Advancements in Isocyanate Exploration for Technical Profundity

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Tech Evolution

Isocyanates have undergone significant technological evolution since their discovery in the mid-19th century. The journey began with the synthesis of the first isocyanate compound by Wurtz in 1848, marking the inception of a field that would revolutionize polymer chemistry and industrial applications.

The early 20th century saw the development of polyurethanes, a major breakthrough in isocyanate technology. Otto Bayer's pioneering work in the 1930s led to the creation of polyurethane foams, elastomers, and coatings, opening up a wide range of industrial applications. This period marked the transition from laboratory curiosity to commercial viability.

Post-World War II, the isocyanate industry experienced rapid growth and diversification. The 1950s and 1960s witnessed the emergence of new isocyanate types, including methylene diphenyl diisocyanate (MDI) and toluene diisocyanate (TDI), which became cornerstone materials in the production of flexible and rigid foams, adhesives, and elastomers.

The 1970s and 1980s were characterized by advancements in production processes and the development of specialized isocyanates for niche applications. This era saw improvements in safety protocols and environmental considerations, addressing concerns about the toxicity of isocyanate compounds.

The late 20th and early 21st centuries brought about a focus on sustainability and eco-friendly alternatives. Research efforts shifted towards developing bio-based isocyanates and exploring greener production methods. Concurrently, there was a push for improving the performance characteristics of isocyanate-based materials, leading to the development of high-performance polyurethanes for automotive, construction, and aerospace industries.

Recent years have seen a surge in nanotechnology applications within isocyanate chemistry. The integration of nanoparticles and nanostructures into isocyanate-based materials has led to enhanced properties and novel functionalities, expanding the potential applications in fields such as biomedicine and smart materials.

The current frontier in isocyanate technology involves the exploration of isocyanate-free alternatives and the development of more environmentally benign production processes. This includes research into non-isocyanate polyurethanes (NIPUs) and the use of carbon dioxide as a raw material in polyurethane synthesis, aligning with global sustainability goals.

As we look to the future, the evolution of isocyanate technology is likely to be driven by the need for more sustainable, safer, and higher-performing materials. Advancements in computational chemistry and high-throughput screening methods are expected to accelerate the discovery of novel isocyanate compounds and formulations, potentially leading to breakthroughs in material properties and applications.

The early 20th century saw the development of polyurethanes, a major breakthrough in isocyanate technology. Otto Bayer's pioneering work in the 1930s led to the creation of polyurethane foams, elastomers, and coatings, opening up a wide range of industrial applications. This period marked the transition from laboratory curiosity to commercial viability.

Post-World War II, the isocyanate industry experienced rapid growth and diversification. The 1950s and 1960s witnessed the emergence of new isocyanate types, including methylene diphenyl diisocyanate (MDI) and toluene diisocyanate (TDI), which became cornerstone materials in the production of flexible and rigid foams, adhesives, and elastomers.

The 1970s and 1980s were characterized by advancements in production processes and the development of specialized isocyanates for niche applications. This era saw improvements in safety protocols and environmental considerations, addressing concerns about the toxicity of isocyanate compounds.

The late 20th and early 21st centuries brought about a focus on sustainability and eco-friendly alternatives. Research efforts shifted towards developing bio-based isocyanates and exploring greener production methods. Concurrently, there was a push for improving the performance characteristics of isocyanate-based materials, leading to the development of high-performance polyurethanes for automotive, construction, and aerospace industries.

Recent years have seen a surge in nanotechnology applications within isocyanate chemistry. The integration of nanoparticles and nanostructures into isocyanate-based materials has led to enhanced properties and novel functionalities, expanding the potential applications in fields such as biomedicine and smart materials.

The current frontier in isocyanate technology involves the exploration of isocyanate-free alternatives and the development of more environmentally benign production processes. This includes research into non-isocyanate polyurethanes (NIPUs) and the use of carbon dioxide as a raw material in polyurethane synthesis, aligning with global sustainability goals.

As we look to the future, the evolution of isocyanate technology is likely to be driven by the need for more sustainable, safer, and higher-performing materials. Advancements in computational chemistry and high-throughput screening methods are expected to accelerate the discovery of novel isocyanate compounds and formulations, potentially leading to breakthroughs in material properties and applications.

Market Demand Analysis

The market demand for isocyanates has been steadily growing, driven by their versatile applications across various industries. The global isocyanate market is experiencing robust expansion, primarily fueled by the increasing demand in construction, automotive, and furniture sectors. In the construction industry, isocyanates are extensively used in the production of polyurethane foams for insulation, sealants, and adhesives, contributing to energy-efficient building solutions.

