How Isocyanates Contribute to Smart Building Technologies?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanates in Smart Buildings: Background and Objectives

Isocyanates have emerged as a crucial component in the development of smart building technologies, revolutionizing the construction industry and enhancing the performance of modern structures. The evolution of isocyanates in this field can be traced back to their initial use in polyurethane foams for insulation purposes. Over time, their applications have expanded significantly, contributing to various aspects of smart building design and functionality.

The primary objective of incorporating isocyanates into smart building technologies is to create more energy-efficient, sustainable, and intelligent structures. These versatile compounds play a pivotal role in improving thermal insulation, moisture resistance, and structural integrity. As the demand for smarter and more environmentally friendly buildings continues to grow, isocyanates have become an integral part of innovative construction materials and systems.

In recent years, the focus has shifted towards developing advanced isocyanate-based materials that can actively respond to environmental changes and user needs. This includes the integration of sensors and smart coatings that can adapt to temperature fluctuations, humidity levels, and even air quality. The goal is to create buildings that not only provide comfort and energy efficiency but also contribute to occupant health and well-being.

The technological trajectory of isocyanates in smart buildings is closely aligned with broader trends in sustainable architecture and the Internet of Things (IoT). As these fields continue to advance, isocyanates are expected to play an increasingly important role in creating interconnected building systems that can optimize energy consumption, enhance security, and improve overall building performance.

One of the key challenges in this domain is balancing the performance benefits of isocyanates with environmental and health considerations. Researchers and industry professionals are actively working on developing safer, more sustainable isocyanate formulations that maintain their exceptional properties while minimizing potential risks. This ongoing research is crucial for the widespread adoption of isocyanate-based smart building technologies.

The future of isocyanates in smart buildings looks promising, with potential applications ranging from self-healing materials to advanced energy storage systems. As the technology continues to evolve, it is expected to contribute significantly to the creation of more resilient, efficient, and intelligent urban environments. The integration of isocyanates with other cutting-edge technologies, such as artificial intelligence and advanced materials science, is likely to open up new possibilities for smart building design and functionality.

The primary objective of incorporating isocyanates into smart building technologies is to create more energy-efficient, sustainable, and intelligent structures. These versatile compounds play a pivotal role in improving thermal insulation, moisture resistance, and structural integrity. As the demand for smarter and more environmentally friendly buildings continues to grow, isocyanates have become an integral part of innovative construction materials and systems.

In recent years, the focus has shifted towards developing advanced isocyanate-based materials that can actively respond to environmental changes and user needs. This includes the integration of sensors and smart coatings that can adapt to temperature fluctuations, humidity levels, and even air quality. The goal is to create buildings that not only provide comfort and energy efficiency but also contribute to occupant health and well-being.

The technological trajectory of isocyanates in smart buildings is closely aligned with broader trends in sustainable architecture and the Internet of Things (IoT). As these fields continue to advance, isocyanates are expected to play an increasingly important role in creating interconnected building systems that can optimize energy consumption, enhance security, and improve overall building performance.

One of the key challenges in this domain is balancing the performance benefits of isocyanates with environmental and health considerations. Researchers and industry professionals are actively working on developing safer, more sustainable isocyanate formulations that maintain their exceptional properties while minimizing potential risks. This ongoing research is crucial for the widespread adoption of isocyanate-based smart building technologies.

The future of isocyanates in smart buildings looks promising, with potential applications ranging from self-healing materials to advanced energy storage systems. As the technology continues to evolve, it is expected to contribute significantly to the creation of more resilient, efficient, and intelligent urban environments. The integration of isocyanates with other cutting-edge technologies, such as artificial intelligence and advanced materials science, is likely to open up new possibilities for smart building design and functionality.

Market Analysis for Smart Building Materials

The smart building materials market is experiencing significant growth, driven by the increasing demand for energy-efficient and sustainable construction solutions. Isocyanates, as key components in polyurethane-based materials, play a crucial role in this expanding sector. The global smart building materials market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) that outpaces traditional construction materials.

The demand for isocyanate-based smart building materials is primarily fueled by the growing emphasis on energy conservation and environmental sustainability in the construction industry. These materials contribute to improved insulation, reduced energy consumption, and enhanced overall building performance. The market for polyurethane foams, which rely heavily on isocyanates, is particularly robust in the smart building sector due to their excellent thermal insulation properties.

