How Isocyanates Drive Material Science Frontier Advancements?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Tech Evolution

Isocyanates have played a pivotal role in driving material science advancements since their discovery in the early 20th century. The evolution of isocyanate technology can be traced through several key milestones that have shaped the landscape of polymer chemistry and materials engineering.

In the 1930s, Otto Bayer's groundbreaking work led to the development of polyurethanes, marking the beginning of the isocyanate revolution in material science. This discovery opened up a vast array of possibilities for creating versatile and customizable materials with unique properties. The 1940s and 1950s saw rapid expansion in isocyanate applications, particularly in the production of foams, coatings, and adhesives.

The 1960s and 1970s witnessed significant advancements in isocyanate chemistry, with the introduction of new formulations and processing techniques. This period saw the development of rigid and flexible polyurethane foams, which found widespread use in insulation, automotive, and furniture industries. Concurrently, researchers explored the potential of isocyanates in creating high-performance elastomers and thermoplastic polyurethanes (TPUs).

The 1980s and 1990s were characterized by a focus on enhancing the environmental and safety aspects of isocyanate technology. This era saw the development of water-based polyurethane dispersions and low-VOC formulations, addressing growing concerns about environmental impact and worker safety. Additionally, the introduction of blocked isocyanates expanded the range of curing options and application methods.

The turn of the millennium brought about a new wave of innovation in isocyanate technology. Researchers began exploring bio-based and sustainable isocyanates, seeking alternatives to petroleum-derived raw materials. This period also saw advancements in nanotechnology, leading to the development of nanocomposite materials with enhanced properties.

In recent years, the focus has shifted towards smart and responsive materials based on isocyanate chemistry. Self-healing polymers, shape-memory materials, and stimuli-responsive coatings have emerged as frontier areas of research. Moreover, the integration of isocyanates with other cutting-edge technologies, such as 3D printing and wearable electronics, has opened up new avenues for material design and fabrication.

The ongoing evolution of isocyanate technology continues to push the boundaries of material science. Current research efforts are directed towards developing more efficient and sustainable production methods, exploring novel molecular structures, and fine-tuning material properties at the nanoscale. As we look to the future, isocyanates are poised to play a crucial role in addressing global challenges, from energy efficiency to healthcare, through innovative material solutions.

In the 1930s, Otto Bayer's groundbreaking work led to the development of polyurethanes, marking the beginning of the isocyanate revolution in material science. This discovery opened up a vast array of possibilities for creating versatile and customizable materials with unique properties. The 1940s and 1950s saw rapid expansion in isocyanate applications, particularly in the production of foams, coatings, and adhesives.

The 1960s and 1970s witnessed significant advancements in isocyanate chemistry, with the introduction of new formulations and processing techniques. This period saw the development of rigid and flexible polyurethane foams, which found widespread use in insulation, automotive, and furniture industries. Concurrently, researchers explored the potential of isocyanates in creating high-performance elastomers and thermoplastic polyurethanes (TPUs).

The 1980s and 1990s were characterized by a focus on enhancing the environmental and safety aspects of isocyanate technology. This era saw the development of water-based polyurethane dispersions and low-VOC formulations, addressing growing concerns about environmental impact and worker safety. Additionally, the introduction of blocked isocyanates expanded the range of curing options and application methods.

The turn of the millennium brought about a new wave of innovation in isocyanate technology. Researchers began exploring bio-based and sustainable isocyanates, seeking alternatives to petroleum-derived raw materials. This period also saw advancements in nanotechnology, leading to the development of nanocomposite materials with enhanced properties.

In recent years, the focus has shifted towards smart and responsive materials based on isocyanate chemistry. Self-healing polymers, shape-memory materials, and stimuli-responsive coatings have emerged as frontier areas of research. Moreover, the integration of isocyanates with other cutting-edge technologies, such as 3D printing and wearable electronics, has opened up new avenues for material design and fabrication.

The ongoing evolution of isocyanate technology continues to push the boundaries of material science. Current research efforts are directed towards developing more efficient and sustainable production methods, exploring novel molecular structures, and fine-tuning material properties at the nanoscale. As we look to the future, isocyanates are poised to play a crucial role in addressing global challenges, from energy efficiency to healthcare, through innovative material solutions.

