Isocyanates in Water-Based Coatings: Efficiency and Applications

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Technology Evolution and Objectives

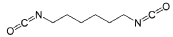

Isocyanates have been a cornerstone in the coatings industry for decades, revolutionizing the performance and durability of various coating systems. The evolution of isocyanate technology in water-based coatings represents a significant shift towards more environmentally friendly and sustainable solutions. This transition began in the late 1980s and early 1990s, driven by increasing environmental regulations and a growing demand for low-VOC (volatile organic compound) products.

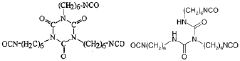

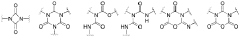

The initial development of water-based isocyanate systems faced numerous challenges, primarily related to the reactivity of isocyanates with water. Early attempts focused on creating stable dispersions of isocyanates in water, which could then be incorporated into coating formulations. This led to the development of hydrophilically modified polyisocyanates and blocked isocyanates, which offered improved stability and compatibility with aqueous systems.

As research progressed, the industry saw the emergence of more sophisticated technologies, such as self-emulsifiable isocyanates and water-dispersible polyisocyanates. These innovations allowed for better control over reaction kinetics and improved film formation properties, addressing many of the early performance limitations of water-based isocyanate coatings.

The primary objectives driving the evolution of isocyanate technology in water-based coatings have been multifaceted. Firstly, there has been a continuous effort to enhance the efficiency of isocyanate utilization, aiming to achieve comparable or superior performance to solvent-based systems while using lower isocyanate concentrations. This not only improves cost-effectiveness but also addresses health and safety concerns associated with isocyanate exposure.

Secondly, researchers have focused on expanding the application range of water-based isocyanate coatings. This has involved developing formulations suitable for various substrates and end-use environments, from automotive and industrial coatings to architectural and wood finishes. The goal has been to create versatile systems that can meet diverse performance requirements while maintaining the environmental benefits of water-based technology.

Another critical objective has been to improve the shelf life and stability of water-based isocyanate coatings. This has led to innovations in packaging, storage, and handling techniques, as well as the development of novel chemistries that delay the onset of unwanted reactions between isocyanates and water.

Looking ahead, the future evolution of isocyanate technology in water-based coatings is likely to focus on further enhancing sustainability and performance. This may include the development of bio-based or renewable isocyanates, as well as exploring hybrid systems that combine the benefits of isocyanates with other complementary technologies. Additionally, there is ongoing research into smart coatings that incorporate isocyanates for self-healing or stimuli-responsive properties, opening up new possibilities for advanced coating applications.

The initial development of water-based isocyanate systems faced numerous challenges, primarily related to the reactivity of isocyanates with water. Early attempts focused on creating stable dispersions of isocyanates in water, which could then be incorporated into coating formulations. This led to the development of hydrophilically modified polyisocyanates and blocked isocyanates, which offered improved stability and compatibility with aqueous systems.

As research progressed, the industry saw the emergence of more sophisticated technologies, such as self-emulsifiable isocyanates and water-dispersible polyisocyanates. These innovations allowed for better control over reaction kinetics and improved film formation properties, addressing many of the early performance limitations of water-based isocyanate coatings.

The primary objectives driving the evolution of isocyanate technology in water-based coatings have been multifaceted. Firstly, there has been a continuous effort to enhance the efficiency of isocyanate utilization, aiming to achieve comparable or superior performance to solvent-based systems while using lower isocyanate concentrations. This not only improves cost-effectiveness but also addresses health and safety concerns associated with isocyanate exposure.

Secondly, researchers have focused on expanding the application range of water-based isocyanate coatings. This has involved developing formulations suitable for various substrates and end-use environments, from automotive and industrial coatings to architectural and wood finishes. The goal has been to create versatile systems that can meet diverse performance requirements while maintaining the environmental benefits of water-based technology.

Another critical objective has been to improve the shelf life and stability of water-based isocyanate coatings. This has led to innovations in packaging, storage, and handling techniques, as well as the development of novel chemistries that delay the onset of unwanted reactions between isocyanates and water.

Looking ahead, the future evolution of isocyanate technology in water-based coatings is likely to focus on further enhancing sustainability and performance. This may include the development of bio-based or renewable isocyanates, as well as exploring hybrid systems that combine the benefits of isocyanates with other complementary technologies. Additionally, there is ongoing research into smart coatings that incorporate isocyanates for self-healing or stimuli-responsive properties, opening up new possibilities for advanced coating applications.

