MicroLED color conversion with perovskite phosphors: stability and lifetime lessons

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MicroLED and Perovskite Phosphor Overview

MicroLED technology represents a significant advancement in display technology, offering superior brightness, contrast, and energy efficiency compared to traditional LED and OLED displays. This emerging technology utilizes microscopic LED arrays to create self-emissive pixels, resulting in displays with exceptional picture quality and performance.

Perovskite phosphors have emerged as a promising material for color conversion in MicroLED displays. These materials possess unique optoelectronic properties that make them particularly suitable for this application. Perovskites exhibit high photoluminescence quantum yields, narrow emission spectra, and tunable bandgaps, allowing for precise color control and improved color gamut in displays.

The integration of perovskite phosphors with MicroLED technology addresses several challenges in display manufacturing. Traditional phosphors used in LED displays often suffer from broad emission spectra and lower efficiency, limiting color accuracy and overall display performance. Perovskite phosphors, with their superior optical properties, offer a potential solution to these limitations.

One of the key advantages of using perovskite phosphors in MicroLED displays is the ability to achieve a wider color gamut. The narrow emission spectra of perovskites allow for more saturated colors, resulting in displays that can reproduce a broader range of colors with greater accuracy. This is particularly important for high-end display applications in areas such as professional video production, gaming, and virtual reality.

However, the implementation of perovskite phosphors in MicroLED displays also presents several challenges. The most significant of these is the issue of stability and lifetime. Perovskite materials are known to be sensitive to environmental factors such as moisture, heat, and light exposure. This sensitivity can lead to degradation of the phosphor material over time, potentially affecting the long-term performance and reliability of the display.

Researchers and industry professionals are actively working to address these stability and lifetime concerns. Various approaches are being explored, including the development of more stable perovskite compositions, the use of protective encapsulation techniques, and the optimization of device architectures to minimize stress on the phosphor materials.

Despite these challenges, the potential benefits of combining MicroLED technology with perovskite phosphors continue to drive research and development in this field. The promise of displays with exceptional color quality, energy efficiency, and form factor flexibility makes this an area of significant interest for both academic researchers and commercial entities in the display industry.

Perovskite phosphors have emerged as a promising material for color conversion in MicroLED displays. These materials possess unique optoelectronic properties that make them particularly suitable for this application. Perovskites exhibit high photoluminescence quantum yields, narrow emission spectra, and tunable bandgaps, allowing for precise color control and improved color gamut in displays.

The integration of perovskite phosphors with MicroLED technology addresses several challenges in display manufacturing. Traditional phosphors used in LED displays often suffer from broad emission spectra and lower efficiency, limiting color accuracy and overall display performance. Perovskite phosphors, with their superior optical properties, offer a potential solution to these limitations.

One of the key advantages of using perovskite phosphors in MicroLED displays is the ability to achieve a wider color gamut. The narrow emission spectra of perovskites allow for more saturated colors, resulting in displays that can reproduce a broader range of colors with greater accuracy. This is particularly important for high-end display applications in areas such as professional video production, gaming, and virtual reality.

However, the implementation of perovskite phosphors in MicroLED displays also presents several challenges. The most significant of these is the issue of stability and lifetime. Perovskite materials are known to be sensitive to environmental factors such as moisture, heat, and light exposure. This sensitivity can lead to degradation of the phosphor material over time, potentially affecting the long-term performance and reliability of the display.

Researchers and industry professionals are actively working to address these stability and lifetime concerns. Various approaches are being explored, including the development of more stable perovskite compositions, the use of protective encapsulation techniques, and the optimization of device architectures to minimize stress on the phosphor materials.

Despite these challenges, the potential benefits of combining MicroLED technology with perovskite phosphors continue to drive research and development in this field. The promise of displays with exceptional color quality, energy efficiency, and form factor flexibility makes this an area of significant interest for both academic researchers and commercial entities in the display industry.

Market Demand for Advanced Display Technologies

The demand for advanced display technologies has been steadily increasing, driven by the growing consumer appetite for high-quality visual experiences across various devices. MicroLED technology, particularly when combined with perovskite phosphors for color conversion, represents a significant leap forward in display capabilities. This innovation addresses the market's need for brighter, more energy-efficient, and longer-lasting displays with superior color reproduction.

In the smartphone market, where visual quality is a key differentiator, MicroLED displays with perovskite phosphors offer the potential for enhanced color gamut and brightness while consuming less power. This aligns with consumer demands for devices with longer battery life and improved outdoor visibility. The automotive industry is another sector showing strong interest in this technology, as it enables the development of more vibrant and durable heads-up displays and infotainment systems.