Geographically, North America and Europe lead the smart building materials market, with Asia-Pacific showing the fastest growth rate. This regional distribution is closely tied to stringent building regulations, energy efficiency standards, and sustainability initiatives in these areas. The adoption of isocyanate-based smart materials is especially strong in countries with extreme climates, where efficient insulation is paramount.

The commercial and residential construction segments are the primary end-users of isocyanate-based smart building materials. The commercial sector, including office buildings, healthcare facilities, and educational institutions, shows higher adoption rates due to the long-term cost benefits and sustainability advantages. However, the residential sector is catching up rapidly as homeowners become more aware of the energy-saving potential of these materials.

Key market drivers include the increasing focus on green building certifications, such as LEED and BREEAM, which often require the use of energy-efficient materials. Government regulations and incentives promoting energy-efficient construction also significantly boost the demand for isocyanate-based smart building materials. Additionally, the rising costs of energy and growing awareness of climate change contribute to the market's expansion.

Despite the positive outlook, the market faces challenges such as the volatility of raw material prices and concerns about the environmental impact of isocyanates. These factors are driving research and development efforts towards more sustainable and bio-based alternatives, which could reshape the market landscape in the long term.

The demand for isocyanate-based smart building materials is primarily fueled by the growing emphasis on energy conservation and environmental sustainability in the construction industry. These materials contribute to improved insulation, reduced energy consumption, and enhanced overall building performance. The market for polyurethane foams, which rely heavily on isocyanates, is particularly robust in the smart building sector due to their excellent thermal insulation properties.

Geographically, North America and Europe lead the smart building materials market, with Asia-Pacific showing the fastest growth rate. This regional distribution is closely tied to stringent building regulations, energy efficiency standards, and sustainability initiatives in these areas. The adoption of isocyanate-based smart materials is especially strong in countries with extreme climates, where efficient insulation is paramount.

The commercial and residential construction segments are the primary end-users of isocyanate-based smart building materials. The commercial sector, including office buildings, healthcare facilities, and educational institutions, shows higher adoption rates due to the long-term cost benefits and sustainability advantages. However, the residential sector is catching up rapidly as homeowners become more aware of the energy-saving potential of these materials.

Key market drivers include the increasing focus on green building certifications, such as LEED and BREEAM, which often require the use of energy-efficient materials. Government regulations and incentives promoting energy-efficient construction also significantly boost the demand for isocyanate-based smart building materials. Additionally, the rising costs of energy and growing awareness of climate change contribute to the market's expansion.

Despite the positive outlook, the market faces challenges such as the volatility of raw material prices and concerns about the environmental impact of isocyanates. These factors are driving research and development efforts towards more sustainable and bio-based alternatives, which could reshape the market landscape in the long term.

Current Challenges in Isocyanate-Based Smart Technologies

The integration of isocyanates into smart building technologies faces several significant challenges that hinder widespread adoption and optimal performance. One of the primary obstacles is the environmental and health concerns associated with isocyanates. These compounds are known for their potential toxicity and can pose risks to both workers during manufacturing and installation processes, as well as building occupants. Ensuring proper safety measures and developing less hazardous alternatives without compromising performance remains a critical challenge.

Another major hurdle is the complexity of formulating isocyanate-based materials for specific smart building applications. Achieving the right balance of properties such as flexibility, durability, and responsiveness to environmental stimuli requires extensive research and development. The variability in building conditions and requirements across different geographical locations further complicates this process, necessitating customized solutions that can adapt to diverse environments.

Durability and long-term performance of isocyanate-based smart materials present ongoing challenges. While these materials offer excellent initial properties, maintaining their smart functionalities over extended periods, especially under varying environmental conditions, remains a concern. Issues such as degradation due to UV exposure, temperature fluctuations, and moisture can impact the longevity and reliability of smart building components incorporating isocyanates.

Integration with existing building systems and infrastructure poses another significant challenge. Retrofitting older buildings with isocyanate-based smart technologies often requires substantial modifications, which can be costly and disruptive. Ensuring seamless compatibility with various building management systems and IoT platforms is crucial for realizing the full potential of these smart technologies.

Cost-effectiveness remains a persistent issue in the widespread adoption of isocyanate-based smart building technologies. The specialized nature of these materials and the complexity of their manufacturing processes often result in higher costs compared to traditional building materials. Balancing the initial investment with long-term energy savings and improved building performance is a delicate equation that needs to be addressed to encourage broader market acceptance.

