MicroLED PWM versus current modulation: impact on color shift and HDR accuracy

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MicroLED Modulation Background and Objectives

MicroLED technology has emerged as a promising display solution, offering superior brightness, contrast, and energy efficiency compared to traditional LED and OLED displays. As the industry progresses towards higher resolution and more advanced display capabilities, the modulation techniques used in MicroLED displays have become a critical area of focus.

The primary objective of this technical research is to investigate and compare two key modulation methods for MicroLED displays: Pulse Width Modulation (PWM) and Current Modulation. These techniques are fundamental in controlling the brightness and color output of individual MicroLED pixels, directly impacting the overall display performance, particularly in terms of color accuracy and High Dynamic Range (HDR) capabilities.

PWM has been widely used in LED displays due to its simplicity and effectiveness in controlling brightness levels. It operates by rapidly switching the LED on and off at varying duty cycles to create different perceived brightness levels. However, as display resolutions increase and refresh rates become higher, the limitations of PWM in MicroLED applications have become more apparent, particularly in terms of color shift and potential visual artifacts.

Current Modulation, on the other hand, involves directly adjusting the current flowing through the MicroLED to control its brightness. This method offers potential advantages in terms of color stability and reduced flicker, but comes with its own set of challenges, including power efficiency and precise current control at low brightness levels.

The evolution of MicroLED technology has been driven by the demand for superior image quality, energy efficiency, and form factor flexibility in various applications, ranging from smartphones and smartwatches to large-scale displays and augmented reality devices. As such, understanding the implications of different modulation techniques on color shift and HDR accuracy is crucial for advancing MicroLED display technology.

This research aims to provide a comprehensive analysis of how PWM and Current Modulation impact color shift and HDR accuracy in MicroLED displays. By examining these modulation techniques, we seek to identify their respective strengths and limitations, and explore potential hybrid or novel approaches that could optimize MicroLED performance.

The findings from this study will contribute to the ongoing development of MicroLED technology, potentially influencing future display designs and driving innovation in the field. As the display industry continues to push the boundaries of visual fidelity and energy efficiency, the insights gained from this research will be invaluable in shaping the next generation of MicroLED displays and their applications across various consumer and professional markets.

The primary objective of this technical research is to investigate and compare two key modulation methods for MicroLED displays: Pulse Width Modulation (PWM) and Current Modulation. These techniques are fundamental in controlling the brightness and color output of individual MicroLED pixels, directly impacting the overall display performance, particularly in terms of color accuracy and High Dynamic Range (HDR) capabilities.

PWM has been widely used in LED displays due to its simplicity and effectiveness in controlling brightness levels. It operates by rapidly switching the LED on and off at varying duty cycles to create different perceived brightness levels. However, as display resolutions increase and refresh rates become higher, the limitations of PWM in MicroLED applications have become more apparent, particularly in terms of color shift and potential visual artifacts.

Current Modulation, on the other hand, involves directly adjusting the current flowing through the MicroLED to control its brightness. This method offers potential advantages in terms of color stability and reduced flicker, but comes with its own set of challenges, including power efficiency and precise current control at low brightness levels.

The evolution of MicroLED technology has been driven by the demand for superior image quality, energy efficiency, and form factor flexibility in various applications, ranging from smartphones and smartwatches to large-scale displays and augmented reality devices. As such, understanding the implications of different modulation techniques on color shift and HDR accuracy is crucial for advancing MicroLED display technology.

This research aims to provide a comprehensive analysis of how PWM and Current Modulation impact color shift and HDR accuracy in MicroLED displays. By examining these modulation techniques, we seek to identify their respective strengths and limitations, and explore potential hybrid or novel approaches that could optimize MicroLED performance.

The findings from this study will contribute to the ongoing development of MicroLED technology, potentially influencing future display designs and driving innovation in the field. As the display industry continues to push the boundaries of visual fidelity and energy efficiency, the insights gained from this research will be invaluable in shaping the next generation of MicroLED displays and their applications across various consumer and professional markets.

Market Demand for HDR and Color Accuracy

The demand for High Dynamic Range (HDR) and color accuracy in display technologies has been steadily increasing across various market segments. This growth is primarily driven by the entertainment industry, professional content creation, and consumer electronics. In the entertainment sector, streaming platforms and content producers are continuously pushing for higher quality visual experiences, making HDR and accurate color reproduction essential features for modern displays.

