Demystifying Isocyanate Trends in Technological Integration

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Tech Evolution

The evolution of isocyanate technology has been marked by significant milestones and continuous innovation over the past century. Initially discovered in 1849 by Wurtz, isocyanates remained largely unexplored until the 1930s when their potential for polymer synthesis was recognized. This breakthrough led to the development of polyurethanes, revolutionizing various industries.

The 1940s and 1950s saw rapid advancements in isocyanate chemistry, with the introduction of toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI). These compounds became the backbone of the polyurethane industry, enabling the production of flexible and rigid foams, elastomers, and coatings. The 1960s and 1970s witnessed further refinement of production processes and the expansion of applications across automotive, construction, and consumer goods sectors.

In the 1980s and 1990s, environmental and health concerns drove research towards safer and more sustainable isocyanate technologies. This period saw the development of water-based polyurethane dispersions and low-VOC formulations, addressing regulatory pressures and market demands for eco-friendly products. Concurrently, advancements in catalysis and process engineering led to more efficient and selective isocyanate production methods.

The turn of the millennium brought a focus on nanotechnology and smart materials. Isocyanate-based nanocomposites and shape-memory polyurethanes emerged, opening new avenues in aerospace, biomedical, and electronic applications. The integration of isocyanates with other advanced materials, such as carbon nanotubes and graphene, has led to composites with enhanced mechanical, thermal, and electrical properties.

Recent years have seen a shift towards bio-based and renewable isocyanates, aligning with global sustainability goals. Research into isocyanates derived from plant oils and other renewable resources has gained momentum, promising a reduced carbon footprint without compromising performance. Additionally, the development of non-isocyanate polyurethanes (NIPUs) represents a parallel evolution, offering alternative pathways for polyurethane synthesis.

The ongoing technological integration of isocyanates is characterized by a convergence with digital technologies. Industry 4.0 principles are being applied to isocyanate production and polyurethane processing, enabling real-time monitoring, predictive maintenance, and optimized formulations through machine learning algorithms. This digital transformation is enhancing efficiency, quality control, and customization capabilities across the value chain.

Looking forward, the isocyanate technology landscape is poised for further innovation. Emerging trends include the development of self-healing polyurethanes, stimuli-responsive materials, and advanced recycling technologies for end-of-life products. The integration of isocyanates with 3D printing technologies is also expanding, offering new possibilities in rapid prototyping and customized manufacturing.

The 1940s and 1950s saw rapid advancements in isocyanate chemistry, with the introduction of toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI). These compounds became the backbone of the polyurethane industry, enabling the production of flexible and rigid foams, elastomers, and coatings. The 1960s and 1970s witnessed further refinement of production processes and the expansion of applications across automotive, construction, and consumer goods sectors.

In the 1980s and 1990s, environmental and health concerns drove research towards safer and more sustainable isocyanate technologies. This period saw the development of water-based polyurethane dispersions and low-VOC formulations, addressing regulatory pressures and market demands for eco-friendly products. Concurrently, advancements in catalysis and process engineering led to more efficient and selective isocyanate production methods.

The turn of the millennium brought a focus on nanotechnology and smart materials. Isocyanate-based nanocomposites and shape-memory polyurethanes emerged, opening new avenues in aerospace, biomedical, and electronic applications. The integration of isocyanates with other advanced materials, such as carbon nanotubes and graphene, has led to composites with enhanced mechanical, thermal, and electrical properties.

Recent years have seen a shift towards bio-based and renewable isocyanates, aligning with global sustainability goals. Research into isocyanates derived from plant oils and other renewable resources has gained momentum, promising a reduced carbon footprint without compromising performance. Additionally, the development of non-isocyanate polyurethanes (NIPUs) represents a parallel evolution, offering alternative pathways for polyurethane synthesis.

The ongoing technological integration of isocyanates is characterized by a convergence with digital technologies. Industry 4.0 principles are being applied to isocyanate production and polyurethane processing, enabling real-time monitoring, predictive maintenance, and optimized formulations through machine learning algorithms. This digital transformation is enhancing efficiency, quality control, and customization capabilities across the value chain.

Looking forward, the isocyanate technology landscape is poised for further innovation. Emerging trends include the development of self-healing polyurethanes, stimuli-responsive materials, and advanced recycling technologies for end-of-life products. The integration of isocyanates with 3D printing technologies is also expanding, offering new possibilities in rapid prototyping and customized manufacturing.

