulatory requirements. This has led to the creation of a diverse range of isocyanate compounds, each tailored for specific applications and performance characteristics.

In recent decades, the isocyanate industry has faced increasing scrutiny due to the potential environmental and health impacts associated with these chemicals. As a result, a significant shift in technological objectives has occurred, with a greater emphasis on developing sustainable alternatives and minimizing the ecological footprint of isocyanate production and use. This has spurred innovation in areas such as bio-based isocyanates, low-emission formulations, and improved end-of-life recyclability for polyurethane products.

The global push towards environmental sustainability has further shaped the trajectory of isocyanate technology. Current research and development efforts are largely focused on aligning isocyanate production and application with international environmental goals, such as reducing greenhouse gas emissions, minimizing waste, and promoting circular economy principles. This has led to the exploration of novel synthesis routes, the optimization of production processes to reduce energy consumption, and the development of isocyanate-free alternatives for certain applications.

As we look towards the future, the objectives of isocyanate technology are increasingly intertwined with broader environmental and societal goals. The industry is striving to balance the continued demand for high-performance polyurethane materials with the imperative to mitigate environmental impacts. This includes efforts to enhance the biodegradability of polyurethane products, improve recycling technologies, and develop isocyanates from renewable feedstocks. The ultimate aim is to position isocyanate technology as a contributor to, rather than a detractor from, global sustainability efforts.

Market Demand Analysis for Isocyanate Alternatives

The global market for isocyanate alternatives is experiencing significant growth driven by increasing environmental concerns and stringent regulations surrounding traditional isocyanates. As governments and industries worldwide strive to meet global environmental goals, the demand for safer, more sustainable alternatives to isocyanates is surging across various sectors.

In the construction industry, which accounts for a substantial portion of isocyanate consumption, there is a growing preference for eco-friendly insulation materials and adhesives. This shift is particularly evident in developed markets where green building certifications and energy efficiency standards are becoming more prevalent. The automotive sector is another major driver of demand for isocyanate alternatives, as manufacturers seek to reduce the environmental impact of their production processes and end products.

The packaging industry is also contributing to the increased demand for isocyanate alternatives, especially in food-contact applications where safety concerns are paramount. As consumers become more environmentally conscious, there is a growing market for biodegradable and recyclable packaging solutions that do not rely on traditional isocyanates.

In the furniture and bedding sector, there is a notable trend towards using plant-based polyols and other bio-based alternatives to isocyanates in the production of foams and adhesives. This shift is driven by both consumer preferences for "green" products and regulatory pressures to reduce volatile organic compound (VOC) emissions.

The medical and healthcare industries are also exploring isocyanate alternatives, particularly for applications in wound care, medical devices, and hospital furnishings. This is driven by concerns over potential health risks associated with isocyanate exposure and the need for materials that can withstand rigorous sterilization processes.

Geographically, the demand for isocyanate alternatives is most pronounced in regions with strict environmental regulations, such as the European Union and North America. However, emerging economies in Asia-Pacific are also showing increased interest as they implement more stringent environmental policies and as local industries seek to compete in global markets with eco-friendly products.

The market for isocyanate alternatives is characterized by ongoing research and development efforts to improve performance characteristics and cost-effectiveness. While current alternatives may not yet match the versatility and performance of traditional isocyanates in all applications, the gap is narrowing as technology advances. This ongoing innovation is expected to further drive market growth and adoption of isocyanate alternatives across industries in the coming years.

In the construction industry, which accounts for a substantial portion of isocyanate consumption, there is a growing preference for eco-friendly insulation materials and adhesives. This shift is particularly evident in developed markets where green building certifications and energy efficiency standards are becoming more prevalent. The automotive sector is another major driver of demand for isocyanate alternatives, as manufacturers seek to reduce the environmental impact of their production processes and end products.

The packaging industry is also contributing to the increased demand for isocyanate alternatives, especially in food-contact applications where safety concerns are paramount. As consumers become more environmentally conscious, there is a growing market for biodegradable and recyclable packaging solutions that do not rely on traditional isocyanates.

In the furniture and bedding sector, there is a notable trend towards using plant-based polyols and other bio-based alternatives to isocyanates in the production of foams and adhesives. This shift is driven by both consumer preferences for "green" products and regulatory pressures to reduce volatile organic compound (VOC) emissions.

The medical and healthcare industries are also exploring isocyanate alternatives, particularly for applications in wound care, medical devices, and hospital furnishings. This is driven by concerns over potential health risks associated with isocyanate exposure and the need for materials that can withstand rigorous sterilization processes.

