Future Directions in Isocyanate-Based Technologies

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Tech Evolution

Isocyanate-based technologies have undergone significant evolution since their inception in the early 20th century. The journey began with Otto Bayer's groundbreaking discovery of polyurethane in 1937, which laid the foundation for a wide range of applications across various industries. Initially, the focus was primarily on developing basic polyurethane foams and coatings.

In the 1950s and 1960s, the technology saw rapid advancement with the introduction of new isocyanate compounds and polyol formulations. This period marked the expansion of isocyanate applications into flexible and rigid foams, elastomers, and adhesives. The automotive industry became a major driver of innovation, utilizing polyurethane foams for seating and insulation.

The 1970s and 1980s witnessed a shift towards improving the performance and environmental profile of isocyanate-based products. Researchers focused on developing low-emission formulations and exploring alternative blowing agents to replace chlorofluorocarbons (CFCs). This era also saw the emergence of specialized isocyanates for high-performance coatings and elastomers.

The 1990s and early 2000s brought about a revolution in isocyanate chemistry with the introduction of water-based and solvent-free systems. These developments were driven by increasing environmental regulations and a growing demand for more sustainable products. Simultaneously, advancements in catalysis and processing technologies enabled the production of more complex and tailored polyurethane systems.

In recent years, the focus has shifted towards bio-based and recyclable isocyanate technologies. Researchers are exploring renewable feedstocks for both isocyanates and polyols, aiming to reduce the carbon footprint of polyurethane products. Additionally, there has been significant progress in developing isocyanate-free alternatives and improving the recyclability of existing polyurethane materials.

The current technological landscape is characterized by a push towards smart and responsive isocyanate-based materials. This includes self-healing polyurethanes, shape-memory polymers, and materials with enhanced thermal and electrical properties. Nanotechnology has also played a crucial role in advancing isocyanate-based composites, leading to materials with unprecedented strength-to-weight ratios and functional properties.

Looking ahead, the future of isocyanate-based technologies is likely to be shaped by sustainability concerns, digitalization, and the need for advanced materials in emerging industries. Research is ongoing to develop fully biodegradable polyurethanes and to establish efficient recycling processes for existing materials. The integration of sensors and smart functionalities into isocyanate-based products is expected to open up new applications in wearable technology, healthcare, and smart infrastructure.

In the 1950s and 1960s, the technology saw rapid advancement with the introduction of new isocyanate compounds and polyol formulations. This period marked the expansion of isocyanate applications into flexible and rigid foams, elastomers, and adhesives. The automotive industry became a major driver of innovation, utilizing polyurethane foams for seating and insulation.

The 1970s and 1980s witnessed a shift towards improving the performance and environmental profile of isocyanate-based products. Researchers focused on developing low-emission formulations and exploring alternative blowing agents to replace chlorofluorocarbons (CFCs). This era also saw the emergence of specialized isocyanates for high-performance coatings and elastomers.

The 1990s and early 2000s brought about a revolution in isocyanate chemistry with the introduction of water-based and solvent-free systems. These developments were driven by increasing environmental regulations and a growing demand for more sustainable products. Simultaneously, advancements in catalysis and processing technologies enabled the production of more complex and tailored polyurethane systems.

In recent years, the focus has shifted towards bio-based and recyclable isocyanate technologies. Researchers are exploring renewable feedstocks for both isocyanates and polyols, aiming to reduce the carbon footprint of polyurethane products. Additionally, there has been significant progress in developing isocyanate-free alternatives and improving the recyclability of existing polyurethane materials.

The current technological landscape is characterized by a push towards smart and responsive isocyanate-based materials. This includes self-healing polyurethanes, shape-memory polymers, and materials with enhanced thermal and electrical properties. Nanotechnology has also played a crucial role in advancing isocyanate-based composites, leading to materials with unprecedented strength-to-weight ratios and functional properties.

Looking ahead, the future of isocyanate-based technologies is likely to be shaped by sustainability concerns, digitalization, and the need for advanced materials in emerging industries. Research is ongoing to develop fully biodegradable polyurethanes and to establish efficient recycling processes for existing materials. The integration of sensors and smart functionalities into isocyanate-based products is expected to open up new applications in wearable technology, healthcare, and smart infrastructure.

