Understanding Isocyanate Chemistry for Progressive Adaptations

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Chemistry Background and Objectives

Isocyanate chemistry has been a cornerstone of polymer science and industrial applications for over a century. The discovery of isocyanates dates back to 1849 when Wurtz first synthesized isocyanic acid esters. However, it wasn't until the 1930s that the potential of isocyanates in polymer chemistry was fully realized, leading to the development of polyurethanes by Otto Bayer and his team at I.G. Farben.

The evolution of isocyanate chemistry has been driven by the unique reactivity of the -N=C=O functional group. This highly electrophilic moiety readily reacts with nucleophiles, particularly those containing active hydrogen atoms. This versatility has enabled the creation of a wide range of materials with diverse properties, from flexible foams to rigid plastics, elastomers, and coatings.

In recent decades, the focus of isocyanate chemistry has shifted towards addressing environmental and health concerns. The toxicity associated with some isocyanates, particularly methylene diphenyl diisocyanate (MDI) and toluene diisocyanate (TDI), has prompted research into safer alternatives and improved handling methods. This has led to the development of blocked isocyanates, water-dispersible systems, and low-free monomer technologies.

The current objectives in isocyanate chemistry research are multifaceted. One primary goal is to enhance the sustainability of isocyanate-based materials. This includes exploring bio-based isocyanates derived from renewable resources, as well as improving the recyclability and biodegradability of polyurethane products. Another key objective is to further reduce the environmental and health impacts associated with isocyanate production and use, through the development of novel catalysts and reaction processes that minimize emissions and exposure risks.

Additionally, there is a growing interest in expanding the application of isocyanate chemistry beyond traditional polyurethane materials. Researchers are exploring the use of isocyanates in the synthesis of advanced functional materials, such as self-healing polymers, shape-memory materials, and stimuli-responsive systems. The potential of isocyanate chemistry in fields like nanotechnology, biomedicine, and energy storage is also being investigated, opening up new avenues for innovation.

As we look to the future, the objectives of isocyanate chemistry research are likely to align closely with global challenges such as climate change, resource scarcity, and the need for advanced materials in emerging technologies. Understanding and adapting isocyanate chemistry to meet these challenges will be crucial for the continued relevance and growth of this field in the coming decades.

The evolution of isocyanate chemistry has been driven by the unique reactivity of the -N=C=O functional group. This highly electrophilic moiety readily reacts with nucleophiles, particularly those containing active hydrogen atoms. This versatility has enabled the creation of a wide range of materials with diverse properties, from flexible foams to rigid plastics, elastomers, and coatings.

In recent decades, the focus of isocyanate chemistry has shifted towards addressing environmental and health concerns. The toxicity associated with some isocyanates, particularly methylene diphenyl diisocyanate (MDI) and toluene diisocyanate (TDI), has prompted research into safer alternatives and improved handling methods. This has led to the development of blocked isocyanates, water-dispersible systems, and low-free monomer technologies.

The current objectives in isocyanate chemistry research are multifaceted. One primary goal is to enhance the sustainability of isocyanate-based materials. This includes exploring bio-based isocyanates derived from renewable resources, as well as improving the recyclability and biodegradability of polyurethane products. Another key objective is to further reduce the environmental and health impacts associated with isocyanate production and use, through the development of novel catalysts and reaction processes that minimize emissions and exposure risks.

Additionally, there is a growing interest in expanding the application of isocyanate chemistry beyond traditional polyurethane materials. Researchers are exploring the use of isocyanates in the synthesis of advanced functional materials, such as self-healing polymers, shape-memory materials, and stimuli-responsive systems. The potential of isocyanate chemistry in fields like nanotechnology, biomedicine, and energy storage is also being investigated, opening up new avenues for innovation.

As we look to the future, the objectives of isocyanate chemistry research are likely to align closely with global challenges such as climate change, resource scarcity, and the need for advanced materials in emerging technologies. Understanding and adapting isocyanate chemistry to meet these challenges will be crucial for the continued relevance and growth of this field in the coming decades.

Market Demand Analysis for Isocyanate Applications

The global market for isocyanates has been experiencing steady growth, driven by increasing demand across various industries. The polyurethane sector, which heavily relies on isocyanates, remains the primary consumer, accounting for a significant portion of the market share. This sector's growth is fueled by the rising need for insulation materials in construction, automotive, and appliance industries, as well as the expanding use of polyurethane foams in furniture and bedding.