Geographically, the demand for isocyanate alternatives is most pronounced in regions with strict environmental regulations, such as the European Union and North America. However, emerging economies in Asia-Pacific are also showing increased interest as they implement more stringent environmental policies and as local industries seek to compete in global markets with eco-friendly products.

The market for isocyanate alternatives is characterized by ongoing research and development efforts to improve performance characteristics and cost-effectiveness. While current alternatives may not yet match the versatility and performance of traditional isocyanates in all applications, the gap is narrowing as technology advances. This ongoing innovation is expected to further drive market growth and adoption of isocyanate alternatives across industries in the coming years.

Current Challenges in Isocyanate Usage and Mitigation

The use of isocyanates in various industries poses significant challenges to global environmental goals. One of the primary concerns is their contribution to air pollution and the formation of ground-level ozone. Isocyanates are volatile organic compounds (VOCs) that can react with nitrogen oxides in the presence of sunlight, leading to smog formation. This not only impacts air quality but also contributes to respiratory issues in urban areas, conflicting with sustainable development goals related to health and well-being.

Another major challenge is the persistence of isocyanates in the environment. These compounds can contaminate soil and water systems, potentially affecting ecosystems and biodiversity. The bioaccumulation of isocyanates in aquatic organisms poses risks to marine life and can disrupt food chains, contradicting efforts to protect life below water and on land as outlined in global environmental objectives.

The production and disposal of isocyanate-containing products also present significant environmental hurdles. The manufacturing process of isocyanates is energy-intensive and often relies on fossil fuel-derived raw materials, contributing to greenhouse gas emissions and climate change. This conflicts with global goals to reduce carbon footprints and transition to more sustainable production methods.

Waste management of isocyanate-based products, particularly polyurethane foams and coatings, is another critical issue. These materials are not easily biodegradable and can release toxic substances when incinerated or left in landfills. This challenges the principles of circular economy and responsible consumption, which are integral to achieving global sustainability targets.

Occupational health risks associated with isocyanate exposure in industrial settings further complicate their usage. Workers in manufacturing, construction, and automotive industries are at risk of developing respiratory sensitization and asthma-like symptoms. This raises concerns about workplace safety and contradicts goals related to decent work conditions and economic growth.

Efforts to mitigate these challenges have led to the development of alternative materials and improved handling practices. However, the widespread use of isocyanates in various applications makes complete substitution difficult. Balancing the performance benefits of isocyanates with their environmental impact remains a complex issue, requiring ongoing research and innovation to align with global environmental objectives.

Regulatory frameworks aimed at controlling isocyanate usage and emissions vary globally, creating inconsistencies in environmental protection. Harmonizing these regulations and enforcing stricter controls on production, use, and disposal of isocyanates is crucial for addressing their environmental impact on a global scale. This aligns with the need for strong institutions and partnerships to achieve sustainable development goals.

Another major challenge is the persistence of isocyanates in the environment. These compounds can contaminate soil and water systems, potentially affecting ecosystems and biodiversity. The bioaccumulation of isocyanates in aquatic organisms poses risks to marine life and can disrupt food chains, contradicting efforts to protect life below water and on land as outlined in global environmental objectives.

The production and disposal of isocyanate-containing products also present significant environmental hurdles. The manufacturing process of isocyanates is energy-intensive and often relies on fossil fuel-derived raw materials, contributing to greenhouse gas emissions and climate change. This conflicts with global goals to reduce carbon footprints and transition to more sustainable production methods.

Waste management of isocyanate-based products, particularly polyurethane foams and coatings, is another critical issue. These materials are not easily biodegradable and can release toxic substances when incinerated or left in landfills. This challenges the principles of circular economy and responsible consumption, which are integral to achieving global sustainability targets.

Occupational health risks associated with isocyanate exposure in industrial settings further complicate their usage. Workers in manufacturing, construction, and automotive industries are at risk of developing respiratory sensitization and asthma-like symptoms. This raises concerns about workplace safety and contradicts goals related to decent work conditions and economic growth.

Efforts to mitigate these challenges have led to the development of alternative materials and improved handling practices. However, the widespread use of isocyanates in various applications makes complete substitution difficult. Balancing the performance benefits of isocyanates with their environmental impact remains a complex issue, requiring ongoing research and innovation to align with global environmental objectives.

Regulatory frameworks aimed at controlling isocyanate usage and emissions vary globally, creating inconsistencies in environmental protection. Harmonizing these regulations and enforcing stricter controls on production, use, and disposal of isocyanates is crucial for addressing their environmental impact on a global scale. This aligns with the need for strong institutions and partnerships to achieve sustainable development goals.