Market Demand Analysis

The market demand for isocyanates continues to grow steadily, driven by their versatile applications in various industries. The global isocyanate market is projected to expand significantly in the coming years, with a compound annual growth rate (CAGR) exceeding 5% through 2025. This growth is primarily fueled by the increasing demand for polyurethane products across multiple sectors.

The construction industry remains a key driver for isocyanate demand, particularly in developing economies. Isocyanates are essential components in the production of rigid and flexible foams used for insulation, sealants, and adhesives. As urbanization accelerates and energy efficiency standards become more stringent, the demand for high-performance insulation materials is expected to rise, further boosting the isocyanate market.

Automotive and transportation sectors also contribute significantly to the market growth. Isocyanates are crucial in manufacturing lightweight materials, interior components, and coatings for vehicles. With the automotive industry's shift towards electric vehicles and the need for improved fuel efficiency, the demand for lightweight materials incorporating isocyanates is anticipated to increase.

The furniture and bedding industry represents another substantial market for isocyanates, particularly in the production of flexible foams for mattresses, cushions, and upholstery. As consumer preferences evolve towards more comfortable and durable products, the demand for high-quality polyurethane foams is expected to grow.

In the electronics and appliance sectors, isocyanates play a vital role in producing insulation materials and protective coatings. With the rapid advancement of technology and the increasing demand for energy-efficient appliances, the market for isocyanate-based materials in these industries is projected to expand.

The healthcare and medical device industry is emerging as a promising market for isocyanates. Their use in producing medical-grade polyurethanes for various applications, including catheters, wound dressings, and prosthetics, is driving demand in this sector. As healthcare needs continue to grow globally, the market for specialized isocyanate-based materials is expected to increase.

However, the market faces challenges related to environmental and health concerns associated with certain isocyanates. This has led to increased research and development efforts focused on developing more sustainable and safer alternatives. Bio-based isocyanates and non-isocyanate polyurethanes are gaining attention as potential solutions to address these concerns while meeting the growing market demand.

The construction industry remains a key driver for isocyanate demand, particularly in developing economies. Isocyanates are essential components in the production of rigid and flexible foams used for insulation, sealants, and adhesives. As urbanization accelerates and energy efficiency standards become more stringent, the demand for high-performance insulation materials is expected to rise, further boosting the isocyanate market.

Automotive and transportation sectors also contribute significantly to the market growth. Isocyanates are crucial in manufacturing lightweight materials, interior components, and coatings for vehicles. With the automotive industry's shift towards electric vehicles and the need for improved fuel efficiency, the demand for lightweight materials incorporating isocyanates is anticipated to increase.

The furniture and bedding industry represents another substantial market for isocyanates, particularly in the production of flexible foams for mattresses, cushions, and upholstery. As consumer preferences evolve towards more comfortable and durable products, the demand for high-quality polyurethane foams is expected to grow.

In the electronics and appliance sectors, isocyanates play a vital role in producing insulation materials and protective coatings. With the rapid advancement of technology and the increasing demand for energy-efficient appliances, the market for isocyanate-based materials in these industries is projected to expand.

The healthcare and medical device industry is emerging as a promising market for isocyanates. Their use in producing medical-grade polyurethanes for various applications, including catheters, wound dressings, and prosthetics, is driving demand in this sector. As healthcare needs continue to grow globally, the market for specialized isocyanate-based materials is expected to increase.

However, the market faces challenges related to environmental and health concerns associated with certain isocyanates. This has led to increased research and development efforts focused on developing more sustainable and safer alternatives. Bio-based isocyanates and non-isocyanate polyurethanes are gaining attention as potential solutions to address these concerns while meeting the growing market demand.

Current Challenges

Isocyanates have been at the forefront of material science advancements for decades, yet their continued development faces several significant challenges. One of the primary obstacles is the toxicity associated with many isocyanate compounds. These chemicals can pose serious health risks, particularly in occupational settings where exposure is more likely. Researchers and manufacturers are grappling with the need to develop safer alternatives or improved handling methods to mitigate these risks without compromising the unique properties that make isocyanates so valuable.