Market Demand Analysis for Water-Based Coatings

The market demand for water-based coatings has been experiencing significant growth in recent years, driven by increasing environmental regulations and consumer preferences for eco-friendly products. This shift towards water-based coatings has created a substantial opportunity for isocyanates, which play a crucial role in enhancing the performance of these coatings.

The global water-based coatings market has been expanding at a steady pace, with a particular focus on applications in construction, automotive, and industrial sectors. The construction industry, in particular, has been a major driver of demand, as water-based coatings offer excellent durability, weather resistance, and low VOC emissions, making them ideal for both interior and exterior applications.

In the automotive sector, there is a growing trend towards water-based coatings for both OEM and refinish applications. This shift is primarily due to stringent environmental regulations and the need for improved process efficiency. Isocyanates in water-based coatings have been instrumental in achieving performance characteristics comparable to solvent-based alternatives, such as excellent scratch resistance, chemical resistance, and overall durability.

The industrial coatings segment has also shown increased adoption of water-based formulations, particularly in metal coatings, wood coatings, and protective coatings. Isocyanates have played a key role in improving the adhesion, hardness, and chemical resistance of these coatings, making them suitable for a wide range of industrial applications.

Market analysis indicates that the Asia-Pacific region is expected to be the fastest-growing market for water-based coatings, driven by rapid industrialization, urbanization, and increasing environmental awareness. North America and Europe continue to be significant markets, with a strong focus on sustainable and high-performance coating solutions.

The demand for isocyanates in water-based coatings is closely tied to the overall growth of the water-based coatings market. Manufacturers are increasingly focusing on developing innovative isocyanate-based solutions that can enhance the performance of water-based coatings while meeting stringent environmental and safety standards. This includes the development of low-VOC and zero-VOC formulations, as well as bio-based alternatives.

As the market continues to evolve, there is a growing emphasis on research and development to address challenges such as pot life, curing time, and overall coating performance. This presents opportunities for isocyanate manufacturers to develop tailored solutions that can meet the specific needs of different applications and industries.

The global water-based coatings market has been expanding at a steady pace, with a particular focus on applications in construction, automotive, and industrial sectors. The construction industry, in particular, has been a major driver of demand, as water-based coatings offer excellent durability, weather resistance, and low VOC emissions, making them ideal for both interior and exterior applications.

In the automotive sector, there is a growing trend towards water-based coatings for both OEM and refinish applications. This shift is primarily due to stringent environmental regulations and the need for improved process efficiency. Isocyanates in water-based coatings have been instrumental in achieving performance characteristics comparable to solvent-based alternatives, such as excellent scratch resistance, chemical resistance, and overall durability.

The industrial coatings segment has also shown increased adoption of water-based formulations, particularly in metal coatings, wood coatings, and protective coatings. Isocyanates have played a key role in improving the adhesion, hardness, and chemical resistance of these coatings, making them suitable for a wide range of industrial applications.

Market analysis indicates that the Asia-Pacific region is expected to be the fastest-growing market for water-based coatings, driven by rapid industrialization, urbanization, and increasing environmental awareness. North America and Europe continue to be significant markets, with a strong focus on sustainable and high-performance coating solutions.

The demand for isocyanates in water-based coatings is closely tied to the overall growth of the water-based coatings market. Manufacturers are increasingly focusing on developing innovative isocyanate-based solutions that can enhance the performance of water-based coatings while meeting stringent environmental and safety standards. This includes the development of low-VOC and zero-VOC formulations, as well as bio-based alternatives.

As the market continues to evolve, there is a growing emphasis on research and development to address challenges such as pot life, curing time, and overall coating performance. This presents opportunities for isocyanate manufacturers to develop tailored solutions that can meet the specific needs of different applications and industries.

Current Challenges in Isocyanate Incorporation

The incorporation of isocyanates into water-based coatings presents several significant challenges that researchers and manufacturers are actively working to overcome. One of the primary obstacles is the inherent reactivity of isocyanates with water. This reactivity can lead to undesired side reactions, resulting in the formation of urea and carbon dioxide, which can compromise the coating's performance and stability.

Another major challenge is achieving proper dispersion and stability of isocyanates in aqueous systems. Due to their hydrophobic nature, isocyanates tend to form aggregates or separate phases in water-based formulations. This can lead to inconsistent curing, reduced crosslinking efficiency, and ultimately, inferior coating properties.