Existing Solutions for Reducing Isocyanate Impact

01 Synthesis and production of isocyanates

Various methods and processes for synthesizing and producing isocyanates are described. These include novel catalysts, reaction conditions, and precursor materials to improve yield, purity, and efficiency in isocyanate production.- Synthesis and production of isocyanates: Various methods and processes for synthesizing and producing isocyanates are described. These include novel catalysts, reaction conditions, and precursor materials to improve yield, purity, and efficiency in isocyanate production.

- Applications of isocyanates in polymer chemistry: Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents describe various formulations, curing methods, and applications of isocyanate-based polymers in coatings, adhesives, and foams.

- Isocyanate-free alternatives and environmentally friendly processes: Research into isocyanate-free alternatives and more environmentally friendly processes for producing similar materials is described. This includes novel chemistries and formulations that aim to reduce or eliminate the use of potentially harmful isocyanates.

- Isocyanate handling and safety measures: Patents related to the safe handling, storage, and use of isocyanates are included. This covers protective equipment, containment systems, and methods for reducing exposure risks associated with these reactive chemicals.

- Specialized isocyanate compounds and derivatives: Development of specialized isocyanate compounds and their derivatives for specific applications is described. This includes modified isocyanates with enhanced properties, blocked isocyanates for controlled reactivity, and novel isocyanate-containing molecules.

02 Applications of isocyanates in polymer chemistry

Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents describe various formulations, reaction conditions, and additives to optimize the properties of isocyanate-based polymers for different applications.Expand Specific Solutions03 Isocyanate-based coatings and adhesives

The use of isocyanates in coatings and adhesives is explored, detailing formulations, curing mechanisms, and additives to enhance performance characteristics such as durability, adhesion, and chemical resistance.Expand Specific Solutions04 Safety and handling of isocyanates

Given the reactive nature of isocyanates, several patents focus on improving safety in handling and storage. This includes developing stabilizers, protective equipment, and methods for detecting and neutralizing isocyanate vapors.Expand Specific Solutions05 Isocyanate-free alternatives and modifications

Some patents explore alternatives to traditional isocyanates or modifications to reduce their reactivity and potential health hazards. This includes developing blocked isocyanates, isocyanate-free polyurethanes, and alternative crosslinking chemistries.Expand Specific Solutions

Key Players in Isocyanate Production and Research

The impact of isocyanates on global environmental goals presents a complex competitive landscape. The industry is in a mature stage, with established players like BASF, Wanhua Chemical, and Covestro dominating the market. However, increasing environmental concerns are driving innovation and market shifts. The global isocyanates market size is substantial, valued at over $20 billion, with steady growth projected. Technologically, companies are focusing on developing eco-friendly alternatives and improving production processes to reduce environmental impact. Wanhua Chemical, BASF, and Covestro are leading in R&D efforts, while newer entrants like Mitsui Chemicals are gaining ground with sustainable solutions. The industry is at a critical juncture, balancing economic interests with environmental responsibilities.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical Group has developed innovative isocyanate production processes that significantly reduce environmental impact. Their MDI (methylene diphenyl diisocyanate) production utilizes a proprietary chlorine recycling technology, which reduces chlorine consumption by up to 35% compared to conventional methods[1]. Additionally, they have implemented a gas-phase phosgenation process that decreases energy consumption by approximately 20% and reduces carbon dioxide emissions by 140,000 tons annually[2]. Wanhua has also invested in water-based polyurethane technologies, which eliminate the need for organic solvents, thereby reducing volatile organic compound (VOC) emissions by up to 90%[3].

Strengths: Advanced chlorine recycling and gas-phase phosgenation technologies significantly reduce environmental impact. Water-based polyurethane solutions offer substantial VOC reduction. Weaknesses: Still reliant on fossil fuel-based raw materials for isocyanate production, which limits overall sustainability.

BASF Corp.

Technical Solution: BASF has developed a range of eco-friendly isocyanate technologies to address global environmental goals. Their Lupranate® ZERO MDI product line is manufactured using a proprietary process that reduces the carbon footprint by up to 40% compared to conventional MDI production[4]. BASF has also introduced bio-based polyurethane systems, incorporating renewable raw materials to partially replace fossil-based isocyanates. Their Elastollan® ECO series, for instance, contains up to 60% renewable content, reducing greenhouse gas emissions by up to 30%[5]. Furthermore, BASF has pioneered solvent-free polyurethane adhesive systems, which eliminate VOC emissions during application and curing processes[6].

Strengths: Significant carbon footprint reduction in MDI production. Integration of bio-based materials in polyurethane systems. Development of solvent-free adhesive solutions. Weaknesses: Complete replacement of fossil-based isocyanates with renewable alternatives remains a challenge.