The television and large-format display market is also poised to benefit from MicroLED technology. Consumers are increasingly seeking ultra-high-definition displays with perfect black levels and wide color gamuts. MicroLED displays with perovskite phosphors can deliver these features while offering better energy efficiency compared to OLED and traditional LED-backlit LCD technologies.

In the professional and commercial display sectors, there is a growing demand for high-brightness, high-contrast displays for digital signage, control rooms, and simulation environments. MicroLED technology with perovskite phosphors is well-positioned to meet these requirements, offering superior image quality and potentially lower total cost of ownership due to improved energy efficiency and longer lifespans.

The wearable technology market, including smartwatches and augmented reality (AR) devices, is another area where MicroLED displays could see significant adoption. The technology's ability to provide high brightness and low power consumption in a compact form factor makes it particularly suitable for these applications, where battery life and display quality are critical factors.

However, the market demand for this technology is tempered by concerns over the stability and lifetime of perovskite phosphors. Potential customers in all sectors are looking for assurances that these displays can maintain their performance over extended periods, particularly in challenging environments such as automotive applications or outdoor digital signage.

As the technology matures and these stability issues are addressed, industry analysts predict a substantial growth in market demand. The global MicroLED market is expected to expand significantly in the coming years, with the integration of perovskite phosphors potentially accelerating this growth by addressing key performance metrics that are important to consumers and businesses alike.

In the smartphone market, where visual quality is a key differentiator, MicroLED displays with perovskite phosphors offer the potential for enhanced color gamut and brightness while consuming less power. This aligns with consumer demands for devices with longer battery life and improved outdoor visibility. The automotive industry is another sector showing strong interest in this technology, as it enables the development of more vibrant and durable heads-up displays and infotainment systems.

The television and large-format display market is also poised to benefit from MicroLED technology. Consumers are increasingly seeking ultra-high-definition displays with perfect black levels and wide color gamuts. MicroLED displays with perovskite phosphors can deliver these features while offering better energy efficiency compared to OLED and traditional LED-backlit LCD technologies.

In the professional and commercial display sectors, there is a growing demand for high-brightness, high-contrast displays for digital signage, control rooms, and simulation environments. MicroLED technology with perovskite phosphors is well-positioned to meet these requirements, offering superior image quality and potentially lower total cost of ownership due to improved energy efficiency and longer lifespans.

The wearable technology market, including smartwatches and augmented reality (AR) devices, is another area where MicroLED displays could see significant adoption. The technology's ability to provide high brightness and low power consumption in a compact form factor makes it particularly suitable for these applications, where battery life and display quality are critical factors.

However, the market demand for this technology is tempered by concerns over the stability and lifetime of perovskite phosphors. Potential customers in all sectors are looking for assurances that these displays can maintain their performance over extended periods, particularly in challenging environments such as automotive applications or outdoor digital signage.

As the technology matures and these stability issues are addressed, industry analysts predict a substantial growth in market demand. The global MicroLED market is expected to expand significantly in the coming years, with the integration of perovskite phosphors potentially accelerating this growth by addressing key performance metrics that are important to consumers and businesses alike.

Current Challenges in MicroLED Color Conversion

MicroLED displays have emerged as a promising technology for next-generation displays, offering advantages such as high brightness, wide color gamut, and energy efficiency. However, the color conversion process in MicroLED displays faces several significant challenges that hinder their widespread adoption and commercialization.

One of the primary challenges is achieving stable and efficient color conversion. While perovskite phosphors have shown great potential for color conversion in MicroLED displays, their stability and lifetime remain major concerns. The inherent instability of perovskite materials, particularly under high-intensity blue light excitation and environmental factors such as moisture and heat, leads to degradation over time. This degradation results in color shift and reduced luminescence efficiency, compromising the display's overall performance and longevity.

Another critical challenge is maintaining color uniformity across the display. The color conversion process must be precisely controlled to ensure consistent color output from each pixel. Variations in phosphor thickness, composition, or distribution can lead to non-uniform color emission, affecting the display's visual quality. Achieving uniform color conversion becomes increasingly difficult as pixel sizes decrease and display resolutions increase.

The thermal management of MicroLED displays with color conversion layers presents another significant challenge. The conversion process generates heat, which can further exacerbate the stability issues of perovskite phosphors and affect the overall performance of the display. Efficient heat dissipation mechanisms must be developed to maintain optimal operating temperatures and prevent thermal degradation of the color conversion materials.

