Methods of Reducing Borosilicate Glass Lead Times

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Borosilicate Glass Manufacturing Background and Objectives

Borosilicate glass has been a cornerstone material in various industries for over a century, prized for its exceptional thermal and chemical resistance properties. The manufacturing process of this specialized glass has evolved significantly since its inception in the late 19th century. Initially developed by Otto Schott in 1893, borosilicate glass quickly gained prominence in laboratory glassware and industrial applications due to its low coefficient of thermal expansion and high durability.

The primary objective in borosilicate glass manufacturing has consistently been to produce high-quality, reliable glass products that meet stringent industry standards. However, as demand has grown across sectors such as pharmaceuticals, electronics, and solar energy, manufacturers have faced increasing pressure to optimize production processes and reduce lead times without compromising quality.

Traditionally, borosilicate glass manufacturing has been characterized by long production cycles, often spanning several weeks from raw material preparation to final product delivery. This extended lead time has been attributed to various factors, including the complex melting and forming processes, annealing requirements, and rigorous quality control measures. As industries relying on borosilicate glass components have accelerated their own production timelines, there has been a growing need to address these lengthy manufacturing cycles.

Recent technological advancements have opened new avenues for improving efficiency in borosilicate glass production. Innovations in furnace design, process automation, and material science have contributed to incremental reductions in manufacturing times. However, significant challenges remain in substantially cutting lead times while maintaining the glass's superior properties and meeting increasingly stringent quality standards.

The current landscape of borosilicate glass manufacturing is marked by a delicate balance between traditional craftsmanship and modern industrial processes. Manufacturers are exploring various strategies to streamline production, including optimizing batch formulations, implementing advanced process control systems, and adopting lean manufacturing principles. The ultimate goal is to develop methods that can significantly reduce lead times without sacrificing the unique properties that make borosilicate glass indispensable in many critical applications.

As we delve deeper into the methods of reducing borosilicate glass lead times, it is essential to consider the historical context, current manufacturing challenges, and the evolving needs of industries reliant on this versatile material. The path forward requires a comprehensive approach that addresses each stage of the production process, from raw material selection to final product delivery, while keeping sight of the fundamental qualities that have made borosilicate glass a staple in scientific and industrial applications for generations.

The primary objective in borosilicate glass manufacturing has consistently been to produce high-quality, reliable glass products that meet stringent industry standards. However, as demand has grown across sectors such as pharmaceuticals, electronics, and solar energy, manufacturers have faced increasing pressure to optimize production processes and reduce lead times without compromising quality.

Traditionally, borosilicate glass manufacturing has been characterized by long production cycles, often spanning several weeks from raw material preparation to final product delivery. This extended lead time has been attributed to various factors, including the complex melting and forming processes, annealing requirements, and rigorous quality control measures. As industries relying on borosilicate glass components have accelerated their own production timelines, there has been a growing need to address these lengthy manufacturing cycles.

Recent technological advancements have opened new avenues for improving efficiency in borosilicate glass production. Innovations in furnace design, process automation, and material science have contributed to incremental reductions in manufacturing times. However, significant challenges remain in substantially cutting lead times while maintaining the glass's superior properties and meeting increasingly stringent quality standards.

The current landscape of borosilicate glass manufacturing is marked by a delicate balance between traditional craftsmanship and modern industrial processes. Manufacturers are exploring various strategies to streamline production, including optimizing batch formulations, implementing advanced process control systems, and adopting lean manufacturing principles. The ultimate goal is to develop methods that can significantly reduce lead times without sacrificing the unique properties that make borosilicate glass indispensable in many critical applications.

As we delve deeper into the methods of reducing borosilicate glass lead times, it is essential to consider the historical context, current manufacturing challenges, and the evolving needs of industries reliant on this versatile material. The path forward requires a comprehensive approach that addresses each stage of the production process, from raw material selection to final product delivery, while keeping sight of the fundamental qualities that have made borosilicate glass a staple in scientific and industrial applications for generations.

Market Demand Analysis for Borosilicate Glass Products

The market demand for borosilicate glass products has been experiencing steady growth, driven by various factors across multiple industries. In the pharmaceutical sector, the increasing production of vaccines, biologics, and other temperature-sensitive drugs has led to a surge in demand for borosilicate glass vials and containers. These products are essential for maintaining the integrity and efficacy of sensitive medications during storage and transportation.