Another challenge lies in the environmental impact of isocyanate production and use. The synthesis of isocyanates often involves energy-intensive processes and the use of hazardous precursors. As global environmental regulations become more stringent, there is increasing pressure to develop greener production methods and more sustainable isocyanate-based materials. This includes exploring bio-based sources for isocyanate precursors and designing products with improved end-of-life recyclability or biodegradability.

The versatility of isocyanates in polymer chemistry has led to their widespread use in various industries. However, this broad application spectrum also presents challenges in terms of optimizing performance for specific end-uses. Researchers are working to fine-tune the molecular structure and reactivity of isocyanates to achieve desired properties in diverse applications, from flexible foams to high-performance coatings. Balancing factors such as cure time, mechanical strength, and durability across different formulations remains an ongoing challenge.

Additionally, the reactive nature of isocyanates poses difficulties in storage, handling, and processing. Moisture sensitivity and the potential for unwanted side reactions during manufacturing can lead to inconsistencies in product quality and performance. Developing more stable isocyanate formulations and improved processing technologies is crucial for advancing their industrial applications.

The global supply chain for isocyanates and their precursors is another area of concern. Geopolitical factors, raw material availability, and market fluctuations can impact the stability and cost-effectiveness of isocyanate production. This volatility challenges manufacturers to secure reliable sources and develop alternative production routes to ensure a consistent supply of these critical materials.

Lastly, as material science pushes towards more advanced functionalities, there is a growing need for isocyanates with novel properties. This includes developing isocyanates that can contribute to smart materials, self-healing polymers, or materials with enhanced thermal and chemical resistance. The challenge lies in synthesizing new isocyanate structures that can meet these emerging requirements while maintaining processability and economic viability.

Another challenge lies in the environmental impact of isocyanate production and use. The synthesis of isocyanates often involves energy-intensive processes and the use of hazardous precursors. As global environmental regulations become more stringent, there is increasing pressure to develop greener production methods and more sustainable isocyanate-based materials. This includes exploring bio-based sources for isocyanate precursors and designing products with improved end-of-life recyclability or biodegradability.

The versatility of isocyanates in polymer chemistry has led to their widespread use in various industries. However, this broad application spectrum also presents challenges in terms of optimizing performance for specific end-uses. Researchers are working to fine-tune the molecular structure and reactivity of isocyanates to achieve desired properties in diverse applications, from flexible foams to high-performance coatings. Balancing factors such as cure time, mechanical strength, and durability across different formulations remains an ongoing challenge.

Additionally, the reactive nature of isocyanates poses difficulties in storage, handling, and processing. Moisture sensitivity and the potential for unwanted side reactions during manufacturing can lead to inconsistencies in product quality and performance. Developing more stable isocyanate formulations and improved processing technologies is crucial for advancing their industrial applications.

The global supply chain for isocyanates and their precursors is another area of concern. Geopolitical factors, raw material availability, and market fluctuations can impact the stability and cost-effectiveness of isocyanate production. This volatility challenges manufacturers to secure reliable sources and develop alternative production routes to ensure a consistent supply of these critical materials.

Lastly, as material science pushes towards more advanced functionalities, there is a growing need for isocyanates with novel properties. This includes developing isocyanates that can contribute to smart materials, self-healing polymers, or materials with enhanced thermal and chemical resistance. The challenge lies in synthesizing new isocyanate structures that can meet these emerging requirements while maintaining processability and economic viability.

Cutting-edge Solutions

01 Synthesis and production of isocyanates

Various methods and processes for synthesizing and producing isocyanates are described. These include novel catalysts, reaction conditions, and precursor materials to improve yield, purity, and efficiency in isocyanate production.- Synthesis and production of isocyanates: Various methods and processes for synthesizing and producing isocyanates are described. These include novel catalysts, reaction conditions, and precursor materials to improve yield, purity, and efficiency in isocyanate production.

- Applications of isocyanates in polymer chemistry: Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents describe various formulations, curing methods, and applications of isocyanate-based polymers in coatings, adhesives, and foams.