The control of reaction kinetics poses an additional hurdle. In water-based systems, it becomes crucial to balance the rate of isocyanate-water reaction with the desired crosslinking reactions. Achieving this delicate equilibrium is essential for optimal coating performance but remains a complex task that requires precise formulation and process control.

Environmental and health concerns associated with isocyanates also present challenges in their incorporation. While water-based coatings are generally considered more environmentally friendly than solvent-based alternatives, the use of isocyanates still raises concerns due to their potential health hazards, particularly respiratory sensitization. This necessitates the development of safer handling procedures and potentially the exploration of less hazardous alternatives.

The shelf life and stability of water-based coatings containing isocyanates are also areas of concern. The presence of moisture in the formulation can lead to gradual degradation of the isocyanate component over time, potentially affecting the long-term performance and reliability of the coating system.

Furthermore, achieving comparable performance to solvent-based systems remains a challenge. Water-based coatings incorporating isocyanates often struggle to match the durability, chemical resistance, and adhesion properties of their solvent-based counterparts. Overcoming these performance gaps is crucial for wider adoption in demanding applications.

Lastly, the cost-effectiveness of incorporating isocyanates into water-based coatings presents an ongoing challenge. The specialized formulations and processing requirements can increase production costs, potentially limiting their competitiveness in price-sensitive markets.

Another major challenge is achieving proper dispersion and stability of isocyanates in aqueous systems. Due to their hydrophobic nature, isocyanates tend to form aggregates or separate phases in water-based formulations. This can lead to inconsistent curing, reduced crosslinking efficiency, and ultimately, inferior coating properties.

The control of reaction kinetics poses an additional hurdle. In water-based systems, it becomes crucial to balance the rate of isocyanate-water reaction with the desired crosslinking reactions. Achieving this delicate equilibrium is essential for optimal coating performance but remains a complex task that requires precise formulation and process control.

Environmental and health concerns associated with isocyanates also present challenges in their incorporation. While water-based coatings are generally considered more environmentally friendly than solvent-based alternatives, the use of isocyanates still raises concerns due to their potential health hazards, particularly respiratory sensitization. This necessitates the development of safer handling procedures and potentially the exploration of less hazardous alternatives.

The shelf life and stability of water-based coatings containing isocyanates are also areas of concern. The presence of moisture in the formulation can lead to gradual degradation of the isocyanate component over time, potentially affecting the long-term performance and reliability of the coating system.

Furthermore, achieving comparable performance to solvent-based systems remains a challenge. Water-based coatings incorporating isocyanates often struggle to match the durability, chemical resistance, and adhesion properties of their solvent-based counterparts. Overcoming these performance gaps is crucial for wider adoption in demanding applications.

Lastly, the cost-effectiveness of incorporating isocyanates into water-based coatings presents an ongoing challenge. The specialized formulations and processing requirements can increase production costs, potentially limiting their competitiveness in price-sensitive markets.

Existing Isocyanate Integration Solutions

01 Improving isocyanate reaction efficiency

Various methods are employed to enhance the efficiency of isocyanate reactions. These include optimizing reaction conditions, using catalysts, and selecting appropriate reactants. Improved efficiency leads to better product yields, reduced waste, and more economical processes in industries such as polyurethane production.- Improving isocyanate reaction efficiency: Various methods are employed to enhance the efficiency of isocyanate reactions. These include optimizing reaction conditions, using catalysts, and selecting appropriate reactants. Improved efficiency can lead to faster reaction rates, higher yields, and better quality end products in applications such as polyurethane production.

- Catalysts for isocyanate reactions: Specific catalysts are utilized to increase the efficiency of isocyanate reactions. These catalysts can accelerate reaction rates, lower activation energies, and improve selectivity. Different types of catalysts, including metal-based and organic compounds, are employed depending on the specific isocyanate reaction and desired outcome.

- Isocyanate formulations for enhanced performance: Specialized formulations of isocyanates are developed to improve their efficiency in various applications. These formulations may include additives, stabilizers, or modifiers that enhance reactivity, stability, or specific properties of the final product. Tailored formulations can lead to improved performance in coatings, adhesives, and other polyurethane-based materials.

- Process optimization for isocyanate production: Techniques for optimizing the production process of isocyanates are developed to increase overall efficiency. This includes improving reactor designs, implementing advanced process control systems, and optimizing reaction parameters such as temperature, pressure, and reactant ratios. These optimizations can lead to higher yields, reduced energy consumption, and improved product quality.