The laboratory and scientific research industry continues to be a significant consumer of borosilicate glass products. The material's excellent chemical resistance, thermal stability, and optical clarity make it ideal for a wide range of laboratory equipment, including beakers, flasks, and test tubes. As research and development activities expand globally, particularly in emerging economies, the demand for high-quality laboratory glassware is expected to rise.

In the food and beverage industry, there is a growing trend towards sustainable and reusable packaging solutions. Borosilicate glass, known for its durability and resistance to thermal shock, has gained popularity for use in food storage containers, bakeware, and beverage bottles. Consumers are increasingly seeking alternatives to plastic, driving the demand for glass products that can withstand repeated use and high temperatures.

The electronics and semiconductor industry also contributes to the market demand for borosilicate glass. Its low coefficient of thermal expansion and excellent electrical insulation properties make it suitable for various applications, including LCD screens, optical lenses, and semiconductor wafer carriers. As the electronics industry continues to innovate and expand, the demand for specialized borosilicate glass components is likely to increase.

The renewable energy sector, particularly solar energy, has emerged as a significant driver of borosilicate glass demand. Solar thermal collectors and concentrated solar power systems often utilize borosilicate glass tubes due to their high heat resistance and light transmission properties. With the global push towards clean energy solutions, this sector is expected to contribute substantially to market growth.

However, the market demand for borosilicate glass products is not without challenges. The ongoing global supply chain disruptions and raw material shortages have impacted production capacities and lead times. This has led to increased interest in methods to reduce borosilicate glass lead times, as manufacturers seek to meet growing demand while maintaining product quality and consistency.

In conclusion, the market demand for borosilicate glass products spans across various industries, each with its unique requirements and growth trajectories. The pharmaceutical, laboratory, food and beverage, electronics, and renewable energy sectors are key drivers of this demand. As industries continue to innovate and prioritize sustainability, the versatility and superior properties of borosilicate glass position it as a material of choice for numerous applications, underscoring the importance of addressing lead time reduction to meet market needs effectively.

The laboratory and scientific research industry continues to be a significant consumer of borosilicate glass products. The material's excellent chemical resistance, thermal stability, and optical clarity make it ideal for a wide range of laboratory equipment, including beakers, flasks, and test tubes. As research and development activities expand globally, particularly in emerging economies, the demand for high-quality laboratory glassware is expected to rise.

In the food and beverage industry, there is a growing trend towards sustainable and reusable packaging solutions. Borosilicate glass, known for its durability and resistance to thermal shock, has gained popularity for use in food storage containers, bakeware, and beverage bottles. Consumers are increasingly seeking alternatives to plastic, driving the demand for glass products that can withstand repeated use and high temperatures.

The electronics and semiconductor industry also contributes to the market demand for borosilicate glass. Its low coefficient of thermal expansion and excellent electrical insulation properties make it suitable for various applications, including LCD screens, optical lenses, and semiconductor wafer carriers. As the electronics industry continues to innovate and expand, the demand for specialized borosilicate glass components is likely to increase.

The renewable energy sector, particularly solar energy, has emerged as a significant driver of borosilicate glass demand. Solar thermal collectors and concentrated solar power systems often utilize borosilicate glass tubes due to their high heat resistance and light transmission properties. With the global push towards clean energy solutions, this sector is expected to contribute substantially to market growth.

However, the market demand for borosilicate glass products is not without challenges. The ongoing global supply chain disruptions and raw material shortages have impacted production capacities and lead times. This has led to increased interest in methods to reduce borosilicate glass lead times, as manufacturers seek to meet growing demand while maintaining product quality and consistency.

In conclusion, the market demand for borosilicate glass products spans across various industries, each with its unique requirements and growth trajectories. The pharmaceutical, laboratory, food and beverage, electronics, and renewable energy sectors are key drivers of this demand. As industries continue to innovate and prioritize sustainability, the versatility and superior properties of borosilicate glass position it as a material of choice for numerous applications, underscoring the importance of addressing lead time reduction to meet market needs effectively.

