Investigating Isocyanate Breakthroughs in Modern Design Applications

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Evolution

Isocyanates have undergone a remarkable evolution since their discovery in the mid-20th century, revolutionizing various industries and design applications. The journey of isocyanates began with their synthesis by Wurtz in 1848, but it wasn't until the 1930s that their potential for polymer production was realized. This breakthrough led to the development of polyurethanes, marking a significant milestone in materials science.

The 1940s and 1950s saw rapid advancements in isocyanate chemistry, with the introduction of toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI). These compounds quickly became the backbone of the polyurethane industry, enabling the creation of flexible and rigid foams, elastomers, and coatings. The versatility of isocyanates allowed for their application in diverse fields, from automotive manufacturing to construction and furniture production.

In the 1960s and 1970s, researchers focused on improving the performance and safety of isocyanate-based products. This period witnessed the development of modified MDIs and specialized isocyanates tailored for specific applications. The introduction of aliphatic isocyanates expanded the use of polyurethanes in exterior applications, offering superior UV resistance and color stability.

The 1980s and 1990s brought increased attention to environmental and health concerns associated with isocyanates. This led to the development of low-emission and water-based polyurethane systems, as well as improved handling and safety protocols. Simultaneously, advancements in catalysis and processing technologies enhanced the efficiency and quality of isocyanate-based products.

The turn of the millennium marked a new era for isocyanates, with a focus on sustainability and bio-based alternatives. Researchers began exploring the use of renewable resources to produce isocyanates, aiming to reduce dependence on petrochemicals. This period also saw the emergence of non-isocyanate polyurethanes (NIPUs) as potential alternatives in certain applications.

Recent years have witnessed groundbreaking developments in isocyanate technology. The advent of nanotechnology has led to the creation of nanostructured isocyanate-based materials with enhanced properties. Additionally, the integration of isocyanates with other advanced materials, such as graphene and carbon nanotubes, has opened up new possibilities in high-performance composites and smart materials.

The evolution of isocyanates continues to be driven by the demand for more sustainable, efficient, and versatile materials. Current research focuses on developing bio-based isocyanates, improving the recyclability of polyurethane products, and exploring novel applications in fields such as 3D printing, energy storage, and biomedical engineering. As we look to the future, the ongoing evolution of isocyanates promises to deliver innovative solutions to complex design challenges across various industries.

The 1940s and 1950s saw rapid advancements in isocyanate chemistry, with the introduction of toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI). These compounds quickly became the backbone of the polyurethane industry, enabling the creation of flexible and rigid foams, elastomers, and coatings. The versatility of isocyanates allowed for their application in diverse fields, from automotive manufacturing to construction and furniture production.

In the 1960s and 1970s, researchers focused on improving the performance and safety of isocyanate-based products. This period witnessed the development of modified MDIs and specialized isocyanates tailored for specific applications. The introduction of aliphatic isocyanates expanded the use of polyurethanes in exterior applications, offering superior UV resistance and color stability.

The 1980s and 1990s brought increased attention to environmental and health concerns associated with isocyanates. This led to the development of low-emission and water-based polyurethane systems, as well as improved handling and safety protocols. Simultaneously, advancements in catalysis and processing technologies enhanced the efficiency and quality of isocyanate-based products.

The turn of the millennium marked a new era for isocyanates, with a focus on sustainability and bio-based alternatives. Researchers began exploring the use of renewable resources to produce isocyanates, aiming to reduce dependence on petrochemicals. This period also saw the emergence of non-isocyanate polyurethanes (NIPUs) as potential alternatives in certain applications.

Recent years have witnessed groundbreaking developments in isocyanate technology. The advent of nanotechnology has led to the creation of nanostructured isocyanate-based materials with enhanced properties. Additionally, the integration of isocyanates with other advanced materials, such as graphene and carbon nanotubes, has opened up new possibilities in high-performance composites and smart materials.

The evolution of isocyanates continues to be driven by the demand for more sustainable, efficient, and versatile materials. Current research focuses on developing bio-based isocyanates, improving the recyclability of polyurethane products, and exploring novel applications in fields such as 3D printing, energy storage, and biomedical engineering. As we look to the future, the ongoing evolution of isocyanates promises to deliver innovative solutions to complex design challenges across various industries.

