How Isocyanates Enable Transition into Renewable Manufacturing?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanates in Renewable Manufacturing: Background and Objectives

Isocyanates have played a pivotal role in the chemical industry for decades, primarily in the production of polyurethanes. However, their significance is evolving as the world transitions towards more sustainable and renewable manufacturing processes. This shift is driven by increasing environmental concerns, regulatory pressures, and the growing demand for eco-friendly products.

The journey of isocyanates in renewable manufacturing begins with understanding their unique chemical properties. These compounds, characterized by the highly reactive -N=C=O functional group, have traditionally been derived from fossil fuels. Their ability to form strong chemical bonds with various molecules makes them versatile in creating polymers, coatings, and adhesives.

As the focus shifts towards sustainability, researchers and industry leaders are exploring ways to incorporate renewable resources into isocyanate production. This includes investigating bio-based feedstocks and developing novel synthesis routes that reduce reliance on petrochemicals. The goal is to maintain the beneficial properties of isocyanates while minimizing their environmental impact.

One of the key objectives in this transition is to develop isocyanates from renewable sources without compromising performance. This involves exploring natural oils, cellulose, and other biomass-derived materials as potential precursors. Researchers are also investigating the use of carbon dioxide as a raw material, which could potentially turn a greenhouse gas into a valuable chemical building block.

Another critical aspect of this transition is the development of more environmentally friendly production processes. This includes exploring catalytic methods that reduce energy consumption and waste generation, as well as investigating alternative reaction pathways that avoid the use of toxic intermediates commonly associated with traditional isocyanate synthesis.

The transition of isocyanates into renewable manufacturing also aims to address health and safety concerns associated with their use. This involves developing safer handling procedures and exploring alternative chemistries that can provide similar functionalities with reduced risks.

As the industry progresses, there is a growing focus on creating circular economy models for isocyanate-based products. This includes designing materials for easier recycling and developing technologies for the efficient breakdown and reuse of polyurethane products at the end of their lifecycle.

The journey towards renewable isocyanate manufacturing is not without challenges. It requires significant investment in research and development, as well as overcoming technical hurdles in scaling up new production methods. However, the potential benefits in terms of sustainability, resource efficiency, and new market opportunities are driving continued innovation in this field.

The journey of isocyanates in renewable manufacturing begins with understanding their unique chemical properties. These compounds, characterized by the highly reactive -N=C=O functional group, have traditionally been derived from fossil fuels. Their ability to form strong chemical bonds with various molecules makes them versatile in creating polymers, coatings, and adhesives.

As the focus shifts towards sustainability, researchers and industry leaders are exploring ways to incorporate renewable resources into isocyanate production. This includes investigating bio-based feedstocks and developing novel synthesis routes that reduce reliance on petrochemicals. The goal is to maintain the beneficial properties of isocyanates while minimizing their environmental impact.

One of the key objectives in this transition is to develop isocyanates from renewable sources without compromising performance. This involves exploring natural oils, cellulose, and other biomass-derived materials as potential precursors. Researchers are also investigating the use of carbon dioxide as a raw material, which could potentially turn a greenhouse gas into a valuable chemical building block.

Another critical aspect of this transition is the development of more environmentally friendly production processes. This includes exploring catalytic methods that reduce energy consumption and waste generation, as well as investigating alternative reaction pathways that avoid the use of toxic intermediates commonly associated with traditional isocyanate synthesis.

The transition of isocyanates into renewable manufacturing also aims to address health and safety concerns associated with their use. This involves developing safer handling procedures and exploring alternative chemistries that can provide similar functionalities with reduced risks.

As the industry progresses, there is a growing focus on creating circular economy models for isocyanate-based products. This includes designing materials for easier recycling and developing technologies for the efficient breakdown and reuse of polyurethane products at the end of their lifecycle.

The journey towards renewable isocyanate manufacturing is not without challenges. It requires significant investment in research and development, as well as overcoming technical hurdles in scaling up new production methods. However, the potential benefits in terms of sustainability, resource efficiency, and new market opportunities are driving continued innovation in this field.

Market Demand for Sustainable Chemical Processes

The global chemical industry is experiencing a significant shift towards sustainable manufacturing processes, driven by increasing environmental concerns, regulatory pressures, and consumer demand for eco-friendly products. This transition has created a substantial market demand for sustainable chemical processes, particularly in the realm of isocyanate production and utilization.