The automotive sector represents another significant market for isocyanates, where they are utilized in manufacturing lightweight components, enhancing fuel efficiency, and improving vehicle performance. As the automotive industry shifts towards electric vehicles and emphasizes weight reduction, the demand for isocyanate-based materials is expected to surge further.

In the furniture industry, isocyanates play a crucial role in producing flexible and rigid foams for cushioning and structural components. The growing consumer preference for comfortable and durable furniture is driving the demand for high-quality polyurethane products, consequently boosting the isocyanate market.

The Asia-Pacific region has emerged as the largest consumer of isocyanates, with China leading the market due to its booming construction and automotive industries. North America and Europe follow closely, with steady growth in demand attributed to technological advancements and stringent regulations promoting energy-efficient solutions.

Environmental concerns and regulatory pressures are shaping the market dynamics, pushing manufacturers to develop eco-friendly and low-emission isocyanate products. This trend is creating new opportunities for innovation and market differentiation, particularly in developed economies where sustainability is a key focus.

The healthcare sector is also contributing to the growing demand for isocyanates, with applications in medical devices, wound dressings, and pharmaceutical packaging. As healthcare infrastructure expands globally, this sector is expected to become an increasingly important market for isocyanate-based products.

Despite the positive growth trajectory, the isocyanate market faces challenges related to raw material price volatility and health concerns associated with exposure during manufacturing processes. These factors are driving research and development efforts towards safer production methods and alternative formulations, potentially opening new avenues for market growth and technological advancements.

The automotive sector represents another significant market for isocyanates, where they are utilized in manufacturing lightweight components, enhancing fuel efficiency, and improving vehicle performance. As the automotive industry shifts towards electric vehicles and emphasizes weight reduction, the demand for isocyanate-based materials is expected to surge further.

In the furniture industry, isocyanates play a crucial role in producing flexible and rigid foams for cushioning and structural components. The growing consumer preference for comfortable and durable furniture is driving the demand for high-quality polyurethane products, consequently boosting the isocyanate market.

The Asia-Pacific region has emerged as the largest consumer of isocyanates, with China leading the market due to its booming construction and automotive industries. North America and Europe follow closely, with steady growth in demand attributed to technological advancements and stringent regulations promoting energy-efficient solutions.

Environmental concerns and regulatory pressures are shaping the market dynamics, pushing manufacturers to develop eco-friendly and low-emission isocyanate products. This trend is creating new opportunities for innovation and market differentiation, particularly in developed economies where sustainability is a key focus.

The healthcare sector is also contributing to the growing demand for isocyanates, with applications in medical devices, wound dressings, and pharmaceutical packaging. As healthcare infrastructure expands globally, this sector is expected to become an increasingly important market for isocyanate-based products.

Despite the positive growth trajectory, the isocyanate market faces challenges related to raw material price volatility and health concerns associated with exposure during manufacturing processes. These factors are driving research and development efforts towards safer production methods and alternative formulations, potentially opening new avenues for market growth and technological advancements.

Current Challenges

The exploration of isocyanates for technical profundity faces several significant challenges in the current landscape. One of the primary obstacles is the high reactivity of isocyanates, which makes them difficult to handle and control during synthesis and application processes. This reactivity, while beneficial for certain applications, poses safety risks and requires specialized equipment and handling procedures, increasing production costs and complexity.

Environmental and health concerns present another major challenge. Isocyanates are known to be potential respiratory sensitizers and can cause severe allergic reactions in some individuals. This has led to increased regulatory scrutiny and the need for stringent safety measures in manufacturing and usage environments. The development of safer alternatives or improved handling methods is an ongoing area of research and development.

The synthesis of isocyanates often involves the use of phosgene, a highly toxic gas. Finding alternative, less hazardous synthesis routes that maintain efficiency and product quality is a significant technical challenge. Researchers are exploring phosgene-free methods, but these often result in lower yields or require more complex process steps, making them less economically viable.

Another challenge lies in the limited raw material sources for isocyanate production. The primary feedstocks are derived from petroleum, making the industry vulnerable to oil price fluctuations and raising sustainability concerns. Developing bio-based or renewable sources for isocyanate precursors is an area of active research but faces hurdles in terms of scalability and cost-effectiveness.