Market Demand Analysis

The market demand for isocyanate-based technologies continues to grow, driven by their versatility and wide-ranging applications across multiple industries. The global isocyanate market is projected to expand significantly in the coming years, with a compound annual growth rate (CAGR) exceeding 5% through 2027. This growth is primarily fueled by increasing demand in construction, automotive, and furniture industries.

In the construction sector, isocyanate-based polyurethanes are extensively used for insulation, sealants, and adhesives. The rising focus on energy-efficient buildings and sustainable construction practices is boosting the demand for high-performance insulation materials, where isocyanate-based products excel. Additionally, the growing trend of prefabricated and modular construction is creating new opportunities for isocyanate-based adhesives and sealants.

The automotive industry represents another major market for isocyanate-based technologies. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, there is an increasing adoption of polyurethane foams for seat cushions, headrests, and interior components. The shift towards electric vehicles is also driving demand for specialized insulation materials and lightweight components, where isocyanate-based products offer significant advantages.

In the furniture and bedding industry, isocyanate-based flexible foams remain a key material for cushioning and comfort. The growing consumer preference for ergonomic and customized furniture is fueling innovation in foam technologies, creating new market opportunities for isocyanate-based products.

The packaging industry is emerging as a promising growth area for isocyanate-based technologies. With the rise of e-commerce and the need for protective packaging solutions, there is increasing demand for high-performance foams and adhesives that can ensure product safety during transit.

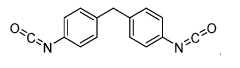

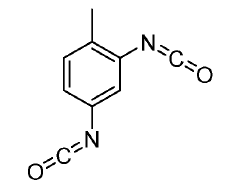

However, the market is also facing challenges. Environmental concerns and regulatory pressures regarding the use of certain isocyanates, particularly methylene diphenyl diisocyanate (MDI) and toluene diisocyanate (TDI), are driving research into more sustainable alternatives. This has led to a growing interest in bio-based isocyanates and isocyanate-free technologies, which could reshape the market landscape in the long term.

Despite these challenges, the overall market outlook for isocyanate-based technologies remains positive. The industry is responding to sustainability concerns by developing greener production processes and exploring new applications that leverage the unique properties of isocyanates. As emerging economies continue to industrialize and urbanize, the demand for isocyanate-based products in construction, automotive, and consumer goods sectors is expected to surge, particularly in Asia-Pacific and Latin American markets.

In the construction sector, isocyanate-based polyurethanes are extensively used for insulation, sealants, and adhesives. The rising focus on energy-efficient buildings and sustainable construction practices is boosting the demand for high-performance insulation materials, where isocyanate-based products excel. Additionally, the growing trend of prefabricated and modular construction is creating new opportunities for isocyanate-based adhesives and sealants.

The automotive industry represents another major market for isocyanate-based technologies. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, there is an increasing adoption of polyurethane foams for seat cushions, headrests, and interior components. The shift towards electric vehicles is also driving demand for specialized insulation materials and lightweight components, where isocyanate-based products offer significant advantages.

In the furniture and bedding industry, isocyanate-based flexible foams remain a key material for cushioning and comfort. The growing consumer preference for ergonomic and customized furniture is fueling innovation in foam technologies, creating new market opportunities for isocyanate-based products.

The packaging industry is emerging as a promising growth area for isocyanate-based technologies. With the rise of e-commerce and the need for protective packaging solutions, there is increasing demand for high-performance foams and adhesives that can ensure product safety during transit.

However, the market is also facing challenges. Environmental concerns and regulatory pressures regarding the use of certain isocyanates, particularly methylene diphenyl diisocyanate (MDI) and toluene diisocyanate (TDI), are driving research into more sustainable alternatives. This has led to a growing interest in bio-based isocyanates and isocyanate-free technologies, which could reshape the market landscape in the long term.

Despite these challenges, the overall market outlook for isocyanate-based technologies remains positive. The industry is responding to sustainability concerns by developing greener production processes and exploring new applications that leverage the unique properties of isocyanates. As emerging economies continue to industrialize and urbanize, the demand for isocyanate-based products in construction, automotive, and consumer goods sectors is expected to surge, particularly in Asia-Pacific and Latin American markets.

Current Tech Challenges

Isocyanate-based technologies, while widely used in various industries, face several significant challenges that hinder their further development and application. One of the primary concerns is the toxicity of isocyanates, particularly their potential to cause respiratory sensitization and occupational asthma. This health risk has led to increased regulatory scrutiny and a push for safer alternatives, creating a complex landscape for manufacturers and end-users alike.

