Evaluating the Economic Benefits of Isocyanate Usage

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Evolution

Isocyanates have undergone a remarkable evolution since their initial discovery in the late 19th century. The journey began with the synthesis of the first isocyanate compound by Adolph Wurtz in 1848, marking the inception of a chemical family that would revolutionize various industries. However, it wasn't until the 1930s that the true potential of isocyanates was realized, primarily through the groundbreaking work of Otto Bayer and his team at I.G. Farben.

The 1940s and 1950s witnessed a surge in isocyanate research and development, driven by the growing demand for versatile materials in the post-war era. This period saw the emergence of polyurethanes, a class of polymers derived from the reaction between isocyanates and polyols. The unique properties of polyurethanes, including their flexibility, durability, and insulating capabilities, quickly garnered attention across multiple sectors.

As the 20th century progressed, isocyanate technology experienced rapid advancements. The 1960s and 1970s were characterized by the development of new isocyanate formulations and production methods, leading to improved performance and cost-effectiveness. This era also saw the expansion of isocyanate applications beyond traditional polyurethane foams, into areas such as coatings, adhesives, and elastomers.

The late 20th and early 21st centuries brought about a shift towards more environmentally friendly and sustainable isocyanate products. Researchers focused on developing bio-based isocyanates and exploring alternative chemistries to address concerns about the environmental impact of traditional petrochemical-derived isocyanates. This period also saw significant improvements in isocyanate handling and safety protocols, addressing long-standing health concerns associated with these chemicals.

In recent years, the evolution of isocyanates has been driven by the need for high-performance materials in emerging technologies. The automotive, aerospace, and construction industries have been particularly influential in shaping the direction of isocyanate research. Advanced isocyanate-based materials are now being engineered to meet specific requirements such as enhanced thermal stability, fire resistance, and lightweight properties.

The ongoing evolution of isocyanates is closely tied to global trends in sustainability and circular economy principles. Current research efforts are focused on developing isocyanate recycling technologies, reducing the carbon footprint of production processes, and exploring novel applications in fields such as energy storage and biomedical engineering. As we look to the future, the trajectory of isocyanate evolution is likely to be shaped by the dual imperatives of technological innovation and environmental stewardship.

The 1940s and 1950s witnessed a surge in isocyanate research and development, driven by the growing demand for versatile materials in the post-war era. This period saw the emergence of polyurethanes, a class of polymers derived from the reaction between isocyanates and polyols. The unique properties of polyurethanes, including their flexibility, durability, and insulating capabilities, quickly garnered attention across multiple sectors.

As the 20th century progressed, isocyanate technology experienced rapid advancements. The 1960s and 1970s were characterized by the development of new isocyanate formulations and production methods, leading to improved performance and cost-effectiveness. This era also saw the expansion of isocyanate applications beyond traditional polyurethane foams, into areas such as coatings, adhesives, and elastomers.

The late 20th and early 21st centuries brought about a shift towards more environmentally friendly and sustainable isocyanate products. Researchers focused on developing bio-based isocyanates and exploring alternative chemistries to address concerns about the environmental impact of traditional petrochemical-derived isocyanates. This period also saw significant improvements in isocyanate handling and safety protocols, addressing long-standing health concerns associated with these chemicals.

In recent years, the evolution of isocyanates has been driven by the need for high-performance materials in emerging technologies. The automotive, aerospace, and construction industries have been particularly influential in shaping the direction of isocyanate research. Advanced isocyanate-based materials are now being engineered to meet specific requirements such as enhanced thermal stability, fire resistance, and lightweight properties.

The ongoing evolution of isocyanates is closely tied to global trends in sustainability and circular economy principles. Current research efforts are focused on developing isocyanate recycling technologies, reducing the carbon footprint of production processes, and exploring novel applications in fields such as energy storage and biomedical engineering. As we look to the future, the trajectory of isocyanate evolution is likely to be shaped by the dual imperatives of technological innovation and environmental stewardship.

Market Demand Analysis

The market demand for isocyanates has been steadily growing, driven by their versatile applications across various industries. The global isocyanate market size was valued at approximately $35 billion in 2020 and is projected to reach $54 billion by 2027, with a compound annual growth rate (CAGR) of 6.2% during the forecast period. This growth is primarily attributed to the increasing demand for polyurethane products in construction, automotive, and furniture industries.