Isocyanates, traditionally derived from fossil fuels, play a crucial role in the production of polyurethanes, which are widely used in various industries such as automotive, construction, and furniture. The growing awareness of the environmental impact of conventional isocyanate production has led to a surge in demand for renewable alternatives and more sustainable manufacturing methods.

One of the key drivers of this market demand is the increasing implementation of stringent environmental regulations worldwide. Governments and international organizations are setting ambitious targets for reducing carbon emissions and promoting circular economy principles. This regulatory landscape has compelled chemical manufacturers to invest in research and development of sustainable processes, including those involving isocyanates.

Consumer preferences have also significantly influenced the market demand for sustainable chemical processes. End-users across various industries are increasingly seeking products with lower environmental footprints, pushing manufacturers to adopt greener production methods. This trend is particularly evident in sectors such as automotive and construction, where sustainability has become a key differentiator in product marketing and consumer choice.

The potential for cost savings and improved efficiency has further fueled the demand for sustainable isocyanate production processes. As renewable feedstocks become more readily available and technologies for their conversion improve, manufacturers are recognizing the long-term economic benefits of transitioning to more sustainable methods. This includes reduced dependency on volatile fossil fuel prices and potential advantages in terms of supply chain resilience.

Moreover, the growing focus on circular economy principles has created new opportunities in the isocyanate market. There is increasing interest in developing processes that enable the recycling and reuse of polyurethane products, further driving the demand for sustainable manufacturing methods that can accommodate these circular economy goals.

The market demand extends beyond just the production of isocyanates to encompass the entire value chain. This includes sustainable sourcing of raw materials, energy-efficient manufacturing processes, and the development of bio-based alternatives to traditional isocyanates. As a result, collaborations between chemical companies, biotechnology firms, and research institutions have intensified, aiming to develop innovative solutions that meet this growing market demand.

Isocyanates, traditionally derived from fossil fuels, play a crucial role in the production of polyurethanes, which are widely used in various industries such as automotive, construction, and furniture. The growing awareness of the environmental impact of conventional isocyanate production has led to a surge in demand for renewable alternatives and more sustainable manufacturing methods.

One of the key drivers of this market demand is the increasing implementation of stringent environmental regulations worldwide. Governments and international organizations are setting ambitious targets for reducing carbon emissions and promoting circular economy principles. This regulatory landscape has compelled chemical manufacturers to invest in research and development of sustainable processes, including those involving isocyanates.

Consumer preferences have also significantly influenced the market demand for sustainable chemical processes. End-users across various industries are increasingly seeking products with lower environmental footprints, pushing manufacturers to adopt greener production methods. This trend is particularly evident in sectors such as automotive and construction, where sustainability has become a key differentiator in product marketing and consumer choice.

The potential for cost savings and improved efficiency has further fueled the demand for sustainable isocyanate production processes. As renewable feedstocks become more readily available and technologies for their conversion improve, manufacturers are recognizing the long-term economic benefits of transitioning to more sustainable methods. This includes reduced dependency on volatile fossil fuel prices and potential advantages in terms of supply chain resilience.

Moreover, the growing focus on circular economy principles has created new opportunities in the isocyanate market. There is increasing interest in developing processes that enable the recycling and reuse of polyurethane products, further driving the demand for sustainable manufacturing methods that can accommodate these circular economy goals.

The market demand extends beyond just the production of isocyanates to encompass the entire value chain. This includes sustainable sourcing of raw materials, energy-efficient manufacturing processes, and the development of bio-based alternatives to traditional isocyanates. As a result, collaborations between chemical companies, biotechnology firms, and research institutions have intensified, aiming to develop innovative solutions that meet this growing market demand.

Current State and Challenges in Isocyanate-based Renewables

The current state of isocyanate-based renewables is characterized by significant progress in developing sustainable alternatives to traditional petroleum-based polyurethanes. Isocyanates, key components in polyurethane production, are increasingly being derived from renewable sources such as plant-based oils and biomass. This shift is driven by growing environmental concerns and the need for more sustainable manufacturing processes.