Furthermore, the integration of color conversion layers with MicroLED arrays poses manufacturing challenges. The deposition of uniform and defect-free phosphor layers on a microscale level requires advanced fabrication techniques. Ensuring proper adhesion between the color conversion layer and the MicroLED structure while maintaining the integrity of both components is crucial for device reliability.

The environmental impact and potential toxicity of some perovskite materials used in color conversion layers also raise concerns. Developing eco-friendly alternatives or encapsulation methods to mitigate these issues is essential for the widespread adoption of this technology.

Lastly, achieving a wide color gamut while maintaining high efficiency remains a challenge. While perovskite phosphors offer the potential for a broad color range, optimizing the balance between color purity and conversion efficiency is crucial. This optimization becomes even more challenging when considering the need for long-term stability and consistent performance over the lifetime of the display.

One of the primary challenges is achieving stable and efficient color conversion. While perovskite phosphors have shown great potential for color conversion in MicroLED displays, their stability and lifetime remain major concerns. The inherent instability of perovskite materials, particularly under high-intensity blue light excitation and environmental factors such as moisture and heat, leads to degradation over time. This degradation results in color shift and reduced luminescence efficiency, compromising the display's overall performance and longevity.

Another critical challenge is maintaining color uniformity across the display. The color conversion process must be precisely controlled to ensure consistent color output from each pixel. Variations in phosphor thickness, composition, or distribution can lead to non-uniform color emission, affecting the display's visual quality. Achieving uniform color conversion becomes increasingly difficult as pixel sizes decrease and display resolutions increase.

The thermal management of MicroLED displays with color conversion layers presents another significant challenge. The conversion process generates heat, which can further exacerbate the stability issues of perovskite phosphors and affect the overall performance of the display. Efficient heat dissipation mechanisms must be developed to maintain optimal operating temperatures and prevent thermal degradation of the color conversion materials.

Furthermore, the integration of color conversion layers with MicroLED arrays poses manufacturing challenges. The deposition of uniform and defect-free phosphor layers on a microscale level requires advanced fabrication techniques. Ensuring proper adhesion between the color conversion layer and the MicroLED structure while maintaining the integrity of both components is crucial for device reliability.

The environmental impact and potential toxicity of some perovskite materials used in color conversion layers also raise concerns. Developing eco-friendly alternatives or encapsulation methods to mitigate these issues is essential for the widespread adoption of this technology.

Lastly, achieving a wide color gamut while maintaining high efficiency remains a challenge. While perovskite phosphors offer the potential for a broad color range, optimizing the balance between color purity and conversion efficiency is crucial. This optimization becomes even more challenging when considering the need for long-term stability and consistent performance over the lifetime of the display.

Existing Perovskite Phosphor Solutions

01 Composition modifications for improved stability

Enhancing the stability and lifetime of perovskite phosphors through compositional adjustments. This includes doping with specific elements, altering the ratio of components, or introducing new materials to the perovskite structure. These modifications aim to reduce degradation and improve the overall durability of the phosphors under various environmental conditions.- Composition modifications for improved stability: Enhancing the stability and lifetime of perovskite phosphors through compositional adjustments, such as doping with specific elements or altering the ratio of constituent materials. These modifications can improve the structural integrity and resistance to environmental factors, leading to increased longevity of the phosphors.

- Encapsulation techniques: Utilizing various encapsulation methods to protect perovskite phosphors from moisture, oxygen, and other degradation factors. This can include coating the phosphors with inert materials or incorporating them into protective matrices, thereby extending their operational lifetime and maintaining their optical properties over time.

- Surface passivation strategies: Implementing surface passivation techniques to reduce defects and trap states on the surface of perovskite phosphors. This approach can minimize non-radiative recombination and improve the overall stability and efficiency of the phosphors, leading to enhanced lifetime performance.

- Thermal management solutions: Developing methods to improve the thermal stability of perovskite phosphors, such as incorporating heat-dissipating materials or designing structures that efficiently manage heat. These solutions can prevent thermal degradation and maintain the phosphors' performance under high-temperature operating conditions.

- Novel synthesis methods: Exploring innovative synthesis techniques to produce perovskite phosphors with enhanced stability and longer lifetimes. This can include low-temperature processes, solution-based methods, or other approaches that result in high-quality, defect-free phosphors with improved resistance to degradation factors.