The demand for high-performance and specialized isocyanates in emerging applications, such as advanced coatings, adhesives, and materials for the automotive and aerospace industries, presents both opportunities and challenges. Meeting these specific performance requirements while maintaining cost-effectiveness and addressing environmental concerns requires significant innovation in molecular design and synthesis techniques.

Recycling and end-of-life management of isocyanate-based products pose additional challenges. Many products containing isocyanates, such as polyurethane foams, are difficult to recycle or dispose of in an environmentally friendly manner. Developing efficient recycling technologies or designing products for easier disassembly and material recovery is crucial for improving the sustainability profile of isocyanate-based materials.

Lastly, the global regulatory landscape for isocyanates is becoming increasingly complex and stringent. Navigating these regulations while maintaining product performance and economic viability is a significant challenge for manufacturers and users of isocyanate-based products. This requires ongoing investment in research and development to find compliant solutions that meet both regulatory requirements and market demands.

Environmental and health concerns present another major challenge. Isocyanates are known to be potential respiratory sensitizers and can cause severe allergic reactions in some individuals. This has led to increased regulatory scrutiny and the need for stringent safety measures in manufacturing and usage environments. The development of safer alternatives or improved handling methods is an ongoing area of research and development.

The synthesis of isocyanates often involves the use of phosgene, a highly toxic gas. Finding alternative, less hazardous synthesis routes that maintain efficiency and product quality is a significant technical challenge. Researchers are exploring phosgene-free methods, but these often result in lower yields or require more complex process steps, making them less economically viable.

Another challenge lies in the limited raw material sources for isocyanate production. The primary feedstocks are derived from petroleum, making the industry vulnerable to oil price fluctuations and raising sustainability concerns. Developing bio-based or renewable sources for isocyanate precursors is an area of active research but faces hurdles in terms of scalability and cost-effectiveness.

The demand for high-performance and specialized isocyanates in emerging applications, such as advanced coatings, adhesives, and materials for the automotive and aerospace industries, presents both opportunities and challenges. Meeting these specific performance requirements while maintaining cost-effectiveness and addressing environmental concerns requires significant innovation in molecular design and synthesis techniques.

Recycling and end-of-life management of isocyanate-based products pose additional challenges. Many products containing isocyanates, such as polyurethane foams, are difficult to recycle or dispose of in an environmentally friendly manner. Developing efficient recycling technologies or designing products for easier disassembly and material recovery is crucial for improving the sustainability profile of isocyanate-based materials.

Lastly, the global regulatory landscape for isocyanates is becoming increasingly complex and stringent. Navigating these regulations while maintaining product performance and economic viability is a significant challenge for manufacturers and users of isocyanate-based products. This requires ongoing investment in research and development to find compliant solutions that meet both regulatory requirements and market demands.

Existing Tech Solutions

01 Synthesis and properties of isocyanates

Isocyanates are a class of highly reactive compounds characterized by the -NCO functional group. They are widely used in the production of polyurethanes and other polymeric materials. The synthesis of isocyanates often involves the reaction of amines with phosgene or other carbonyl compounds. Their properties, such as reactivity and stability, are crucial for various industrial applications.- Synthesis and modification of isocyanates: Various methods for synthesizing and modifying isocyanates are explored, including novel reaction pathways and catalysts. These techniques aim to improve the efficiency and selectivity of isocyanate production, as well as to create new isocyanate derivatives with enhanced properties for specific applications.

- Isocyanate-based polymers and coatings: Isocyanates are widely used in the production of polymers and coatings. Research focuses on developing new formulations and curing methods to enhance the performance of polyurethanes, polyureas, and other isocyanate-based materials. Applications include adhesives, sealants, and protective coatings for various industries.

- Isocyanate-free alternatives: Due to health and environmental concerns associated with isocyanates, there is growing interest in developing isocyanate-free alternatives. This includes research into new chemistries and materials that can provide similar properties and performance to isocyanate-based products without the associated risks.

- Safety and handling of isocyanates: Given the reactive nature of isocyanates and their potential health hazards, significant research is dedicated to improving safety measures in their handling and use. This includes developing better personal protective equipment, exposure monitoring systems, and safer processing techniques to minimize risks in industrial settings.

- Environmental impact and sustainability: Research is ongoing to assess and mitigate the environmental impact of isocyanates and their derivatives. This includes studies on biodegradability, eco-friendly production methods, and the development of sustainable alternatives derived from renewable resources to reduce reliance on petroleum-based isocyanates.

