Microcrystalline Cellulose’s Impact in Structural Health Monitoring Systems

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MCC in SHM: Background and Objectives

Microcrystalline Cellulose (MCC) has emerged as a promising material in the field of Structural Health Monitoring (SHM) systems, offering unique properties that enhance the capabilities of these critical monitoring tools. The integration of MCC into SHM systems represents a convergence of materials science and structural engineering, aimed at improving the safety, reliability, and longevity of various infrastructures.

The development of MCC-enhanced SHM systems can be traced back to the early 2000s when researchers began exploring bio-based materials for sensing applications. As environmental concerns grew and the demand for sustainable technologies increased, MCC, derived from abundant cellulose sources, gained attention for its potential to create eco-friendly and high-performance sensing elements.

The primary objective of incorporating MCC into SHM systems is to enhance the sensitivity, durability, and cost-effectiveness of monitoring solutions. MCC's unique crystalline structure and mechanical properties make it an ideal candidate for developing advanced sensors capable of detecting minute structural changes, vibrations, and stress distributions in various structures, including buildings, bridges, and aerospace components.

One of the key technological goals in this field is to leverage MCC's piezoelectric properties to create self-powered sensing systems. This approach aims to eliminate the need for external power sources, thereby reducing maintenance requirements and extending the operational lifespan of SHM systems in remote or hard-to-access locations.

Another significant objective is to exploit MCC's biodegradability and biocompatibility to develop environmentally friendly SHM solutions. This aligns with the growing global emphasis on sustainable technologies and circular economy principles in infrastructure development and maintenance.

Researchers are also focusing on enhancing the multifunctionality of MCC-based sensors. The aim is to create integrated systems capable of simultaneously monitoring multiple structural parameters, such as strain, temperature, and humidity, providing a comprehensive health assessment of the monitored structure.

The evolution of MCC in SHM systems is closely tied to advancements in nanotechnology and materials engineering. Current research trends indicate a move towards developing nanocomposites that combine MCC with other advanced materials like graphene or carbon nanotubes to further enhance sensing capabilities and structural integrity.

As the field progresses, there is a growing emphasis on developing standardized protocols for the integration and calibration of MCC-based sensors in SHM systems. This standardization is crucial for widespread adoption across various industries and for ensuring reliable performance under diverse environmental conditions.

The development of MCC-enhanced SHM systems can be traced back to the early 2000s when researchers began exploring bio-based materials for sensing applications. As environmental concerns grew and the demand for sustainable technologies increased, MCC, derived from abundant cellulose sources, gained attention for its potential to create eco-friendly and high-performance sensing elements.

The primary objective of incorporating MCC into SHM systems is to enhance the sensitivity, durability, and cost-effectiveness of monitoring solutions. MCC's unique crystalline structure and mechanical properties make it an ideal candidate for developing advanced sensors capable of detecting minute structural changes, vibrations, and stress distributions in various structures, including buildings, bridges, and aerospace components.

One of the key technological goals in this field is to leverage MCC's piezoelectric properties to create self-powered sensing systems. This approach aims to eliminate the need for external power sources, thereby reducing maintenance requirements and extending the operational lifespan of SHM systems in remote or hard-to-access locations.

Another significant objective is to exploit MCC's biodegradability and biocompatibility to develop environmentally friendly SHM solutions. This aligns with the growing global emphasis on sustainable technologies and circular economy principles in infrastructure development and maintenance.

Researchers are also focusing on enhancing the multifunctionality of MCC-based sensors. The aim is to create integrated systems capable of simultaneously monitoring multiple structural parameters, such as strain, temperature, and humidity, providing a comprehensive health assessment of the monitored structure.

The evolution of MCC in SHM systems is closely tied to advancements in nanotechnology and materials engineering. Current research trends indicate a move towards developing nanocomposites that combine MCC with other advanced materials like graphene or carbon nanotubes to further enhance sensing capabilities and structural integrity.