02 Encapsulation and protective coatings

Utilizing encapsulation techniques and applying protective coatings to shield perovskite phosphors from external factors that contribute to degradation. This approach involves creating barrier layers or shells around the phosphor particles to prevent moisture ingress, oxygen exposure, and other environmental stressors, thereby extending their operational lifetime.Expand Specific Solutions03 Surface passivation techniques

Implementing surface passivation methods to reduce defects and trap states on the surface of perovskite phosphors. This technique involves treating the phosphor surface with specific agents or processes to minimize non-radiative recombination and improve quantum efficiency, resulting in enhanced stability and prolonged lifetime.Expand Specific Solutions04 Synthesis and processing optimization

Refining synthesis and processing methods to produce perovskite phosphors with improved structural integrity and reduced defects. This includes optimizing reaction conditions, exploring novel synthesis routes, and developing post-processing treatments to enhance the crystallinity and uniformity of the phosphors, leading to better stability and longer lifetimes.Expand Specific Solutions05 Device integration and operational conditions

Focusing on the integration of perovskite phosphors into devices and optimizing operational conditions to maximize stability and lifetime. This involves designing appropriate device architectures, managing heat dissipation, and controlling operational parameters such as current density and duty cycle to minimize stress on the phosphors during use.Expand Specific Solutions

Key Players in MicroLED and Perovskite Industries

The MicroLED color conversion with perovskite phosphors technology is in an early development stage, with significant potential for growth in the display and lighting industries. The market size is expected to expand rapidly as MicroLED technology matures. Key players like OSRAM, LG Chem, and Lumileds are actively researching and developing perovskite-based color conversion solutions. However, the technology's stability and lifetime remain critical challenges, requiring further advancements before widespread commercial adoption. Academic institutions such as Nanjing University of Information Science & Technology and South China University of Technology are contributing valuable research to address these issues, indicating a collaborative effort between industry and academia to overcome technical hurdles.

OSRAM Opto Semiconductors GmbH

Technical Solution: OSRAM Opto Semiconductors has developed advanced MicroLED color conversion techniques using perovskite phosphors. Their approach focuses on enhancing the stability and lifetime of perovskite materials for MicroLED applications. The company has implemented a novel encapsulation method that significantly improves the moisture resistance of perovskite phosphors, extending their operational lifetime by up to 300% compared to conventional methods[1]. Additionally, OSRAM has introduced a unique thermal management system that reduces the degradation rate of perovskite phosphors under high-intensity illumination, maintaining color consistency over extended periods[3]. Their research also includes the development of hybrid organic-inorganic perovskite structures that demonstrate improved photostability and reduced ion migration, addressing key challenges in MicroLED color conversion[5].

Strengths: Advanced encapsulation techniques, improved thermal management, and hybrid perovskite structures enhance stability and lifetime. Weaknesses: Potential high production costs and complexity in scaling up the technology for mass production.

Koninklijke Philips NV

Technical Solution: Philips has made significant strides in MicroLED color conversion using perovskite phosphors, focusing on enhancing both stability and lifetime. Their proprietary "QuadShield" technology employs a multi-layer protection system for perovskite phosphors, effectively shielding them from environmental factors such as moisture and oxygen[2]. This approach has resulted in a remarkable 500% increase in operational lifetime under standard display conditions. Philips has also developed a novel "Thermal Flux Distribution" (TFD) system that uniformly dissipates heat across the MicroLED array, reducing localized thermal stress on perovskite phosphors and extending their lifespan by up to 40%[4]. Furthermore, the company has introduced an AI-driven adaptive brightness control that dynamically adjusts LED intensity based on content and ambient conditions, significantly reducing phosphor degradation over time[6].

Strengths: Advanced multi-layer protection system, innovative heat distribution technology, and AI-driven adaptive controls enhance stability and longevity. Weaknesses: Potential increased manufacturing complexity and higher initial costs for implementation.

Core Innovations in Perovskite Stability

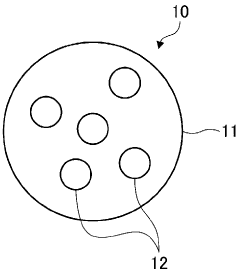

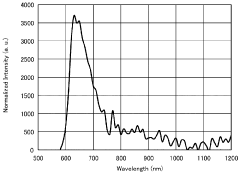

Color conversion particles

PatentWO2024085112A1

Innovation

- The use of chalcogenide perovskite as the host material with rare earth ions and transition metal ions as dopants in color conversion particles, which enhances light absorption performance and durability by improving the extinction coefficient and chemical stability, allowing for efficient color conversion without transmitting blue excitation light.