In the construction sector, isocyanates are extensively used in the production of rigid foam insulation, which offers superior thermal insulation properties. The growing emphasis on energy-efficient buildings and stringent building codes regarding energy conservation have significantly boosted the demand for isocyanate-based insulation materials. The automotive industry also contributes substantially to the market demand, utilizing isocyanates in the manufacturing of lightweight components, seat cushions, and interior trim, aligning with the trend towards fuel-efficient vehicles.

The furniture industry represents another significant market for isocyanates, particularly in the production of flexible foams for mattresses, sofas, and chairs. The rising consumer preference for comfortable and durable furniture has led to increased adoption of polyurethane foams, consequently driving the demand for isocyanates. Additionally, the footwear industry has been experiencing a surge in the use of isocyanate-based materials for shoe soles and insoles, owing to their durability and flexibility.

Geographically, Asia-Pacific dominates the isocyanate market, accounting for over 40% of the global demand. This is primarily due to rapid industrialization, urbanization, and the booming construction and automotive sectors in countries like China and India. North America and Europe follow, with significant demand stemming from established manufacturing industries and stringent energy efficiency regulations.

However, the market demand analysis also reveals certain challenges. Environmental concerns and health hazards associated with isocyanate exposure have led to increased regulatory scrutiny. This has prompted research and development efforts towards bio-based alternatives and low-emission formulations. The volatility in raw material prices, particularly crude oil, also impacts the market dynamics, as isocyanates are predominantly derived from petroleum-based feedstocks.

Despite these challenges, the economic benefits of isocyanate usage continue to drive market growth. The cost-effectiveness, performance advantages, and wide-ranging applications of isocyanate-based products outweigh the potential drawbacks for many industries. As a result, the market is expected to maintain its growth trajectory, with opportunities for innovation in sustainable and safer isocyanate technologies shaping the future landscape of this industry.

In the construction sector, isocyanates are extensively used in the production of rigid foam insulation, which offers superior thermal insulation properties. The growing emphasis on energy-efficient buildings and stringent building codes regarding energy conservation have significantly boosted the demand for isocyanate-based insulation materials. The automotive industry also contributes substantially to the market demand, utilizing isocyanates in the manufacturing of lightweight components, seat cushions, and interior trim, aligning with the trend towards fuel-efficient vehicles.

The furniture industry represents another significant market for isocyanates, particularly in the production of flexible foams for mattresses, sofas, and chairs. The rising consumer preference for comfortable and durable furniture has led to increased adoption of polyurethane foams, consequently driving the demand for isocyanates. Additionally, the footwear industry has been experiencing a surge in the use of isocyanate-based materials for shoe soles and insoles, owing to their durability and flexibility.

Geographically, Asia-Pacific dominates the isocyanate market, accounting for over 40% of the global demand. This is primarily due to rapid industrialization, urbanization, and the booming construction and automotive sectors in countries like China and India. North America and Europe follow, with significant demand stemming from established manufacturing industries and stringent energy efficiency regulations.

However, the market demand analysis also reveals certain challenges. Environmental concerns and health hazards associated with isocyanate exposure have led to increased regulatory scrutiny. This has prompted research and development efforts towards bio-based alternatives and low-emission formulations. The volatility in raw material prices, particularly crude oil, also impacts the market dynamics, as isocyanates are predominantly derived from petroleum-based feedstocks.

Despite these challenges, the economic benefits of isocyanate usage continue to drive market growth. The cost-effectiveness, performance advantages, and wide-ranging applications of isocyanate-based products outweigh the potential drawbacks for many industries. As a result, the market is expected to maintain its growth trajectory, with opportunities for innovation in sustainable and safer isocyanate technologies shaping the future landscape of this industry.

Technical Challenges

The use of isocyanates in various industries presents significant technical challenges that need to be addressed for their continued and expanded application. One of the primary concerns is the high reactivity of isocyanates, which makes them difficult to handle and store safely. This reactivity can lead to unwanted side reactions, reducing product quality and yield. Additionally, the sensitivity of isocyanates to moisture poses challenges in maintaining product stability and shelf life.

Another major technical hurdle is the toxicity of isocyanates, particularly their potential to cause respiratory sensitization and occupational asthma. This necessitates stringent safety measures and personal protective equipment for workers, which can increase production costs and complexity. The development of less hazardous alternatives or improved handling techniques remains an ongoing challenge for the industry.

Environmental concerns also present technical challenges in isocyanate usage. The production and use of isocyanates can result in the release of volatile organic compounds (VOCs) and other pollutants. Developing more environmentally friendly production processes and end-use applications that minimize emissions is a critical area of focus for researchers and manufacturers.