As the field progresses, there is a growing emphasis on developing standardized protocols for the integration and calibration of MCC-based sensors in SHM systems. This standardization is crucial for widespread adoption across various industries and for ensuring reliable performance under diverse environmental conditions.

Market Analysis for MCC-Enhanced SHM Systems

The market for Microcrystalline Cellulose (MCC) enhanced Structural Health Monitoring (SHM) systems is experiencing significant growth, driven by the increasing demand for advanced infrastructure monitoring solutions across various industries. The global SHM market is projected to expand at a compound annual growth rate of 13.5% from 2021 to 2028, with MCC-enhanced systems expected to capture a substantial share of this growth.

The construction industry represents the largest market segment for MCC-enhanced SHM systems, particularly in the monitoring of bridges, high-rise buildings, and critical infrastructure. The ability of MCC to improve the sensitivity and durability of sensors has made it an attractive option for long-term monitoring applications. Additionally, the aerospace and automotive sectors are emerging as key adopters of this technology, utilizing MCC-enhanced systems for real-time structural integrity assessment of aircraft and vehicles.

Market demand is primarily driven by the need for cost-effective, reliable, and long-lasting monitoring solutions. MCC-enhanced SHM systems offer improved sensor performance, extended operational life, and reduced maintenance requirements compared to traditional systems. These benefits translate into lower total cost of ownership, making them increasingly attractive to both public and private sector clients.

Geographically, North America and Europe currently dominate the market for MCC-enhanced SHM systems, owing to their advanced infrastructure and stringent safety regulations. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, fueled by rapid urbanization, infrastructure development, and increasing awareness of the importance of structural health monitoring.

The market is characterized by a mix of established players and innovative startups. Major companies in the SHM industry are investing heavily in research and development to incorporate MCC into their existing product lines. Simultaneously, new entrants are focusing on niche applications and novel sensor designs that leverage the unique properties of MCC.

Despite the positive outlook, the market faces challenges such as high initial implementation costs and the need for specialized expertise in system integration. However, these barriers are expected to diminish as the technology matures and becomes more widely adopted. The increasing emphasis on smart cities and the Internet of Things (IoT) is likely to create new opportunities for MCC-enhanced SHM systems, particularly in the development of integrated, city-wide monitoring networks.

In conclusion, the market for MCC-enhanced SHM systems shows strong growth potential, driven by technological advancements, increasing safety concerns, and the need for efficient infrastructure management. As the technology continues to evolve and demonstrate its value across various applications, it is poised to become an integral component of modern structural health monitoring solutions.

The construction industry represents the largest market segment for MCC-enhanced SHM systems, particularly in the monitoring of bridges, high-rise buildings, and critical infrastructure. The ability of MCC to improve the sensitivity and durability of sensors has made it an attractive option for long-term monitoring applications. Additionally, the aerospace and automotive sectors are emerging as key adopters of this technology, utilizing MCC-enhanced systems for real-time structural integrity assessment of aircraft and vehicles.

Market demand is primarily driven by the need for cost-effective, reliable, and long-lasting monitoring solutions. MCC-enhanced SHM systems offer improved sensor performance, extended operational life, and reduced maintenance requirements compared to traditional systems. These benefits translate into lower total cost of ownership, making them increasingly attractive to both public and private sector clients.

Geographically, North America and Europe currently dominate the market for MCC-enhanced SHM systems, owing to their advanced infrastructure and stringent safety regulations. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, fueled by rapid urbanization, infrastructure development, and increasing awareness of the importance of structural health monitoring.

The market is characterized by a mix of established players and innovative startups. Major companies in the SHM industry are investing heavily in research and development to incorporate MCC into their existing product lines. Simultaneously, new entrants are focusing on niche applications and novel sensor designs that leverage the unique properties of MCC.

Despite the positive outlook, the market faces challenges such as high initial implementation costs and the need for specialized expertise in system integration. However, these barriers are expected to diminish as the technology matures and becomes more widely adopted. The increasing emphasis on smart cities and the Internet of Things (IoT) is likely to create new opportunities for MCC-enhanced SHM systems, particularly in the development of integrated, city-wide monitoring networks.