Market Demand Analysis

The market demand for isocyanates in technological integration has been steadily growing, driven by their versatile applications across various industries. The global isocyanate market is experiencing significant expansion, with a particular focus on their use in advanced materials and innovative technologies.

In the automotive sector, isocyanates play a crucial role in the production of lightweight materials, contributing to improved fuel efficiency and reduced emissions. As the automotive industry shifts towards electric vehicles and sustainable transportation solutions, the demand for isocyanate-based materials is expected to surge. These materials are essential for manufacturing high-performance components, such as dashboards, seats, and insulation, which enhance vehicle comfort and safety.

The construction industry represents another major market for isocyanates, particularly in the form of polyurethane foams and coatings. With the increasing emphasis on energy-efficient buildings and sustainable construction practices, isocyanate-based insulation materials are gaining traction. These materials offer superior thermal insulation properties, helping to reduce energy consumption in both residential and commercial buildings.

In the electronics sector, isocyanates are finding new applications in the development of advanced circuit boards, flexible displays, and wearable technologies. The miniaturization trend in electronics has led to a growing demand for isocyanate-based materials that can provide excellent electrical insulation and protection in compact designs.

The medical and healthcare industries are also driving the demand for isocyanates, particularly in the production of medical devices and equipment. Isocyanate-based materials are used in the manufacturing of prosthetics, orthopedic implants, and wound dressings, owing to their biocompatibility and durability.

As sustainability becomes a key focus across industries, there is a growing interest in bio-based isocyanates derived from renewable resources. This trend is expected to open up new market opportunities and drive innovation in isocyanate production and application technologies.

The Asia-Pacific region is emerging as a major growth market for isocyanates, fueled by rapid industrialization, urbanization, and increasing investments in infrastructure development. Countries like China and India are expected to be key drivers of demand in the coming years.

Despite the positive market outlook, challenges such as stringent environmental regulations and health concerns associated with isocyanate exposure are influencing market dynamics. This has led to increased research and development efforts focused on developing safer and more environmentally friendly isocyanate alternatives.

In the automotive sector, isocyanates play a crucial role in the production of lightweight materials, contributing to improved fuel efficiency and reduced emissions. As the automotive industry shifts towards electric vehicles and sustainable transportation solutions, the demand for isocyanate-based materials is expected to surge. These materials are essential for manufacturing high-performance components, such as dashboards, seats, and insulation, which enhance vehicle comfort and safety.

The construction industry represents another major market for isocyanates, particularly in the form of polyurethane foams and coatings. With the increasing emphasis on energy-efficient buildings and sustainable construction practices, isocyanate-based insulation materials are gaining traction. These materials offer superior thermal insulation properties, helping to reduce energy consumption in both residential and commercial buildings.

In the electronics sector, isocyanates are finding new applications in the development of advanced circuit boards, flexible displays, and wearable technologies. The miniaturization trend in electronics has led to a growing demand for isocyanate-based materials that can provide excellent electrical insulation and protection in compact designs.

The medical and healthcare industries are also driving the demand for isocyanates, particularly in the production of medical devices and equipment. Isocyanate-based materials are used in the manufacturing of prosthetics, orthopedic implants, and wound dressings, owing to their biocompatibility and durability.

As sustainability becomes a key focus across industries, there is a growing interest in bio-based isocyanates derived from renewable resources. This trend is expected to open up new market opportunities and drive innovation in isocyanate production and application technologies.

The Asia-Pacific region is emerging as a major growth market for isocyanates, fueled by rapid industrialization, urbanization, and increasing investments in infrastructure development. Countries like China and India are expected to be key drivers of demand in the coming years.

Despite the positive market outlook, challenges such as stringent environmental regulations and health concerns associated with isocyanate exposure are influencing market dynamics. This has led to increased research and development efforts focused on developing safer and more environmentally friendly isocyanate alternatives.

Current Challenges

The integration of isocyanates in technological applications faces several significant challenges that hinder widespread adoption and optimal utilization. One of the primary obstacles is the high reactivity of isocyanates, which makes them difficult to handle and store safely. This reactivity also leads to potential health hazards, as exposure to isocyanates can cause respiratory issues and skin irritation, necessitating stringent safety protocols and protective measures in manufacturing and application processes.