The energy-intensive nature of isocyanate production is another significant challenge. Current manufacturing processes often require high temperatures and pressures, leading to substantial energy consumption and associated costs. Improving process efficiency and exploring alternative synthesis routes that require less energy input are important areas for technological advancement.

Recycling and disposal of isocyanate-containing products pose additional technical difficulties. Many products, such as polyurethane foams, are challenging to recycle due to their complex chemical structure. Developing effective recycling technologies or designing products for easier end-of-life management is crucial for improving the sustainability of isocyanate usage.

Furthermore, the variability in raw material quality and availability can impact the consistency and performance of isocyanate-based products. Developing robust processes that can accommodate fluctuations in feedstock quality while maintaining product specifications is an ongoing technical challenge for manufacturers.

Lastly, the increasing demand for bio-based and sustainable alternatives to petroleum-derived isocyanates presents both a challenge and an opportunity. While progress has been made in developing bio-based isocyanates, scaling up production and ensuring comparable performance to traditional isocyanates remain significant hurdles. Overcoming these challenges could lead to more environmentally friendly and economically viable isocyanate products in the future.

Another major technical hurdle is the toxicity of isocyanates, particularly their potential to cause respiratory sensitization and occupational asthma. This necessitates stringent safety measures and personal protective equipment for workers, which can increase production costs and complexity. The development of less hazardous alternatives or improved handling techniques remains an ongoing challenge for the industry.

Environmental concerns also present technical challenges in isocyanate usage. The production and use of isocyanates can result in the release of volatile organic compounds (VOCs) and other pollutants. Developing more environmentally friendly production processes and end-use applications that minimize emissions is a critical area of focus for researchers and manufacturers.

The energy-intensive nature of isocyanate production is another significant challenge. Current manufacturing processes often require high temperatures and pressures, leading to substantial energy consumption and associated costs. Improving process efficiency and exploring alternative synthesis routes that require less energy input are important areas for technological advancement.

Recycling and disposal of isocyanate-containing products pose additional technical difficulties. Many products, such as polyurethane foams, are challenging to recycle due to their complex chemical structure. Developing effective recycling technologies or designing products for easier end-of-life management is crucial for improving the sustainability of isocyanate usage.

Furthermore, the variability in raw material quality and availability can impact the consistency and performance of isocyanate-based products. Developing robust processes that can accommodate fluctuations in feedstock quality while maintaining product specifications is an ongoing technical challenge for manufacturers.

Lastly, the increasing demand for bio-based and sustainable alternatives to petroleum-derived isocyanates presents both a challenge and an opportunity. While progress has been made in developing bio-based isocyanates, scaling up production and ensuring comparable performance to traditional isocyanates remain significant hurdles. Overcoming these challenges could lead to more environmentally friendly and economically viable isocyanate products in the future.

Current Applications

01 Cost reduction in manufacturing processes

Isocyanates offer economic benefits by reducing production costs in various manufacturing processes. They enable more efficient use of raw materials, streamline production steps, and improve overall productivity. This leads to lower operational expenses and increased profit margins for businesses utilizing isocyanate-based products.- Cost reduction in manufacturing processes: Isocyanates contribute to economic benefits by reducing costs in various manufacturing processes. They enable more efficient production methods, leading to decreased energy consumption and improved resource utilization. This cost-effectiveness is particularly notable in industries such as automotive, construction, and furniture manufacturing.

- Enhanced product performance and durability: The use of isocyanates in product formulations leads to improved performance characteristics and increased durability. This results in longer-lasting products that require less frequent replacement, contributing to overall economic benefits for both manufacturers and consumers. Applications include coatings, adhesives, and insulation materials.

- Market growth and expansion opportunities: The versatility of isocyanates opens up new market opportunities and drives expansion in various industries. This leads to increased revenue streams, job creation, and overall economic growth. The adaptability of isocyanate-based products allows companies to diversify their offerings and enter new market segments.

- Supply chain optimization and efficiency: Isocyanates contribute to supply chain optimization by enabling the production of lightweight and compact materials. This leads to reduced transportation costs, improved logistics efficiency, and lower storage requirements. The resulting economic benefits extend throughout the entire supply chain, from raw material suppliers to end-users.