Environmental concerns also pose a substantial challenge to isocyanate-based technologies. The production and use of isocyanates often involve volatile organic compounds (VOCs) and other environmentally harmful substances. As global environmental regulations become more stringent, companies are under pressure to develop more sustainable production methods and end products, which can be technically challenging and costly.

Another significant hurdle is the dependency on fossil fuel-derived raw materials for isocyanate production. With the growing emphasis on sustainability and the finite nature of fossil resources, there is an urgent need to explore bio-based alternatives. However, developing bio-based isocyanates that match the performance of traditional ones while remaining cost-effective is a complex technical challenge that requires substantial research and development efforts.

The curing process of isocyanate-based products, particularly in polyurethane applications, presents additional technical difficulties. Achieving consistent curing across different environmental conditions, such as varying humidity levels, remains a challenge. This can lead to quality inconsistencies in final products, especially in large-scale applications like construction or automotive manufacturing.

Furthermore, the recyclability and end-of-life management of isocyanate-based products pose significant challenges. Many polyurethane products, for instance, are difficult to recycle due to their thermoset nature. Developing effective recycling technologies or designing products for easier disassembly and material recovery is a critical area that requires innovative solutions.

Lastly, the industry faces challenges in optimizing the reactivity and stability of isocyanate-based systems. Balancing these properties is crucial for improving product performance and shelf life while maintaining processability. This requires advanced formulation techniques and a deep understanding of the chemical kinetics involved in isocyanate reactions.

Environmental concerns also pose a substantial challenge to isocyanate-based technologies. The production and use of isocyanates often involve volatile organic compounds (VOCs) and other environmentally harmful substances. As global environmental regulations become more stringent, companies are under pressure to develop more sustainable production methods and end products, which can be technically challenging and costly.

Another significant hurdle is the dependency on fossil fuel-derived raw materials for isocyanate production. With the growing emphasis on sustainability and the finite nature of fossil resources, there is an urgent need to explore bio-based alternatives. However, developing bio-based isocyanates that match the performance of traditional ones while remaining cost-effective is a complex technical challenge that requires substantial research and development efforts.

The curing process of isocyanate-based products, particularly in polyurethane applications, presents additional technical difficulties. Achieving consistent curing across different environmental conditions, such as varying humidity levels, remains a challenge. This can lead to quality inconsistencies in final products, especially in large-scale applications like construction or automotive manufacturing.

Furthermore, the recyclability and end-of-life management of isocyanate-based products pose significant challenges. Many polyurethane products, for instance, are difficult to recycle due to their thermoset nature. Developing effective recycling technologies or designing products for easier disassembly and material recovery is a critical area that requires innovative solutions.

Lastly, the industry faces challenges in optimizing the reactivity and stability of isocyanate-based systems. Balancing these properties is crucial for improving product performance and shelf life while maintaining processability. This requires advanced formulation techniques and a deep understanding of the chemical kinetics involved in isocyanate reactions.

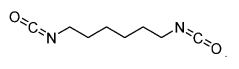

Current Isocyanate Apps

01 Polyurethane synthesis and applications

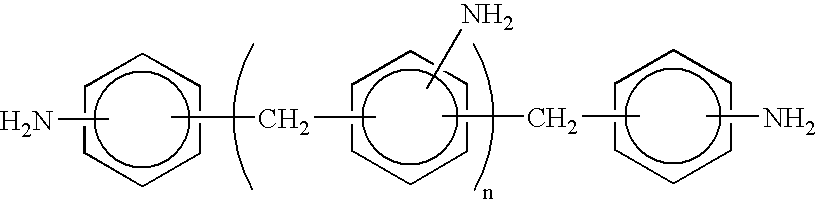

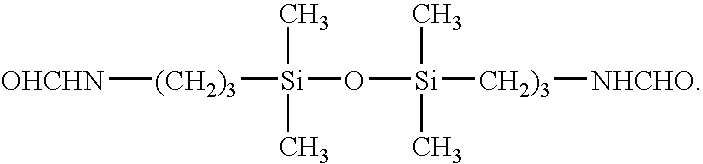

Isocyanate-based technologies are widely used in the synthesis of polyurethanes. These materials find applications in various industries, including coatings, adhesives, sealants, and elastomers. The reaction between isocyanates and polyols forms the basis of polyurethane chemistry, allowing for the creation of materials with diverse properties and characteristics.- Polyurethane synthesis and applications: Isocyanate-based technologies are widely used in the synthesis of polyurethanes. These materials find applications in various industries, including coatings, adhesives, foams, and elastomers. The reaction between isocyanates and polyols forms the basis of polyurethane chemistry, allowing for the creation of materials with diverse properties and characteristics.