In the automotive industry, isocyanates play a crucial role in manufacturing lightweight components, contributing to improved fuel efficiency and reduced emissions. As environmental regulations become more stringent worldwide, the demand for isocyanate-based materials in automotive applications is expected to surge. Similarly, the construction industry's focus on energy-efficient buildings has led to increased adoption of polyurethane insulation materials, further boosting the isocyanate market.

The adhesives and sealants segment has also shown substantial growth potential for isocyanates. The packaging industry, in particular, has been a key driver, with the rise of e-commerce and the need for robust, lightweight packaging solutions. Additionally, the growing trend of using isocyanate-based adhesives in woodworking and furniture manufacturing has opened up new market opportunities.

Emerging economies, particularly in Asia-Pacific, are expected to be the fastest-growing markets for isocyanates. Rapid industrialization, urbanization, and increasing disposable incomes in countries like China and India are driving demand across various end-use industries. The region's booming construction and automotive sectors are particularly significant contributors to this growth.

However, the market faces challenges related to environmental and health concerns associated with isocyanates. Regulatory bodies worldwide are imposing stricter guidelines on the use and handling of these chemicals, which could potentially impact market growth. This has led to increased research and development efforts focused on developing safer, more environmentally friendly alternatives or improved handling methods for isocyanates.

Despite these challenges, the overall market outlook for isocyanates remains positive. The versatility of these chemicals and their critical role in producing high-performance materials continue to drive demand across multiple industries. As technology advances, new applications for isocyanates are likely to emerge, potentially expanding the market further. The industry's ability to address environmental concerns and develop sustainable practices will be crucial in shaping the long-term growth trajectory of the isocyanate market.

In the automotive industry, isocyanates play a crucial role in manufacturing lightweight components, contributing to improved fuel efficiency and reduced emissions. As environmental regulations become more stringent worldwide, the demand for isocyanate-based materials in automotive applications is expected to surge. Similarly, the construction industry's focus on energy-efficient buildings has led to increased adoption of polyurethane insulation materials, further boosting the isocyanate market.

The adhesives and sealants segment has also shown substantial growth potential for isocyanates. The packaging industry, in particular, has been a key driver, with the rise of e-commerce and the need for robust, lightweight packaging solutions. Additionally, the growing trend of using isocyanate-based adhesives in woodworking and furniture manufacturing has opened up new market opportunities.

Emerging economies, particularly in Asia-Pacific, are expected to be the fastest-growing markets for isocyanates. Rapid industrialization, urbanization, and increasing disposable incomes in countries like China and India are driving demand across various end-use industries. The region's booming construction and automotive sectors are particularly significant contributors to this growth.

However, the market faces challenges related to environmental and health concerns associated with isocyanates. Regulatory bodies worldwide are imposing stricter guidelines on the use and handling of these chemicals, which could potentially impact market growth. This has led to increased research and development efforts focused on developing safer, more environmentally friendly alternatives or improved handling methods for isocyanates.

Despite these challenges, the overall market outlook for isocyanates remains positive. The versatility of these chemicals and their critical role in producing high-performance materials continue to drive demand across multiple industries. As technology advances, new applications for isocyanates are likely to emerge, potentially expanding the market further. The industry's ability to address environmental concerns and develop sustainable practices will be crucial in shaping the long-term growth trajectory of the isocyanate market.

Current Challenges in Isocyanate Technology

Isocyanate technology, while widely used in various industries, faces several significant challenges that hinder its further development and application. One of the primary concerns is the toxicity of isocyanates, particularly their potential to cause respiratory sensitization and occupational asthma. This health risk necessitates stringent safety measures in production and handling, increasing operational costs and complexity.

Environmental concerns also pose a significant challenge. The production of isocyanates often involves the use of phosgene, a highly toxic gas, which raises environmental and safety issues. Additionally, the disposal of isocyanate-containing products can lead to environmental contamination if not managed properly. This has led to increased pressure for the development of more environmentally friendly alternatives or production methods.

Another major challenge lies in the reactivity of isocyanates. While their high reactivity is beneficial for many applications, it also makes them sensitive to moisture and prone to side reactions. This can lead to quality issues in final products, such as foam instability or inadequate curing in coatings. Controlling these reactions precisely, especially in complex formulations or varying environmental conditions, remains a significant technical hurdle.

The volatility of certain isocyanates, particularly methylene diphenyl diisocyanate (MDI) and toluene diisocyanate (TDI), presents challenges in terms of emission control and worker exposure. Developing low-volatility alternatives or improved emission control technologies is an ongoing area of research and development in the industry.