Market Demand Analysis

The market demand for isocyanate-based products has been steadily growing across various industries, driven by their versatile applications in modern design. The global isocyanate market is projected to expand significantly in the coming years, with a compound annual growth rate (CAGR) exceeding 5% through 2025. This growth is primarily fueled by the increasing demand for polyurethane products in construction, automotive, and furniture industries.

In the construction sector, isocyanates play a crucial role in the production of rigid foam insulation, which is essential for improving energy efficiency in buildings. The push for sustainable and energy-efficient construction practices has led to a surge in demand for high-performance insulation materials. This trend is particularly pronounced in developed countries where stringent building codes and regulations are driving the adoption of advanced insulation solutions.

The automotive industry represents another major market for isocyanates, particularly in the manufacturing of lightweight components and interior materials. As automakers strive to reduce vehicle weight and improve fuel efficiency, the use of polyurethane-based parts has become increasingly prevalent. This trend is expected to continue, especially with the growing emphasis on electric vehicles, where weight reduction is critical for extending battery range.

In the furniture and bedding industry, isocyanates are widely used in the production of flexible foams for mattresses, sofas, and other upholstered products. The rising consumer preference for comfortable and durable furniture, coupled with the growth of the e-commerce sector, has contributed to the increased demand for isocyanate-based materials in this segment.

The packaging industry is also witnessing a growing demand for isocyanate-based adhesives and coatings. These materials offer superior bonding strength and chemical resistance, making them ideal for use in food packaging and industrial applications. The shift towards sustainable packaging solutions has further boosted the demand for bio-based isocyanates, opening up new opportunities for market growth.

Despite the positive market outlook, there are challenges that could impact the demand for isocyanates. Environmental concerns and regulatory pressures regarding the use of certain isocyanates, particularly those classified as hazardous substances, have led to increased research and development efforts focused on developing safer alternatives. This has created a market opportunity for eco-friendly and low-toxicity isocyanate formulations, driving innovation in the industry.

In conclusion, the market demand for isocyanates in modern design applications remains robust, with significant growth potential across multiple sectors. The ongoing technological advancements and the development of safer, more sustainable isocyanate-based products are expected to further expand market opportunities and drive innovation in the coming years.

In the construction sector, isocyanates play a crucial role in the production of rigid foam insulation, which is essential for improving energy efficiency in buildings. The push for sustainable and energy-efficient construction practices has led to a surge in demand for high-performance insulation materials. This trend is particularly pronounced in developed countries where stringent building codes and regulations are driving the adoption of advanced insulation solutions.

The automotive industry represents another major market for isocyanates, particularly in the manufacturing of lightweight components and interior materials. As automakers strive to reduce vehicle weight and improve fuel efficiency, the use of polyurethane-based parts has become increasingly prevalent. This trend is expected to continue, especially with the growing emphasis on electric vehicles, where weight reduction is critical for extending battery range.

In the furniture and bedding industry, isocyanates are widely used in the production of flexible foams for mattresses, sofas, and other upholstered products. The rising consumer preference for comfortable and durable furniture, coupled with the growth of the e-commerce sector, has contributed to the increased demand for isocyanate-based materials in this segment.

The packaging industry is also witnessing a growing demand for isocyanate-based adhesives and coatings. These materials offer superior bonding strength and chemical resistance, making them ideal for use in food packaging and industrial applications. The shift towards sustainable packaging solutions has further boosted the demand for bio-based isocyanates, opening up new opportunities for market growth.

Despite the positive market outlook, there are challenges that could impact the demand for isocyanates. Environmental concerns and regulatory pressures regarding the use of certain isocyanates, particularly those classified as hazardous substances, have led to increased research and development efforts focused on developing safer alternatives. This has created a market opportunity for eco-friendly and low-toxicity isocyanate formulations, driving innovation in the industry.

In conclusion, the market demand for isocyanates in modern design applications remains robust, with significant growth potential across multiple sectors. The ongoing technological advancements and the development of safer, more sustainable isocyanate-based products are expected to further expand market opportunities and drive innovation in the coming years.

Technical Challenges

The development of isocyanates in modern design applications faces several significant technical challenges. One of the primary obstacles is the toxicity associated with isocyanates, particularly during the manufacturing and application processes. Exposure to isocyanates can cause severe respiratory issues and skin irritation, necessitating stringent safety measures and protective equipment. This challenge has led to increased research into less hazardous alternatives and improved handling techniques.