One of the primary challenges in this field is the development of bio-based isocyanates that can match or exceed the performance of their petrochemical counterparts. While progress has been made, issues such as reactivity, stability, and scalability still need to be addressed. Researchers are exploring various plant-based feedstocks, including soybean oil, castor oil, and lignocellulosic biomass, to produce isocyanates with comparable properties to traditional ones.

Another significant challenge is the cost-effectiveness of renewable isocyanate production. Currently, bio-based alternatives are often more expensive than petroleum-derived isocyanates, which can hinder widespread adoption in industry. Efforts are underway to optimize production processes and reduce costs through improved catalysts and more efficient conversion methods.

The environmental impact of isocyanate production remains a concern, even with renewable sources. While bio-based isocyanates offer reduced carbon footprints, the use of potentially harmful chemicals in their synthesis still poses challenges. Researchers are working on developing greener synthesis routes and exploring alternative chemistries to minimize environmental impact.

Regulatory compliance is another hurdle in the transition to renewable isocyanates. As new bio-based materials are developed, they must meet stringent safety and performance standards. This requires extensive testing and validation, which can slow down the commercialization process.

Despite these challenges, the field of isocyanate-based renewables is advancing rapidly. Innovations in catalyst technology, process engineering, and molecular design are driving improvements in both performance and sustainability. Collaborative efforts between academia and industry are accelerating the development of novel bio-based isocyanates and their applications in various sectors, including automotive, construction, and consumer goods.

The geographical distribution of research and development in this field is primarily concentrated in North America, Europe, and Asia, with emerging contributions from other regions. This global effort is fostering a diverse range of approaches and solutions to the challenges faced in transitioning to renewable isocyanate manufacturing.

One of the primary challenges in this field is the development of bio-based isocyanates that can match or exceed the performance of their petrochemical counterparts. While progress has been made, issues such as reactivity, stability, and scalability still need to be addressed. Researchers are exploring various plant-based feedstocks, including soybean oil, castor oil, and lignocellulosic biomass, to produce isocyanates with comparable properties to traditional ones.

Another significant challenge is the cost-effectiveness of renewable isocyanate production. Currently, bio-based alternatives are often more expensive than petroleum-derived isocyanates, which can hinder widespread adoption in industry. Efforts are underway to optimize production processes and reduce costs through improved catalysts and more efficient conversion methods.

The environmental impact of isocyanate production remains a concern, even with renewable sources. While bio-based isocyanates offer reduced carbon footprints, the use of potentially harmful chemicals in their synthesis still poses challenges. Researchers are working on developing greener synthesis routes and exploring alternative chemistries to minimize environmental impact.

Regulatory compliance is another hurdle in the transition to renewable isocyanates. As new bio-based materials are developed, they must meet stringent safety and performance standards. This requires extensive testing and validation, which can slow down the commercialization process.

Despite these challenges, the field of isocyanate-based renewables is advancing rapidly. Innovations in catalyst technology, process engineering, and molecular design are driving improvements in both performance and sustainability. Collaborative efforts between academia and industry are accelerating the development of novel bio-based isocyanates and their applications in various sectors, including automotive, construction, and consumer goods.

The geographical distribution of research and development in this field is primarily concentrated in North America, Europe, and Asia, with emerging contributions from other regions. This global effort is fostering a diverse range of approaches and solutions to the challenges faced in transitioning to renewable isocyanate manufacturing.

Existing Solutions for Isocyanate-enabled Renewable Production

01 Synthesis and production of isocyanates

Various methods and processes for synthesizing and producing isocyanates are described. These include novel catalysts, reaction conditions, and precursor materials to improve yield, purity, and efficiency in isocyanate production.- Synthesis and production of isocyanates: Various methods and processes for synthesizing and producing isocyanates are described. These include novel catalysts, reaction conditions, and precursor materials to improve efficiency and yield in isocyanate production.

- Applications of isocyanates in polymer chemistry: Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents discuss different formulations, curing processes, and applications of isocyanate-based polymers in various industries.

- Isocyanate-based coatings and adhesives: The use of isocyanates in the development of high-performance coatings and adhesives is explored. These formulations offer improved durability, chemical resistance, and bonding properties for various substrates.

- Safety and handling of isocyanates: Given the reactive nature of isocyanates, several patents focus on improving safety measures in their handling, storage, and use. This includes the development of less hazardous alternatives and methods to reduce exposure risks.