Raw material availability and cost fluctuations also pose challenges. Isocyanates are derived from petroleum-based feedstocks, making them susceptible to oil price volatility. This dependency on non-renewable resources raises concerns about long-term sustainability and drives research into bio-based alternatives.

Regulatory pressures present another significant challenge. Increasingly stringent regulations regarding the use and handling of isocyanates, particularly in consumer products, are forcing manufacturers to adapt their formulations and processes. This regulatory landscape varies globally, adding complexity for companies operating in international markets.

Lastly, there is a growing demand for isocyanate-free alternatives in various applications, driven by health and environmental concerns. This trend challenges the industry to innovate and develop new chemistries that can match the performance of isocyanate-based products while addressing these concerns. The search for viable alternatives that maintain the desirable properties of isocyanates without their drawbacks remains a significant technological challenge.

Environmental concerns also pose a significant challenge. The production of isocyanates often involves the use of phosgene, a highly toxic gas, which raises environmental and safety issues. Additionally, the disposal of isocyanate-containing products can lead to environmental contamination if not managed properly. This has led to increased pressure for the development of more environmentally friendly alternatives or production methods.

Another major challenge lies in the reactivity of isocyanates. While their high reactivity is beneficial for many applications, it also makes them sensitive to moisture and prone to side reactions. This can lead to quality issues in final products, such as foam instability or inadequate curing in coatings. Controlling these reactions precisely, especially in complex formulations or varying environmental conditions, remains a significant technical hurdle.

The volatility of certain isocyanates, particularly methylene diphenyl diisocyanate (MDI) and toluene diisocyanate (TDI), presents challenges in terms of emission control and worker exposure. Developing low-volatility alternatives or improved emission control technologies is an ongoing area of research and development in the industry.

Raw material availability and cost fluctuations also pose challenges. Isocyanates are derived from petroleum-based feedstocks, making them susceptible to oil price volatility. This dependency on non-renewable resources raises concerns about long-term sustainability and drives research into bio-based alternatives.

Regulatory pressures present another significant challenge. Increasingly stringent regulations regarding the use and handling of isocyanates, particularly in consumer products, are forcing manufacturers to adapt their formulations and processes. This regulatory landscape varies globally, adding complexity for companies operating in international markets.

Lastly, there is a growing demand for isocyanate-free alternatives in various applications, driven by health and environmental concerns. This trend challenges the industry to innovate and develop new chemistries that can match the performance of isocyanate-based products while addressing these concerns. The search for viable alternatives that maintain the desirable properties of isocyanates without their drawbacks remains a significant technological challenge.

Existing Isocyanate Adaptation Solutions

01 Synthesis and modification of isocyanates

This category focuses on the synthesis of isocyanates and their chemical modifications. It includes methods for producing various isocyanate compounds, as well as techniques for altering their properties through chemical reactions. These processes are crucial for creating isocyanates with specific characteristics for different applications.- Synthesis and modification of isocyanates: This category focuses on the synthesis of isocyanates and their chemical modifications. It includes methods for producing various isocyanate compounds, as well as techniques for altering their properties through chemical reactions. These processes are crucial for creating isocyanates with specific characteristics for different applications.

- Polyurethane production using isocyanates: Isocyanates are key components in the production of polyurethanes. This category covers methods for using isocyanates in polyurethane synthesis, including reaction conditions, catalysts, and formulation techniques. It also encompasses the development of specialized polyurethanes for various applications, such as coatings, foams, and adhesives.

- Isocyanate-based coating technologies: This category deals with the use of isocyanates in coating formulations. It includes the development of isocyanate-based coatings with improved properties such as durability, chemical resistance, and adhesion. The category also covers curing mechanisms, application techniques, and the incorporation of additives to enhance coating performance.

- Safety and handling of isocyanates: Given the reactive nature of isocyanates, this category focuses on safety measures and handling procedures. It includes methods for reducing exposure risks, developing safer isocyanate formulations, and improving storage and transportation techniques. Additionally, it covers detection and monitoring systems for isocyanate exposure in industrial settings.

- Isocyanate applications in specialty chemicals: This category explores the use of isocyanates in the production of specialty chemicals beyond traditional polyurethanes. It includes applications in pharmaceuticals, agrochemicals, and other fine chemical industries. The category covers novel reaction pathways, selective functionalization of isocyanates, and their integration into complex molecular structures for various high-value products.