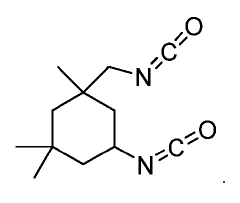

- Isocyanate-based coatings and films: Isocyanates are crucial components in the development of high-performance coatings and films. These technologies enable the creation of durable, chemical-resistant, and weather-resistant surfaces. The versatility of isocyanate chemistry allows for the formulation of coatings with specific properties tailored to various applications, such as automotive finishes, industrial protective coatings, and decorative films.

- Isocyanate-based adhesives and sealants: Isocyanate technologies play a significant role in the development of high-strength adhesives and sealants. These products offer excellent bonding properties, durability, and resistance to environmental factors. Isocyanate-based adhesives find applications in automotive assembly, construction, and various industrial sectors where strong and reliable bonding is required.

- Isocyanate-based foams and insulation materials: Isocyanates are key components in the production of various types of foams, including rigid and flexible polyurethane foams. These materials are widely used for insulation in construction, automotive, and appliance industries. Isocyanate-based foams offer excellent thermal insulation properties, lightweight characteristics, and can be formulated to meet specific performance requirements.

- Isocyanate-based elastomers and rubbers: Isocyanate technologies are employed in the development of high-performance elastomers and synthetic rubbers. These materials offer a combination of elasticity, durability, and chemical resistance. Isocyanate-based elastomers find applications in automotive parts, industrial rollers, seals, and various other products requiring flexible and resilient properties.

02 Isocyanate-based coatings and films

Isocyanates are crucial components in the development of high-performance coatings and films. These technologies enable the creation of durable, chemical-resistant, and weather-resistant surfaces. Isocyanate-based coatings are used in automotive, industrial, and architectural applications, providing protection and aesthetic properties to various substrates.Expand Specific Solutions03 Isocyanate-modified polymers and resins

Isocyanate-based technologies are employed to modify existing polymers and resins, enhancing their properties and expanding their applications. This includes the development of isocyanate-terminated prepolymers, which can be used to create materials with improved mechanical strength, chemical resistance, and adhesion properties.Expand Specific Solutions04 Isocyanate-based adhesives and sealants

Isocyanates play a crucial role in the formulation of high-performance adhesives and sealants. These technologies enable the development of products with excellent bonding strength, flexibility, and durability. Isocyanate-based adhesives and sealants are used in various industries, including construction, automotive, and aerospace.Expand Specific Solutions05 Environmental and safety considerations in isocyanate technologies

As isocyanates can pose health and environmental risks, research focuses on developing safer alternatives and improving handling procedures. This includes the exploration of bio-based isocyanates, low-VOC formulations, and technologies to reduce worker exposure during manufacturing and application processes.Expand Specific Solutions

Key Industry Players

The market for isocyanate-based technologies is in a mature stage but continues to evolve, driven by environmental regulations and sustainability concerns. The global market size is substantial, estimated to be over $20 billion annually. Technologically, the field is well-established but still sees innovation, particularly in eco-friendly alternatives and enhanced performance. Key players like Covestro, Wanhua Chemical, and BASF are at the forefront, investing heavily in R&D to develop next-generation products. Emerging companies and research institutions are also contributing to advancements, focusing on bio-based isocyanates and improved production processes. The competitive landscape is characterized by a mix of large chemical conglomerates and specialized manufacturers, with increasing emphasis on sustainability and cost-effectiveness.

Covestro Deutschland AG

Technical Solution: Covestro is pioneering bio-based and CO2-based isocyanates to reduce the carbon footprint of polyurethane production. Their innovative approach involves using plant-based raw materials and captured CO2 as feedstock for isocyanate synthesis[1]. This method can potentially reduce fossil resource consumption by up to 70%[2]. Additionally, Covestro is developing novel catalysts to improve the efficiency and selectivity of isocyanate production, potentially lowering energy requirements and increasing yield[3]. The company is also exploring isocyanate-free technologies, such as non-isocyanate polyurethanes (NIPUs), which offer improved chemical resistance and weatherability[4].