The professional content creation market, including film production, photography, and graphic design, requires displays with exceptional color accuracy and HDR capabilities to ensure precise color grading and image editing. This demand has led to the development of specialized monitors and display technologies that can accurately represent a wide color gamut and high contrast ratios.

Consumer electronics, particularly in the high-end smartphone and television markets, have seen a significant uptick in demand for HDR and color-accurate displays. Consumers are becoming more discerning about display quality, expecting vibrant, lifelike colors and enhanced contrast in their viewing experiences. This trend has prompted manufacturers to invest heavily in advanced display technologies, including MicroLED, which offers the potential for superior HDR performance and color accuracy.

The automotive industry is another emerging market for HDR and color-accurate displays. As in-vehicle infotainment systems become more sophisticated and autonomous driving technologies advance, there is a growing need for high-quality displays that can provide clear, accurate information in various lighting conditions.

Market research indicates that the global HDR TV market is expected to grow significantly in the coming years, with consumers showing a willingness to pay premium prices for displays with superior HDR capabilities. Similarly, the demand for color-accurate displays in the professional market is projected to increase, driven by the growing adoption of 4K and 8K content creation workflows.

The rise of virtual and augmented reality technologies is also contributing to the demand for HDR and color-accurate displays. These immersive experiences require displays that can deliver high contrast ratios and precise color reproduction to create convincing and comfortable visual environments for users.

As the market demand for HDR and color accuracy continues to grow, display manufacturers are exploring various technologies to meet these requirements. The comparison between MicroLED PWM and current modulation techniques for achieving HDR and color accuracy becomes increasingly relevant in this context, as manufacturers seek to optimize display performance while addressing challenges such as color shift and maintaining HDR accuracy across different brightness levels.

The professional content creation market, including film production, photography, and graphic design, requires displays with exceptional color accuracy and HDR capabilities to ensure precise color grading and image editing. This demand has led to the development of specialized monitors and display technologies that can accurately represent a wide color gamut and high contrast ratios.

Consumer electronics, particularly in the high-end smartphone and television markets, have seen a significant uptick in demand for HDR and color-accurate displays. Consumers are becoming more discerning about display quality, expecting vibrant, lifelike colors and enhanced contrast in their viewing experiences. This trend has prompted manufacturers to invest heavily in advanced display technologies, including MicroLED, which offers the potential for superior HDR performance and color accuracy.

The automotive industry is another emerging market for HDR and color-accurate displays. As in-vehicle infotainment systems become more sophisticated and autonomous driving technologies advance, there is a growing need for high-quality displays that can provide clear, accurate information in various lighting conditions.

Market research indicates that the global HDR TV market is expected to grow significantly in the coming years, with consumers showing a willingness to pay premium prices for displays with superior HDR capabilities. Similarly, the demand for color-accurate displays in the professional market is projected to increase, driven by the growing adoption of 4K and 8K content creation workflows.

The rise of virtual and augmented reality technologies is also contributing to the demand for HDR and color-accurate displays. These immersive experiences require displays that can deliver high contrast ratios and precise color reproduction to create convincing and comfortable visual environments for users.

As the market demand for HDR and color accuracy continues to grow, display manufacturers are exploring various technologies to meet these requirements. The comparison between MicroLED PWM and current modulation techniques for achieving HDR and color accuracy becomes increasingly relevant in this context, as manufacturers seek to optimize display performance while addressing challenges such as color shift and maintaining HDR accuracy across different brightness levels.

PWM vs Current Modulation: Technical Challenges

The technical challenges associated with PWM (Pulse Width Modulation) and current modulation in MicroLED displays primarily revolve around their impact on color shift and HDR (High Dynamic Range) accuracy. These two modulation techniques present distinct advantages and drawbacks, each with its own set of technical hurdles to overcome.

PWM, widely used in LED displays, faces challenges in maintaining color accuracy across different brightness levels. As the duty cycle of the PWM signal changes to adjust brightness, it can lead to perceptible color shifts, especially at lower brightness levels. This phenomenon is particularly problematic in HDR content, where accurate color reproduction across a wide range of luminance levels is crucial.