02 Polyurethane production using isocyanates

Isocyanates are key components in the production of polyurethanes. This category covers methods for using isocyanates in polyurethane synthesis, including reaction conditions, catalysts, and formulation techniques. It also encompasses the development of specialized polyurethanes for various applications, such as coatings, foams, and adhesives.Expand Specific Solutions03 Isocyanate-based coating technologies

This category deals with the application of isocyanates in coating technologies. It includes formulations for isocyanate-based coatings, curing mechanisms, and methods for improving coating properties such as durability, chemical resistance, and adhesion. The category also covers novel coating systems that utilize isocyanate chemistry for specific industrial or consumer applications.Expand Specific Solutions04 Safety and handling of isocyanates

Given the reactive nature of isocyanates, this category focuses on safety measures and handling procedures. It includes methods for reducing exposure risks, personal protective equipment, storage and transportation guidelines, and techniques for neutralizing or disposing of isocyanate-containing materials. This category also covers the development of less hazardous isocyanate alternatives.Expand Specific Solutions05 Analytical methods for isocyanates

This category encompasses analytical techniques for detecting, quantifying, and characterizing isocyanates. It includes spectroscopic methods, chromatography, and other instrumental analyses for identifying isocyanate compounds and their reaction products. The category also covers the development of sensors and monitoring systems for isocyanates in various environments.Expand Specific Solutions

Key Players in Isocyanate Industry

The field of isocyanate chemistry is in a mature stage of development, with a well-established market and significant industrial applications. The global isocyanate market size is substantial, driven by demand in polyurethane production for various sectors. Technologically, the field is advanced, with major players like Covestro, BASF, and Wanhua Chemical Group leading innovation. These companies, along with others such as Asahi Kasei and Bayer, have developed sophisticated processes and products, indicating a high level of technical maturity. However, ongoing research in areas like bio-based isocyanates and improved environmental performance suggests potential for further advancements and market growth.

Covestro Deutschland AG

Technical Solution: Covestro has made significant advancements in isocyanate chemistry, particularly in the development of more sustainable and efficient production processes. Their innovative approach includes the use of carbon dioxide as a raw material in polyurethane production, reducing the reliance on fossil-based resources[1]. Covestro has also developed novel catalysts that improve the selectivity and yield of isocyanate reactions, leading to higher quality products with reduced waste[2]. Their research extends to the creation of isocyanate-free alternatives for certain applications, addressing health and safety concerns associated with traditional isocyanates[3]. Additionally, Covestro has pioneered the use of bio-based raw materials in isocyanate production, further enhancing the sustainability profile of their products[4].

Strengths: Strong focus on sustainability, innovative CO2 utilization, development of safer alternatives. Weaknesses: Potential higher production costs, market adaptation to new technologies may be slow.

BASF Corp.

Technical Solution: BASF has developed innovative isocyanate chemistry solutions for progressive adaptations in various industries. Their approach includes the development of novel aliphatic isocyanates with improved reactivity and durability[1]. BASF's research focuses on enhancing the performance of polyurethane systems through tailored isocyanate structures, resulting in materials with superior mechanical properties and chemical resistance[2]. They have also made significant strides in developing bio-based isocyanates, addressing sustainability concerns in the industry[3]. BASF's technology allows for precise control of isocyanate reactivity, enabling the creation of customized polyurethane products for specific applications, from automotive parts to high-performance coatings[4].

Strengths: Wide range of applications, sustainability focus, customizable solutions. Weaknesses: Potential higher costs for bio-based alternatives, regulatory challenges for new isocyanate compounds.

Core Innovations in Isocyanate Chemistry

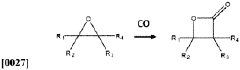

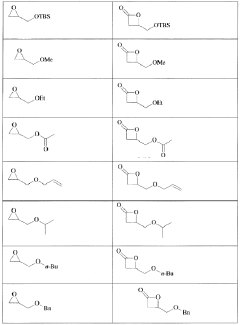

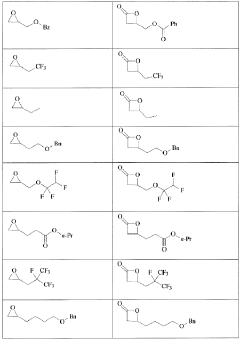

Isocyanates, derivatives, and processes for producing the same

PatentWO2019070981A1

Innovation

- The development of processes using epoxide and carbon monoxide reagents to produce isocyanates and isocyanate derivatives through chemical pathways such as Schmidt, Hofmann, Curtius, and Lossen rearrangements, allowing for the production of bio-based polyurethanes with customizable properties.