Regulatory compliance and standardization present additional challenges. The evolving nature of smart building technologies, combined with varying regulations across different regions, creates a complex landscape for manufacturers and implementers. Developing universally accepted standards for the performance, safety, and environmental impact of isocyanate-based smart materials is crucial for fostering innovation and ensuring consistent quality across the industry.

Another major hurdle is the complexity of formulating isocyanate-based materials for specific smart building applications. Achieving the right balance of properties such as flexibility, durability, and responsiveness to environmental stimuli requires extensive research and development. The variability in building conditions and requirements across different geographical locations further complicates this process, necessitating customized solutions that can adapt to diverse environments.

Durability and long-term performance of isocyanate-based smart materials present ongoing challenges. While these materials offer excellent initial properties, maintaining their smart functionalities over extended periods, especially under varying environmental conditions, remains a concern. Issues such as degradation due to UV exposure, temperature fluctuations, and moisture can impact the longevity and reliability of smart building components incorporating isocyanates.

Integration with existing building systems and infrastructure poses another significant challenge. Retrofitting older buildings with isocyanate-based smart technologies often requires substantial modifications, which can be costly and disruptive. Ensuring seamless compatibility with various building management systems and IoT platforms is crucial for realizing the full potential of these smart technologies.

Cost-effectiveness remains a persistent issue in the widespread adoption of isocyanate-based smart building technologies. The specialized nature of these materials and the complexity of their manufacturing processes often result in higher costs compared to traditional building materials. Balancing the initial investment with long-term energy savings and improved building performance is a delicate equation that needs to be addressed to encourage broader market acceptance.

Regulatory compliance and standardization present additional challenges. The evolving nature of smart building technologies, combined with varying regulations across different regions, creates a complex landscape for manufacturers and implementers. Developing universally accepted standards for the performance, safety, and environmental impact of isocyanate-based smart materials is crucial for fostering innovation and ensuring consistent quality across the industry.

Existing Isocyanate Applications in Smart Buildings

01 Synthesis and production of isocyanates

Various methods and processes for synthesizing and producing isocyanates are described. These include novel catalysts, reaction conditions, and precursor materials to improve yield, purity, and efficiency in isocyanate production.- Synthesis and production of isocyanates: Various methods and processes for synthesizing and producing isocyanates are described. These include novel catalysts, reaction conditions, and precursor materials to improve yield, purity, and efficiency in isocyanate production.

- Applications of isocyanates in polymer chemistry: Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents describe various applications, including coatings, adhesives, foams, and elastomers, as well as novel formulations and processing techniques.

- Isocyanate-based catalysts and additives: Some patents focus on the development of isocyanate-based catalysts and additives for various chemical processes. These include novel compounds that enhance reaction rates, improve selectivity, or provide specific properties to the final products.

- Safety and handling of isocyanates: Given the reactive nature of isocyanates, several patents address safety concerns and improved handling methods. These include storage techniques, exposure prevention, and the development of less hazardous isocyanate derivatives.

- Isocyanate-free alternatives and substitutes: Some patents explore alternatives to traditional isocyanates, aiming to address environmental and health concerns. These include bio-based substitutes, non-isocyanate polyurethanes, and alternative chemistries that provide similar functionalities.

02 Applications of isocyanates in polymer chemistry

Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents describe various formulations, curing methods, and applications of isocyanate-based polymers in coatings, adhesives, and foams.Expand Specific Solutions03 Isocyanate-modified compounds and materials

Several patents focus on the modification of existing compounds or materials with isocyanates to impart new properties or functionalities. This includes isocyanate-modified resins, fibers, and other substrates for improved performance in various applications.Expand Specific Solutions04 Safety and handling of isocyanates

Given the reactive nature of isocyanates, several patents address safety concerns and handling procedures. This includes methods for reducing toxicity, improving storage stability, and developing safer alternatives to traditional isocyanates.Expand Specific Solutions05 Analytical methods for isocyanates

Various analytical techniques and methods for detecting, quantifying, and characterizing isocyanates are described. These include spectroscopic methods, chromatographic techniques, and novel sensor technologies for monitoring isocyanate levels in different environments.Expand Specific Solutions

Key Players in Isocyanate and Smart Building Industries

The market for smart building technologies incorporating isocyanates is in a growth phase, driven by increasing demand for energy-efficient and sustainable construction solutions. The global market size is estimated to reach several billion dollars by 2025, with a compound annual growth rate of 10-15%. Technologically, isocyanate-based materials for smart buildings are moderately mature, with ongoing innovations focused on improving performance and sustainability. Key players like BASF, Covestro, and Wanhua Chemical are leading R&D efforts, while companies such as Dow, Bayer, and Huntsman are also significant contributors to advancing isocyanate technologies for smart building applications.