Furthermore, PWM can introduce visible flickering at low frequencies, which may cause eye strain and discomfort for some viewers. Increasing the PWM frequency to mitigate this issue can lead to increased power consumption and potential electromagnetic interference (EMI) problems, presenting additional technical challenges for display designers.

Current modulation, on the other hand, offers smoother brightness control and potentially better color consistency across different luminance levels. However, it faces its own set of technical challenges. One of the primary issues is the non-linear relationship between current and light output in LEDs, which can make precise brightness control difficult, especially at lower current levels.

Additionally, current modulation can lead to changes in the emission spectrum of the LEDs as the current varies, potentially causing color shifts. This effect is particularly pronounced in blue LEDs, which are crucial components in most MicroLED displays. Compensating for these spectral shifts requires sophisticated color management algorithms and potentially additional hardware, increasing the complexity and cost of the display system.

Another significant challenge for current modulation is power efficiency. Unlike PWM, where the LED is either fully on or off, current modulation requires the LED to operate in intermediate states, which can be less energy-efficient. This inefficiency can lead to increased power consumption and heat generation, potentially affecting the longevity and reliability of the MicroLED display.

Both modulation techniques also face challenges in achieving the extreme contrast ratios required for true HDR performance. PWM struggles with accurately representing very low brightness levels due to the limitations of minimum pulse width, while current modulation may introduce noise and instability at very low current levels.

Addressing these technical challenges requires a multifaceted approach, combining advancements in LED manufacturing, driver circuitry design, and sophisticated control algorithms. Hybrid solutions that leverage the strengths of both PWM and current modulation are being explored to mitigate their respective drawbacks and achieve optimal performance in MicroLED displays.

PWM, widely used in LED displays, faces challenges in maintaining color accuracy across different brightness levels. As the duty cycle of the PWM signal changes to adjust brightness, it can lead to perceptible color shifts, especially at lower brightness levels. This phenomenon is particularly problematic in HDR content, where accurate color reproduction across a wide range of luminance levels is crucial.

Furthermore, PWM can introduce visible flickering at low frequencies, which may cause eye strain and discomfort for some viewers. Increasing the PWM frequency to mitigate this issue can lead to increased power consumption and potential electromagnetic interference (EMI) problems, presenting additional technical challenges for display designers.

Current modulation, on the other hand, offers smoother brightness control and potentially better color consistency across different luminance levels. However, it faces its own set of technical challenges. One of the primary issues is the non-linear relationship between current and light output in LEDs, which can make precise brightness control difficult, especially at lower current levels.

Additionally, current modulation can lead to changes in the emission spectrum of the LEDs as the current varies, potentially causing color shifts. This effect is particularly pronounced in blue LEDs, which are crucial components in most MicroLED displays. Compensating for these spectral shifts requires sophisticated color management algorithms and potentially additional hardware, increasing the complexity and cost of the display system.

Another significant challenge for current modulation is power efficiency. Unlike PWM, where the LED is either fully on or off, current modulation requires the LED to operate in intermediate states, which can be less energy-efficient. This inefficiency can lead to increased power consumption and heat generation, potentially affecting the longevity and reliability of the MicroLED display.

Both modulation techniques also face challenges in achieving the extreme contrast ratios required for true HDR performance. PWM struggles with accurately representing very low brightness levels due to the limitations of minimum pulse width, while current modulation may introduce noise and instability at very low current levels.

Addressing these technical challenges requires a multifaceted approach, combining advancements in LED manufacturing, driver circuitry design, and sophisticated control algorithms. Hybrid solutions that leverage the strengths of both PWM and current modulation are being explored to mitigate their respective drawbacks and achieve optimal performance in MicroLED displays.

Current Solutions for Color Shift Mitigation

01 Color shift compensation in MicroLED displays

Techniques for compensating color shift in MicroLED displays involve analyzing and adjusting the output of individual LED elements. This may include real-time monitoring of color output, applying correction factors, and using advanced algorithms to maintain color accuracy across the display, especially important for HDR content.- Color shift compensation in MicroLED displays: Techniques for compensating color shift in MicroLED displays involve adjusting the driving signals or implementing correction algorithms to maintain color accuracy across different viewing angles. This may include pixel-level calibration and real-time adjustment based on viewing conditions to ensure consistent color reproduction.

