Steering Isocyanate Methodologies Toward Climate Goals

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Evolution

The evolution of isocyanates has been closely tied to the development of polyurethane chemistry and industrial applications. Initially discovered in the 1930s, isocyanates gained significant attention in the 1940s when their potential for polymer synthesis was recognized. The early stages of isocyanate development focused primarily on toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI), which remain key players in the industry today.

Throughout the 1950s and 1960s, research efforts concentrated on optimizing production processes and expanding the range of isocyanate derivatives. This period saw the introduction of aliphatic isocyanates, which offered improved color stability and weathering resistance compared to their aromatic counterparts. The 1970s marked a significant milestone with the commercialization of polymeric MDI, which opened up new possibilities for rigid foam applications.

The 1980s and 1990s witnessed a shift towards more environmentally friendly and safer isocyanate technologies. This era saw the development of low-emission formulations and blocked isocyanates, which reduced exposure risks during handling and application. Concurrently, advancements in catalysis and process engineering led to more efficient and selective isocyanate production methods.

Entering the 21st century, the focus of isocyanate evolution has increasingly aligned with sustainability goals. Bio-based isocyanates derived from renewable resources have gained traction as alternatives to petroleum-based products. Research into CO2-based isocyanates has also intensified, aiming to reduce the carbon footprint of production processes.

Recent years have seen a surge in efforts to develop non-isocyanate polyurethane (NIPU) technologies, driven by regulatory pressures and environmental concerns. While these alternatives show promise, traditional isocyanates continue to evolve through innovations in molecular design and application techniques.

The current trajectory of isocyanate evolution is strongly influenced by climate goals and circular economy principles. Researchers are exploring ways to enhance the recyclability and biodegradability of isocyanate-based materials. Additionally, there is growing interest in developing isocyanates with lower toxicity profiles and reduced environmental impact throughout their lifecycle.

As we look towards the future, the evolution of isocyanates is likely to be characterized by a balance between performance optimization and sustainability. Emerging technologies such as artificial intelligence and high-throughput screening are expected to accelerate the discovery of novel isocyanate structures and formulations that meet increasingly stringent environmental and safety standards while maintaining or improving functional properties.

Throughout the 1950s and 1960s, research efforts concentrated on optimizing production processes and expanding the range of isocyanate derivatives. This period saw the introduction of aliphatic isocyanates, which offered improved color stability and weathering resistance compared to their aromatic counterparts. The 1970s marked a significant milestone with the commercialization of polymeric MDI, which opened up new possibilities for rigid foam applications.

The 1980s and 1990s witnessed a shift towards more environmentally friendly and safer isocyanate technologies. This era saw the development of low-emission formulations and blocked isocyanates, which reduced exposure risks during handling and application. Concurrently, advancements in catalysis and process engineering led to more efficient and selective isocyanate production methods.

Entering the 21st century, the focus of isocyanate evolution has increasingly aligned with sustainability goals. Bio-based isocyanates derived from renewable resources have gained traction as alternatives to petroleum-based products. Research into CO2-based isocyanates has also intensified, aiming to reduce the carbon footprint of production processes.

Recent years have seen a surge in efforts to develop non-isocyanate polyurethane (NIPU) technologies, driven by regulatory pressures and environmental concerns. While these alternatives show promise, traditional isocyanates continue to evolve through innovations in molecular design and application techniques.

The current trajectory of isocyanate evolution is strongly influenced by climate goals and circular economy principles. Researchers are exploring ways to enhance the recyclability and biodegradability of isocyanate-based materials. Additionally, there is growing interest in developing isocyanates with lower toxicity profiles and reduced environmental impact throughout their lifecycle.

As we look towards the future, the evolution of isocyanates is likely to be characterized by a balance between performance optimization and sustainability. Emerging technologies such as artificial intelligence and high-throughput screening are expected to accelerate the discovery of novel isocyanate structures and formulations that meet increasingly stringent environmental and safety standards while maintaining or improving functional properties.

Green Market Demand

The global market for green and sustainable products has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations aimed at reducing carbon emissions. This trend has created a substantial demand for eco-friendly alternatives in various industries, including those that rely on isocyanate-based products. As consumers and businesses alike prioritize sustainability, there is a growing market for isocyanate methodologies that align with climate goals.