In conclusion, the market for MCC-enhanced SHM systems shows strong growth potential, driven by technological advancements, increasing safety concerns, and the need for efficient infrastructure management. As the technology continues to evolve and demonstrate its value across various applications, it is poised to become an integral component of modern structural health monitoring solutions.

Current Challenges in MCC Integration for SHM

The integration of Microcrystalline Cellulose (MCC) into Structural Health Monitoring (SHM) systems presents several significant challenges that researchers and engineers must address. One of the primary obstacles is the difficulty in achieving uniform dispersion of MCC within the host material. The tendency of MCC particles to agglomerate due to their high surface energy can lead to inconsistent mechanical properties and reduced effectiveness in sensing applications.

Another challenge lies in maintaining the structural integrity of MCC during the integration process. The harsh conditions often involved in material processing, such as high temperatures or pressures, can potentially degrade the cellulose structure, compromising its unique properties that make it valuable for SHM applications. This degradation can result in reduced sensitivity and reliability of the monitoring system.

The interface between MCC and the host material poses yet another hurdle. Ensuring strong adhesion and compatibility between the cellulose particles and the matrix material is crucial for effective stress transfer and sensing capabilities. Poor interfacial bonding can lead to premature failure of the composite and inaccurate structural health assessments.

Scalability and cost-effectiveness remain significant concerns in the widespread adoption of MCC-based SHM systems. While MCC shows promise in laboratory-scale experiments, translating these results to large-scale, real-world applications presents logistical and economic challenges. The production of high-quality MCC in sufficient quantities for industrial-scale SHM applications is still a bottleneck in the manufacturing process.

Environmental stability is another critical issue that needs addressing. MCC, being a natural material, is susceptible to moisture absorption and biodegradation. This vulnerability can affect the long-term performance and reliability of SHM systems, particularly in harsh or humid environments. Developing effective methods to protect MCC from environmental degradation without compromising its sensing capabilities is an ongoing challenge.

The integration of MCC into existing SHM technologies also presents compatibility issues. Current sensing and data acquisition systems may require modifications to effectively capture and interpret the signals generated by MCC-based sensors. This necessitates the development of new algorithms and hardware solutions tailored to the unique characteristics of MCC-enhanced structural monitoring.

Lastly, the lack of standardized testing and characterization methods for MCC-based SHM systems hinders their widespread acceptance and implementation. Establishing reliable protocols for assessing the performance, durability, and long-term stability of these systems is crucial for gaining industry confidence and regulatory approval.

Another challenge lies in maintaining the structural integrity of MCC during the integration process. The harsh conditions often involved in material processing, such as high temperatures or pressures, can potentially degrade the cellulose structure, compromising its unique properties that make it valuable for SHM applications. This degradation can result in reduced sensitivity and reliability of the monitoring system.

The interface between MCC and the host material poses yet another hurdle. Ensuring strong adhesion and compatibility between the cellulose particles and the matrix material is crucial for effective stress transfer and sensing capabilities. Poor interfacial bonding can lead to premature failure of the composite and inaccurate structural health assessments.

Scalability and cost-effectiveness remain significant concerns in the widespread adoption of MCC-based SHM systems. While MCC shows promise in laboratory-scale experiments, translating these results to large-scale, real-world applications presents logistical and economic challenges. The production of high-quality MCC in sufficient quantities for industrial-scale SHM applications is still a bottleneck in the manufacturing process.

Environmental stability is another critical issue that needs addressing. MCC, being a natural material, is susceptible to moisture absorption and biodegradation. This vulnerability can affect the long-term performance and reliability of SHM systems, particularly in harsh or humid environments. Developing effective methods to protect MCC from environmental degradation without compromising its sensing capabilities is an ongoing challenge.