Strengths: Sustainable raw materials, reduced carbon footprint, potential for significant fossil resource reduction. Weaknesses: Higher production costs, limited availability of bio-based feedstocks, potential performance trade-offs compared to traditional isocyanates.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical is focusing on developing high-performance and specialty isocyanates for niche applications. They have introduced a range of low-free monomer technology (LFM) products, which significantly reduce the amount of residual monomeric diisocyanates in prepolymers and final products[5]. This technology addresses health and safety concerns associated with isocyanate exposure. Wanhua is also investing in waterborne polyurethane dispersions (PUDs) based on novel isocyanate chemistries, offering improved environmental compatibility and reduced VOC emissions[6]. Furthermore, the company is exploring the use of bio-based polyols in combination with their isocyanates to create more sustainable polyurethane systems[7].

Strengths: Advanced LFM technology, focus on safety and environmental concerns, diverse product portfolio. Weaknesses: Potential regulatory challenges, competition in specialty markets, dependence on petrochemical feedstocks for most products.

Key Isocyanate Patents

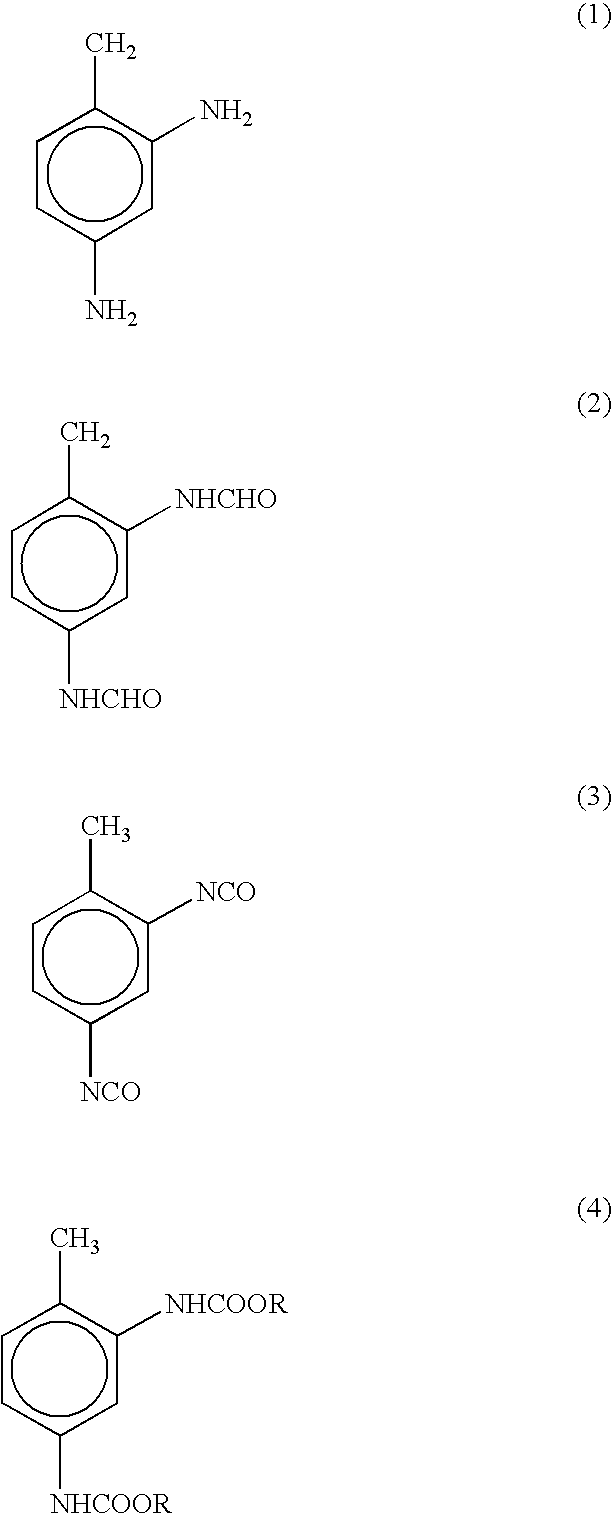

Flow chemistry synthesis of isocyanates

PatentWO2021119606A1

Innovation

- A continuous flow process involving the mixing of acyl hydrazides with nitrous acid to form acyl azides, followed by heating in the presence of an organic solvent to produce isocyanates through Curtius rearrangement, offering a safer and more scalable method for isocyanate synthesis.