- Isocyanate-modified compounds and materials: Several patents focus on the modification of existing compounds or materials using isocyanates. This includes the creation of isocyanate-terminated prepolymers, isocyanate-functional silanes, and other modified materials with enhanced properties.

- Handling and safety of isocyanates: Given the reactive nature of isocyanates, several patents address safety concerns and handling procedures. This includes methods for reducing toxicity, improving storage stability, and developing safer formulations for various applications.

- Analytical methods for isocyanates: Patents in this category describe various analytical techniques for detecting, quantifying, and characterizing isocyanates. This includes spectroscopic methods, chromatographic techniques, and other analytical approaches for quality control and research purposes.

02 Applications of isocyanates in polymer chemistry

Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents describe various formulations, curing methods, and applications of isocyanate-based polymers in coatings, adhesives, and foams.Expand Specific Solutions03 Isocyanate-modified compounds and materials

Techniques for modifying various compounds and materials with isocyanates are presented. These modifications can impart new properties or enhance existing characteristics of the base materials, leading to improved performance in specific applications.Expand Specific Solutions04 Safety and handling of isocyanates

Given the reactive nature of isocyanates, several patents focus on improved methods for safe handling, storage, and disposal. This includes stabilization techniques, protective equipment, and risk mitigation strategies for working with isocyanates.Expand Specific Solutions05 Analytical methods for isocyanates

Various analytical techniques and methods for detecting, quantifying, and characterizing isocyanates are described. These include spectroscopic methods, chromatography, and specialized sensors for monitoring isocyanate levels in different environments.Expand Specific Solutions

Key Industry Players

The isocyanates market is in a mature growth phase, driven by increasing demand in various industries such as automotive, construction, and electronics. The global market size is projected to reach significant value, with steady growth expected in the coming years. Technologically, isocyanates are well-established, but innovation continues in areas like eco-friendly formulations and enhanced performance characteristics. Key players like BASF, Covestro, Wanhua Chemical, and Mitsui Chemicals are at the forefront of research and development, focusing on sustainable solutions and novel applications. Emerging companies and research institutions are also contributing to advancements in isocyanate technology, particularly in specialized niche markets and green chemistry initiatives.

Bayer AG

Technical Solution: Bayer AG has been at the forefront of isocyanate technology, particularly in the development of polyurethane materials. Their innovative approach includes the creation of bio-based isocyanates, which are derived from renewable resources. This technology involves the conversion of plant-based raw materials into isocyanates, reducing the reliance on fossil fuels. Bayer has successfully developed a process to produce pentamethylene diisocyanate (PDI) from corn-derived raw materials[1]. This bio-based isocyanate offers similar performance characteristics to traditional petroleum-based isocyanates while significantly reducing the carbon footprint. Additionally, Bayer has made advancements in aliphatic isocyanates, which provide superior UV stability and color retention in coatings applications[2].

Strengths: Sustainable sourcing, reduced environmental impact, and maintained performance characteristics. Weaknesses: Potentially higher production costs and limited scalability of bio-based processes compared to traditional methods.

Covestro Deutschland AG

Technical Solution: Covestro, formerly part of Bayer, has made significant strides in isocyanate technology, particularly in the realm of sustainable and high-performance materials. Their flagship innovation is the development of carbon dioxide-based polyols for use in polyurethane production. This technology, known as cardyon®, incorporates up to 20% CO2 as a raw material, replacing a portion of the fossil-based resources typically used[3]. The CO2 is sourced from industrial exhaust gases, effectively recycling a greenhouse gas into valuable materials. Covestro has also advanced the production of aliphatic isocyanates, such as hexamethylene diisocyanate (HDI), which are crucial for weather-resistant coatings and high-performance adhesives. Their proprietary gas-phase technology for HDI production has significantly improved efficiency and reduced environmental impact[4].

Strengths: Innovative CO2 utilization, reduced carbon footprint, and improved production efficiency. Weaknesses: Limited CO2 incorporation percentage and potential challenges in scaling up novel production methods.