Heterogeneously catalyzed carbamate dissociation for synthesis of isocyanates over solid lewis acids

PatentInactiveUS20110313192A1

Innovation

- The use of a heterogeneous Lewis-acidic catalyst, such as a supported zeolite catalyst with zinc, significantly increases the reaction rate and selectivity of carbamate dissociation to form isocyanates, preventing the formation of unwanted byproducts by optimizing the reaction conditions and separation of products.

Environmental Impact of Isocyanates

Isocyanates, widely used in the production of polyurethanes, have significant environmental implications that warrant careful consideration. The production, use, and disposal of isocyanate-containing products can lead to various environmental impacts, primarily through air and water pollution. During manufacturing processes, volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) may be released, contributing to air quality degradation and potentially affecting local ecosystems.

Water contamination is another critical concern, as isocyanates can react with water to form insoluble polyureas. This reaction can lead to the formation of solid masses in aquatic environments, potentially harming marine life and disrupting ecosystems. Furthermore, the breakdown products of isocyanates in water can include toxic substances such as aromatic amines, which pose risks to aquatic organisms and may bioaccumulate in the food chain.

The persistence of isocyanates in the environment is relatively low due to their high reactivity, particularly with water. However, this reactivity can lead to the formation of other compounds that may have longer-lasting environmental effects. For instance, the degradation of toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI) in soil can result in the formation of toluenediamine (TDA) and methylenedianiline (MDA), respectively, which are more persistent and potentially more toxic than their parent compounds.

Waste management of isocyanate-containing products presents additional environmental challenges. Improper disposal can lead to soil contamination and groundwater pollution. Incineration of polyurethane products, while effective in destroying isocyanates, can produce toxic emissions if not carried out under controlled conditions. Recycling efforts for polyurethane products are growing but remain limited due to the complex nature of these materials and the potential release of hazardous substances during the recycling process.

The environmental impact of isocyanates extends to their role in climate change. The production of isocyanates is energy-intensive and often relies on fossil fuel-derived raw materials, contributing to greenhouse gas emissions. Additionally, some polyurethane foams produced with isocyanates use blowing agents that can have high global warming potential, although regulations have led to the development of more environmentally friendly alternatives in recent years.

To mitigate these environmental impacts, industry and researchers are exploring various strategies. These include developing bio-based isocyanates, improving production processes to reduce emissions, and enhancing end-of-life management for isocyanate-containing products. Advances in green chemistry are also leading to the creation of isocyanate-free alternatives for some applications, potentially reducing the overall environmental footprint of polyurethane production and use.

Water contamination is another critical concern, as isocyanates can react with water to form insoluble polyureas. This reaction can lead to the formation of solid masses in aquatic environments, potentially harming marine life and disrupting ecosystems. Furthermore, the breakdown products of isocyanates in water can include toxic substances such as aromatic amines, which pose risks to aquatic organisms and may bioaccumulate in the food chain.

The persistence of isocyanates in the environment is relatively low due to their high reactivity, particularly with water. However, this reactivity can lead to the formation of other compounds that may have longer-lasting environmental effects. For instance, the degradation of toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI) in soil can result in the formation of toluenediamine (TDA) and methylenedianiline (MDA), respectively, which are more persistent and potentially more toxic than their parent compounds.

Waste management of isocyanate-containing products presents additional environmental challenges. Improper disposal can lead to soil contamination and groundwater pollution. Incineration of polyurethane products, while effective in destroying isocyanates, can produce toxic emissions if not carried out under controlled conditions. Recycling efforts for polyurethane products are growing but remain limited due to the complex nature of these materials and the potential release of hazardous substances during the recycling process.

The environmental impact of isocyanates extends to their role in climate change. The production of isocyanates is energy-intensive and often relies on fossil fuel-derived raw materials, contributing to greenhouse gas emissions. Additionally, some polyurethane foams produced with isocyanates use blowing agents that can have high global warming potential, although regulations have led to the development of more environmentally friendly alternatives in recent years.

To mitigate these environmental impacts, industry and researchers are exploring various strategies. These include developing bio-based isocyanates, improving production processes to reduce emissions, and enhancing end-of-life management for isocyanate-containing products. Advances in green chemistry are also leading to the creation of isocyanate-free alternatives for some applications, potentially reducing the overall environmental footprint of polyurethane production and use.