- Novel applications leveraging isocyanate efficiency: Innovative applications are explored that take advantage of improved isocyanate efficiency. These may include new types of polymers, composite materials, or functional coatings. By leveraging enhanced isocyanate reactivity and performance, novel products with superior properties or unique functionalities can be developed for various industries.

02 Catalysts for isocyanate reactions

Specific catalysts are developed to accelerate isocyanate reactions and improve their efficiency. These catalysts can be metal-based, organic compounds, or novel formulations designed to enhance reaction rates and selectivity. The use of appropriate catalysts can significantly reduce reaction times and energy requirements.Expand Specific Solutions03 Isocyanate formulations for specific applications

Tailored isocyanate formulations are developed for specific industrial applications. These formulations may include additives, stabilizers, or modifiers to enhance performance in areas such as adhesives, coatings, and foams. The efficiency of these formulations is optimized for their intended use.Expand Specific Solutions04 Isocyanate production processes

Innovative production processes are designed to improve the efficiency of isocyanate synthesis. These may involve new reaction pathways, continuous flow processes, or advanced separation techniques. Efficient production methods contribute to higher yields, lower costs, and reduced environmental impact.Expand Specific Solutions05 Measuring and monitoring isocyanate efficiency

Techniques and instruments are developed to accurately measure and monitor the efficiency of isocyanate reactions. These may include spectroscopic methods, chromatography, or real-time monitoring systems. Precise measurement allows for better process control and optimization of reaction conditions.Expand Specific Solutions

Key Players in Water-Based Coating Industry

The market for isocyanates in water-based coatings is in a growth phase, driven by increasing demand for eco-friendly and low-VOC coating solutions. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like Bayer AG, BASF Corp., and Covestro Deutschland AG leading innovation in isocyanate chemistry and application techniques. These industry leaders, along with DuPont de Nemours, Inc. and Dow Global Technologies LLC, are investing heavily in R&D to improve efficiency and broaden applications. The technology is maturing, but there's still room for breakthrough developments in areas such as durability, curing speed, and environmental impact reduction.

BASF Corp.

Technical Solution: BASF has developed innovative water-based polyurethane dispersions (PUDs) using isocyanate technology for coatings applications. Their Basonat® product line includes water-dispersible polyisocyanates that enable the formulation of high-performance, low-VOC two-component polyurethane coatings[1]. These PUDs offer excellent adhesion, chemical resistance, and durability comparable to solvent-based systems. BASF's technology involves encapsulating isocyanates in a hydrophilic shell, allowing stable dispersion in water while maintaining reactivity[2]. This approach addresses challenges of isocyanate sensitivity to water while providing the benefits of polyurethane chemistry in environmentally friendly formulations.

Strengths: Low VOC emissions, high performance comparable to solvent-based systems, improved worker safety. Weaknesses: Potentially higher cost, limited pot life after mixing components, requires careful formulation to balance reactivity and stability.

Covestro Deutschland AG

Technical Solution: Covestro has pioneered water-based polyurethane (PU) coating technologies using blocked isocyanates. Their Bayhydur® product line includes water-dispersible polyisocyanates designed for two-component waterborne PU coatings[3]. These systems employ innovative blocking technologies that prevent premature reaction of isocyanates with water, allowing stable one-component formulations that cure at elevated temperatures. Covestro's approach involves careful selection of blocking agents and optimization of deblocking temperatures to achieve desired performance properties[4]. This technology enables the formulation of low-VOC, high-performance coatings for various applications, including automotive, industrial, and wood coatings.

Strengths: One-component stability, tailored curing temperatures, excellent chemical and mechanical resistance. Weaknesses: May require heat for full curing, potential for residual blocking agents, higher raw material costs compared to conventional systems.

Core Innovations in Isocyanate Chemistry

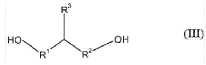

Water-dispersible polyisocyanates

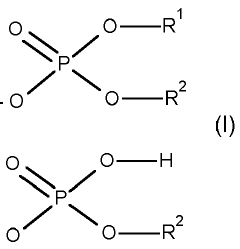

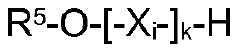

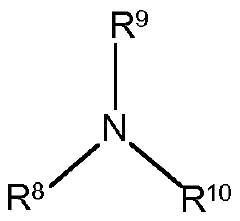

PatentWO2017097668A1

Innovation

- The development of water-dispersible polyisocyanates comprising a diisocyanate or polyisocyanate, a surfactant with specific amine and monoester-type and diester-type compounds, monofunctional polyalkylene glycol, and optional high or low molecular mass diols, along with a solvent having a hydrophilic-lipophilic balance (HLB) value of 7.8 or less, which enhances ease of incorporation and optical properties.