The construction industry, a major consumer of isocyanate-based materials, has shown a strong inclination towards green building practices. This shift has led to an increased demand for sustainable insulation materials, adhesives, and coatings that offer improved energy efficiency and reduced environmental impact. The automotive sector, another significant user of isocyanates, is also experiencing a surge in demand for lightweight, eco-friendly materials that can help reduce vehicle emissions and improve fuel efficiency.

In the packaging industry, there is a rising need for biodegradable and recyclable materials, creating opportunities for innovative isocyanate-based solutions that meet these criteria. The textile sector is seeking sustainable alternatives for waterproof and breathable fabrics, driving the demand for environmentally friendly isocyanate applications in this area.

The healthcare industry has also shown interest in green isocyanate methodologies, particularly for medical devices and equipment that require biocompatibility and reduced environmental impact. This trend is further amplified by the increasing focus on sustainable healthcare practices and the need for materials that can be safely disposed of or recycled.

Consumer goods manufacturers are responding to the growing eco-consciousness of their customers by incorporating sustainable materials into their products. This has created a market for isocyanate-based materials that offer durability and performance while minimizing environmental harm. The electronics industry is also exploring green alternatives for components and casings, presenting opportunities for innovative isocyanate applications that meet both technical and environmental requirements.

The market demand for green isocyanate methodologies is further bolstered by government initiatives and regulations promoting sustainable development. Many countries have implemented policies that incentivize the use of environmentally friendly materials and production processes, creating a favorable market environment for green isocyanate technologies.

As the global community continues to prioritize climate action, the demand for sustainable isocyanate methodologies is expected to grow exponentially. Companies that can develop and commercialize innovative, eco-friendly isocyanate-based products are likely to gain a significant competitive advantage in this evolving market landscape.

The construction industry, a major consumer of isocyanate-based materials, has shown a strong inclination towards green building practices. This shift has led to an increased demand for sustainable insulation materials, adhesives, and coatings that offer improved energy efficiency and reduced environmental impact. The automotive sector, another significant user of isocyanates, is also experiencing a surge in demand for lightweight, eco-friendly materials that can help reduce vehicle emissions and improve fuel efficiency.

In the packaging industry, there is a rising need for biodegradable and recyclable materials, creating opportunities for innovative isocyanate-based solutions that meet these criteria. The textile sector is seeking sustainable alternatives for waterproof and breathable fabrics, driving the demand for environmentally friendly isocyanate applications in this area.

The healthcare industry has also shown interest in green isocyanate methodologies, particularly for medical devices and equipment that require biocompatibility and reduced environmental impact. This trend is further amplified by the increasing focus on sustainable healthcare practices and the need for materials that can be safely disposed of or recycled.

Consumer goods manufacturers are responding to the growing eco-consciousness of their customers by incorporating sustainable materials into their products. This has created a market for isocyanate-based materials that offer durability and performance while minimizing environmental harm. The electronics industry is also exploring green alternatives for components and casings, presenting opportunities for innovative isocyanate applications that meet both technical and environmental requirements.

The market demand for green isocyanate methodologies is further bolstered by government initiatives and regulations promoting sustainable development. Many countries have implemented policies that incentivize the use of environmentally friendly materials and production processes, creating a favorable market environment for green isocyanate technologies.

As the global community continues to prioritize climate action, the demand for sustainable isocyanate methodologies is expected to grow exponentially. Companies that can develop and commercialize innovative, eco-friendly isocyanate-based products are likely to gain a significant competitive advantage in this evolving market landscape.

Eco-Challenges

The production and use of isocyanates present significant environmental challenges that must be addressed to align with global climate goals. One of the primary concerns is the high carbon footprint associated with isocyanate manufacturing processes. These processes often rely heavily on fossil fuel-derived raw materials and energy-intensive production methods, contributing substantially to greenhouse gas emissions.

Furthermore, the release of volatile organic compounds (VOCs) during isocyanate production and application poses air quality issues. VOCs are precursors to ground-level ozone formation, which can have detrimental effects on human health and ecosystems. The chemical industry faces increasing pressure to reduce VOC emissions and implement more sustainable production practices.

Water pollution is another critical eco-challenge in isocyanate production. Wastewater from manufacturing facilities may contain toxic compounds that, if not properly treated, can contaminate water sources and harm aquatic ecosystems. Ensuring effective wastewater treatment and minimizing water usage in production processes are essential steps towards environmental stewardship.