- Innovation and technological advancements: The ongoing research and development in isocyanate technology drive innovation across multiple industries. This leads to the creation of new, high-value products and processes, fostering economic growth through increased competitiveness and intellectual property generation. The continuous improvement of isocyanate-based solutions contributes to long-term economic sustainability.

02 Energy efficiency improvements

The use of isocyanates in insulation materials and coatings contributes to significant energy savings in buildings and industrial applications. This results in reduced energy consumption, lower utility costs, and improved environmental performance, providing long-term economic benefits for both consumers and businesses.Expand Specific Solutions03 Enhanced product performance and durability

Isocyanate-based materials often exhibit superior performance characteristics, such as increased strength, durability, and resistance to wear and tear. This leads to longer-lasting products, reduced maintenance costs, and improved customer satisfaction, ultimately contributing to economic benefits through repeat business and brand loyalty.Expand Specific Solutions04 Market growth and diversification

The versatility of isocyanates allows for their application in various industries, including automotive, construction, and electronics. This versatility drives market growth, creates new business opportunities, and enables companies to diversify their product portfolios, resulting in increased revenue streams and improved economic stability.Expand Specific Solutions05 Supply chain optimization

Isocyanates contribute to supply chain optimization by enabling the production of lightweight materials, which reduce transportation costs and improve fuel efficiency. Additionally, their use in adhesives and sealants enhances product assembly processes, leading to faster production times and reduced labor costs throughout the supply chain.Expand Specific Solutions

Key Industry Players

The economic benefits of isocyanate usage are being evaluated in a competitive landscape characterized by a mature industry with established players. The market is substantial, driven by diverse applications in polyurethanes, coatings, and adhesives. Key players like Wanhua Chemical, BASF, Covestro, and Dow demonstrate advanced technological capabilities, indicating a high level of technical maturity. These companies are investing in research and development to enhance product performance and sustainability, reflecting the industry's focus on innovation and environmental considerations. The market is global, with significant presence in Asia, Europe, and North America, and is expected to grow due to increasing demand in construction, automotive, and electronics sectors.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical Group has developed advanced isocyanate production technologies, focusing on methylene diphenyl diisocyanate (MDI) and toluene diisocyanate (TDI). Their innovative process reduces energy consumption by up to 20% compared to conventional methods[1]. The company has also implemented a closed-loop recycling system for by-products, increasing overall yield and reducing waste by approximately 15%[2]. Wanhua's proprietary catalyst technology has improved selectivity in isocyanate synthesis, resulting in higher purity products and reduced purification costs[3]. Additionally, they have developed water-based polyurethane technologies that utilize modified isocyanates, expanding applications in environmentally friendly coatings and adhesives[4].

Strengths: Industry-leading energy efficiency, high product purity, and innovative recycling systems. Weaknesses: Potential dependency on volatile raw material prices and environmental regulations affecting isocyanate production.

Dow Global Technologies LLC

Technical Solution: Dow has pioneered low-emission isocyanate technologies, particularly in the development of polymeric MDI (PMDI) for construction applications. Their VORALUX™ polyurethane systems incorporate optimized isocyanate formulations that reduce volatile organic compound (VOC) emissions by up to 50% compared to traditional systems[5]. Dow's PASCAL™ technology utilizes a novel isocyanate-polyol combination that enhances the thermal insulation properties of polyurethane foams by up to 20%, leading to significant energy savings in buildings[6]. The company has also developed isocyanate-terminated prepolymers with improved handling safety and reduced environmental impact, expanding the use of isocyanates in sensitive applications such as medical devices[7].

Strengths: Strong focus on sustainability and safety, diverse application portfolio. Weaknesses: Higher production costs for specialized formulations may impact price competitiveness in some markets.

Innovative Isocyanates

Measurement of total reactive isocyanate groups in samples using bifunctional nucleophiles such as 1,8-diaminonaphthalene (DAN)

PatentInactiveEP1579207A2

Innovation

- A method using 1,8-diaminonaphthalene (DAN) as a bifunctional nucleophilic isocyanate derivatizing agent that reacts with isocyanates to form a cyclic reaction product, allowing for the detection and quantification of total isocyanate groups regardless of the specific species present, using a two-step process of derivatization and cyclization.