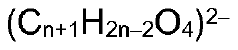

Frost-resistant water paints based on polyisocyanates

PatentWO2019121387A1

Innovation

- The use of hydrophilized polyisocyanates in water-diluted coating compositions with specific molar ratios of isocyanate groups to isocyanate-reactive groups, where the isocyanate component A is predominantly monomeric and oligomeric polyisocyanates, and the addition of water reduces viscosity, allowing for stable and processable paints without encapsulation, enabling direct contact with water.

Environmental Impact Assessment

The environmental impact of isocyanates in water-based coatings is a critical consideration for manufacturers, regulators, and end-users. While water-based coatings generally offer reduced volatile organic compound (VOC) emissions compared to solvent-based alternatives, the use of isocyanates introduces specific environmental concerns that require careful assessment.

Isocyanates, when released into the environment, can have detrimental effects on both aquatic and terrestrial ecosystems. In water bodies, isocyanates can react with water to form insoluble polyureas, potentially affecting water quality and aquatic life. The decomposition of these compounds may lead to the formation of toxic by-products, impacting the food chain and biodiversity of aquatic ecosystems.

Atmospheric release of isocyanates during the application or curing of water-based coatings can contribute to air pollution. These compounds can participate in photochemical reactions, potentially contributing to the formation of ground-level ozone and other air pollutants. The persistence of isocyanates in the atmosphere and their potential for long-range transport are areas of ongoing research and concern.

Soil contamination is another potential environmental risk associated with isocyanates in water-based coatings. Improper disposal or accidental spills can lead to soil pollution, affecting soil microorganisms and potentially entering groundwater systems. The mobility and degradation pathways of isocyanates in soil environments are complex and depend on various factors, including soil composition and climatic conditions.

The production and disposal of isocyanate-containing coatings also present environmental challenges. Manufacturing processes may generate hazardous waste streams that require specialized treatment and disposal methods. End-of-life considerations for coated products are equally important, as the presence of isocyanates may complicate recycling efforts and contribute to the accumulation of potentially harmful substances in landfills.

To mitigate these environmental impacts, industry and researchers are exploring several strategies. These include the development of isocyanate-free formulations, improved application techniques to minimize overspray and emissions, and enhanced waste management practices. Additionally, life cycle assessments are being conducted to comprehensively evaluate the environmental footprint of isocyanate-containing water-based coatings from production to disposal.

Regulatory frameworks are evolving to address the environmental concerns associated with isocyanates. Many jurisdictions have implemented strict guidelines for the handling, use, and disposal of isocyanate-containing products. These regulations aim to minimize environmental exposure and protect ecosystems from potential harm. Ongoing monitoring and research efforts are essential to inform policy decisions and drive the development of more environmentally friendly coating technologies.

Isocyanates, when released into the environment, can have detrimental effects on both aquatic and terrestrial ecosystems. In water bodies, isocyanates can react with water to form insoluble polyureas, potentially affecting water quality and aquatic life. The decomposition of these compounds may lead to the formation of toxic by-products, impacting the food chain and biodiversity of aquatic ecosystems.

Atmospheric release of isocyanates during the application or curing of water-based coatings can contribute to air pollution. These compounds can participate in photochemical reactions, potentially contributing to the formation of ground-level ozone and other air pollutants. The persistence of isocyanates in the atmosphere and their potential for long-range transport are areas of ongoing research and concern.

Soil contamination is another potential environmental risk associated with isocyanates in water-based coatings. Improper disposal or accidental spills can lead to soil pollution, affecting soil microorganisms and potentially entering groundwater systems. The mobility and degradation pathways of isocyanates in soil environments are complex and depend on various factors, including soil composition and climatic conditions.

The production and disposal of isocyanate-containing coatings also present environmental challenges. Manufacturing processes may generate hazardous waste streams that require specialized treatment and disposal methods. End-of-life considerations for coated products are equally important, as the presence of isocyanates may complicate recycling efforts and contribute to the accumulation of potentially harmful substances in landfills.

To mitigate these environmental impacts, industry and researchers are exploring several strategies. These include the development of isocyanate-free formulations, improved application techniques to minimize overspray and emissions, and enhanced waste management practices. Additionally, life cycle assessments are being conducted to comprehensively evaluate the environmental footprint of isocyanate-containing water-based coatings from production to disposal.