The end-of-life management of isocyanate-based products also presents environmental concerns. Many products containing isocyanates, such as polyurethane foams and coatings, are not easily recyclable or biodegradable. This leads to accumulation in landfills or incineration, both of which have negative environmental impacts. Developing more sustainable disposal methods and improving product recyclability are crucial challenges that need to be addressed.

Additionally, the potential for accidental releases or spills during transportation and handling of isocyanates poses risks to both human health and the environment. Implementing robust safety protocols and developing less hazardous alternatives are important considerations in mitigating these risks.

The industry also faces challenges in sourcing sustainable raw materials for isocyanate production. Many current feedstocks are derived from non-renewable petroleum sources, contributing to resource depletion and environmental degradation. Transitioning to bio-based or recycled feedstocks is a significant challenge that requires innovation in chemistry and process engineering.

Lastly, the energy intensity of isocyanate production processes contributes to their overall environmental impact. Improving energy efficiency and transitioning to renewable energy sources in manufacturing facilities are critical steps in reducing the carbon footprint of isocyanate production. These efforts align with broader industry goals to decrease energy consumption and increase the use of clean energy technologies.

Furthermore, the release of volatile organic compounds (VOCs) during isocyanate production and application poses air quality issues. VOCs are precursors to ground-level ozone formation, which can have detrimental effects on human health and ecosystems. The chemical industry faces increasing pressure to reduce VOC emissions and implement more sustainable production practices.

Water pollution is another critical eco-challenge in isocyanate production. Wastewater from manufacturing facilities may contain toxic compounds that, if not properly treated, can contaminate water sources and harm aquatic ecosystems. Ensuring effective wastewater treatment and minimizing water usage in production processes are essential steps towards environmental stewardship.

The end-of-life management of isocyanate-based products also presents environmental concerns. Many products containing isocyanates, such as polyurethane foams and coatings, are not easily recyclable or biodegradable. This leads to accumulation in landfills or incineration, both of which have negative environmental impacts. Developing more sustainable disposal methods and improving product recyclability are crucial challenges that need to be addressed.

Additionally, the potential for accidental releases or spills during transportation and handling of isocyanates poses risks to both human health and the environment. Implementing robust safety protocols and developing less hazardous alternatives are important considerations in mitigating these risks.

The industry also faces challenges in sourcing sustainable raw materials for isocyanate production. Many current feedstocks are derived from non-renewable petroleum sources, contributing to resource depletion and environmental degradation. Transitioning to bio-based or recycled feedstocks is a significant challenge that requires innovation in chemistry and process engineering.

Lastly, the energy intensity of isocyanate production processes contributes to their overall environmental impact. Improving energy efficiency and transitioning to renewable energy sources in manufacturing facilities are critical steps in reducing the carbon footprint of isocyanate production. These efforts align with broader industry goals to decrease energy consumption and increase the use of clean energy technologies.

Green Synthesis

01 Isocyanate-based materials for climate change mitigation

Isocyanate-based materials, such as polyurethanes, can be used in various applications to reduce greenhouse gas emissions and improve energy efficiency. These materials can be utilized in insulation, lightweight components for vehicles, and energy-efficient building materials, contributing to climate change mitigation efforts.- Isocyanate-based materials for climate change mitigation: Isocyanate-based materials, such as polyurethanes, can be used in various applications to reduce greenhouse gas emissions and improve energy efficiency. These materials can be utilized in insulation, lightweight components for vehicles, and energy-efficient building materials, contributing to climate change mitigation efforts.

- Low-emission isocyanate production methods: Development of innovative production methods for isocyanates that reduce carbon emissions and energy consumption. These methods may include catalytic processes, renewable feedstocks, or process optimizations that minimize the environmental impact of isocyanate manufacturing.

- Isocyanate-free alternatives for climate-friendly products: Research into isocyanate-free alternatives that offer similar performance characteristics while reducing environmental impact. These alternatives may include bio-based materials, water-based systems, or novel chemistries that provide comparable properties to traditional isocyanate-based products with lower carbon footprints.

- Recycling and upcycling of isocyanate-based products: Development of methodologies for recycling and upcycling isocyanate-based products, such as polyurethanes, to reduce waste and minimize environmental impact. These processes may include chemical recycling, mechanical recycling, or innovative upcycling techniques that extend the lifecycle of isocyanate-containing materials.