Current Challenges in Borosilicate Glass Production

The production of borosilicate glass faces several significant challenges that impact lead times and overall efficiency. One of the primary issues is the complexity of the manufacturing process, which requires precise control of temperature, composition, and forming techniques. The high melting point of borosilicate glass, typically around 1,600°C, necessitates specialized equipment and energy-intensive operations, leading to longer production cycles and increased costs.

Raw material sourcing and quality control present another major challenge. Borosilicate glass requires high-purity silica, boron oxide, and other additives. Fluctuations in raw material availability or quality can cause production delays and inconsistencies in the final product. Additionally, the stringent quality standards for borosilicate glass, particularly for scientific and industrial applications, demand extensive testing and quality assurance processes, further extending lead times.

The forming and shaping of borosilicate glass products pose unique difficulties due to the material's low thermal expansion coefficient. This property, while beneficial for the end-user, makes the glass more susceptible to thermal shock during production. Consequently, cooling and annealing processes must be carefully controlled, often resulting in longer production times compared to conventional glass types.

Another significant challenge lies in the specialized workforce required for borosilicate glass production. The industry faces a shortage of skilled technicians and engineers with expertise in this specific type of glass manufacturing. Training new personnel is time-consuming and can temporarily reduce production efficiency, contributing to extended lead times.

Equipment maintenance and upgrades also present ongoing challenges. The high-temperature environment and corrosive nature of molten glass lead to accelerated wear on furnaces, molds, and other production equipment. Regular maintenance and occasional replacements are necessary, potentially causing production interruptions and delays.

Lastly, the increasing demand for customized borosilicate glass products in various industries, such as pharmaceuticals, electronics, and laboratory equipment, adds complexity to production scheduling. Manufacturers must balance the need for flexibility in product specifications with the desire for efficient, large-scale production runs. This balancing act often results in longer lead times for specialized or small-batch orders.

Addressing these challenges requires a multifaceted approach, including technological innovations, process optimizations, and strategic investments in equipment and workforce development. By tackling these issues, manufacturers can work towards reducing lead times and improving the overall efficiency of borosilicate glass production.

Raw material sourcing and quality control present another major challenge. Borosilicate glass requires high-purity silica, boron oxide, and other additives. Fluctuations in raw material availability or quality can cause production delays and inconsistencies in the final product. Additionally, the stringent quality standards for borosilicate glass, particularly for scientific and industrial applications, demand extensive testing and quality assurance processes, further extending lead times.

The forming and shaping of borosilicate glass products pose unique difficulties due to the material's low thermal expansion coefficient. This property, while beneficial for the end-user, makes the glass more susceptible to thermal shock during production. Consequently, cooling and annealing processes must be carefully controlled, often resulting in longer production times compared to conventional glass types.

Another significant challenge lies in the specialized workforce required for borosilicate glass production. The industry faces a shortage of skilled technicians and engineers with expertise in this specific type of glass manufacturing. Training new personnel is time-consuming and can temporarily reduce production efficiency, contributing to extended lead times.

Equipment maintenance and upgrades also present ongoing challenges. The high-temperature environment and corrosive nature of molten glass lead to accelerated wear on furnaces, molds, and other production equipment. Regular maintenance and occasional replacements are necessary, potentially causing production interruptions and delays.

Lastly, the increasing demand for customized borosilicate glass products in various industries, such as pharmaceuticals, electronics, and laboratory equipment, adds complexity to production scheduling. Manufacturers must balance the need for flexibility in product specifications with the desire for efficient, large-scale production runs. This balancing act often results in longer lead times for specialized or small-batch orders.

Addressing these challenges requires a multifaceted approach, including technological innovations, process optimizations, and strategic investments in equipment and workforce development. By tackling these issues, manufacturers can work towards reducing lead times and improving the overall efficiency of borosilicate glass production.

Existing Solutions for Reducing Lead Times

01 Manufacturing processes affecting lead times

The lead times for borosilicate glass production can be influenced by various manufacturing processes. These may include melting, forming, annealing, and finishing steps. Optimizing these processes can help reduce lead times and improve production efficiency.- Manufacturing process optimization: Optimizing the manufacturing process of borosilicate glass can significantly reduce lead times. This includes improving melting techniques, refining the forming process, and enhancing annealing procedures. Advanced automation and process control systems can also contribute to faster production cycles.