Another major hurdle is the moisture sensitivity of isocyanates. These compounds readily react with water, which can lead to undesired side reactions and compromised product quality. This sensitivity complicates storage, transportation, and application processes, requiring careful environmental control and specialized packaging solutions. Manufacturers must invest in moisture-free production environments and develop innovative sealing technologies to maintain product integrity.

The curing process of isocyanate-based products presents additional challenges. Achieving consistent and complete curing across various environmental conditions is crucial for product performance. Factors such as temperature, humidity, and substrate composition can significantly impact curing rates and final properties. Researchers are working on developing more robust curing systems and catalysts to address these variabilities.

Sustainability concerns pose another significant challenge in isocyanate applications. Many traditional isocyanates are derived from petroleum-based sources, raising environmental issues. The industry is under pressure to develop bio-based alternatives and more sustainable production methods. However, matching the performance characteristics of conventional isocyanates with eco-friendly options remains a complex task.

Compatibility with diverse substrates and materials is an ongoing technical challenge. Isocyanates are used in a wide range of applications, from coatings to adhesives, and must adhere effectively to various surfaces. Developing formulations that maintain strong adhesion and desired properties across different materials requires extensive research and testing.

Lastly, the regulatory landscape surrounding isocyanates presents a significant challenge. Stringent regulations regarding their use, handling, and disposal are continually evolving, necessitating ongoing adaptations in manufacturing processes and product formulations. Companies must invest in compliance measures and stay abreast of changing regulatory requirements across different regions.

Addressing these technical challenges requires a multidisciplinary approach, combining chemistry, materials science, and engineering. Innovations in molecular design, process engineering, and application technologies are crucial for overcoming these obstacles and advancing the use of isocyanates in modern design applications.

Another major hurdle is the moisture sensitivity of isocyanates. These compounds readily react with water, which can lead to undesired side reactions and compromised product quality. This sensitivity complicates storage, transportation, and application processes, requiring careful environmental control and specialized packaging solutions. Manufacturers must invest in moisture-free production environments and develop innovative sealing technologies to maintain product integrity.

The curing process of isocyanate-based products presents additional challenges. Achieving consistent and complete curing across various environmental conditions is crucial for product performance. Factors such as temperature, humidity, and substrate composition can significantly impact curing rates and final properties. Researchers are working on developing more robust curing systems and catalysts to address these variabilities.

Sustainability concerns pose another significant challenge in isocyanate applications. Many traditional isocyanates are derived from petroleum-based sources, raising environmental issues. The industry is under pressure to develop bio-based alternatives and more sustainable production methods. However, matching the performance characteristics of conventional isocyanates with eco-friendly options remains a complex task.

Compatibility with diverse substrates and materials is an ongoing technical challenge. Isocyanates are used in a wide range of applications, from coatings to adhesives, and must adhere effectively to various surfaces. Developing formulations that maintain strong adhesion and desired properties across different materials requires extensive research and testing.

Lastly, the regulatory landscape surrounding isocyanates presents a significant challenge. Stringent regulations regarding their use, handling, and disposal are continually evolving, necessitating ongoing adaptations in manufacturing processes and product formulations. Companies must invest in compliance measures and stay abreast of changing regulatory requirements across different regions.

Addressing these technical challenges requires a multidisciplinary approach, combining chemistry, materials science, and engineering. Innovations in molecular design, process engineering, and application technologies are crucial for overcoming these obstacles and advancing the use of isocyanates in modern design applications.

Current Applications

01 Synthesis and production of isocyanates

Various methods and processes for synthesizing and producing isocyanates are described. These include novel catalysts, reaction conditions, and precursor materials to improve yield, purity, and efficiency in isocyanate production.- Synthesis and production of isocyanates: Various methods and processes for synthesizing and producing isocyanates are described. These include novel catalysts, reaction conditions, and precursor materials to improve yield, purity, and efficiency in isocyanate production.

- Applications of isocyanates in polymer chemistry: Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents describe various applications, including coatings, adhesives, foams, and elastomers, as well as novel formulations and processing techniques.

- Isocyanate-based catalysts and additives: Several patents focus on the development of isocyanate-based catalysts and additives for various chemical processes. These include novel catalyst systems, stabilizers, and modifiers that enhance reaction rates, selectivity, or product properties.

- Safety and handling of isocyanates: Given the reactive nature of isocyanates, patents address safety concerns and handling procedures. These include methods for reducing toxicity, improving storage stability, and developing safer alternatives or modified isocyanates with reduced health risks.