- Life cycle assessment of isocyanate products: Comprehensive life cycle assessment methodologies for isocyanate-based products to evaluate their overall environmental impact, including production, use phase, and end-of-life considerations. These assessments help identify areas for improvement and guide the development of more sustainable isocyanate technologies.

02 Low-emission isocyanate production methods

Development of innovative production methods for isocyanates that reduce carbon emissions and energy consumption. These methods may include catalytic processes, renewable feedstocks, or improved reactor designs that minimize environmental impact while maintaining product quality.Expand Specific Solutions03 Isocyanate-free alternatives for climate-friendly products

Research into isocyanate-free alternatives that offer similar performance characteristics but with reduced environmental impact. These alternatives may include bio-based materials, water-based systems, or novel polymer chemistries that address climate concerns while meeting industry requirements.Expand Specific Solutions04 Recycling and upcycling of isocyanate-based products

Development of technologies and methodologies for recycling and upcycling isocyanate-based products, such as polyurethane foams and coatings. These processes aim to reduce waste, conserve resources, and minimize the overall carbon footprint of isocyanate-containing materials throughout their lifecycle.Expand Specific Solutions05 Climate impact assessment of isocyanate production and use

Implementation of comprehensive life cycle assessments and environmental impact studies to evaluate the climate effects of isocyanate production, use, and disposal. These assessments help identify areas for improvement and guide the development of more sustainable isocyanate methodologies.Expand Specific Solutions

Industry Leaders

The steering of isocyanate methodologies towards climate goals is currently in a transitional phase, with the market showing significant growth potential. The global isocyanate market is expanding, driven by increasing demand in various industries such as construction, automotive, and electronics. Technologically, the field is evolving rapidly, with companies like Wanhua Chemical Group, BASF, and Covestro leading innovation efforts. These firms are focusing on developing more sustainable and eco-friendly isocyanate production methods, aligning with global climate objectives. The industry is witnessing a shift towards bio-based isocyanates and improved production processes to reduce environmental impact, indicating a moderate level of technological maturity with room for further advancements.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has developed innovative isocyanate production methods aimed at reducing carbon emissions. Their approach includes using renewable raw materials and implementing energy-efficient catalytic processes. The company has invested in bio-based polyols derived from natural oils, which can be used in conjunction with isocyanates to produce more sustainable polyurethanes[1]. Additionally, Wanhua has implemented carbon capture and utilization technologies in their isocyanate production facilities, converting CO2 into valuable chemical feedstocks[2]. Their proprietary microreactor technology for isocyanate synthesis has shown to reduce energy consumption by up to 30% compared to conventional methods[3].

Strengths: Integrated production chain, strong R&D capabilities, and a focus on sustainability. Weaknesses: High capital investment required for new technologies and potential regulatory challenges in different markets.

BASF Corp.

Technical Solution: BASF has developed a comprehensive approach to steering isocyanate methodologies towards climate goals. Their strategy includes the use of biomass-balanced raw materials in isocyanate production, which can reduce the carbon footprint by up to 50% compared to conventional fossil-based alternatives[4]. BASF has also implemented a novel gas-phase technology for TDI (toluene diisocyanate) production, which significantly reduces energy consumption and CO2 emissions[5]. Furthermore, the company is exploring the use of green hydrogen in their isocyanate production processes to further decrease reliance on fossil fuels[6]. BASF's ChemCycling project aims to incorporate chemically recycled plastic waste as a feedstock for isocyanate production, promoting a circular economy approach[7].

Strengths: Extensive R&D resources, global presence, and a strong commitment to sustainability. Weaknesses: Dependence on fossil fuel-based raw materials in some processes and potential challenges in scaling up new technologies.

Catalytic Innovations

A process for manufacturing isocyanates and/or polycarbonates

PatentInactiveIN201817038268A

Innovation

- A process involving a chlorine stream with less than 500 ppm bromine, reacting it with carbon monoxide at a specific mole ratio to form a phosgene stream, cooling, separating, and removing residual chlorine to create a chlorine-depleted phosgene stream that can be used to produce light-colored isocyanates and polycarbonates without bromophosgene compounds.