Breakthrough Patents

Preparation and use of gamma-butyrolactones as cross-linking agents

PatentInactiveEP1448541A2

Innovation

- Gamma-butyrolactones with adjustable aminolysis reaction rates, achieved by appending substituents with specific field effect values, are used as cross-linking agents, allowing for predictable and customizable reaction rates to suit various coating processes without the health risks associated with isocyanates.

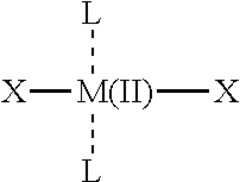

Oxidative carbonylation of primary amines to isocycanates catalyzed by group x divalent noble metal compounds or complexes

PatentInactiveUS20150353481A1

Innovation

- A method involving a homogeneous reaction mixture of a monomeric or oligomeric primary amine or diamine, carbon monoxide, a Group X divalent noble metal compound or complex catalyst, a quinone oxidizing agent, and a polar aprotic solvent, operating at atmospheric pressure and without phosgene, to produce isocyanates efficiently.

Environmental Impact

Isocyanates, while pivotal in advancing material science, pose significant environmental challenges that demand careful consideration. The production and use of isocyanates contribute to various forms of pollution, including air, water, and soil contamination. During manufacturing processes, volatile organic compounds (VOCs) are released, contributing to smog formation and potentially harming local ecosystems. Additionally, the disposal of isocyanate-containing products can lead to long-term environmental persistence, as these materials often do not biodegrade easily.

The environmental impact of isocyanates extends to their role in the formation of microplastics. As polyurethane products degrade, they can break down into smaller particles that persist in aquatic environments, potentially entering the food chain and affecting marine life. This has raised concerns about bioaccumulation and the long-term effects on ecosystem health.

Climate change implications are also associated with isocyanate production and use. The energy-intensive manufacturing processes contribute to greenhouse gas emissions, while the petroleum-based raw materials used in isocyanate synthesis further exacerbate carbon footprint concerns. As global efforts to reduce carbon emissions intensify, the isocyanate industry faces pressure to adopt more sustainable practices and explore alternative, bio-based feedstocks.

Water pollution is another critical environmental issue linked to isocyanates. Accidental spills or improper disposal can lead to contamination of water bodies, potentially harming aquatic life and compromising water quality for human consumption. The reactive nature of isocyanates means they can form harmful byproducts when they come into contact with water, further complicating remediation efforts.

Despite these challenges, the material science community is actively working on mitigating the environmental impact of isocyanates. Research into green chemistry approaches aims to develop less toxic alternatives and more environmentally friendly production methods. Efforts to improve recycling technologies for polyurethane products are also underway, with the goal of creating a more circular economy for isocyanate-based materials.

Regulatory bodies worldwide are implementing stricter controls on isocyanate use and disposal, driving innovation in safer handling practices and emission reduction technologies. These measures, combined with industry initiatives to develop more sustainable products, are gradually shifting the environmental profile of isocyanate-based materials towards a more positive trajectory.

The environmental impact of isocyanates extends to their role in the formation of microplastics. As polyurethane products degrade, they can break down into smaller particles that persist in aquatic environments, potentially entering the food chain and affecting marine life. This has raised concerns about bioaccumulation and the long-term effects on ecosystem health.

Climate change implications are also associated with isocyanate production and use. The energy-intensive manufacturing processes contribute to greenhouse gas emissions, while the petroleum-based raw materials used in isocyanate synthesis further exacerbate carbon footprint concerns. As global efforts to reduce carbon emissions intensify, the isocyanate industry faces pressure to adopt more sustainable practices and explore alternative, bio-based feedstocks.

Water pollution is another critical environmental issue linked to isocyanates. Accidental spills or improper disposal can lead to contamination of water bodies, potentially harming aquatic life and compromising water quality for human consumption. The reactive nature of isocyanates means they can form harmful byproducts when they come into contact with water, further complicating remediation efforts.

Despite these challenges, the material science community is actively working on mitigating the environmental impact of isocyanates. Research into green chemistry approaches aims to develop less toxic alternatives and more environmentally friendly production methods. Efforts to improve recycling technologies for polyurethane products are also underway, with the goal of creating a more circular economy for isocyanate-based materials.