02 Applications of isocyanates in coatings and adhesives

Isocyanates play a significant role in the formulation of high-performance coatings and adhesives. They react with polyols to form polyurethanes, which offer excellent durability, chemical resistance, and adhesion properties. These materials find applications in automotive coatings, industrial finishes, and structural adhesives.Expand Specific Solutions03 Isocyanate-based foam production

Isocyanates are crucial components in the production of polyurethane foams. When combined with polyols and appropriate catalysts and blowing agents, they form flexible or rigid foams used in insulation, cushioning, and packaging applications. The reaction kinetics and foam properties can be tailored by adjusting the isocyanate chemistry and formulation.Expand Specific Solutions04 Safety and handling of isocyanates

Due to their high reactivity, isocyanates pose potential health and safety risks. Proper handling, storage, and use of personal protective equipment are essential when working with these compounds. Exposure control measures and risk assessment protocols are implemented in industrial settings to ensure worker safety and environmental protection.Expand Specific Solutions05 Novel isocyanate derivatives and modifications

Research in isocyanate chemistry focuses on developing novel derivatives and modifications to enhance performance or address specific application needs. This includes the synthesis of blocked isocyanates, isocyanate-terminated prepolymers, and water-dispersible isocyanates. These innovations aim to improve processing, reduce volatility, or enable new functionalities in various polymer systems.Expand Specific Solutions

Key Industry Players

The isocyanate exploration field is currently in a growth phase, with increasing market demand driven by applications in polyurethane production and other industries. The global market size for isocyanates is projected to reach significant levels in the coming years. Technologically, the field is moderately mature, with established players like BASF, Covestro, and Wanhua Chemical Group leading in production and innovation. However, there's ongoing research for more sustainable and efficient processes. Companies like Evonik and Dow are focusing on specialty isocyanates, while academic institutions such as the Chinese Academy of Sciences are contributing to fundamental research, indicating potential for further advancements in this technical domain.

BASF Corp.

Technical Solution: BASF has made significant advancements in isocyanate exploration, focusing on sustainable and high-performance solutions. Their innovative approach includes the development of bio-based isocyanates, reducing reliance on fossil resources. BASF's research has led to the creation of novel isocyanate-based polyurethanes with improved thermal and mechanical properties[1]. They have also pioneered water-based polyurethane dispersions using specialized isocyanates, addressing environmental concerns while maintaining performance[2]. BASF's commitment to technical profundity is evident in their exploration of isocyanate-free technologies, such as non-isocyanate polyurethanes (NIPUs), which offer comparable properties to traditional polyurethanes while eliminating exposure risks associated with isocyanates[3].

Strengths: Strong R&D capabilities, focus on sustainability, diverse product portfolio. Weaknesses: Potential regulatory challenges with traditional isocyanates, competition from emerging technologies.

Bayer AG

Technical Solution: Bayer AG has made substantial progress in isocyanate technology, particularly in the development of aliphatic isocyanates for high-performance coatings. Their research focuses on enhancing durability and weather resistance of polyurethane coatings using advanced isocyanate chemistries[4]. Bayer has also explored novel curing mechanisms for isocyanate-based systems, improving processing efficiency and reducing energy consumption. Their innovations include the development of blocked isocyanates for one-component systems, offering improved shelf life and easier handling[5]. Additionally, Bayer has invested in the exploration of bio-based precursors for isocyanate production, aligning with sustainability goals while maintaining high performance standards[6].

Strengths: Expertise in specialty chemicals, strong market presence in coatings. Weaknesses: Potential environmental concerns with some isocyanate products, need for continuous innovation to stay competitive.

Core Isocyanate Patents

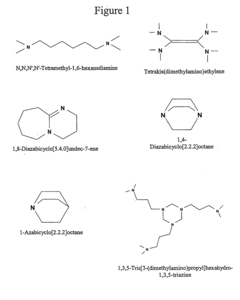

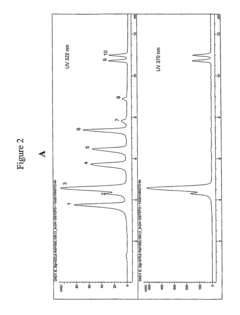

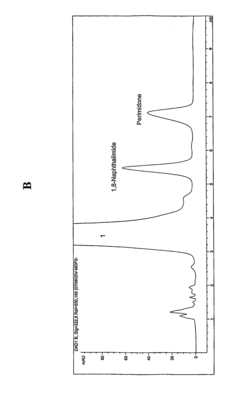

Measurement of total reactive isocyanate groups in samples using bifunctional nucleophiles such as 1,8-diaminonaphthalene (DAN)

PatentInactiveEP1579207A2

Innovation

- A method using 1,8-diaminonaphthalene (DAN) as a bifunctional nucleophilic isocyanate derivatizing agent that reacts with isocyanates to form a cyclic reaction product, allowing for the detection and quantification of total isocyanate groups regardless of the specific species present, using a two-step process of derivatization and cyclization.