- HDR accuracy enhancement for MicroLED displays: Methods to improve HDR accuracy in MicroLED displays focus on expanding the dynamic range and color gamut. This involves optimizing the light emission characteristics of individual LEDs, implementing advanced local dimming techniques, and utilizing sophisticated image processing algorithms to preserve detail in both bright and dark areas of the image.

- Color management and calibration for MicroLED displays: Advanced color management systems for MicroLED displays involve precise calibration of individual LED elements, color space conversion, and gamut mapping techniques. These systems aim to achieve accurate color reproduction across different content types and ensure consistency between multiple display units.

- Pixel structure and driving methods for improved color performance: Innovative pixel structures and driving methods for MicroLED displays are designed to enhance color performance and reduce color shift. These may include novel subpixel arrangements, pulse-width modulation techniques, and current control methods to achieve better color uniformity and accuracy.

- Image processing techniques for HDR and color accuracy: Advanced image processing algorithms are developed to optimize HDR content display and maintain color accuracy on MicroLED screens. These techniques may include tone mapping, color space conversion, and adaptive content analysis to ensure optimal representation of HDR content while preserving color fidelity.

02 HDR accuracy improvement for MicroLED displays

Methods to enhance HDR accuracy in MicroLED displays focus on optimizing the dynamic range and color gamut. This involves precise control of LED brightness levels, implementing local dimming techniques, and utilizing advanced color management systems to ensure accurate representation of HDR content.Expand Specific Solutions03 Calibration techniques for MicroLED displays

Calibration methods for MicroLED displays aim to maintain color consistency and accuracy. These may include factory calibration processes, in-field recalibration techniques, and the use of sensors to detect and correct color variations over time, ensuring long-term HDR accuracy and minimizing color shift.Expand Specific Solutions04 Advanced image processing for MicroLED HDR displays

Sophisticated image processing algorithms are developed to enhance HDR performance in MicroLED displays. These may include tone mapping techniques, color space conversion methods, and adaptive content analysis to optimize the display output for different types of HDR content, reducing color shift and improving overall accuracy.Expand Specific Solutions05 MicroLED driver circuitry for improved color and HDR performance

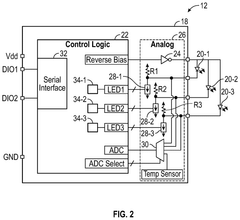

Specialized driver circuits are designed for MicroLED displays to enhance color stability and HDR accuracy. These circuits may incorporate features such as precise current control, temperature compensation, and feedback mechanisms to maintain consistent LED performance across different brightness levels and over the lifespan of the display.Expand Specific Solutions

Key Players in MicroLED Display Industry

The MicroLED PWM versus current modulation technology landscape is in a competitive and rapidly evolving phase. The market is experiencing significant growth, driven by increasing demand for high-quality displays in various applications. Major players like Samsung Electronics, BOE Technology, and Sharp are investing heavily in research and development to advance this technology. The market is characterized by a mix of established electronics giants and specialized display technology firms, indicating a diverse competitive landscape. While the technology is progressing, it's not yet fully mature, with companies like Texas Instruments and NXP Semiconductors contributing to ongoing innovations in driver technologies. The race to achieve optimal color shift management and HDR accuracy is intensifying, with firms like Dolby Laboratories and Semiconductor Energy Laboratory pushing the boundaries of display performance.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced MicroLED technology utilizing both PWM and current modulation techniques. Their approach combines high-frequency PWM with precise current control to achieve superior color accuracy and HDR performance. Samsung's MicroLED displays employ a hybrid driving method that dynamically switches between PWM and current modulation based on brightness levels and color requirements[1]. This adaptive system minimizes color shift across the luminance range while maintaining high contrast ratios. Additionally, Samsung has implemented advanced color management algorithms that compensate for potential shifts caused by different driving methods, ensuring consistent color reproduction across various content types[2].

Strengths: Excellent color accuracy, high contrast ratios, and advanced color management. Weaknesses: Complexity of implementation and potential cost implications for mass production.