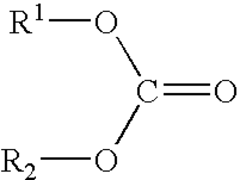

Non-phosgene route to the manufacture of organic isocyanates

PatentInactiveUS6781010B1

Innovation

- The synthesis of organic isocyanates through the reaction of formamides with diorganocarbonates, where the major byproducts can be thermolyzed to additional isocyanates or recycled to generate raw materials, resulting in a high-yield, efficient process with minimal waste.

Environmental Impact

The environmental impact of isocyanate-based technologies has been a growing concern in recent years, prompting researchers and industry leaders to explore more sustainable alternatives and improved production methods. As these technologies continue to evolve, there is a significant focus on reducing their ecological footprint and enhancing their overall environmental performance.

One of the primary environmental challenges associated with isocyanate-based technologies is the release of volatile organic compounds (VOCs) during production and application processes. These emissions contribute to air pollution and can have adverse effects on both human health and the environment. To address this issue, future directions in isocyanate-based technologies are likely to emphasize the development of low-VOC and zero-VOC formulations. This may involve the use of alternative raw materials or the implementation of advanced emission control systems in manufacturing facilities.

Another critical area of focus is the reduction of energy consumption and greenhouse gas emissions throughout the lifecycle of isocyanate-based products. This includes optimizing production processes to minimize energy requirements, as well as exploring more efficient transportation and application methods. Additionally, researchers are investigating the potential for bio-based isocyanates derived from renewable resources, which could significantly reduce the carbon footprint of these technologies.

The end-of-life management of isocyanate-based products is also a key consideration for future developments. Improving the recyclability and biodegradability of these materials is crucial for minimizing their long-term environmental impact. This may involve the development of novel chemical structures that facilitate easier decomposition or the creation of closed-loop recycling systems for isocyanate-based products.

Water consumption and pollution are additional environmental concerns associated with isocyanate-based technologies. Future research is likely to focus on water-based formulations and production methods that reduce water usage and minimize the release of harmful substances into aquatic ecosystems. This may include the development of advanced wastewater treatment technologies specifically designed for isocyanate-containing effluents.

As regulatory pressures increase and consumer demand for environmentally friendly products grows, the isocyanate industry is expected to invest heavily in green chemistry principles. This approach will prioritize the design of chemical products and processes that reduce or eliminate the use and generation of hazardous substances. Future isocyanate-based technologies may incorporate safer alternatives to traditional catalysts and additives, further reducing their environmental impact.

Lastly, the development of more accurate and comprehensive life cycle assessment (LCA) tools for isocyanate-based products will play a crucial role in guiding future environmental improvements. These tools will enable manufacturers to better understand the environmental impacts of their products across all stages of their lifecycle, from raw material extraction to disposal or recycling. This knowledge will inform decision-making processes and drive innovation towards more sustainable isocyanate-based technologies.

One of the primary environmental challenges associated with isocyanate-based technologies is the release of volatile organic compounds (VOCs) during production and application processes. These emissions contribute to air pollution and can have adverse effects on both human health and the environment. To address this issue, future directions in isocyanate-based technologies are likely to emphasize the development of low-VOC and zero-VOC formulations. This may involve the use of alternative raw materials or the implementation of advanced emission control systems in manufacturing facilities.

Another critical area of focus is the reduction of energy consumption and greenhouse gas emissions throughout the lifecycle of isocyanate-based products. This includes optimizing production processes to minimize energy requirements, as well as exploring more efficient transportation and application methods. Additionally, researchers are investigating the potential for bio-based isocyanates derived from renewable resources, which could significantly reduce the carbon footprint of these technologies.

The end-of-life management of isocyanate-based products is also a key consideration for future developments. Improving the recyclability and biodegradability of these materials is crucial for minimizing their long-term environmental impact. This may involve the development of novel chemical structures that facilitate easier decomposition or the creation of closed-loop recycling systems for isocyanate-based products.