Regulatory frameworks are evolving to address the environmental concerns associated with isocyanates. Many jurisdictions have implemented strict guidelines for the handling, use, and disposal of isocyanate-containing products. These regulations aim to minimize environmental exposure and protect ecosystems from potential harm. Ongoing monitoring and research efforts are essential to inform policy decisions and drive the development of more environmentally friendly coating technologies.

Regulatory Compliance and Safety Measures

The regulatory landscape surrounding isocyanates in water-based coatings is complex and continually evolving. Governments and regulatory bodies worldwide have implemented strict guidelines to ensure the safe use of these chemicals in various applications, including coatings. The Occupational Safety and Health Administration (OSHA) in the United States has established permissible exposure limits (PELs) for different types of isocyanates, typically ranging from 0.005 to 0.02 parts per million (ppm) for an 8-hour time-weighted average.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation plays a crucial role in controlling the use of isocyanates. Under REACH, manufacturers and importers must register substances and provide safety data sheets detailing proper handling and exposure prevention measures. The EU has also implemented specific restrictions on certain diisocyanates, requiring additional training for industrial and professional users.

Safety measures for handling isocyanates in water-based coatings are paramount. Personal protective equipment (PPE) is essential, including chemical-resistant gloves, safety goggles, and respiratory protection. Proper ventilation systems must be in place to minimize exposure risks. Many manufacturers have developed low-VOC and ultra-low-VOC formulations to comply with increasingly stringent environmental regulations.

Training programs for workers handling isocyanate-containing products are mandatory in many jurisdictions. These programs cover topics such as proper handling techniques, emergency procedures, and the importance of regular health monitoring. Some countries require medical surveillance for workers regularly exposed to isocyanates, including periodic lung function tests and skin examinations.

Waste management and disposal of isocyanate-containing materials are also subject to strict regulations. Proper disposal methods must be employed to prevent environmental contamination and protect public health. Many jurisdictions require specialized handling and treatment of isocyanate waste before disposal.

As environmental concerns grow, there is an increasing focus on developing alternatives to traditional isocyanates in water-based coatings. This has led to research into bio-based isocyanates and non-isocyanate polyurethanes (NIPUs). Regulatory bodies are closely monitoring these developments and may adjust compliance requirements accordingly in the future.

Manufacturers and users of isocyanate-containing water-based coatings must stay informed about regulatory changes and emerging safety standards. Compliance with these regulations not only ensures legal operation but also promotes worker safety and environmental protection. As the industry continues to innovate, it is likely that regulatory frameworks will evolve to address new formulations and applications of isocyanates in coatings.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation plays a crucial role in controlling the use of isocyanates. Under REACH, manufacturers and importers must register substances and provide safety data sheets detailing proper handling and exposure prevention measures. The EU has also implemented specific restrictions on certain diisocyanates, requiring additional training for industrial and professional users.

Safety measures for handling isocyanates in water-based coatings are paramount. Personal protective equipment (PPE) is essential, including chemical-resistant gloves, safety goggles, and respiratory protection. Proper ventilation systems must be in place to minimize exposure risks. Many manufacturers have developed low-VOC and ultra-low-VOC formulations to comply with increasingly stringent environmental regulations.

Training programs for workers handling isocyanate-containing products are mandatory in many jurisdictions. These programs cover topics such as proper handling techniques, emergency procedures, and the importance of regular health monitoring. Some countries require medical surveillance for workers regularly exposed to isocyanates, including periodic lung function tests and skin examinations.

Waste management and disposal of isocyanate-containing materials are also subject to strict regulations. Proper disposal methods must be employed to prevent environmental contamination and protect public health. Many jurisdictions require specialized handling and treatment of isocyanate waste before disposal.

As environmental concerns grow, there is an increasing focus on developing alternatives to traditional isocyanates in water-based coatings. This has led to research into bio-based isocyanates and non-isocyanate polyurethanes (NIPUs). Regulatory bodies are closely monitoring these developments and may adjust compliance requirements accordingly in the future.

Manufacturers and users of isocyanate-containing water-based coatings must stay informed about regulatory changes and emerging safety standards. Compliance with these regulations not only ensures legal operation but also promotes worker safety and environmental protection. As the industry continues to innovate, it is likely that regulatory frameworks will evolve to address new formulations and applications of isocyanates in coatings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!