Regulatory bodies worldwide are implementing stricter controls on isocyanate use and disposal, driving innovation in safer handling practices and emission reduction technologies. These measures, combined with industry initiatives to develop more sustainable products, are gradually shifting the environmental profile of isocyanate-based materials towards a more positive trajectory.

Safety Regulations

The safety regulations surrounding isocyanates play a crucial role in driving material science advancements while ensuring the protection of workers and the environment. As isocyanates are highly reactive chemicals with potential health hazards, stringent safety measures have been implemented globally to govern their production, handling, and use.

In the United States, the Occupational Safety and Health Administration (OSHA) has established comprehensive guidelines for isocyanate exposure limits and protective measures. These regulations mandate the use of personal protective equipment (PPE), including respirators, gloves, and protective clothing, when working with isocyanates. Additionally, OSHA requires employers to provide proper training and implement engineering controls to minimize exposure risks.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which imposes strict requirements on the registration and assessment of isocyanates. This regulatory framework has prompted manufacturers to invest in research and development of safer alternatives and improved handling techniques, driving innovation in material science.

Japan's Industrial Safety and Health Law sets forth specific regulations for isocyanate handling, including mandatory health checkups for workers exposed to these chemicals. These measures have encouraged the development of advanced monitoring systems and exposure prevention technologies.

The evolving safety regulations have spurred advancements in isocyanate-based materials with reduced toxicity and improved environmental profiles. For instance, the development of water-based polyurethane systems and blocked isocyanates has gained traction as a result of regulatory pressures. These innovations not only enhance safety but also expand the application range of isocyanate-derived materials.

Furthermore, the push for compliance with safety regulations has led to the creation of sophisticated analytical techniques for detecting and measuring isocyanate levels in various environments. This has resulted in the development of highly sensitive sensors and monitoring devices, contributing to the overall advancement of material science and analytical chemistry.

The emphasis on worker safety has also driven research into alternative curing mechanisms and crosslinking agents that can potentially replace traditional isocyanates in certain applications. This exploration has opened new avenues for material scientists to develop novel polymers and composites with enhanced properties and reduced health risks.

In conclusion, safety regulations have been a significant driving force behind material science advancements related to isocyanates. By necessitating safer handling practices and encouraging the development of alternative materials and technologies, these regulations have not only improved workplace safety but also catalyzed innovation in the field of material science.

In the United States, the Occupational Safety and Health Administration (OSHA) has established comprehensive guidelines for isocyanate exposure limits and protective measures. These regulations mandate the use of personal protective equipment (PPE), including respirators, gloves, and protective clothing, when working with isocyanates. Additionally, OSHA requires employers to provide proper training and implement engineering controls to minimize exposure risks.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which imposes strict requirements on the registration and assessment of isocyanates. This regulatory framework has prompted manufacturers to invest in research and development of safer alternatives and improved handling techniques, driving innovation in material science.

Japan's Industrial Safety and Health Law sets forth specific regulations for isocyanate handling, including mandatory health checkups for workers exposed to these chemicals. These measures have encouraged the development of advanced monitoring systems and exposure prevention technologies.

The evolving safety regulations have spurred advancements in isocyanate-based materials with reduced toxicity and improved environmental profiles. For instance, the development of water-based polyurethane systems and blocked isocyanates has gained traction as a result of regulatory pressures. These innovations not only enhance safety but also expand the application range of isocyanate-derived materials.

Furthermore, the push for compliance with safety regulations has led to the creation of sophisticated analytical techniques for detecting and measuring isocyanate levels in various environments. This has resulted in the development of highly sensitive sensors and monitoring devices, contributing to the overall advancement of material science and analytical chemistry.

The emphasis on worker safety has also driven research into alternative curing mechanisms and crosslinking agents that can potentially replace traditional isocyanates in certain applications. This exploration has opened new avenues for material scientists to develop novel polymers and composites with enhanced properties and reduced health risks.

In conclusion, safety regulations have been a significant driving force behind material science advancements related to isocyanates. By necessitating safer handling practices and encouraging the development of alternative materials and technologies, these regulations have not only improved workplace safety but also catalyzed innovation in the field of material science.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!