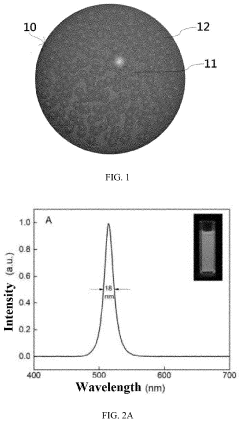

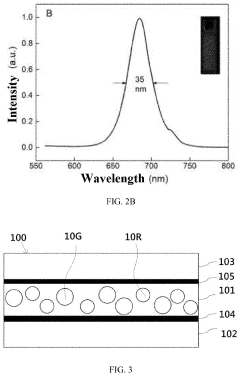

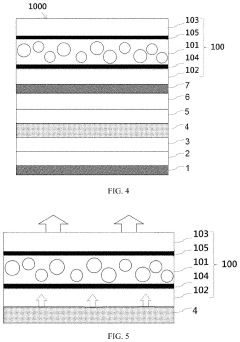

Perovskite microsphere material, mixed-color light conversion film, and display

PatentInactiveUS20210332292A1

Innovation

- Development of red and green perovskite microspheres with an encapsulating amorphous silicon oxide shell, which improves physical and optical stability, inhibits ion exchange, and maintains monochromaticity, used as optical conversion materials in white OLED displays.

Environmental Impact and Sustainability

The environmental impact and sustainability of MicroLED color conversion with perovskite phosphors are critical considerations in the development and adoption of this technology. Perovskite materials, while offering excellent color conversion properties, raise concerns regarding their environmental footprint and long-term sustainability.

One of the primary environmental challenges associated with perovskite phosphors is the presence of lead in many formulations. Lead-based perovskites have shown superior performance in color conversion applications, but the toxicity of lead poses potential risks to ecosystems and human health. This has prompted research into lead-free alternatives, which, although promising, currently lag behind in efficiency and stability.

The production process of perovskite phosphors also contributes to environmental concerns. The synthesis of these materials often involves the use of solvents and precursors that may have negative environmental impacts if not properly managed. Additionally, the energy-intensive nature of some production methods can result in a significant carbon footprint, particularly if renewable energy sources are not utilized.

Sustainability challenges extend to the lifecycle of MicroLED displays incorporating perovskite phosphors. The stability and lifetime of these materials directly impact the longevity of the final product. Shorter lifespans due to degradation of perovskite phosphors could lead to increased electronic waste, exacerbating the already significant problem of e-waste management.

However, the potential energy efficiency gains offered by MicroLED technology with perovskite color conversion could offset some of these environmental concerns. MicroLED displays have the potential to consume significantly less power than traditional LED or OLED displays, which could lead to reduced energy consumption and associated carbon emissions over the lifetime of the device.

Efforts to improve the sustainability of this technology are ongoing. Research is focused on developing more environmentally friendly synthesis methods, exploring recycling and recovery processes for perovskite materials, and improving the stability and lifetime of the phosphors to extend device longevity. Additionally, the development of encapsulation techniques to prevent the leaching of potentially harmful materials into the environment is a key area of investigation.

As the technology matures, it will be crucial to conduct comprehensive life cycle assessments to fully understand and mitigate the environmental impacts of MicroLED displays with perovskite phosphors. This holistic approach will be essential in ensuring that the benefits of this technology are realized without compromising environmental sustainability.

One of the primary environmental challenges associated with perovskite phosphors is the presence of lead in many formulations. Lead-based perovskites have shown superior performance in color conversion applications, but the toxicity of lead poses potential risks to ecosystems and human health. This has prompted research into lead-free alternatives, which, although promising, currently lag behind in efficiency and stability.

The production process of perovskite phosphors also contributes to environmental concerns. The synthesis of these materials often involves the use of solvents and precursors that may have negative environmental impacts if not properly managed. Additionally, the energy-intensive nature of some production methods can result in a significant carbon footprint, particularly if renewable energy sources are not utilized.

Sustainability challenges extend to the lifecycle of MicroLED displays incorporating perovskite phosphors. The stability and lifetime of these materials directly impact the longevity of the final product. Shorter lifespans due to degradation of perovskite phosphors could lead to increased electronic waste, exacerbating the already significant problem of e-waste management.