Method for preparing aliphatic diisocyanate

PatentInactiveUS20140303399A1

Innovation

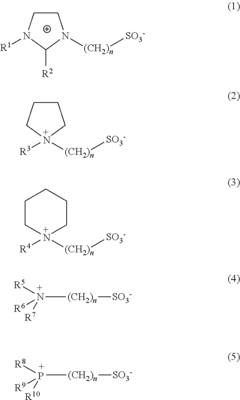

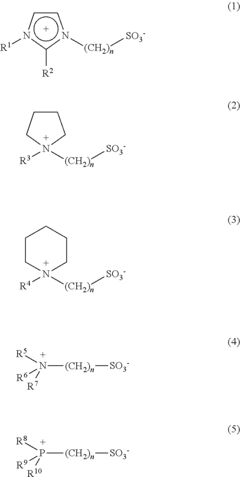

- Pyrolyzing aliphatic dicarbamates in a liquid phase with a tin (II) or (IV) compound as a catalyst and a zwitterionic compound as a stabilizer to inhibit the formation of high-boiling by-products and enhance yield.

Regulatory Landscape

The regulatory landscape surrounding isocyanate methodologies and climate goals is complex and evolving rapidly. Governments worldwide are implementing stricter regulations to address environmental concerns and promote sustainable practices in the chemical industry. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has set a precedent for comprehensive chemical management, including isocyanates. This framework requires manufacturers and importers to assess and manage the risks associated with these substances, emphasizing the need for safer alternatives and improved production processes.

In the United States, the Environmental Protection Agency (EPA) has been actively reviewing and updating regulations related to isocyanates under the Toxic Substances Control Act (TSCA). The agency has identified certain isocyanates as high-priority substances for risk evaluation, which may lead to additional restrictions or requirements for their use and production. Furthermore, the Occupational Safety and Health Administration (OSHA) has established exposure limits and safety protocols for workers handling isocyanates, reflecting the growing awareness of both environmental and health concerns.

Many countries are adopting or strengthening their chemical management policies, often aligning with international standards such as the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). This trend is driving the isocyanate industry towards more sustainable practices and the development of eco-friendly alternatives. Japan's Chemical Substances Control Law and China's Measures for Environmental Management of New Chemical Substances are examples of regulatory frameworks that are becoming increasingly stringent in their approach to chemical management, including isocyanates.

Climate-focused regulations are also impacting the isocyanate industry indirectly. Carbon pricing mechanisms, such as cap-and-trade systems and carbon taxes, are being implemented in various regions, incentivizing companies to reduce their carbon footprint. This has led to increased interest in bio-based isocyanates and more energy-efficient production methods. Additionally, regulations promoting circular economy principles are encouraging the development of recyclable and biodegradable polyurethane products, which in turn affects isocyanate production and use.

The regulatory landscape is further complicated by regional variations and the potential for regulatory divergence. While there is a general trend towards stricter environmental standards, the specific requirements and timelines can differ significantly between jurisdictions. This creates challenges for global companies operating in multiple markets, necessitating a comprehensive understanding of diverse regulatory environments and the ability to adapt quickly to changes.

In the United States, the Environmental Protection Agency (EPA) has been actively reviewing and updating regulations related to isocyanates under the Toxic Substances Control Act (TSCA). The agency has identified certain isocyanates as high-priority substances for risk evaluation, which may lead to additional restrictions or requirements for their use and production. Furthermore, the Occupational Safety and Health Administration (OSHA) has established exposure limits and safety protocols for workers handling isocyanates, reflecting the growing awareness of both environmental and health concerns.

Many countries are adopting or strengthening their chemical management policies, often aligning with international standards such as the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). This trend is driving the isocyanate industry towards more sustainable practices and the development of eco-friendly alternatives. Japan's Chemical Substances Control Law and China's Measures for Environmental Management of New Chemical Substances are examples of regulatory frameworks that are becoming increasingly stringent in their approach to chemical management, including isocyanates.

Climate-focused regulations are also impacting the isocyanate industry indirectly. Carbon pricing mechanisms, such as cap-and-trade systems and carbon taxes, are being implemented in various regions, incentivizing companies to reduce their carbon footprint. This has led to increased interest in bio-based isocyanates and more energy-efficient production methods. Additionally, regulations promoting circular economy principles are encouraging the development of recyclable and biodegradable polyurethane products, which in turn affects isocyanate production and use.