Water consumption and pollution are additional environmental concerns associated with isocyanate-based technologies. Future research is likely to focus on water-based formulations and production methods that reduce water usage and minimize the release of harmful substances into aquatic ecosystems. This may include the development of advanced wastewater treatment technologies specifically designed for isocyanate-containing effluents.

As regulatory pressures increase and consumer demand for environmentally friendly products grows, the isocyanate industry is expected to invest heavily in green chemistry principles. This approach will prioritize the design of chemical products and processes that reduce or eliminate the use and generation of hazardous substances. Future isocyanate-based technologies may incorporate safer alternatives to traditional catalysts and additives, further reducing their environmental impact.

Lastly, the development of more accurate and comprehensive life cycle assessment (LCA) tools for isocyanate-based products will play a crucial role in guiding future environmental improvements. These tools will enable manufacturers to better understand the environmental impacts of their products across all stages of their lifecycle, from raw material extraction to disposal or recycling. This knowledge will inform decision-making processes and drive innovation towards more sustainable isocyanate-based technologies.

Regulatory Framework

The regulatory framework surrounding isocyanate-based technologies is becoming increasingly stringent, reflecting growing concerns about environmental and health impacts. Globally, regulatory bodies are implementing stricter controls on the production, use, and disposal of isocyanates and their derivatives. In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has placed isocyanates under close scrutiny, requiring extensive safety data and risk assessments for their continued use.

In the United States, the Environmental Protection Agency (EPA) has proposed new rules under the Toxic Substances Control Act (TSCA) to address potential risks associated with certain diisocyanates. These regulations aim to limit exposure in the workplace and during consumer use of products containing uncured diisocyanates. Additionally, the Occupational Safety and Health Administration (OSHA) has established permissible exposure limits for various isocyanates to protect workers.

The regulatory landscape is also evolving in Asia, with countries like China and Japan introducing more comprehensive chemical management systems. These regulations often align with international standards but may include country-specific requirements, creating a complex regulatory environment for global manufacturers.

Future regulatory trends are likely to focus on sustainable alternatives and circular economy principles. Policymakers are increasingly emphasizing the need for safer substitutes and improved recycling processes for isocyanate-based products. This shift is driving research into bio-based isocyanates and more environmentally friendly production methods.

The automotive and construction industries, major consumers of isocyanate-based products, are particularly affected by these regulatory changes. Manufacturers in these sectors are under pressure to adapt their formulations and processes to comply with new standards while maintaining product performance.

As regulations tighten, companies are investing in advanced monitoring and control technologies to ensure compliance. This includes the development of more sensitive detection methods for isocyanates in air and water, as well as improved personal protective equipment for workers handling these materials.

The regulatory framework is also influencing innovation in isocyanate chemistry. There is a growing focus on developing lower-toxicity alternatives and improving the safety profile of existing products. This regulatory pressure is expected to drive significant advancements in isocyanate technology over the coming years, potentially reshaping the industry landscape.

In the United States, the Environmental Protection Agency (EPA) has proposed new rules under the Toxic Substances Control Act (TSCA) to address potential risks associated with certain diisocyanates. These regulations aim to limit exposure in the workplace and during consumer use of products containing uncured diisocyanates. Additionally, the Occupational Safety and Health Administration (OSHA) has established permissible exposure limits for various isocyanates to protect workers.

The regulatory landscape is also evolving in Asia, with countries like China and Japan introducing more comprehensive chemical management systems. These regulations often align with international standards but may include country-specific requirements, creating a complex regulatory environment for global manufacturers.

Future regulatory trends are likely to focus on sustainable alternatives and circular economy principles. Policymakers are increasingly emphasizing the need for safer substitutes and improved recycling processes for isocyanate-based products. This shift is driving research into bio-based isocyanates and more environmentally friendly production methods.

The automotive and construction industries, major consumers of isocyanate-based products, are particularly affected by these regulatory changes. Manufacturers in these sectors are under pressure to adapt their formulations and processes to comply with new standards while maintaining product performance.

As regulations tighten, companies are investing in advanced monitoring and control technologies to ensure compliance. This includes the development of more sensitive detection methods for isocyanates in air and water, as well as improved personal protective equipment for workers handling these materials.

The regulatory framework is also influencing innovation in isocyanate chemistry. There is a growing focus on developing lower-toxicity alternatives and improving the safety profile of existing products. This regulatory pressure is expected to drive significant advancements in isocyanate technology over the coming years, potentially reshaping the industry landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!