- Isocyanate-free alternatives and modifications: Research into developing isocyanate-free or modified isocyanate compounds is presented. These alternatives aim to maintain the beneficial properties of isocyanates while addressing environmental and health concerns associated with traditional isocyanates.

02 Applications of isocyanates in polymer chemistry

Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents describe various applications, including coatings, adhesives, foams, and elastomers, as well as novel formulations and processing techniques.Expand Specific Solutions03 Isocyanate-based catalysts and additives

Several patents focus on the development of isocyanate-based catalysts and additives for various chemical processes. These include novel catalyst systems, stabilizers, and modifiers that enhance reaction rates, selectivity, or product properties.Expand Specific Solutions04 Safety and handling of isocyanates

Given the reactive nature of isocyanates, patents in this category address safety concerns and handling procedures. This includes methods for reducing toxicity, improving storage stability, and developing safer alternatives or modified isocyanates with reduced health risks.Expand Specific Solutions05 Isocyanate-free alternatives and substitutes

Some patents focus on developing alternatives or substitutes for isocyanates in various applications. These include novel chemistries, bio-based materials, and modified compounds that can replace traditional isocyanates while maintaining similar performance characteristics.Expand Specific Solutions

Key Players in Renewable Isocyanate Manufacturing

The transition to renewable manufacturing using isocyanates is in an early growth stage, with a rapidly expanding market driven by increasing environmental concerns and sustainability initiatives. The global market for bio-based isocyanates is projected to grow significantly in the coming years. Technologically, the field is advancing quickly but still maturing, with key players like Covestro, BASF, and Wanhua Chemical leading innovation. These companies are investing heavily in R&D to develop more efficient and sustainable isocyanate production methods from renewable feedstocks. While progress has been made, challenges remain in scaling up production and reducing costs to compete with traditional petroleum-based isocyanates. Collaboration between industry leaders and research institutions is accelerating technological advancements in this promising area.

Covestro Deutschland AG

Technical Solution: Covestro has pioneered a novel approach to renewable isocyanate manufacturing through their innovative carbon capture and utilization (CCU) technology. This process involves capturing CO2 emissions and using them as a raw material for producing isocyanate precursors[2]. By incorporating up to 20% CO2 into their polyol production, Covestro has significantly reduced the petroleum-based content in their isocyanates[4]. The company has also developed bio-based aniline, a key component in isocyanate production, derived from biomass sources such as straw or wood[6]. These advancements have enabled Covestro to offer a range of more sustainable polyurethane products while maintaining high performance standards.

Strengths: Utilization of waste CO2, reduced reliance on fossil resources, scalable technology. Weaknesses: Limited CO2 incorporation percentage, potential energy requirements for CO2 capture and conversion.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has developed an innovative approach to renewable isocyanate manufacturing by focusing on bio-based raw materials and green chemistry principles. Their process involves the use of bio-derived polyols and novel catalytic systems to produce isocyanates with a significantly lower environmental impact[7]. Wanhua has also invested in advanced fermentation technologies to produce bio-based precursors for isocyanate synthesis, reducing reliance on petroleum-based feedstocks[9]. The company's commitment to sustainability is further demonstrated by their development of water-based polyurethane systems, which reduce VOC emissions and improve overall product lifecycle sustainability[11].

Strengths: Diverse portfolio of bio-based solutions, integration of green chemistry principles, reduced environmental impact. Weaknesses: Potential challenges in scaling up bio-based precursor production, market acceptance of new technologies.

Core Innovations in Isocyanate-based Green Synthesis

Sustainable preparation of organic amino compounds for the production of organic isocyanates

PatentWO2024017890A2

Innovation

- A process using green hydrogen and green ammonia to produce organic amino compounds, which are then used to synthesize isocyanates, incorporating renewable energy sources and reducing waste through closed-loop recycling of materials.

Sustainable preparation of hexamethylene diisocyanate for the production of polyurethane

PatentWO2024208940A2

Innovation

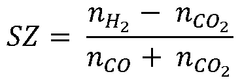

- A sustainable production process for hexamethylene diisocyanate using renewable raw materials and renewable energy sources, involving steps such as the partial reduction of CO2 to CO, partial oxidation of organic materials, and electrolysis to produce methanol and ammonia, followed by catalytic conversions to form hexamethylene diisocyanate, reducing energy consumption and emissions.