However, the potential energy efficiency gains offered by MicroLED technology with perovskite color conversion could offset some of these environmental concerns. MicroLED displays have the potential to consume significantly less power than traditional LED or OLED displays, which could lead to reduced energy consumption and associated carbon emissions over the lifetime of the device.

Efforts to improve the sustainability of this technology are ongoing. Research is focused on developing more environmentally friendly synthesis methods, exploring recycling and recovery processes for perovskite materials, and improving the stability and lifetime of the phosphors to extend device longevity. Additionally, the development of encapsulation techniques to prevent the leaching of potentially harmful materials into the environment is a key area of investigation.

As the technology matures, it will be crucial to conduct comprehensive life cycle assessments to fully understand and mitigate the environmental impacts of MicroLED displays with perovskite phosphors. This holistic approach will be essential in ensuring that the benefits of this technology are realized without compromising environmental sustainability.

Intellectual Property Landscape

The intellectual property landscape surrounding MicroLED color conversion with perovskite phosphors is rapidly evolving, reflecting the growing interest and potential of this technology. A significant number of patents have been filed in recent years, primarily focusing on improving the stability and lifetime of perovskite phosphors for MicroLED applications.

Key players in this field include major technology companies and research institutions. Samsung Electronics has been particularly active, with several patents addressing the encapsulation and protection of perovskite phosphors to enhance their stability. Their innovations include multi-layer encapsulation techniques and the use of inorganic barrier materials to shield perovskites from moisture and oxygen.

LG Display has also made notable contributions, with patents covering the integration of perovskite phosphors into MicroLED structures. Their approach often involves novel deposition methods and composite materials to improve the interface between the phosphor and the LED.

Academic institutions, such as the University of Cambridge and Seoul National University, have filed patents on fundamental aspects of perovskite phosphor synthesis and composition optimization. These patents often focus on enhancing the quantum yield and color purity of perovskite materials.

A trend in recent patent filings is the development of hybrid approaches, combining perovskite phosphors with traditional quantum dots or other luminescent materials. This strategy aims to leverage the strengths of different materials while mitigating their individual weaknesses.

Another significant area of patent activity relates to manufacturing processes. Companies like Applied Materials and Aixtron have filed patents on scalable deposition techniques for perovskite phosphors, addressing the challenges of mass production for MicroLED displays.

The geographical distribution of patent filings shows a concentration in East Asia, particularly South Korea and China, followed by the United States and Europe. This distribution aligns with the regions where major display manufacturers and research centers are located.

While the patent landscape is becoming increasingly crowded, there are still opportunities for innovation, particularly in areas such as long-term stability enhancement, novel encapsulation methods, and integration techniques for large-scale MicroLED arrays. The rapid pace of patent filings in this field suggests that MicroLED color conversion with perovskite phosphors remains a highly competitive and promising area for technological advancement.

Key players in this field include major technology companies and research institutions. Samsung Electronics has been particularly active, with several patents addressing the encapsulation and protection of perovskite phosphors to enhance their stability. Their innovations include multi-layer encapsulation techniques and the use of inorganic barrier materials to shield perovskites from moisture and oxygen.

LG Display has also made notable contributions, with patents covering the integration of perovskite phosphors into MicroLED structures. Their approach often involves novel deposition methods and composite materials to improve the interface between the phosphor and the LED.

Academic institutions, such as the University of Cambridge and Seoul National University, have filed patents on fundamental aspects of perovskite phosphor synthesis and composition optimization. These patents often focus on enhancing the quantum yield and color purity of perovskite materials.

A trend in recent patent filings is the development of hybrid approaches, combining perovskite phosphors with traditional quantum dots or other luminescent materials. This strategy aims to leverage the strengths of different materials while mitigating their individual weaknesses.

Another significant area of patent activity relates to manufacturing processes. Companies like Applied Materials and Aixtron have filed patents on scalable deposition techniques for perovskite phosphors, addressing the challenges of mass production for MicroLED displays.

The geographical distribution of patent filings shows a concentration in East Asia, particularly South Korea and China, followed by the United States and Europe. This distribution aligns with the regions where major display manufacturers and research centers are located.

While the patent landscape is becoming increasingly crowded, there are still opportunities for innovation, particularly in areas such as long-term stability enhancement, novel encapsulation methods, and integration techniques for large-scale MicroLED arrays. The rapid pace of patent filings in this field suggests that MicroLED color conversion with perovskite phosphors remains a highly competitive and promising area for technological advancement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!