Measurement of total reactive isocyanate groups in samples using bifunctional nucleophiles such as 1,8-diaminonaphthalene (dan)

PatentInactiveUS20060130565A1

Innovation

- A method using a bifunctional nucleophilic isocyanate derivatizing agent, such as 1,8-diaminonaphthalene, which forms a single reaction product capable of detection, allowing for the quantification of total isocyanate groups regardless of the species present, and can be used in conjunction with conventional sampling devices to detect isocyanates in air, surfaces, and other samples.

Environmental Impact

The environmental impact of isocyanates has become a critical concern in recent years, particularly as their use in various industries continues to expand. Isocyanates, primarily used in the production of polyurethanes, have significant implications for both human health and ecological systems. The production, use, and disposal of isocyanate-containing products contribute to various environmental challenges that require careful consideration and mitigation strategies.

One of the primary environmental concerns associated with isocyanates is their potential for air pollution. During manufacturing processes and application of isocyanate-based products, volatile organic compounds (VOCs) are released into the atmosphere. These emissions can contribute to the formation of ground-level ozone and smog, which have detrimental effects on air quality and human respiratory health. Additionally, some isocyanates have been identified as potential greenhouse gases, raising concerns about their long-term impact on climate change.

Water contamination is another significant environmental issue related to isocyanates. Improper disposal of isocyanate-containing waste or accidental spills can lead to the introduction of these chemicals into aquatic ecosystems. Once in water bodies, isocyanates can react with water to form potentially harmful byproducts, affecting aquatic life and potentially entering the food chain. The persistence of these compounds in the environment and their potential for bioaccumulation in organisms further exacerbate the ecological risks.

Soil contamination is also a concern, particularly in areas where isocyanate-based products are manufactured or heavily used. Leaching of isocyanates from landfills or industrial sites can lead to soil degradation and potentially impact groundwater quality. This contamination can have long-lasting effects on soil ecosystems and potentially affect agricultural productivity in affected areas.

The lifecycle impact of isocyanate-containing products is another crucial aspect of their environmental footprint. While polyurethanes derived from isocyanates offer excellent insulation properties and can contribute to energy efficiency in buildings, the end-of-life disposal of these materials presents challenges. Many polyurethane products are not easily recyclable, leading to increased waste in landfills or the need for energy-intensive incineration processes.

To address these environmental concerns, ongoing research and development efforts are focused on developing more environmentally friendly alternatives to traditional isocyanates. This includes exploring bio-based isocyanates derived from renewable resources, which could potentially reduce the carbon footprint of polyurethane production. Additionally, advancements in green chemistry are driving the development of isocyanate-free polyurethane technologies, aiming to maintain the beneficial properties of these materials while minimizing environmental impact.

One of the primary environmental concerns associated with isocyanates is their potential for air pollution. During manufacturing processes and application of isocyanate-based products, volatile organic compounds (VOCs) are released into the atmosphere. These emissions can contribute to the formation of ground-level ozone and smog, which have detrimental effects on air quality and human respiratory health. Additionally, some isocyanates have been identified as potential greenhouse gases, raising concerns about their long-term impact on climate change.

Water contamination is another significant environmental issue related to isocyanates. Improper disposal of isocyanate-containing waste or accidental spills can lead to the introduction of these chemicals into aquatic ecosystems. Once in water bodies, isocyanates can react with water to form potentially harmful byproducts, affecting aquatic life and potentially entering the food chain. The persistence of these compounds in the environment and their potential for bioaccumulation in organisms further exacerbate the ecological risks.

Soil contamination is also a concern, particularly in areas where isocyanate-based products are manufactured or heavily used. Leaching of isocyanates from landfills or industrial sites can lead to soil degradation and potentially impact groundwater quality. This contamination can have long-lasting effects on soil ecosystems and potentially affect agricultural productivity in affected areas.

The lifecycle impact of isocyanate-containing products is another crucial aspect of their environmental footprint. While polyurethanes derived from isocyanates offer excellent insulation properties and can contribute to energy efficiency in buildings, the end-of-life disposal of these materials presents challenges. Many polyurethane products are not easily recyclable, leading to increased waste in landfills or the need for energy-intensive incineration processes.