- Raw material selection and preparation: Careful selection and preparation of raw materials can impact lead times for borosilicate glass production. Using high-quality, pre-processed materials and optimizing the batch composition can reduce melting time and improve overall efficiency in the manufacturing process.

- Advanced forming techniques: Implementing advanced forming techniques, such as precision molding or advanced drawing processes, can reduce the time required for shaping borosilicate glass products. These methods can improve dimensional accuracy and reduce the need for secondary processing, thereby shortening lead times.

- Heat treatment and annealing optimization: Optimizing heat treatment and annealing processes can significantly reduce lead times in borosilicate glass production. Advanced temperature control systems and innovative cooling techniques can minimize internal stresses and reduce the time required for stress relief, resulting in faster production cycles.

- Quality control and inspection methods: Implementing advanced quality control and inspection methods throughout the production process can help identify and address issues early, reducing rework and minimizing delays. Non-destructive testing techniques and in-line monitoring systems can contribute to faster production and shorter lead times for borosilicate glass products.

02 Composition and raw material availability

The specific composition of borosilicate glass and the availability of raw materials can impact lead times. Factors such as the sourcing of high-quality silica, boron compounds, and other additives may affect production schedules and delivery timelines.Expand Specific Solutions03 Quality control and testing procedures

Rigorous quality control and testing procedures are essential for borosilicate glass production. These processes, while necessary for ensuring product quality, can contribute to longer lead times. Implementing efficient testing methods and automated inspection systems may help reduce overall production time.Expand Specific Solutions04 Specialized equipment and technology

The use of specialized equipment and advanced technology in borosilicate glass production can affect lead times. Factors such as equipment maintenance, upgrades, and the implementation of new manufacturing technologies may impact production schedules and delivery times.Expand Specific Solutions05 Supply chain and logistics considerations

Supply chain management and logistics play a crucial role in determining lead times for borosilicate glass products. Factors such as transportation, inventory management, and global market demands can influence the overall time required from production to delivery.Expand Specific Solutions

Key Players in Borosilicate Glass Industry

The market for reducing borosilicate glass lead times is in a growth phase, driven by increasing demand across industries like pharmaceuticals, electronics, and solar energy. The global borosilicate glass market size is projected to reach $5.7 billion by 2027, growing at a CAGR of 5.2%. Technologically, the field is moderately mature but evolving, with companies like SCHOTT AG, Corning, and Nippon Electric Glass leading innovations in manufacturing processes and material formulations. These industry leaders are investing in advanced production techniques and automation to improve efficiency and reduce lead times. Emerging players like Hunan Kibing and Qingyuan CSG are also contributing to market competitiveness by focusing on specialized applications and regional markets.

SCHOTT AG

Technical Solution: SCHOTT AG has developed advanced melting and forming technologies to reduce borosilicate glass lead times. Their SCHOTT RealTime Process Control system utilizes AI and machine learning to optimize furnace operations, resulting in up to 20% faster melting cycles[1]. They have also implemented a modular production line concept, allowing for rapid changeovers between different glass compositions and product types. This flexibility reduces setup times by up to 30%[2]. Additionally, SCHOTT's proprietary glass formulations enable faster annealing processes, cutting post-production cooling times by up to 25%[3].

Strengths: Advanced process control, flexible production, and optimized formulations significantly reduce overall lead times. Weaknesses: High initial investment costs for implementing new technologies and potential challenges in scaling up production volumes.

Corning, Inc.

Technical Solution: Corning has developed a proprietary fusion draw process for manufacturing borosilicate glass, which significantly reduces lead times compared to traditional methods. This process allows for continuous production of thin, flat glass sheets with exceptional surface quality, eliminating the need for grinding and polishing[4]. Corning has also implemented advanced robotics and automation in their production lines, reducing human intervention and increasing efficiency. Their smart factory initiatives utilize IoT sensors and real-time data analytics to optimize production schedules and minimize downtime, resulting in up to 15% reduction in overall lead times[5].