Innovative Approaches to Isocyanate Alternatives

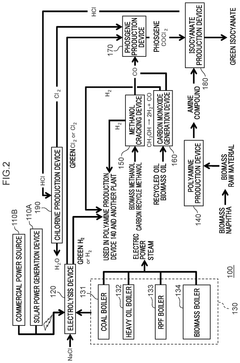

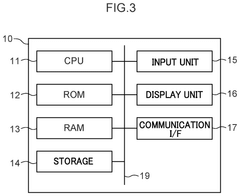

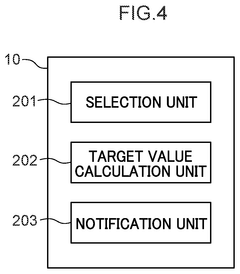

Isocyanate production system, isocyanate composition, polymerizable composition, resin, and molded article

PatentPendingUS20240343684A1

Innovation

- An isocyanate production system incorporating biomass boilers, carbon monoxide and hydrogen production from biomass or recycled methanol, and polyamine compounds derived from biomass raw materials, along with a control device that optimizes energy use and selects production methods to minimize environmental load, thereby reducing carbon dioxide emissions.

Sustainable preparation of organic amino compounds for the production of organic isocyanates

PatentWO2024017890A2

Innovation

- A process using green hydrogen and green ammonia to produce organic amino compounds, which are then used to synthesize isocyanates, incorporating renewable energy sources and reducing waste through closed-loop recycling of materials.

Global Environmental Policies and Isocyanate Regulation

Global environmental policies have increasingly focused on regulating isocyanates due to their significant impact on environmental goals. These policies aim to mitigate the adverse effects of isocyanates on air quality, water resources, and human health. The European Union has been at the forefront of isocyanate regulation, implementing stringent measures through the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) framework.

Under REACH, isocyanates are classified as substances of very high concern (SVHCs), requiring manufacturers and importers to register their use and provide detailed safety information. This regulation has led to increased transparency in the isocyanate supply chain and encouraged the development of safer alternatives. Additionally, the EU has set specific exposure limits for workers handling isocyanates, promoting occupational safety and reducing environmental contamination.

In North America, the United States Environmental Protection Agency (EPA) has implemented regulations under the Toxic Substances Control Act (TSCA) to monitor and control isocyanate production and use. The EPA requires manufacturers to report production volumes, exposure data, and environmental release information for isocyanates. These measures have contributed to a better understanding of isocyanate distribution in the environment and facilitated targeted interventions.

Asian countries, particularly China and Japan, have also strengthened their regulatory frameworks for isocyanates. China's Ministry of Ecology and Environment has introduced stricter emission standards for industrial facilities producing or using isocyanates, aligning with global efforts to reduce air and water pollution. Japan has implemented a comprehensive chemical management system that includes rigorous safety assessments for isocyanate-containing products.

International agreements, such as the Stockholm Convention on Persistent Organic Pollutants, have indirectly influenced isocyanate regulation by promoting the phase-out of certain chemicals used in their production. This has encouraged research into more environmentally friendly alternatives and production methods for isocyanates.

The global push for sustainable development has further shaped isocyanate regulations. Many countries have incorporated isocyanate management into their broader environmental protection strategies, emphasizing circular economy principles and waste reduction. This approach has led to increased investment in recycling technologies for isocyanate-based products and the development of bio-based alternatives.

As climate change concerns intensify, policies addressing isocyanates have begun to consider their carbon footprint and potential contributions to greenhouse gas emissions. Some jurisdictions have introduced carbon pricing mechanisms that indirectly affect isocyanate production, incentivizing manufacturers to adopt cleaner technologies and more efficient processes.

Under REACH, isocyanates are classified as substances of very high concern (SVHCs), requiring manufacturers and importers to register their use and provide detailed safety information. This regulation has led to increased transparency in the isocyanate supply chain and encouraged the development of safer alternatives. Additionally, the EU has set specific exposure limits for workers handling isocyanates, promoting occupational safety and reducing environmental contamination.

In North America, the United States Environmental Protection Agency (EPA) has implemented regulations under the Toxic Substances Control Act (TSCA) to monitor and control isocyanate production and use. The EPA requires manufacturers to report production volumes, exposure data, and environmental release information for isocyanates. These measures have contributed to a better understanding of isocyanate distribution in the environment and facilitated targeted interventions.