BASF Corp.

Technical Solution: BASF has developed innovative polyurethane systems based on isocyanates for smart building technologies. Their Elastospray® LWP (Low Warming Potential) spray foam insulation utilizes a new hydrofluoroolefin (HFO) blowing agent, reducing the global warming potential by 99% compared to traditional HFC-based systems[1]. This spray foam provides superior insulation performance, air sealing, and moisture control in buildings. BASF has also introduced Elastocool®, a polyurethane rigid foam system for commercial refrigeration applications, offering excellent thermal insulation and energy efficiency[2]. These technologies contribute to smart buildings by enhancing energy efficiency, reducing carbon footprint, and improving overall building performance.

Strengths: Industry-leading R&D capabilities, wide range of polyurethane products for various applications, strong focus on sustainability. Weaknesses: Dependence on petrochemical raw materials, potential regulatory challenges related to isocyanates.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has developed advanced isocyanate-based solutions for smart building technologies. Their WANNATE® MDI (Methylene Diphenyl Diisocyanate) products are used in the production of high-performance polyurethane insulation materials, contributing to energy-efficient buildings[3]. Wanhua's innovative PU systems include spray foam insulation with low global warming potential blowing agents, rigid foam boards for continuous insulation, and structural insulated panels (SIPs) for modular construction[4]. These solutions offer excellent thermal insulation, moisture resistance, and structural integrity. Wanhua has also developed smart coatings using isocyanate-based technologies, which can change properties in response to environmental stimuli, enhancing building durability and energy efficiency[5].

Strengths: Vertically integrated production, strong R&D capabilities, wide range of isocyanate products. Weaknesses: Potential environmental concerns associated with isocyanate production, regulatory challenges in some markets.

Innovative Isocyanate Formulations for Smart Materials

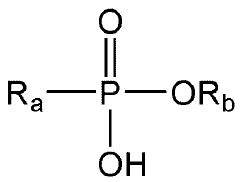

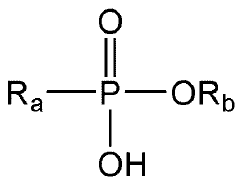

Isocyanate composition

PatentWO2024090855A1

Innovation

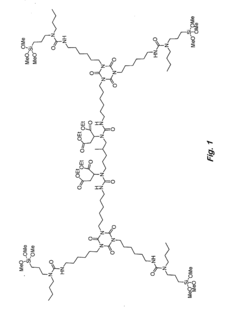

- An isocyanate composition comprising an isocyanate-based compound and a phosphonate-based compound, which slows down oligomerization and suppresses discoloration, along with a phenol-based stabilizer to prevent side reactions, improving storage stability and workability.

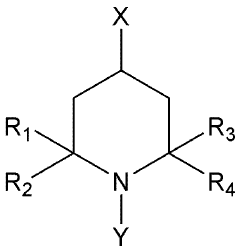

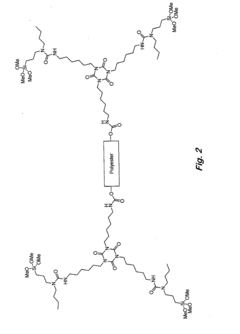

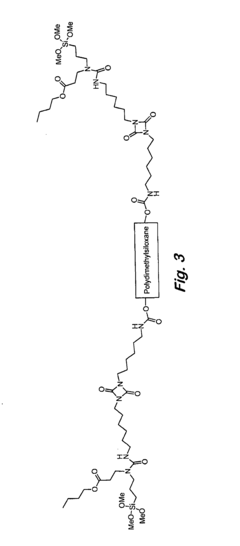

Siloxane-based coatings containing polymers with urea linkages and terminal alkoxysilanes

PatentActiveUS20170183534A1

Innovation

- Development of flexible, two-component siloxane-based coatings using alkoxysilane-terminated urea polymers with urea linkages and moisture-curable alkoxysilane groups, which reduce crosslink density for improved flexibility while maintaining durability and solvent resistance, eliminating the need for isocyanates.