Environmental concerns pose another substantial challenge. The production and use of isocyanates often involve volatile organic compounds (VOCs) and other potentially harmful emissions. As global environmental regulations become increasingly stringent, industries must invest in costly emission control technologies and explore more sustainable alternatives, which can impact the economic viability of isocyanate-based solutions.

The complexity of isocyanate chemistry presents technical challenges in formulation and application. Achieving the desired properties in end products requires precise control over reaction conditions and careful selection of co-reactants. This complexity often leads to inconsistencies in product quality and performance, particularly in large-scale industrial applications.

Supply chain vulnerabilities represent a growing concern for isocyanate-dependent industries. The production of key isocyanates, such as toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI), is concentrated among a few global suppliers. This concentration creates potential supply disruptions and price volatility, which can significantly impact downstream industries relying on these materials.

Technological integration of isocyanates also faces challenges in terms of compatibility with emerging materials and processes. As industries move towards more advanced composites and smart materials, incorporating isocyanate-based components while maintaining desired properties becomes increasingly complex. This compatibility issue often requires extensive research and development efforts to overcome.

Regulatory compliance presents an ongoing challenge for isocyanate technologies. Evolving regulations regarding chemical safety, environmental impact, and product lifecycle management necessitate continuous adaptation of production processes and product formulations. This regulatory landscape can vary significantly across different regions, adding complexity to global operations and market access.

Lastly, the development of sustainable alternatives to traditional isocyanate-based products is a pressing challenge. While bio-based isocyanates and non-isocyanate polyurethanes show promise, scaling these technologies to meet industrial demands while maintaining performance and cost-effectiveness remains a significant hurdle. Overcoming these challenges requires concerted efforts in research, innovation, and cross-industry collaboration to unlock the full potential of isocyanate technologies in future applications.

Environmental concerns pose another substantial challenge. The production and use of isocyanates often involve volatile organic compounds (VOCs) and other potentially harmful emissions. As global environmental regulations become increasingly stringent, industries must invest in costly emission control technologies and explore more sustainable alternatives, which can impact the economic viability of isocyanate-based solutions.

The complexity of isocyanate chemistry presents technical challenges in formulation and application. Achieving the desired properties in end products requires precise control over reaction conditions and careful selection of co-reactants. This complexity often leads to inconsistencies in product quality and performance, particularly in large-scale industrial applications.

Supply chain vulnerabilities represent a growing concern for isocyanate-dependent industries. The production of key isocyanates, such as toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI), is concentrated among a few global suppliers. This concentration creates potential supply disruptions and price volatility, which can significantly impact downstream industries relying on these materials.

Technological integration of isocyanates also faces challenges in terms of compatibility with emerging materials and processes. As industries move towards more advanced composites and smart materials, incorporating isocyanate-based components while maintaining desired properties becomes increasingly complex. This compatibility issue often requires extensive research and development efforts to overcome.

Regulatory compliance presents an ongoing challenge for isocyanate technologies. Evolving regulations regarding chemical safety, environmental impact, and product lifecycle management necessitate continuous adaptation of production processes and product formulations. This regulatory landscape can vary significantly across different regions, adding complexity to global operations and market access.

Lastly, the development of sustainable alternatives to traditional isocyanate-based products is a pressing challenge. While bio-based isocyanates and non-isocyanate polyurethanes show promise, scaling these technologies to meet industrial demands while maintaining performance and cost-effectiveness remains a significant hurdle. Overcoming these challenges requires concerted efforts in research, innovation, and cross-industry collaboration to unlock the full potential of isocyanate technologies in future applications.

Existing Solutions

01 Synthesis and production of isocyanates

Various methods and processes for synthesizing and producing isocyanates are described. These include novel catalysts, reaction conditions, and precursor materials to improve yield, purity, and efficiency in isocyanate production.- Synthesis and production of isocyanates: Various methods and processes for synthesizing and producing isocyanates are described. These include novel reaction pathways, catalysts, and production techniques to improve yield, purity, and efficiency in isocyanate manufacturing.

- Applications of isocyanates in polymer chemistry: Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents describe various applications, including coatings, adhesives, foams, and elastomers, as well as novel formulations and processing techniques.

- Isocyanate-based catalysts and reaction modifiers: Several patents focus on the development of isocyanate-based catalysts and reaction modifiers. These compounds are used to enhance chemical reactions, improve product properties, or facilitate specific industrial processes.