The integration of MCC into existing SHM technologies also presents compatibility issues. Current sensing and data acquisition systems may require modifications to effectively capture and interpret the signals generated by MCC-based sensors. This necessitates the development of new algorithms and hardware solutions tailored to the unique characteristics of MCC-enhanced structural monitoring.

Lastly, the lack of standardized testing and characterization methods for MCC-based SHM systems hinders their widespread acceptance and implementation. Establishing reliable protocols for assessing the performance, durability, and long-term stability of these systems is crucial for gaining industry confidence and regulatory approval.

Existing MCC-Based SHM Solutions

01 Production methods of microcrystalline cellulose

Various methods are employed to produce microcrystalline cellulose, including acid hydrolysis of cellulose fibers, mechanical processing, and enzymatic treatments. These processes aim to break down cellulose into smaller crystalline particles while maintaining its structural integrity. The production methods can be optimized to control particle size, crystallinity, and other physical properties of the resulting microcrystalline cellulose.- Production and modification of microcrystalline cellulose: Various methods are employed to produce and modify microcrystalline cellulose, including acid hydrolysis, enzymatic treatment, and mechanical processing. These techniques aim to improve the properties of microcrystalline cellulose for specific applications, such as enhancing its stability, particle size distribution, or surface characteristics.

- Applications in pharmaceutical formulations: Microcrystalline cellulose is widely used in pharmaceutical formulations as an excipient. It serves various functions, including as a binder, disintegrant, and filler in tablet and capsule formulations. Its properties contribute to improved drug release, stability, and overall performance of pharmaceutical products.

- Use in food and cosmetic industries: Microcrystalline cellulose finds applications in food and cosmetic products as a stabilizer, thickener, and texturizing agent. It is used to improve the consistency, mouthfeel, and shelf-life of various food products, as well as in cosmetic formulations to enhance texture and stability.

- Composite materials and reinforcement: Microcrystalline cellulose is utilized in the development of composite materials, where it acts as a reinforcing agent. It can enhance the mechanical properties, thermal stability, and biodegradability of various materials, including plastics, paper, and construction materials.

- Functionalization and surface modification: Research focuses on the functionalization and surface modification of microcrystalline cellulose to tailor its properties for specific applications. This includes grafting of functional groups, chemical modifications, and surface treatments to improve compatibility with other materials or enhance specific characteristics.

02 Applications in pharmaceutical formulations

Microcrystalline cellulose is widely used in pharmaceutical formulations as an excipient. It serves as a binder, disintegrant, and filler in tablet and capsule formulations. Its properties, such as compressibility, flowability, and compatibility with active ingredients, make it valuable in drug delivery systems. It can be used to improve the stability, dissolution, and bioavailability of various pharmaceutical products.Expand Specific Solutions03 Use in food and cosmetic industries

Microcrystalline cellulose finds applications in food and cosmetic products as a stabilizer, thickener, and texturizing agent. In food products, it can improve consistency, prevent separation, and enhance mouthfeel. In cosmetics, it is used in creams, lotions, and other personal care products to modify texture and improve product stability. Its natural origin and safety profile make it a preferred choice in these industries.Expand Specific Solutions04 Modifications and composite materials

Microcrystalline cellulose can be modified or combined with other materials to create composite materials with enhanced properties. These modifications can include surface treatments, chemical derivatization, or blending with polymers or nanoparticles. Such composites may exhibit improved mechanical strength, barrier properties, or functionality, expanding the range of potential applications in various industries.Expand Specific Solutions05 Environmental and sustainability aspects

As a naturally derived and biodegradable material, microcrystalline cellulose aligns with sustainability goals in various industries. Research focuses on developing eco-friendly production methods, exploring renewable sources for cellulose, and investigating its potential in biodegradable packaging and other sustainable applications. Its use can contribute to reducing environmental impact and promoting circular economy principles.Expand Specific Solutions