Environmental Impact Assessment of Isocyanate Processes

The environmental impact assessment of isocyanate processes is crucial for understanding the sustainability and ecological implications of transitioning to renewable manufacturing using isocyanates. This assessment encompasses various aspects of the production, use, and disposal of isocyanates, as well as their potential effects on ecosystems and human health.

Isocyanate production processes typically involve the reaction of amines with phosgene or its derivatives. These processes can generate significant amounts of hazardous waste and emissions, including volatile organic compounds (VOCs) and greenhouse gases. The environmental impact of these emissions includes air pollution, contribution to climate change, and potential harm to local ecosystems. Additionally, the production of isocyanates often requires substantial energy inputs, further contributing to their carbon footprint.

Water pollution is another critical concern in isocyanate manufacturing. Wastewater from production facilities may contain toxic compounds that, if not properly treated, can contaminate local water sources and harm aquatic life. Proper wastewater treatment and management systems are essential to mitigate these risks and ensure compliance with environmental regulations.

The use of isocyanates in various applications, such as polyurethane production, also presents environmental challenges. While polyurethanes offer excellent insulation properties that can improve energy efficiency in buildings and vehicles, their production and disposal can have negative environmental impacts. The release of unreacted isocyanates during manufacturing or application processes can pose risks to workers and nearby communities.

End-of-life considerations for isocyanate-based products are equally important in assessing their overall environmental impact. Many polyurethane products are not easily recyclable, leading to increased waste in landfills or incineration facilities. However, recent advancements in chemical recycling technologies offer promising solutions for recovering and reusing isocyanate components, potentially reducing the environmental burden of these materials.

In the context of renewable manufacturing, the environmental impact assessment must also consider the sourcing of raw materials for isocyanate production. Transitioning to bio-based feedstocks for isocyanate synthesis can potentially reduce reliance on fossil fuels and decrease overall carbon emissions. However, the cultivation and processing of these renewable resources must be carefully evaluated to ensure they do not lead to other environmental issues, such as deforestation or competition with food crops.

Lifecycle assessment (LCA) methodologies play a crucial role in comprehensively evaluating the environmental impacts of isocyanate processes. These assessments consider all stages of the product lifecycle, from raw material extraction to disposal, providing a holistic view of the environmental footprint. LCA studies can help identify hotspots in the production chain where environmental improvements can be made, guiding the development of more sustainable manufacturing practices.

Isocyanate production processes typically involve the reaction of amines with phosgene or its derivatives. These processes can generate significant amounts of hazardous waste and emissions, including volatile organic compounds (VOCs) and greenhouse gases. The environmental impact of these emissions includes air pollution, contribution to climate change, and potential harm to local ecosystems. Additionally, the production of isocyanates often requires substantial energy inputs, further contributing to their carbon footprint.

Water pollution is another critical concern in isocyanate manufacturing. Wastewater from production facilities may contain toxic compounds that, if not properly treated, can contaminate local water sources and harm aquatic life. Proper wastewater treatment and management systems are essential to mitigate these risks and ensure compliance with environmental regulations.

The use of isocyanates in various applications, such as polyurethane production, also presents environmental challenges. While polyurethanes offer excellent insulation properties that can improve energy efficiency in buildings and vehicles, their production and disposal can have negative environmental impacts. The release of unreacted isocyanates during manufacturing or application processes can pose risks to workers and nearby communities.

End-of-life considerations for isocyanate-based products are equally important in assessing their overall environmental impact. Many polyurethane products are not easily recyclable, leading to increased waste in landfills or incineration facilities. However, recent advancements in chemical recycling technologies offer promising solutions for recovering and reusing isocyanate components, potentially reducing the environmental burden of these materials.

In the context of renewable manufacturing, the environmental impact assessment must also consider the sourcing of raw materials for isocyanate production. Transitioning to bio-based feedstocks for isocyanate synthesis can potentially reduce reliance on fossil fuels and decrease overall carbon emissions. However, the cultivation and processing of these renewable resources must be carefully evaluated to ensure they do not lead to other environmental issues, such as deforestation or competition with food crops.