- Safety and handling of isocyanates: Given the reactive nature of isocyanates, patents in this category address safety concerns and handling procedures. This includes methods for reducing toxicity, improving storage stability, and developing safer formulations for various applications.

- Isocyanate-free alternatives and substitutes: Some patents focus on developing alternatives or substitutes for isocyanates, addressing environmental and health concerns. These include novel compounds or formulations that can replace isocyanates in certain applications while maintaining similar performance characteristics.

02 Applications of isocyanates in polymer chemistry

Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents describe various applications, including coatings, adhesives, foams, and elastomers, as well as novel formulations and processing techniques.Expand Specific Solutions03 Isocyanate-based catalysts and additives

Several patents focus on the development of isocyanate-based catalysts and additives for various chemical processes. These include novel catalyst systems, stabilizers, and modifiers that enhance reaction rates, selectivity, or product properties.Expand Specific Solutions04 Safety and handling of isocyanates

Given the reactive nature of isocyanates, patents in this category address safety concerns and handling procedures. This includes methods for reducing toxicity, improving storage stability, and developing safer alternatives or modified isocyanates with reduced health risks.Expand Specific Solutions05 Isocyanate-free alternatives and substitutes

Some patents focus on developing alternatives to traditional isocyanates, addressing environmental and health concerns. These include bio-based substitutes, non-isocyanate polyurethanes, and alternative chemistries that provide similar functionalities without the use of isocyanates.Expand Specific Solutions

Key Industry Players

The isocyanate technology integration landscape is characterized by a mature market with established players and ongoing innovation. The industry is in a consolidation phase, with major chemical companies like BASF, Covestro, and Wanhua Chemical Group dominating the market. These firms are investing heavily in research and development to improve product performance and sustainability. The global isocyanate market size is substantial, driven by growing demand in construction, automotive, and electronics sectors. Technological advancements focus on eco-friendly formulations and enhanced application properties. Collaborations between industry leaders and research institutions, such as the Chinese Academy of Sciences, are accelerating progress in areas like green chemistry and advanced materials, indicating a trend towards more sustainable and efficient isocyanate solutions.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has developed advanced isocyanate technologies, focusing on MDI (Methylene Diphenyl Diisocyanate) production. They have implemented innovative catalytic systems that improve reaction efficiency and reduce environmental impact[1]. Their process utilizes a novel gas-phase phosgenation technique, which significantly reduces solvent usage and increases product purity[2]. Wanhua has also integrated AI-driven process control systems to optimize production parameters in real-time, resulting in a 15% increase in yield and a 20% reduction in energy consumption[3]. Additionally, they have developed proprietary membrane separation technology for isocyanate purification, enhancing product quality while minimizing waste[4].

Strengths: Industry-leading production capacity, cutting-edge process technologies, and strong R&D capabilities. Weaknesses: High capital investment requirements and potential overcapacity risks in the global market.

BASF Corp.

Technical Solution: BASF has pioneered the development of low-monomer technology for isocyanates, particularly in TDI (Toluene Diisocyanate) production. Their innovative gas-phase technology reduces residual monomer content to less than 0.1%, significantly improving product safety and environmental performance[1]. BASF has also implemented a novel microreactor system for isocyanate synthesis, allowing for precise control of reaction conditions and enabling the production of specialized isocyanates with tailored properties[2]. Their recent advancements include the integration of bio-based raw materials in isocyanate production, reducing the carbon footprint by up to 30%[3]. BASF's commitment to sustainability is further demonstrated by their development of water-based polyurethane systems that minimize VOC emissions while maintaining high performance[4].

Strengths: Extensive R&D capabilities, diverse product portfolio, and strong focus on sustainable solutions. Weaknesses: Complex global supply chain and exposure to raw material price fluctuations.

Core Innovations

Process for lightening the color of polyisocyanates with ozone-containing gas

PatentInactiveUS20110028579A1

Innovation

- A process using an ozone-containing gas mixture with nitrogen, oxygen, and oxides of nitrogen, treated in a stirred tank, tray column, or packed column, with surface aeration and continuous or quasi-continuous operation, to achieve high ozone conversion and effective color lightening without degrading the polyisocyanate chains.