Key Industry Players in MCC-SHM Integration

The microcrystalline cellulose market in structural health monitoring systems is in its early growth stage, with increasing adoption across various industries. The market size is expanding as awareness of the material's benefits grows, particularly in aerospace, civil engineering, and automotive sectors. Technologically, microcrystalline cellulose applications are advancing rapidly, with companies like Boeing, Lockheed Martin, and NASA leading research and development efforts. Universities such as MIT and Southeast University are contributing to technological advancements, while specialized firms like Acellent Technologies and MesoMat are developing innovative sensing solutions incorporating microcrystalline cellulose. The technology's maturity is progressing, but there's still significant room for improvement and wider implementation across different structural health monitoring applications.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed an advanced structural health monitoring system that incorporates microcrystalline cellulose (MCC) as a key component in their sensor technology. Their approach utilizes MCC-based nanocomposites to create a network of distributed sensors throughout the structure. These sensors are designed to detect minute changes in stress, strain, and vibration patterns[2]. Honeywell's system integrates MCC into fiber optic sensors, leveraging the material's unique properties to enhance sensitivity and durability. The company has also developed proprietary algorithms that analyze data from the MCC-enhanced sensors in real-time, providing accurate assessments of structural integrity and predicting potential failures before they occur[4]. This system is particularly tailored for aerospace applications, where weight savings and reliability are crucial.

Strengths: High precision and reliability, aerospace-grade technology, integrated data analytics for predictive maintenance. Weaknesses: Potentially higher initial implementation costs, may require specialized training for installation and maintenance.

The Boeing Co.

Technical Solution: Boeing has pioneered the use of microcrystalline cellulose (MCC) in their structural health monitoring systems for aircraft. Their approach integrates MCC into composite materials used in aircraft structures, creating a self-sensing network throughout the airframe. Boeing's system utilizes the piezoelectric properties of MCC-enhanced composites to detect and localize structural changes in real-time[5]. The company has developed a proprietary network of MCC-based sensors that are seamlessly integrated into the aircraft's structure during manufacturing, minimizing additional weight and complexity. Boeing's system employs advanced signal processing techniques and machine learning algorithms to analyze data from these sensors, providing continuous monitoring of structural integrity during flight operations[6]. This technology enables predictive maintenance strategies and enhances overall aircraft safety.

Strengths: Seamless integration with existing aircraft structures, minimal weight addition, comprehensive real-time monitoring capabilities. Weaknesses: High development and certification costs, potential challenges in retrofitting existing aircraft.

Innovative MCC Technologies for SHM

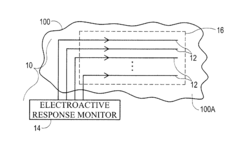

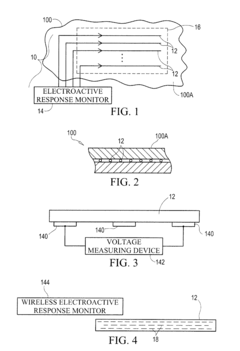

Structural Health Monitoring System/Method Using Electroactive Polymer Fibers

PatentInactiveUS20100201384A1

Innovation

- The use of electroactive polymer fibers, which are coupled to structures to monitor load-induced changes, generating electrical signals that can be read by a monitor, either wired or wirelessly, allowing for continuous health assessment and tailored sensing capabilities through controlled manufacturing processes.

Structural health monitoring system

PatentInactiveIN202011036449A

Innovation

- An automatic structural health monitoring system comprising embedded sensors on silicon fiber sheets, a monitoring device, and a processor that identifies and records sensor readings, displays them in real-time, and sends alerts via a communication module to authorized personnel, utilizing piezoelectric, moisture, and corrosion sensors, with machine learning-driven algorithms for early detection and proactive maintenance.

Environmental Impact of MCC in SHM Systems

The integration of Microcrystalline Cellulose (MCC) in Structural Health Monitoring (SHM) systems presents both opportunities and challenges from an environmental perspective. As a biodegradable and renewable material derived from natural sources, MCC offers potential advantages in terms of sustainability compared to traditional synthetic materials used in SHM applications.