Strengths: Unique fusion draw process enables faster production of high-quality glass. Advanced automation and smart factory technologies improve efficiency. Weaknesses: Process may be limited to certain glass thicknesses and shapes, potentially reducing versatility.

Innovative Technologies in Glass Production

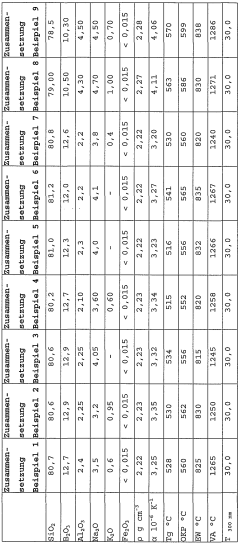

Method for producing borosilicate glasses

PatentInactiveEP1266872A1

Innovation

- The method involves adding sulfates as refining agents between 0.01% and 0.8% by weight as SO3 to initiate gas bubble formation and growth in the glass melt, allowing effective refining without the need for additional reducing agents, and can be combined with fluoride and chloride for enhanced refining.

Method for the production of borosilicate glass with a surface suitable for modification, glass obtained according to said method and the use thereof

PatentWO2003045862A2

Innovation

- Introducing water into molten borosilicate glass, particularly using water of crystallization and gaseous water in a high-water-content atmosphere, to create a glass with a high concentration of reactive SiOH groups, enhancing surface reactivity and reducing fluorescence.

Supply Chain Optimization Strategies

Supply chain optimization strategies play a crucial role in reducing lead times for borosilicate glass production. One key approach is to implement just-in-time (JIT) inventory management, which minimizes excess stock while ensuring materials are available when needed. This requires close collaboration with suppliers and accurate demand forecasting to maintain a lean inventory without risking stockouts.

Another effective strategy is to establish strategic partnerships with key suppliers. By developing long-term relationships, manufacturers can negotiate better terms, secure priority access to raw materials, and potentially co-locate facilities to reduce transportation times. This approach can significantly streamline the supply chain and improve overall efficiency.

Vertical integration is another consideration for borosilicate glass manufacturers. By controlling more stages of the production process, companies can reduce dependencies on external suppliers and have greater control over lead times. This could involve investing in raw material production facilities or acquiring suppliers to create a more integrated supply chain.

Implementing advanced analytics and artificial intelligence can greatly enhance supply chain visibility and decision-making. These technologies can help predict demand fluctuations, optimize inventory levels, and identify potential bottlenecks in the production process. Real-time data analysis allows for proactive adjustments to the supply chain, minimizing delays and improving overall responsiveness.

Diversifying the supplier base is also a critical strategy for reducing lead times. By having multiple sources for key materials and components, manufacturers can mitigate the risk of supply chain disruptions and potentially reduce lead times through competitive sourcing. This approach requires careful supplier qualification and management to maintain quality standards across the supply base.

Lastly, adopting lean manufacturing principles throughout the supply chain can significantly reduce waste and improve efficiency. This includes implementing continuous improvement processes, standardizing workflows, and eliminating non-value-added activities. By streamlining operations at every stage of the supply chain, manufacturers can achieve substantial reductions in lead times for borosilicate glass production.

Another effective strategy is to establish strategic partnerships with key suppliers. By developing long-term relationships, manufacturers can negotiate better terms, secure priority access to raw materials, and potentially co-locate facilities to reduce transportation times. This approach can significantly streamline the supply chain and improve overall efficiency.

Vertical integration is another consideration for borosilicate glass manufacturers. By controlling more stages of the production process, companies can reduce dependencies on external suppliers and have greater control over lead times. This could involve investing in raw material production facilities or acquiring suppliers to create a more integrated supply chain.

Implementing advanced analytics and artificial intelligence can greatly enhance supply chain visibility and decision-making. These technologies can help predict demand fluctuations, optimize inventory levels, and identify potential bottlenecks in the production process. Real-time data analysis allows for proactive adjustments to the supply chain, minimizing delays and improving overall responsiveness.

Diversifying the supplier base is also a critical strategy for reducing lead times. By having multiple sources for key materials and components, manufacturers can mitigate the risk of supply chain disruptions and potentially reduce lead times through competitive sourcing. This approach requires careful supplier qualification and management to maintain quality standards across the supply base.