- Isocyanate-free alternatives and substitutes: Some patents explore alternatives to traditional isocyanates, addressing environmental and health concerns. These include bio-based isocyanates, isocyanate-free polyurethanes, and alternative chemistries that mimic isocyanate reactivity without the associated risks.

02 Applications of isocyanates in polymer chemistry

Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents describe various formulations, curing methods, and applications of isocyanate-based polymers in industries such as coatings, adhesives, and foams.Expand Specific Solutions03 Isocyanate-free alternatives and environmentally friendly processes

Due to health and environmental concerns associated with isocyanates, research has focused on developing isocyanate-free alternatives and more environmentally friendly processes. These include novel polymer systems, bio-based materials, and alternative curing mechanisms.Expand Specific Solutions04 Safety and handling of isocyanates

Given the reactive nature of isocyanates, several patents focus on improving safety in handling, storage, and use of these compounds. This includes development of protective equipment, containment systems, and methods for neutralizing or disposing of isocyanate waste.Expand Specific Solutions05 Specialized isocyanate compounds and derivatives

Research into specialized isocyanate compounds and their derivatives for specific applications is ongoing. This includes modified isocyanates with enhanced properties, blocked isocyanates for controlled reactivity, and novel isocyanate-containing molecules for use in various industries.Expand Specific Solutions

Industry Leaders

The isocyanate market in modern design applications is in a mature growth phase, with a global market size expected to reach $38 billion by 2027. The technology has evolved significantly, with major players like Covestro, Dow, and Wanhua Chemical leading innovation. These companies are focusing on developing eco-friendly and high-performance isocyanates to meet stringent environmental regulations and growing demand in automotive, construction, and electronics sectors. The competitive landscape is characterized by intense R&D activities, strategic partnerships, and mergers to gain technological advantages and expand market presence. Emerging players from Asia, particularly China, are increasingly challenging established Western companies, driving further innovation and market dynamics.

Covestro Deutschland AG

Technical Solution: Covestro has developed innovative isocyanate-based solutions for modern design applications, focusing on sustainability and performance. Their breakthrough includes the use of bio-based raw materials to produce isocyanates, reducing the carbon footprint by up to 70% compared to fossil-based alternatives[1]. They have also introduced novel aliphatic isocyanates with improved UV stability and weathering resistance, ideal for high-performance coatings in automotive and architectural applications[2]. Covestro's research has led to the development of isocyanate-free polyurethane dispersions, addressing environmental concerns while maintaining excellent adhesion and chemical resistance properties[3].

Strengths: Sustainable bio-based solutions, improved UV stability, and environmental-friendly alternatives. Weaknesses: Potential higher production costs for bio-based materials and market acceptance of new formulations.

Dow Global Technologies LLC

Technical Solution: Dow has made significant advancements in isocyanate technology for modern design applications. They have developed a new generation of low-emission isocyanates that reduce volatile organic compound (VOC) emissions by up to 50% compared to traditional formulations[4]. Dow's research has also led to the creation of hybrid isocyanate systems that combine the benefits of different isocyanate types, resulting in improved durability and flexibility in end products[5]. Additionally, they have introduced water-based polyurethane dispersions using novel isocyanate chemistries, enabling solvent-free applications in various industries, including textiles and automotive interiors[6].

Strengths: Low-emission formulations, hybrid systems for enhanced properties, and water-based solutions. Weaknesses: Potential limitations in certain high-performance applications and the need for specialized application equipment.

Key Innovations

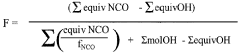

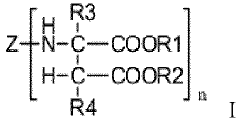

Blocked isocyanates and their use in coating compositions

PatentActiveEP1789466A1

Innovation

- A thermally dissociative blocked polyisocyanate composition containing isocyanurate moieties derived from bis(isocyanatomethyl)cyclohexane, specifically comprising a mixture of cis- and trans-1,3- and cis- and trans-1,4-isomers with at least 5 weight percent of the 1,4-isomer, reacted with a blocking agent and trimerization catalyst to achieve high reactivity and optimal isocyanate group distribution, enhancing the coating's properties.