One of the primary environmental benefits of incorporating MCC into SHM systems is the reduction of carbon footprint associated with material production. The manufacturing process of MCC typically requires less energy and produces fewer greenhouse gas emissions compared to the production of synthetic polymers or metal-based components commonly used in SHM devices. This aligns with global efforts to mitigate climate change and promote eco-friendly industrial practices.

Furthermore, the biodegradability of MCC contributes to reduced environmental impact at the end of the product lifecycle. As SHM systems reach their operational lifespan, the disposal or recycling of MCC-based components poses less of a burden on waste management systems and ecosystems compared to non-biodegradable alternatives. This characteristic is particularly valuable in applications where SHM devices may be deployed in environmentally sensitive areas or where retrieval is challenging.

However, the environmental impact of MCC in SHM systems is not without complexities. The sourcing of raw materials for MCC production, primarily from wood pulp or cotton linters, raises questions about sustainable forestry practices and land use. Ensuring that MCC is derived from responsibly managed sources is crucial to maintaining its environmental credentials.

Additionally, the durability and longevity of MCC-based components in SHM systems must be carefully considered. While biodegradability is an asset in terms of end-of-life management, it may necessitate more frequent replacement of components, potentially leading to increased resource consumption over time. Balancing the trade-offs between biodegradability and long-term performance is a key challenge in optimizing the environmental impact of MCC in SHM applications.

The use of MCC in SHM systems also intersects with broader environmental monitoring capabilities. By enhancing the sensitivity and reliability of structural health monitoring, MCC-based sensors could contribute to early detection of environmental stressors on infrastructure, potentially preventing catastrophic failures that could have severe environmental consequences.

In conclusion, the environmental impact of MCC in SHM systems is multifaceted, offering promising benefits in terms of sustainability and biodegradability, while also presenting challenges related to sourcing and long-term performance. As research and development in this field progress, a holistic approach to environmental assessment will be essential to fully leverage the potential of MCC in creating more sustainable and environmentally responsible SHM solutions.

One of the primary environmental benefits of incorporating MCC into SHM systems is the reduction of carbon footprint associated with material production. The manufacturing process of MCC typically requires less energy and produces fewer greenhouse gas emissions compared to the production of synthetic polymers or metal-based components commonly used in SHM devices. This aligns with global efforts to mitigate climate change and promote eco-friendly industrial practices.

Furthermore, the biodegradability of MCC contributes to reduced environmental impact at the end of the product lifecycle. As SHM systems reach their operational lifespan, the disposal or recycling of MCC-based components poses less of a burden on waste management systems and ecosystems compared to non-biodegradable alternatives. This characteristic is particularly valuable in applications where SHM devices may be deployed in environmentally sensitive areas or where retrieval is challenging.

However, the environmental impact of MCC in SHM systems is not without complexities. The sourcing of raw materials for MCC production, primarily from wood pulp or cotton linters, raises questions about sustainable forestry practices and land use. Ensuring that MCC is derived from responsibly managed sources is crucial to maintaining its environmental credentials.

Additionally, the durability and longevity of MCC-based components in SHM systems must be carefully considered. While biodegradability is an asset in terms of end-of-life management, it may necessitate more frequent replacement of components, potentially leading to increased resource consumption over time. Balancing the trade-offs between biodegradability and long-term performance is a key challenge in optimizing the environmental impact of MCC in SHM applications.

The use of MCC in SHM systems also intersects with broader environmental monitoring capabilities. By enhancing the sensitivity and reliability of structural health monitoring, MCC-based sensors could contribute to early detection of environmental stressors on infrastructure, potentially preventing catastrophic failures that could have severe environmental consequences.

In conclusion, the environmental impact of MCC in SHM systems is multifaceted, offering promising benefits in terms of sustainability and biodegradability, while also presenting challenges related to sourcing and long-term performance. As research and development in this field progress, a holistic approach to environmental assessment will be essential to fully leverage the potential of MCC in creating more sustainable and environmentally responsible SHM solutions.