Environmental Impact and Sustainability Considerations

The use of isocyanates in smart building technologies presents both environmental challenges and sustainability opportunities. These compounds, while effective in creating high-performance insulation and structural materials, raise concerns about their ecological footprint throughout their lifecycle.

During production, isocyanates require energy-intensive processes and petrochemical feedstocks, contributing to greenhouse gas emissions and resource depletion. However, advancements in manufacturing techniques have led to more efficient production methods, reducing overall environmental impact. Some manufacturers have implemented closed-loop systems and solvent recovery processes to minimize waste and emissions.

In the application phase, isocyanate-based materials significantly enhance building energy efficiency. Polyurethane foams, for instance, provide superior insulation properties, reducing heating and cooling demands in smart buildings. This translates to lower energy consumption and decreased carbon emissions over the building's lifespan, potentially offsetting the initial production-related environmental costs.

End-of-life considerations for isocyanate-containing materials pose challenges. Many polyurethane products are difficult to recycle due to their complex chemical structure. However, innovative recycling technologies are emerging, such as chemical depolymerization and mechanical recycling, which could improve the circularity of these materials in the future.

The durability of isocyanate-based products contributes to their sustainability profile. Materials like polyurethane coatings and sealants extend the lifespan of building components, reducing the need for frequent replacements and associated resource consumption. This longevity aligns with the principles of sustainable construction and lifecycle thinking in smart building design.

Health and safety concerns related to isocyanate exposure during installation and demolition necessitate strict handling protocols. While these measures ensure worker safety, they also add to the overall environmental management requirements of smart building projects.

Ongoing research focuses on developing bio-based alternatives to traditional isocyanates, aiming to reduce reliance on fossil fuel-derived raw materials. These efforts could lead to more environmentally friendly smart building solutions without compromising performance.

In conclusion, while isocyanates present environmental challenges, their contribution to energy efficiency and durability in smart buildings offers significant sustainability benefits. The industry's focus on improving production processes, enhancing recyclability, and developing bio-based alternatives demonstrates a commitment to addressing environmental concerns while leveraging the unique properties of isocyanates in smart building technologies.

During production, isocyanates require energy-intensive processes and petrochemical feedstocks, contributing to greenhouse gas emissions and resource depletion. However, advancements in manufacturing techniques have led to more efficient production methods, reducing overall environmental impact. Some manufacturers have implemented closed-loop systems and solvent recovery processes to minimize waste and emissions.

In the application phase, isocyanate-based materials significantly enhance building energy efficiency. Polyurethane foams, for instance, provide superior insulation properties, reducing heating and cooling demands in smart buildings. This translates to lower energy consumption and decreased carbon emissions over the building's lifespan, potentially offsetting the initial production-related environmental costs.

End-of-life considerations for isocyanate-containing materials pose challenges. Many polyurethane products are difficult to recycle due to their complex chemical structure. However, innovative recycling technologies are emerging, such as chemical depolymerization and mechanical recycling, which could improve the circularity of these materials in the future.

The durability of isocyanate-based products contributes to their sustainability profile. Materials like polyurethane coatings and sealants extend the lifespan of building components, reducing the need for frequent replacements and associated resource consumption. This longevity aligns with the principles of sustainable construction and lifecycle thinking in smart building design.

Health and safety concerns related to isocyanate exposure during installation and demolition necessitate strict handling protocols. While these measures ensure worker safety, they also add to the overall environmental management requirements of smart building projects.

Ongoing research focuses on developing bio-based alternatives to traditional isocyanates, aiming to reduce reliance on fossil fuel-derived raw materials. These efforts could lead to more environmentally friendly smart building solutions without compromising performance.

In conclusion, while isocyanates present environmental challenges, their contribution to energy efficiency and durability in smart buildings offers significant sustainability benefits. The industry's focus on improving production processes, enhancing recyclability, and developing bio-based alternatives demonstrates a commitment to addressing environmental concerns while leveraging the unique properties of isocyanates in smart building technologies.

Health and Safety Regulations for Isocyanate Use

The use of isocyanates in smart building technologies has necessitated stringent health and safety regulations to protect workers and occupants. These regulations are crucial due to the potential health hazards associated with isocyanate exposure, including respiratory sensitization and occupational asthma.