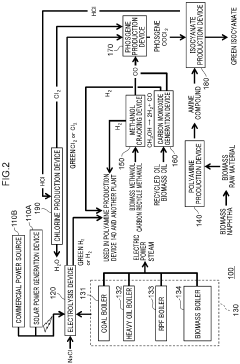

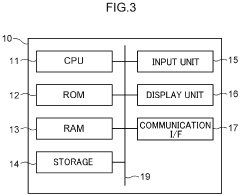

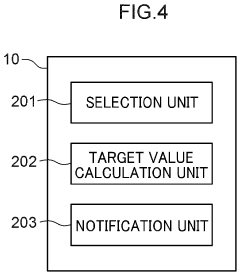

Isocyanate production system, isocyanate composition, polymerizable composition, resin, and molded article

PatentPendingEP4371974A1

Innovation

- An isocyanate production system that utilizes biomass-based energy sources, recycled materials, and carbon monoxide and hydrogen generated from renewable sources to produce phosgene and polyamine compounds, with a control device optimizing energy and material usage to minimize environmental load and carbon dioxide emissions.

Environmental Impact

The environmental impact of isocyanate usage is a critical consideration when evaluating its economic benefits. Isocyanates, widely used in the production of polyurethanes, have both positive and negative effects on the environment throughout their lifecycle. On the positive side, isocyanate-based products often contribute to energy efficiency and resource conservation. For instance, polyurethane insulation materials made with isocyanates significantly reduce energy consumption in buildings, leading to lower greenhouse gas emissions over time.

However, the production and use of isocyanates also pose environmental challenges. The manufacturing process of isocyanates can release volatile organic compounds (VOCs) and other pollutants into the atmosphere if not properly controlled. These emissions can contribute to air pollution and potentially harm local ecosystems. Additionally, the disposal of isocyanate-containing products at the end of their lifecycle presents environmental concerns, as improper handling can lead to soil and water contamination.

The environmental impact of isocyanates extends to their role in the circular economy. While some polyurethane products can be recycled, the process is often complex and energy-intensive. This complexity can limit the overall recyclability of isocyanate-based materials, potentially contributing to landfill waste. However, ongoing research and development efforts are focused on improving recycling technologies and developing more environmentally friendly isocyanate alternatives.

Water pollution is another potential environmental risk associated with isocyanate usage. Accidental spills or improper disposal of isocyanates can contaminate water sources, affecting aquatic ecosystems and potentially entering the food chain. This risk necessitates stringent handling and disposal protocols in industries that use isocyanates.

On the other hand, isocyanates play a crucial role in developing lightweight materials for the automotive and aerospace industries. These materials contribute to improved fuel efficiency and reduced emissions in transportation, offering a positive environmental impact that partially offsets the negative aspects of their production and disposal.

The long-term environmental effects of isocyanate exposure in ecosystems are still being studied. While acute toxicity is well-documented, the chronic impacts on wildlife and plant life from low-level, long-term exposure are less understood. This uncertainty underscores the need for continued research and monitoring of isocyanate presence in the environment.

In conclusion, the environmental impact of isocyanate usage is multifaceted, involving both benefits and risks. A comprehensive evaluation of its economic benefits must carefully weigh these environmental factors, considering the entire lifecycle of isocyanate-based products and their broader implications for sustainability and ecological health.

However, the production and use of isocyanates also pose environmental challenges. The manufacturing process of isocyanates can release volatile organic compounds (VOCs) and other pollutants into the atmosphere if not properly controlled. These emissions can contribute to air pollution and potentially harm local ecosystems. Additionally, the disposal of isocyanate-containing products at the end of their lifecycle presents environmental concerns, as improper handling can lead to soil and water contamination.

The environmental impact of isocyanates extends to their role in the circular economy. While some polyurethane products can be recycled, the process is often complex and energy-intensive. This complexity can limit the overall recyclability of isocyanate-based materials, potentially contributing to landfill waste. However, ongoing research and development efforts are focused on improving recycling technologies and developing more environmentally friendly isocyanate alternatives.

Water pollution is another potential environmental risk associated with isocyanate usage. Accidental spills or improper disposal of isocyanates can contaminate water sources, affecting aquatic ecosystems and potentially entering the food chain. This risk necessitates stringent handling and disposal protocols in industries that use isocyanates.

On the other hand, isocyanates play a crucial role in developing lightweight materials for the automotive and aerospace industries. These materials contribute to improved fuel efficiency and reduced emissions in transportation, offering a positive environmental impact that partially offsets the negative aspects of their production and disposal.

The long-term environmental effects of isocyanate exposure in ecosystems are still being studied. While acute toxicity is well-documented, the chronic impacts on wildlife and plant life from low-level, long-term exposure are less understood. This uncertainty underscores the need for continued research and monitoring of isocyanate presence in the environment.