Standardization of MCC-SHM Technologies

The standardization of Microcrystalline Cellulose-based Structural Health Monitoring (MCC-SHM) technologies is a critical step towards widespread adoption and integration in various industries. As these innovative systems gain traction, establishing uniform protocols and guidelines becomes essential to ensure consistency, reliability, and interoperability across different applications and platforms.

One of the primary focus areas for standardization is the development of consistent measurement and data collection methodologies. This includes defining standard procedures for sensor placement, data acquisition rates, and signal processing techniques specific to MCC-SHM systems. By establishing these protocols, researchers and engineers can more easily compare results across different studies and implementations, fostering a more cohesive understanding of the technology's capabilities and limitations.

Another crucial aspect of standardization involves the creation of uniform performance metrics and evaluation criteria for MCC-SHM systems. This encompasses defining key parameters such as sensitivity, accuracy, and long-term stability, as well as establishing standardized testing procedures to assess these metrics. Such standardization will enable more objective comparisons between different MCC-SHM solutions and help end-users make informed decisions when selecting appropriate systems for their specific applications.

Interoperability is a key consideration in the standardization process. Developing common data formats and communication protocols for MCC-SHM systems will facilitate seamless integration with existing structural health monitoring platforms and data management systems. This standardization effort should also address issues related to data security and privacy, ensuring that sensitive structural information is adequately protected while still allowing for necessary data sharing and analysis.

The development of industry-wide best practices for the installation, calibration, and maintenance of MCC-SHM systems is another critical component of standardization. These guidelines should cover aspects such as environmental considerations, sensor durability, and long-term performance optimization. By establishing these standards, the industry can ensure consistent and reliable performance across various applications and environments.

Collaboration between academic institutions, industry leaders, and regulatory bodies is essential for the successful standardization of MCC-SHM technologies. International organizations such as ISO (International Organization for Standardization) and IEEE (Institute of Electrical and Electronics Engineers) can play a crucial role in facilitating this process and ensuring global alignment of standards. As the technology continues to evolve, these standards will need to be regularly reviewed and updated to reflect advancements in the field and changing industry requirements.

One of the primary focus areas for standardization is the development of consistent measurement and data collection methodologies. This includes defining standard procedures for sensor placement, data acquisition rates, and signal processing techniques specific to MCC-SHM systems. By establishing these protocols, researchers and engineers can more easily compare results across different studies and implementations, fostering a more cohesive understanding of the technology's capabilities and limitations.

Another crucial aspect of standardization involves the creation of uniform performance metrics and evaluation criteria for MCC-SHM systems. This encompasses defining key parameters such as sensitivity, accuracy, and long-term stability, as well as establishing standardized testing procedures to assess these metrics. Such standardization will enable more objective comparisons between different MCC-SHM solutions and help end-users make informed decisions when selecting appropriate systems for their specific applications.

Interoperability is a key consideration in the standardization process. Developing common data formats and communication protocols for MCC-SHM systems will facilitate seamless integration with existing structural health monitoring platforms and data management systems. This standardization effort should also address issues related to data security and privacy, ensuring that sensitive structural information is adequately protected while still allowing for necessary data sharing and analysis.

The development of industry-wide best practices for the installation, calibration, and maintenance of MCC-SHM systems is another critical component of standardization. These guidelines should cover aspects such as environmental considerations, sensor durability, and long-term performance optimization. By establishing these standards, the industry can ensure consistent and reliable performance across various applications and environments.

Collaboration between academic institutions, industry leaders, and regulatory bodies is essential for the successful standardization of MCC-SHM technologies. International organizations such as ISO (International Organization for Standardization) and IEEE (Institute of Electrical and Electronics Engineers) can play a crucial role in facilitating this process and ensuring global alignment of standards. As the technology continues to evolve, these standards will need to be regularly reviewed and updated to reflect advancements in the field and changing industry requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!