To address these environmental concerns, ongoing research and development efforts are focused on developing more environmentally friendly alternatives to traditional isocyanates. This includes exploring bio-based isocyanates derived from renewable resources, which could potentially reduce the carbon footprint of polyurethane production. Additionally, advancements in green chemistry are driving the development of isocyanate-free polyurethane technologies, aiming to maintain the beneficial properties of these materials while minimizing environmental impact.

Safety Regulations

Safety regulations play a crucial role in the advancement of isocyanate exploration and technical profundity. As the use of isocyanates continues to expand across various industries, regulatory bodies have implemented stringent guidelines to protect workers, consumers, and the environment from potential hazards associated with these chemicals.

The Occupational Safety and Health Administration (OSHA) in the United States has established comprehensive standards for isocyanate handling and exposure. These regulations mandate the use of personal protective equipment (PPE), including respiratory protection, impervious gloves, and chemical-resistant clothing. Employers are required to conduct regular air monitoring and provide medical surveillance for workers exposed to isocyanates.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of isocyanates. REACH requires manufacturers and importers to register substances and provide detailed safety information. The regulation also imposes restrictions on certain isocyanates, such as methylene diphenyl diisocyanate (MDI), to minimize risks to human health and the environment.

The Global Harmonized System (GHS) of Classification and Labeling of Chemicals has been widely adopted to standardize hazard communication for isocyanates. This system ensures consistent labeling and safety data sheets across different countries, facilitating international trade while maintaining safety standards.

Specific industry sectors have developed additional safety guidelines for isocyanate use. For instance, the automotive industry has implemented strict protocols for the application of isocyanate-based coatings and adhesives. These guidelines often exceed regulatory requirements, focusing on engineering controls, worker training, and emergency response procedures.

Environmental regulations have also evolved to address concerns related to isocyanate emissions and waste disposal. Many countries have established limits on volatile organic compound (VOC) emissions from isocyanate-containing products, driving innovation in low-VOC and water-based formulations.

As research continues to uncover potential long-term health effects of isocyanate exposure, regulatory bodies are continuously updating their guidelines. Recent focus areas include the development of more sensitive analytical methods for detecting isocyanates in air and biological samples, as well as the establishment of lower occupational exposure limits.

The advancement of isocyanate technology has led to the creation of safer alternatives and improved handling methods. Regulatory frameworks are adapting to these innovations, encouraging the adoption of less hazardous isocyanate variants and promoting the use of automated systems that minimize direct human contact with these chemicals.

The Occupational Safety and Health Administration (OSHA) in the United States has established comprehensive standards for isocyanate handling and exposure. These regulations mandate the use of personal protective equipment (PPE), including respiratory protection, impervious gloves, and chemical-resistant clothing. Employers are required to conduct regular air monitoring and provide medical surveillance for workers exposed to isocyanates.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of isocyanates. REACH requires manufacturers and importers to register substances and provide detailed safety information. The regulation also imposes restrictions on certain isocyanates, such as methylene diphenyl diisocyanate (MDI), to minimize risks to human health and the environment.

The Global Harmonized System (GHS) of Classification and Labeling of Chemicals has been widely adopted to standardize hazard communication for isocyanates. This system ensures consistent labeling and safety data sheets across different countries, facilitating international trade while maintaining safety standards.

Specific industry sectors have developed additional safety guidelines for isocyanate use. For instance, the automotive industry has implemented strict protocols for the application of isocyanate-based coatings and adhesives. These guidelines often exceed regulatory requirements, focusing on engineering controls, worker training, and emergency response procedures.

Environmental regulations have also evolved to address concerns related to isocyanate emissions and waste disposal. Many countries have established limits on volatile organic compound (VOC) emissions from isocyanate-containing products, driving innovation in low-VOC and water-based formulations.

As research continues to uncover potential long-term health effects of isocyanate exposure, regulatory bodies are continuously updating their guidelines. Recent focus areas include the development of more sensitive analytical methods for detecting isocyanates in air and biological samples, as well as the establishment of lower occupational exposure limits.

The advancement of isocyanate technology has led to the creation of safer alternatives and improved handling methods. Regulatory frameworks are adapting to these innovations, encouraging the adoption of less hazardous isocyanate variants and promoting the use of automated systems that minimize direct human contact with these chemicals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!