In conclusion, the environmental impact of isocyanate usage is multifaceted, involving both benefits and risks. A comprehensive evaluation of its economic benefits must carefully weigh these environmental factors, considering the entire lifecycle of isocyanate-based products and their broader implications for sustainability and ecological health.

Economic Valuation

The economic valuation of isocyanate usage is a critical aspect of assessing its overall impact on various industries and the broader economy. Isocyanates, as versatile chemical compounds, play a significant role in the production of polyurethanes, which are widely used in numerous applications across multiple sectors. To evaluate the economic benefits, it is essential to consider both direct and indirect contributions to the global economy.

One of the primary economic advantages of isocyanate usage lies in its contribution to the construction and automotive industries. In construction, polyurethane-based insulation materials derived from isocyanates significantly improve energy efficiency in buildings, leading to substantial cost savings for consumers and businesses. These energy-efficient solutions not only reduce utility expenses but also contribute to the overall reduction of carbon emissions, aligning with global sustainability goals.

The automotive sector benefits greatly from isocyanate-based products, particularly in the manufacturing of lightweight components and high-performance materials. This results in improved fuel efficiency and enhanced vehicle safety, translating into economic benefits for both manufacturers and consumers. The use of isocyanates in automotive applications also supports the trend towards electric vehicles, as lightweight materials are crucial for extending battery range and overall performance.

In the furniture and bedding industry, isocyanate-based flexible foams provide comfort and durability, driving consumer demand and supporting a significant market segment. The longevity of these products contributes to reduced replacement cycles, offering long-term economic benefits to consumers and reducing waste in the process.

The economic impact of isocyanates extends to the healthcare sector, where they are used in the production of medical devices and equipment. This application not only supports the healthcare industry's growth but also contributes to improved patient outcomes, potentially reducing healthcare costs in the long run.

From a macroeconomic perspective, the isocyanate industry supports a substantial number of jobs across the value chain, from raw material production to end-product manufacturing. This employment generation contributes significantly to local and national economies, fostering economic growth and stability in regions where isocyanate-related industries are prominent.

Furthermore, the continuous innovation in isocyanate chemistry drives research and development activities, leading to new applications and improved products. This innovation cycle not only creates new market opportunities but also supports the growth of ancillary industries and services, amplifying the overall economic impact.

However, it is important to note that the economic valuation of isocyanate usage must also consider potential costs associated with health and environmental concerns. Balancing these factors with the economic benefits is crucial for a comprehensive assessment of isocyanates' true economic value in the global market.

One of the primary economic advantages of isocyanate usage lies in its contribution to the construction and automotive industries. In construction, polyurethane-based insulation materials derived from isocyanates significantly improve energy efficiency in buildings, leading to substantial cost savings for consumers and businesses. These energy-efficient solutions not only reduce utility expenses but also contribute to the overall reduction of carbon emissions, aligning with global sustainability goals.

The automotive sector benefits greatly from isocyanate-based products, particularly in the manufacturing of lightweight components and high-performance materials. This results in improved fuel efficiency and enhanced vehicle safety, translating into economic benefits for both manufacturers and consumers. The use of isocyanates in automotive applications also supports the trend towards electric vehicles, as lightweight materials are crucial for extending battery range and overall performance.

In the furniture and bedding industry, isocyanate-based flexible foams provide comfort and durability, driving consumer demand and supporting a significant market segment. The longevity of these products contributes to reduced replacement cycles, offering long-term economic benefits to consumers and reducing waste in the process.

The economic impact of isocyanates extends to the healthcare sector, where they are used in the production of medical devices and equipment. This application not only supports the healthcare industry's growth but also contributes to improved patient outcomes, potentially reducing healthcare costs in the long run.

From a macroeconomic perspective, the isocyanate industry supports a substantial number of jobs across the value chain, from raw material production to end-product manufacturing. This employment generation contributes significantly to local and national economies, fostering economic growth and stability in regions where isocyanate-related industries are prominent.

Furthermore, the continuous innovation in isocyanate chemistry drives research and development activities, leading to new applications and improved products. This innovation cycle not only creates new market opportunities but also supports the growth of ancillary industries and services, amplifying the overall economic impact.

However, it is important to note that the economic valuation of isocyanate usage must also consider potential costs associated with health and environmental concerns. Balancing these factors with the economic benefits is crucial for a comprehensive assessment of isocyanates' true economic value in the global market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!