The regulatory landscape is further complicated by regional variations and the potential for regulatory divergence. While there is a general trend towards stricter environmental standards, the specific requirements and timelines can differ significantly between jurisdictions. This creates challenges for global companies operating in multiple markets, necessitating a comprehensive understanding of diverse regulatory environments and the ability to adapt quickly to changes.

Life Cycle Assessment

Life Cycle Assessment (LCA) plays a crucial role in steering isocyanate methodologies toward climate goals. This comprehensive approach evaluates the environmental impacts associated with all stages of a product's life, from raw material extraction to disposal. In the context of isocyanates, LCA provides valuable insights into the carbon footprint and overall environmental performance of various production methods and end-use applications.

The assessment typically begins with the extraction and processing of raw materials used in isocyanate production, such as crude oil and natural gas. This stage accounts for a significant portion of the overall environmental impact, particularly in terms of energy consumption and greenhouse gas emissions. The production phase, involving the synthesis of isocyanates through various chemical processes, is another critical area of focus in LCA studies.

Transportation and distribution of isocyanate products contribute to the overall environmental impact, with factors such as distance, mode of transport, and packaging materials being considered. The use phase of isocyanate-based products, which can span several years or even decades in some applications, is also evaluated for its long-term environmental implications.

End-of-life scenarios, including recycling, incineration, and landfilling, are assessed to determine the most environmentally friendly disposal methods for isocyanate-containing products. This stage is particularly important in identifying opportunities for circular economy approaches and reducing waste.

LCA studies on isocyanates have revealed several key areas for improvement in terms of climate impact. Energy efficiency in production processes has been identified as a major factor, with potential for significant reductions in greenhouse gas emissions through the adoption of more efficient technologies and renewable energy sources.

The choice of feedstocks also plays a crucial role in the overall environmental performance of isocyanates. Bio-based alternatives to traditional petroleum-derived raw materials have shown promise in reducing carbon footprints, although their scalability and long-term sustainability remain subjects of ongoing research.

Water consumption and wastewater management in isocyanate production have been highlighted as areas requiring attention, with opportunities for improvement through water recycling and more efficient treatment processes. Additionally, the potential for reducing volatile organic compound (VOC) emissions during production and use phases has been identified as a key target for environmental improvement.

By providing a holistic view of environmental impacts, LCA enables informed decision-making in the development of more sustainable isocyanate methodologies. This approach supports the identification of hotspots in the product life cycle where interventions can yield the most significant environmental benefits, aligning isocyanate production and use more closely with global climate goals.

The assessment typically begins with the extraction and processing of raw materials used in isocyanate production, such as crude oil and natural gas. This stage accounts for a significant portion of the overall environmental impact, particularly in terms of energy consumption and greenhouse gas emissions. The production phase, involving the synthesis of isocyanates through various chemical processes, is another critical area of focus in LCA studies.

Transportation and distribution of isocyanate products contribute to the overall environmental impact, with factors such as distance, mode of transport, and packaging materials being considered. The use phase of isocyanate-based products, which can span several years or even decades in some applications, is also evaluated for its long-term environmental implications.

End-of-life scenarios, including recycling, incineration, and landfilling, are assessed to determine the most environmentally friendly disposal methods for isocyanate-containing products. This stage is particularly important in identifying opportunities for circular economy approaches and reducing waste.

LCA studies on isocyanates have revealed several key areas for improvement in terms of climate impact. Energy efficiency in production processes has been identified as a major factor, with potential for significant reductions in greenhouse gas emissions through the adoption of more efficient technologies and renewable energy sources.

The choice of feedstocks also plays a crucial role in the overall environmental performance of isocyanates. Bio-based alternatives to traditional petroleum-derived raw materials have shown promise in reducing carbon footprints, although their scalability and long-term sustainability remain subjects of ongoing research.

Water consumption and wastewater management in isocyanate production have been highlighted as areas requiring attention, with opportunities for improvement through water recycling and more efficient treatment processes. Additionally, the potential for reducing volatile organic compound (VOC) emissions during production and use phases has been identified as a key target for environmental improvement.

By providing a holistic view of environmental impacts, LCA enables informed decision-making in the development of more sustainable isocyanate methodologies. This approach supports the identification of hotspots in the product life cycle where interventions can yield the most significant environmental benefits, aligning isocyanate production and use more closely with global climate goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!