Lifecycle assessment (LCA) methodologies play a crucial role in comprehensively evaluating the environmental impacts of isocyanate processes. These assessments consider all stages of the product lifecycle, from raw material extraction to disposal, providing a holistic view of the environmental footprint. LCA studies can help identify hotspots in the production chain where environmental improvements can be made, guiding the development of more sustainable manufacturing practices.

Regulatory Framework for Renewable Chemical Manufacturing

The regulatory framework for renewable chemical manufacturing plays a crucial role in facilitating the transition towards sustainable production methods, including the use of isocyanates in renewable manufacturing processes. This framework encompasses a complex web of policies, standards, and incentives designed to promote the adoption of environmentally friendly practices while ensuring safety and compliance.

At the international level, agreements such as the Paris Agreement and the United Nations Sustainable Development Goals provide overarching guidance for nations to develop their own regulatory structures. These global initiatives emphasize the importance of reducing carbon emissions and promoting sustainable industrial practices, which directly impact the renewable chemical manufacturing sector.

In the United States, the Environmental Protection Agency (EPA) oversees the implementation of key regulations such as the Toxic Substances Control Act (TSCA) and the Resource Conservation and Recovery Act (RCRA). These regulations set standards for the production, use, and disposal of chemicals, including those derived from renewable sources. The EPA also administers the Renewable Fuel Standard program, which incentivizes the production of biofuels and bio-based chemicals.

The European Union has established a comprehensive regulatory framework through initiatives like REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and the European Green Deal. These regulations aim to ensure the safe use of chemicals while promoting innovation in sustainable manufacturing processes. The EU's Circular Economy Action Plan further supports the transition to renewable chemical manufacturing by encouraging the use of bio-based materials and recycled content.

Many countries have implemented specific policies to support the growth of renewable chemical manufacturing. For instance, tax incentives, research grants, and preferential procurement policies are common tools used to encourage investment in sustainable technologies. These measures help offset the initial costs associated with transitioning to renewable manufacturing processes, including those involving isocyanates.

Certification schemes and eco-labeling programs also form an important part of the regulatory landscape. These voluntary standards, such as the USDA BioPreferred program or the EU Ecolabel, provide guidelines for manufacturers and help consumers identify products made with renewable materials. Such programs can drive market demand for sustainably produced chemicals and materials.

As the field of renewable chemical manufacturing continues to evolve, regulatory frameworks are adapting to address new challenges and opportunities. This includes developing standards for emerging technologies, addressing potential environmental and health impacts, and harmonizing regulations across different regions to facilitate global trade in renewable chemicals.

At the international level, agreements such as the Paris Agreement and the United Nations Sustainable Development Goals provide overarching guidance for nations to develop their own regulatory structures. These global initiatives emphasize the importance of reducing carbon emissions and promoting sustainable industrial practices, which directly impact the renewable chemical manufacturing sector.

In the United States, the Environmental Protection Agency (EPA) oversees the implementation of key regulations such as the Toxic Substances Control Act (TSCA) and the Resource Conservation and Recovery Act (RCRA). These regulations set standards for the production, use, and disposal of chemicals, including those derived from renewable sources. The EPA also administers the Renewable Fuel Standard program, which incentivizes the production of biofuels and bio-based chemicals.

The European Union has established a comprehensive regulatory framework through initiatives like REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and the European Green Deal. These regulations aim to ensure the safe use of chemicals while promoting innovation in sustainable manufacturing processes. The EU's Circular Economy Action Plan further supports the transition to renewable chemical manufacturing by encouraging the use of bio-based materials and recycled content.

Many countries have implemented specific policies to support the growth of renewable chemical manufacturing. For instance, tax incentives, research grants, and preferential procurement policies are common tools used to encourage investment in sustainable technologies. These measures help offset the initial costs associated with transitioning to renewable manufacturing processes, including those involving isocyanates.

Certification schemes and eco-labeling programs also form an important part of the regulatory landscape. These voluntary standards, such as the USDA BioPreferred program or the EU Ecolabel, provide guidelines for manufacturers and help consumers identify products made with renewable materials. Such programs can drive market demand for sustainably produced chemicals and materials.

As the field of renewable chemical manufacturing continues to evolve, regulatory frameworks are adapting to address new challenges and opportunities. This includes developing standards for emerging technologies, addressing potential environmental and health impacts, and harmonizing regulations across different regions to facilitate global trade in renewable chemicals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!