Safety Regulations for Isocyanate Handling

Safety regulations for isocyanate handling are crucial due to the highly reactive nature of these compounds. Regulatory bodies worldwide have established stringent guidelines to protect workers and the environment from potential hazards associated with isocyanate exposure.

The Occupational Safety and Health Administration (OSHA) in the United States has set permissible exposure limits (PELs) for various isocyanates. For instance, the PEL for toluene diisocyanate (TDI) is 0.02 parts per million (ppm) as a ceiling limit. Similarly, the National Institute for Occupational Safety and Health (NIOSH) recommends a more conservative exposure limit of 0.005 ppm for up to a 10-hour workday.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of isocyanates. REACH requires manufacturers and importers to register substances and provide safety data sheets detailing proper handling procedures and exposure controls.

Personal protective equipment (PPE) is a critical component of isocyanate safety regulations. Workers must wear appropriate respiratory protection, such as supplied-air respirators or self-contained breathing apparatus (SCBA), depending on the concentration and type of isocyanate present. Impervious gloves, protective clothing, and eye protection are also mandatory to prevent skin and eye contact.

Ventilation requirements are another key aspect of isocyanate safety regulations. Local exhaust ventilation systems must be installed in areas where isocyanates are used or processed to minimize airborne concentrations. Regular air monitoring is essential to ensure that exposure levels remain below established limits.

Storage and handling regulations for isocyanates are equally important. These chemicals must be stored in tightly sealed containers in cool, dry, well-ventilated areas away from incompatible materials. Spill response procedures and proper disposal methods are also regulated to prevent environmental contamination.

Training and education form a significant part of isocyanate safety regulations. Workers must receive comprehensive training on the hazards of isocyanates, proper handling techniques, emergency procedures, and the correct use of PPE. Regular refresher courses are often mandated to ensure ongoing compliance and safety awareness.

Medical surveillance programs are required in many jurisdictions for workers regularly exposed to isocyanates. These programs typically include baseline and periodic medical examinations, pulmonary function tests, and health monitoring to detect any adverse effects of isocyanate exposure.

As research continues to reveal more about the long-term effects of isocyanate exposure, regulatory bodies frequently update their guidelines. Companies working with isocyanates must stay informed about these changes and adapt their safety protocols accordingly to ensure ongoing compliance and worker protection.

The Occupational Safety and Health Administration (OSHA) in the United States has set permissible exposure limits (PELs) for various isocyanates. For instance, the PEL for toluene diisocyanate (TDI) is 0.02 parts per million (ppm) as a ceiling limit. Similarly, the National Institute for Occupational Safety and Health (NIOSH) recommends a more conservative exposure limit of 0.005 ppm for up to a 10-hour workday.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of isocyanates. REACH requires manufacturers and importers to register substances and provide safety data sheets detailing proper handling procedures and exposure controls.

Personal protective equipment (PPE) is a critical component of isocyanate safety regulations. Workers must wear appropriate respiratory protection, such as supplied-air respirators or self-contained breathing apparatus (SCBA), depending on the concentration and type of isocyanate present. Impervious gloves, protective clothing, and eye protection are also mandatory to prevent skin and eye contact.

Ventilation requirements are another key aspect of isocyanate safety regulations. Local exhaust ventilation systems must be installed in areas where isocyanates are used or processed to minimize airborne concentrations. Regular air monitoring is essential to ensure that exposure levels remain below established limits.

Storage and handling regulations for isocyanates are equally important. These chemicals must be stored in tightly sealed containers in cool, dry, well-ventilated areas away from incompatible materials. Spill response procedures and proper disposal methods are also regulated to prevent environmental contamination.

Training and education form a significant part of isocyanate safety regulations. Workers must receive comprehensive training on the hazards of isocyanates, proper handling techniques, emergency procedures, and the correct use of PPE. Regular refresher courses are often mandated to ensure ongoing compliance and safety awareness.

Medical surveillance programs are required in many jurisdictions for workers regularly exposed to isocyanates. These programs typically include baseline and periodic medical examinations, pulmonary function tests, and health monitoring to detect any adverse effects of isocyanate exposure.

As research continues to reveal more about the long-term effects of isocyanate exposure, regulatory bodies frequently update their guidelines. Companies working with isocyanates must stay informed about these changes and adapt their safety protocols accordingly to ensure ongoing compliance and worker protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!