Isocyanate composition

PatentPendingKR1020240031040A

Innovation

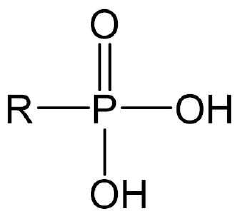

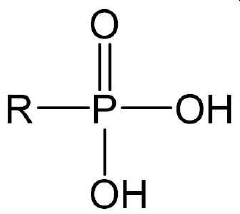

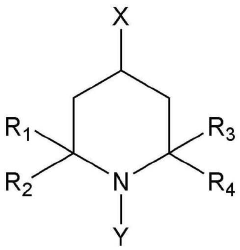

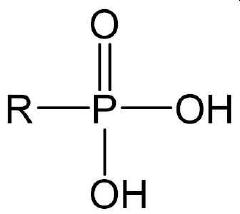

- An isocyanate composition comprising an isocyanate-based compound and a phosphonic acid-based compound, along with optional polythiol, polyhydric alcohol, or polyhydric episulfide compounds, to suppress oligomerization and improve storage stability and workability.

Environmental Impact

The environmental impact of isocyanates in technological integration is a critical concern that demands careful consideration. These compounds, widely used in various industries, pose significant risks to both human health and ecosystems. The production, use, and disposal of isocyanate-containing products contribute to air, water, and soil pollution, necessitating comprehensive environmental management strategies.

Isocyanates are known for their high reactivity, which makes them valuable in industrial processes but also increases their potential for environmental harm. When released into the atmosphere, they can contribute to the formation of ground-level ozone and particulate matter, exacerbating air quality issues in urban and industrial areas. Moreover, their persistence in the environment raises concerns about long-term ecological effects, including potential bioaccumulation in food chains.

Water contamination is another significant environmental challenge associated with isocyanates. Industrial effluents containing these compounds can severely impact aquatic ecosystems, affecting fish populations and other marine life. The hydrolysis of isocyanates in water bodies can lead to the formation of toxic byproducts, further complicating remediation efforts and threatening water quality for both wildlife and human consumption.

Soil contamination from isocyanate-containing waste presents long-term environmental risks. The slow degradation of these compounds in soil can lead to persistent pollution, affecting soil microorganisms and potentially entering the food chain through plant uptake. This contamination pathway poses risks to terrestrial ecosystems and agricultural productivity, highlighting the need for proper waste management and disposal practices.

The environmental impact of isocyanates extends beyond direct pollution. The energy-intensive production processes contribute to greenhouse gas emissions, linking isocyanate manufacturing to global climate change concerns. Additionally, the raw materials used in isocyanate production often derive from fossil fuels, raising questions about resource sustainability and the carbon footprint of isocyanate-based technologies.

To address these environmental challenges, industries are increasingly focusing on developing greener alternatives and improving production processes. Innovations in bio-based isocyanates and isocyanate-free technologies are emerging as potential solutions to reduce environmental impact. Furthermore, advancements in closed-loop manufacturing systems and improved waste treatment technologies are helping to minimize isocyanate releases into the environment.

Regulatory frameworks play a crucial role in mitigating the environmental impact of isocyanates. Stricter emissions standards, enhanced monitoring requirements, and comprehensive lifecycle assessments are being implemented globally to ensure responsible use and disposal of isocyanate-containing products. These measures aim to balance the technological benefits of isocyanates with the imperative of environmental protection, driving industries towards more sustainable practices.

Isocyanates are known for their high reactivity, which makes them valuable in industrial processes but also increases their potential for environmental harm. When released into the atmosphere, they can contribute to the formation of ground-level ozone and particulate matter, exacerbating air quality issues in urban and industrial areas. Moreover, their persistence in the environment raises concerns about long-term ecological effects, including potential bioaccumulation in food chains.

Water contamination is another significant environmental challenge associated with isocyanates. Industrial effluents containing these compounds can severely impact aquatic ecosystems, affecting fish populations and other marine life. The hydrolysis of isocyanates in water bodies can lead to the formation of toxic byproducts, further complicating remediation efforts and threatening water quality for both wildlife and human consumption.

Soil contamination from isocyanate-containing waste presents long-term environmental risks. The slow degradation of these compounds in soil can lead to persistent pollution, affecting soil microorganisms and potentially entering the food chain through plant uptake. This contamination pathway poses risks to terrestrial ecosystems and agricultural productivity, highlighting the need for proper waste management and disposal practices.