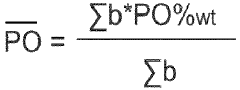

Polyether-modified polyisocyanate composition

PatentInactiveEP3988596A1

Innovation

- A polyether-modified polyisocyanate composition is developed by reacting a polyisocyanate with a polyoxyalkylene monoether alcohol, having a specific molecular weight and oxypropylene content, to achieve a balanced isocyanate functionality and content, which is used as a crosslinking agent in coatings, improving working time and drying efficiency while maintaining high hardness.

Environmental Impact

The environmental impact of isocyanates in modern design applications is a critical consideration as these compounds continue to play a significant role in various industries. Isocyanates, while versatile and effective in many applications, pose potential risks to both human health and the environment throughout their lifecycle.

During the production process, the synthesis of isocyanates often involves the use of hazardous chemicals and energy-intensive processes. This can lead to air and water pollution if not properly managed. Emissions of volatile organic compounds (VOCs) and other pollutants during manufacturing require stringent control measures to minimize environmental contamination.

In the application phase, isocyanate-based products can release harmful substances into the environment. For instance, spray foam insulation, a common use of isocyanates in construction, can emit VOCs during and after installation. These emissions contribute to indoor air pollution and may have broader atmospheric impacts if released outdoors.

The disposal of isocyanate-containing products presents another environmental challenge. Many isocyanate-based materials, such as polyurethane foams, are not easily biodegradable. Improper disposal can lead to long-term soil and water contamination. Incineration, a common disposal method, can produce toxic fumes if not carried out under controlled conditions.

However, recent breakthroughs in isocyanate technology are addressing these environmental concerns. The development of water-based and solvent-free isocyanate formulations has significantly reduced VOC emissions. These eco-friendly alternatives maintain performance while minimizing environmental impact during application and use.

Advancements in bio-based isocyanates derived from renewable resources are also promising. These sustainable alternatives reduce reliance on petrochemicals and potentially offer improved biodegradability. Research into the production of isocyanates from biomass feedstocks is gaining traction, aligning with global efforts to transition towards a circular economy.

Improved end-of-life management strategies for isocyanate-based products are emerging. Novel recycling techniques for polyurethane foams and other isocyanate-derived materials are being developed, aiming to reduce waste and conserve resources. These innovations contribute to closing the loop in the product lifecycle and minimizing environmental footprint.

As regulations tighten and consumer demand for sustainable products grows, the isocyanate industry is increasingly focusing on green chemistry principles. This shift involves designing products and processes that reduce or eliminate the use and generation of hazardous substances, thereby mitigating environmental risks associated with isocyanates.

During the production process, the synthesis of isocyanates often involves the use of hazardous chemicals and energy-intensive processes. This can lead to air and water pollution if not properly managed. Emissions of volatile organic compounds (VOCs) and other pollutants during manufacturing require stringent control measures to minimize environmental contamination.

In the application phase, isocyanate-based products can release harmful substances into the environment. For instance, spray foam insulation, a common use of isocyanates in construction, can emit VOCs during and after installation. These emissions contribute to indoor air pollution and may have broader atmospheric impacts if released outdoors.

The disposal of isocyanate-containing products presents another environmental challenge. Many isocyanate-based materials, such as polyurethane foams, are not easily biodegradable. Improper disposal can lead to long-term soil and water contamination. Incineration, a common disposal method, can produce toxic fumes if not carried out under controlled conditions.

However, recent breakthroughs in isocyanate technology are addressing these environmental concerns. The development of water-based and solvent-free isocyanate formulations has significantly reduced VOC emissions. These eco-friendly alternatives maintain performance while minimizing environmental impact during application and use.

Advancements in bio-based isocyanates derived from renewable resources are also promising. These sustainable alternatives reduce reliance on petrochemicals and potentially offer improved biodegradability. Research into the production of isocyanates from biomass feedstocks is gaining traction, aligning with global efforts to transition towards a circular economy.

Improved end-of-life management strategies for isocyanate-based products are emerging. Novel recycling techniques for polyurethane foams and other isocyanate-derived materials are being developed, aiming to reduce waste and conserve resources. These innovations contribute to closing the loop in the product lifecycle and minimizing environmental footprint.

As regulations tighten and consumer demand for sustainable products grows, the isocyanate industry is increasingly focusing on green chemistry principles. This shift involves designing products and processes that reduce or eliminate the use and generation of hazardous substances, thereby mitigating environmental risks associated with isocyanates.