Lastly, adopting lean manufacturing principles throughout the supply chain can significantly reduce waste and improve efficiency. This includes implementing continuous improvement processes, standardizing workflows, and eliminating non-value-added activities. By streamlining operations at every stage of the supply chain, manufacturers can achieve substantial reductions in lead times for borosilicate glass production.

Environmental Impact of Rapid Glass Production

The rapid production of borosilicate glass, while addressing lead time challenges, raises significant environmental concerns that warrant careful consideration. The manufacturing process of borosilicate glass typically involves high-temperature melting of raw materials, including silica sand, boric oxide, and other additives. Accelerating this process to reduce lead times may lead to increased energy consumption and associated greenhouse gas emissions.

One of the primary environmental impacts stems from the intensified use of fossil fuels to power the furnaces required for glass melting. The higher temperatures and shorter melting cycles necessary for rapid production can result in a substantial increase in carbon dioxide emissions. This contributes to the overall carbon footprint of the glass industry and exacerbates climate change concerns.

Furthermore, the extraction and processing of raw materials for borosilicate glass production can have detrimental effects on local ecosystems. Increased demand for these materials may lead to more intensive mining activities, potentially causing habitat destruction, soil erosion, and water pollution. The accelerated production timeline might also limit opportunities for sustainable sourcing practices and responsible resource management.

Water usage is another critical environmental factor affected by rapid glass production. The cooling processes and cleaning operations in glass manufacturing require significant amounts of water. Expedited production schedules may result in higher water consumption rates and increased wastewater generation, potentially straining local water resources and treatment facilities.

The generation of waste and byproducts is also a concern in rapid glass production. Accelerated manufacturing processes may lead to higher rates of defective products or off-specification materials, resulting in increased waste generation. Proper disposal or recycling of these materials becomes more challenging under tight production timelines, potentially leading to greater environmental burdens.

Air quality is another aspect impacted by rapid borosilicate glass production. The release of particulate matter, volatile organic compounds, and other air pollutants may increase due to the intensified manufacturing processes. This can have adverse effects on local air quality and potentially impact the health of nearby communities.

To mitigate these environmental impacts, glass manufacturers must invest in advanced technologies and sustainable practices. This may include the implementation of energy-efficient furnaces, waste heat recovery systems, and closed-loop water recycling processes. Additionally, exploring alternative raw materials and developing more environmentally friendly formulations for borosilicate glass could help reduce the overall ecological footprint of rapid production methods.

One of the primary environmental impacts stems from the intensified use of fossil fuels to power the furnaces required for glass melting. The higher temperatures and shorter melting cycles necessary for rapid production can result in a substantial increase in carbon dioxide emissions. This contributes to the overall carbon footprint of the glass industry and exacerbates climate change concerns.

Furthermore, the extraction and processing of raw materials for borosilicate glass production can have detrimental effects on local ecosystems. Increased demand for these materials may lead to more intensive mining activities, potentially causing habitat destruction, soil erosion, and water pollution. The accelerated production timeline might also limit opportunities for sustainable sourcing practices and responsible resource management.

Water usage is another critical environmental factor affected by rapid glass production. The cooling processes and cleaning operations in glass manufacturing require significant amounts of water. Expedited production schedules may result in higher water consumption rates and increased wastewater generation, potentially straining local water resources and treatment facilities.

The generation of waste and byproducts is also a concern in rapid glass production. Accelerated manufacturing processes may lead to higher rates of defective products or off-specification materials, resulting in increased waste generation. Proper disposal or recycling of these materials becomes more challenging under tight production timelines, potentially leading to greater environmental burdens.

Air quality is another aspect impacted by rapid borosilicate glass production. The release of particulate matter, volatile organic compounds, and other air pollutants may increase due to the intensified manufacturing processes. This can have adverse effects on local air quality and potentially impact the health of nearby communities.

To mitigate these environmental impacts, glass manufacturers must invest in advanced technologies and sustainable practices. This may include the implementation of energy-efficient furnaces, waste heat recovery systems, and closed-loop water recycling processes. Additionally, exploring alternative raw materials and developing more environmentally friendly formulations for borosilicate glass could help reduce the overall ecological footprint of rapid production methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!