The environmental impact of isocyanates extends beyond direct pollution. The energy-intensive production processes contribute to greenhouse gas emissions, linking isocyanate manufacturing to global climate change concerns. Additionally, the raw materials used in isocyanate production often derive from fossil fuels, raising questions about resource sustainability and the carbon footprint of isocyanate-based technologies.

To address these environmental challenges, industries are increasingly focusing on developing greener alternatives and improving production processes. Innovations in bio-based isocyanates and isocyanate-free technologies are emerging as potential solutions to reduce environmental impact. Furthermore, advancements in closed-loop manufacturing systems and improved waste treatment technologies are helping to minimize isocyanate releases into the environment.

Regulatory frameworks play a crucial role in mitigating the environmental impact of isocyanates. Stricter emissions standards, enhanced monitoring requirements, and comprehensive lifecycle assessments are being implemented globally to ensure responsible use and disposal of isocyanate-containing products. These measures aim to balance the technological benefits of isocyanates with the imperative of environmental protection, driving industries towards more sustainable practices.

Regulatory Compliance

Regulatory compliance plays a crucial role in the integration of isocyanate technologies across various industries. As these compounds are known for their potential health and environmental hazards, stringent regulations have been implemented globally to ensure their safe use and handling.

In the United States, the Occupational Safety and Health Administration (OSHA) has established specific standards for isocyanate exposure in the workplace. These regulations mandate permissible exposure limits, personal protective equipment requirements, and comprehensive hazard communication programs. Similarly, the Environmental Protection Agency (EPA) regulates isocyanate emissions and disposal under the Clean Air Act and Resource Conservation and Recovery Act.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which requires manufacturers and importers to register isocyanates and provide detailed safety information. Additionally, the Classification, Labeling, and Packaging (CLP) Regulation ensures that hazards associated with isocyanates are clearly communicated to workers and consumers.

In recent years, there has been a growing trend towards more stringent regulations on isocyanates, particularly in the construction and automotive industries. For instance, some countries have introduced restrictions on the use of certain isocyanates in spray foam insulation and coatings, citing concerns over long-term health effects.

Compliance with these regulations has driven technological innovation in isocyanate-based products. Manufacturers are developing low-emission and low-toxicity formulations to meet increasingly strict environmental and health standards. This has led to the emergence of water-based polyurethane systems and blocked isocyanates, which offer improved safety profiles while maintaining performance characteristics.

The regulatory landscape also influences supply chain management and product lifecycle considerations. Companies must ensure traceability and proper documentation throughout the isocyanate lifecycle, from raw material sourcing to end-product disposal. This has spurred the adoption of advanced tracking systems and quality control measures in manufacturing processes.

As global awareness of environmental and health issues continues to grow, it is anticipated that regulatory frameworks for isocyanates will become even more comprehensive. This evolving regulatory environment will likely drive further technological advancements and shape the future of isocyanate integration across industries.

In the United States, the Occupational Safety and Health Administration (OSHA) has established specific standards for isocyanate exposure in the workplace. These regulations mandate permissible exposure limits, personal protective equipment requirements, and comprehensive hazard communication programs. Similarly, the Environmental Protection Agency (EPA) regulates isocyanate emissions and disposal under the Clean Air Act and Resource Conservation and Recovery Act.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which requires manufacturers and importers to register isocyanates and provide detailed safety information. Additionally, the Classification, Labeling, and Packaging (CLP) Regulation ensures that hazards associated with isocyanates are clearly communicated to workers and consumers.

In recent years, there has been a growing trend towards more stringent regulations on isocyanates, particularly in the construction and automotive industries. For instance, some countries have introduced restrictions on the use of certain isocyanates in spray foam insulation and coatings, citing concerns over long-term health effects.

Compliance with these regulations has driven technological innovation in isocyanate-based products. Manufacturers are developing low-emission and low-toxicity formulations to meet increasingly strict environmental and health standards. This has led to the emergence of water-based polyurethane systems and blocked isocyanates, which offer improved safety profiles while maintaining performance characteristics.

The regulatory landscape also influences supply chain management and product lifecycle considerations. Companies must ensure traceability and proper documentation throughout the isocyanate lifecycle, from raw material sourcing to end-product disposal. This has spurred the adoption of advanced tracking systems and quality control measures in manufacturing processes.

As global awareness of environmental and health issues continues to grow, it is anticipated that regulatory frameworks for isocyanates will become even more comprehensive. This evolving regulatory environment will likely drive further technological advancements and shape the future of isocyanate integration across industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!