In the United States, the Occupational Safety and Health Administration (OSHA) has established permissible exposure limits (PELs) for various isocyanates. For instance, the PEL for methylene bisphenyl isocyanate (MDI) is set at 0.02 parts per million (ppm) as a ceiling limit. OSHA also mandates the use of personal protective equipment (PPE) and engineering controls to minimize worker exposure during the application and handling of isocyanate-containing materials.

The National Institute for Occupational Safety and Health (NIOSH) has recommended exposure limits (RELs) that are even more stringent than OSHA's PELs. NIOSH recommends a REL of 0.005 ppm for MDI as a 10-hour time-weighted average (TWA). These guidelines aim to further reduce the risk of adverse health effects associated with isocyanate exposure in smart building applications.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of isocyanates. REACH requires manufacturers and importers to register substances and provide safety information. For isocyanates, specific risk management measures and operational conditions must be implemented to ensure safe use.

The EU has also introduced additional restrictions on diisocyanates under REACH. As of August 24, 2023, all industrial and professional users of products containing diisocyanates in concentrations of 0.1% or more must complete specific training on their safe use. This regulation aims to reduce the incidence of occupational asthma and other respiratory issues associated with isocyanate exposure.

In smart building applications, regulations often focus on the proper installation and maintenance of isocyanate-containing materials. For example, spray polyurethane foam (SPF) insulation, which contains isocyanates, is subject to specific guidelines for application and curing. The U.S. Environmental Protection Agency (EPA) provides recommendations for ventilation, re-occupancy times, and proper disposal of isocyanate-containing waste.

To ensure compliance with these regulations, many jurisdictions require regular air monitoring and health surveillance programs for workers involved in the application of isocyanate-containing materials in smart buildings. These programs typically include periodic medical examinations, lung function tests, and exposure assessments to detect any early signs of isocyanate-related health effects.

As smart building technologies continue to evolve, health and safety regulations for isocyanate use are likely to become more stringent. Future regulations may focus on the development of safer alternatives, improved exposure monitoring techniques, and more comprehensive worker training programs to further mitigate the risks associated with isocyanate use in the construction and maintenance of smart buildings.

In the United States, the Occupational Safety and Health Administration (OSHA) has established permissible exposure limits (PELs) for various isocyanates. For instance, the PEL for methylene bisphenyl isocyanate (MDI) is set at 0.02 parts per million (ppm) as a ceiling limit. OSHA also mandates the use of personal protective equipment (PPE) and engineering controls to minimize worker exposure during the application and handling of isocyanate-containing materials.

The National Institute for Occupational Safety and Health (NIOSH) has recommended exposure limits (RELs) that are even more stringent than OSHA's PELs. NIOSH recommends a REL of 0.005 ppm for MDI as a 10-hour time-weighted average (TWA). These guidelines aim to further reduce the risk of adverse health effects associated with isocyanate exposure in smart building applications.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of isocyanates. REACH requires manufacturers and importers to register substances and provide safety information. For isocyanates, specific risk management measures and operational conditions must be implemented to ensure safe use.

The EU has also introduced additional restrictions on diisocyanates under REACH. As of August 24, 2023, all industrial and professional users of products containing diisocyanates in concentrations of 0.1% or more must complete specific training on their safe use. This regulation aims to reduce the incidence of occupational asthma and other respiratory issues associated with isocyanate exposure.

In smart building applications, regulations often focus on the proper installation and maintenance of isocyanate-containing materials. For example, spray polyurethane foam (SPF) insulation, which contains isocyanates, is subject to specific guidelines for application and curing. The U.S. Environmental Protection Agency (EPA) provides recommendations for ventilation, re-occupancy times, and proper disposal of isocyanate-containing waste.

To ensure compliance with these regulations, many jurisdictions require regular air monitoring and health surveillance programs for workers involved in the application of isocyanate-containing materials in smart buildings. These programs typically include periodic medical examinations, lung function tests, and exposure assessments to detect any early signs of isocyanate-related health effects.

As smart building technologies continue to evolve, health and safety regulations for isocyanate use are likely to become more stringent. Future regulations may focus on the development of safer alternatives, improved exposure monitoring techniques, and more comprehensive worker training programs to further mitigate the risks associated with isocyanate use in the construction and maintenance of smart buildings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!