Asian countries, particularly China and Japan, have also strengthened their regulatory frameworks for isocyanates. China's Ministry of Ecology and Environment has introduced stricter emission standards for industrial facilities producing or using isocyanates, aligning with global efforts to reduce air and water pollution. Japan has implemented a comprehensive chemical management system that includes rigorous safety assessments for isocyanate-containing products.

International agreements, such as the Stockholm Convention on Persistent Organic Pollutants, have indirectly influenced isocyanate regulation by promoting the phase-out of certain chemicals used in their production. This has encouraged research into more environmentally friendly alternatives and production methods for isocyanates.

The global push for sustainable development has further shaped isocyanate regulations. Many countries have incorporated isocyanate management into their broader environmental protection strategies, emphasizing circular economy principles and waste reduction. This approach has led to increased investment in recycling technologies for isocyanate-based products and the development of bio-based alternatives.

As climate change concerns intensify, policies addressing isocyanates have begun to consider their carbon footprint and potential contributions to greenhouse gas emissions. Some jurisdictions have introduced carbon pricing mechanisms that indirectly affect isocyanate production, incentivizing manufacturers to adopt cleaner technologies and more efficient processes.

Life Cycle Assessment of Isocyanate-based Products

Life Cycle Assessment (LCA) of isocyanate-based products is a crucial tool for evaluating their environmental impact throughout their entire lifecycle. This comprehensive analysis encompasses raw material extraction, manufacturing processes, product use, and end-of-life disposal or recycling. The assessment typically focuses on key environmental indicators such as greenhouse gas emissions, energy consumption, water usage, and waste generation.

In the production phase, isocyanates require significant energy inputs and often involve the use of fossil fuel-derived raw materials. The manufacturing process can release volatile organic compounds (VOCs) and other potentially harmful emissions, which must be carefully controlled and mitigated. However, the durability and performance characteristics of isocyanate-based products often lead to extended lifespans, potentially offsetting some of the initial environmental costs.

During the use phase, isocyanate-based products, such as polyurethane insulation, can contribute to energy savings in buildings, thereby reducing overall environmental impact. This positive effect must be weighed against the potential release of harmful substances over time, particularly in the case of products that may degrade or off-gas.

End-of-life considerations for isocyanate-based products present significant challenges. Many of these materials are not easily recyclable and may require specialized disposal methods to prevent environmental contamination. Incineration is often employed but can lead to the release of toxic substances if not properly controlled.

Recent advancements in green chemistry have led to the development of bio-based isocyanates and alternative production methods that aim to reduce the environmental footprint of these products. These innovations include the use of renewable feedstocks and more energy-efficient manufacturing processes. However, the overall impact of these new approaches must be carefully evaluated through comprehensive LCAs to ensure they truly offer environmental benefits across the entire lifecycle.

Comparative LCAs between isocyanate-based products and alternative materials are essential for informed decision-making in various industries. These studies often reveal complex trade-offs between different environmental impacts, highlighting the importance of considering multiple factors when assessing sustainability. For instance, while an isocyanate-based insulation material might have a higher production-phase impact, its superior insulating properties could lead to significant energy savings over its lifetime, potentially resulting in a net positive environmental effect.

In the production phase, isocyanates require significant energy inputs and often involve the use of fossil fuel-derived raw materials. The manufacturing process can release volatile organic compounds (VOCs) and other potentially harmful emissions, which must be carefully controlled and mitigated. However, the durability and performance characteristics of isocyanate-based products often lead to extended lifespans, potentially offsetting some of the initial environmental costs.

During the use phase, isocyanate-based products, such as polyurethane insulation, can contribute to energy savings in buildings, thereby reducing overall environmental impact. This positive effect must be weighed against the potential release of harmful substances over time, particularly in the case of products that may degrade or off-gas.

End-of-life considerations for isocyanate-based products present significant challenges. Many of these materials are not easily recyclable and may require specialized disposal methods to prevent environmental contamination. Incineration is often employed but can lead to the release of toxic substances if not properly controlled.

Recent advancements in green chemistry have led to the development of bio-based isocyanates and alternative production methods that aim to reduce the environmental footprint of these products. These innovations include the use of renewable feedstocks and more energy-efficient manufacturing processes. However, the overall impact of these new approaches must be carefully evaluated through comprehensive LCAs to ensure they truly offer environmental benefits across the entire lifecycle.

Comparative LCAs between isocyanate-based products and alternative materials are essential for informed decision-making in various industries. These studies often reveal complex trade-offs between different environmental impacts, highlighting the importance of considering multiple factors when assessing sustainability. For instance, while an isocyanate-based insulation material might have a higher production-phase impact, its superior insulating properties could lead to significant energy savings over its lifetime, potentially resulting in a net positive environmental effect.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!