Safety Regulations

The safety regulations surrounding isocyanates in modern design applications have become increasingly stringent due to the potential health hazards associated with these compounds. Regulatory bodies worldwide have implemented comprehensive guidelines to ensure the safe handling, use, and disposal of isocyanates in various industries.

In the United States, the Occupational Safety and Health Administration (OSHA) has established permissible exposure limits (PELs) for different types of isocyanates. These limits are typically set at very low levels, often in the range of parts per billion, to minimize worker exposure. OSHA also mandates the use of personal protective equipment (PPE), including respirators, gloves, and protective clothing, when working with isocyanates.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which includes specific provisions for isocyanates. Under REACH, manufacturers and importers must register isocyanates and provide detailed safety information. The EU has also introduced restrictions on the use of certain diisocyanates in industrial and professional applications, requiring mandatory training for users.

In recent years, there has been a growing focus on the development of low-isocyanate and isocyanate-free alternatives in response to these regulations. This has led to innovations in polyurethane chemistry, such as the use of blocked isocyanates, which release the active compound only under specific conditions, reducing exposure risks during handling and application.

Safety regulations have also driven advancements in monitoring and detection technologies. Real-time isocyanate monitors and improved analytical methods have been developed to ensure compliance with exposure limits and to quickly identify potential hazards in the workplace. These technologies play a crucial role in maintaining safe working environments and preventing occupational diseases related to isocyanate exposure.

The automotive and construction industries, which are major users of isocyanate-based products, have been particularly affected by these regulations. Manufacturers in these sectors have had to adapt their processes and formulations to meet the new safety standards while maintaining product performance. This has led to the development of novel application techniques and curing methods that minimize worker exposure and environmental release.

Environmental regulations have also impacted isocyanate use in modern design applications. Many jurisdictions now require strict controls on emissions and waste disposal to prevent environmental contamination. This has prompted the development of more environmentally friendly production processes and end-of-life recycling methods for isocyanate-containing products.

As research continues to reveal the long-term health effects of isocyanate exposure, it is likely that safety regulations will continue to evolve. Future regulatory trends may include further restrictions on certain isocyanate compounds, increased emphasis on substitution with safer alternatives, and more comprehensive worker health monitoring programs. These ongoing regulatory developments will continue to shape the landscape of isocyanate use in modern design applications, driving innovation and improving safety standards across industries.

In the United States, the Occupational Safety and Health Administration (OSHA) has established permissible exposure limits (PELs) for different types of isocyanates. These limits are typically set at very low levels, often in the range of parts per billion, to minimize worker exposure. OSHA also mandates the use of personal protective equipment (PPE), including respirators, gloves, and protective clothing, when working with isocyanates.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which includes specific provisions for isocyanates. Under REACH, manufacturers and importers must register isocyanates and provide detailed safety information. The EU has also introduced restrictions on the use of certain diisocyanates in industrial and professional applications, requiring mandatory training for users.

In recent years, there has been a growing focus on the development of low-isocyanate and isocyanate-free alternatives in response to these regulations. This has led to innovations in polyurethane chemistry, such as the use of blocked isocyanates, which release the active compound only under specific conditions, reducing exposure risks during handling and application.

Safety regulations have also driven advancements in monitoring and detection technologies. Real-time isocyanate monitors and improved analytical methods have been developed to ensure compliance with exposure limits and to quickly identify potential hazards in the workplace. These technologies play a crucial role in maintaining safe working environments and preventing occupational diseases related to isocyanate exposure.

The automotive and construction industries, which are major users of isocyanate-based products, have been particularly affected by these regulations. Manufacturers in these sectors have had to adapt their processes and formulations to meet the new safety standards while maintaining product performance. This has led to the development of novel application techniques and curing methods that minimize worker exposure and environmental release.

Environmental regulations have also impacted isocyanate use in modern design applications. Many jurisdictions now require strict controls on emissions and waste disposal to prevent environmental contamination. This has prompted the development of more environmentally friendly production processes and end-of-life recycling methods for isocyanate-containing products.

As research continues to reveal the long-term health effects of isocyanate exposure, it is likely that safety regulations will continue to evolve. Future regulatory trends may include further restrictions on certain isocyanate compounds, increased emphasis on substitution with safer alternatives, and more comprehensive worker health monitoring programs. These ongoing regulatory developments will continue to shape the landscape of isocyanate use in modern design applications, driving innovation and improving safety standards across industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!