Beijing BOE Optoelectronics Technology Co., Ltd.

Technical Solution: BOE has developed a proprietary MicroLED driving technology that addresses the challenges of color shift and HDR accuracy. Their approach utilizes a multi-level current modulation technique combined with adaptive PWM control. This system allows for fine-grained brightness adjustment while minimizing color distortion across different luminance levels. BOE's technology incorporates a real-time color compensation algorithm that continuously adjusts the driving parameters based on the displayed content and ambient lighting conditions[3]. Furthermore, BOE has implemented an advanced calibration process during manufacturing to ensure each MicroLED pixel maintains consistent color performance throughout its lifespan[4].

Strengths: Fine-grained brightness control, real-time color compensation, and long-term color consistency. Weaknesses: Potential power consumption issues at high brightness levels and complexity in mass production.

Core Innovations in MicroLED Modulation

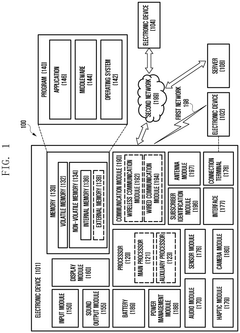

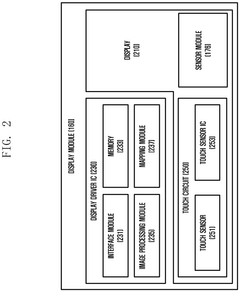

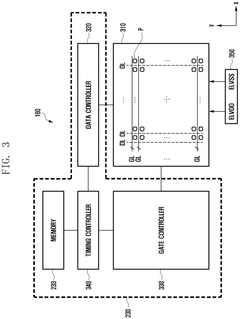

Electronic device, and operation method therefor

PatentPendingEP4506932A1

Innovation

- Incorporating a pulse width modulation (PWM) signal generation circuit in the driving circuit to control the luminance of micro LEDs or OLEDs using a PWM scheme, preventing color changes with grayscale.

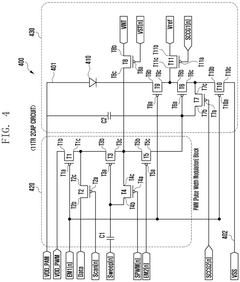

Light-emitting diode packages with varying current pulse width modulation and related methods

PatentPendingUS20250081307A1

Innovation

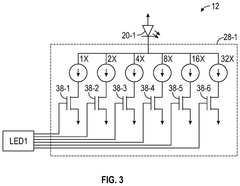

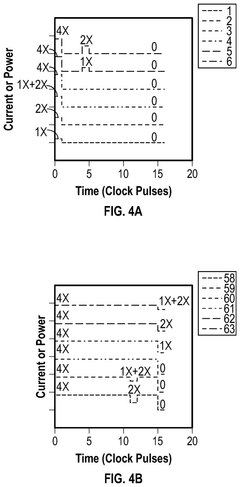

- The implementation of LED packages with multiple current sources at different levels for each LED chip, allowing for varying current pulse width modulation (PWM) signals. This configuration enables increased dynamic range by providing more non-zero PWM levels without increasing PWM clock frequency.

Power Efficiency Considerations

Power efficiency is a critical consideration in the implementation of MicroLED displays, particularly when comparing PWM (Pulse Width Modulation) and current modulation techniques for controlling brightness and color. The choice between these two methods can significantly impact the overall power consumption of the display system.

PWM modulation operates by rapidly switching the LEDs on and off at a fixed current level, with the duty cycle determining the perceived brightness. This approach offers excellent linearity and precision in brightness control. However, PWM can be less power-efficient at lower brightness levels, as the LEDs are driven at full current during their on-time, regardless of the desired brightness.

In contrast, current modulation directly adjusts the current flowing through the LEDs to control brightness. This method can potentially offer better power efficiency, especially at lower brightness levels, as the current is reduced proportionally to the desired output. However, current modulation may face challenges in maintaining color accuracy across the full brightness range due to potential shifts in the LED's emission spectrum at different current levels.

The impact on power efficiency becomes particularly pronounced when considering HDR (High Dynamic Range) content. HDR displays require a wide range of brightness levels, from very low to very high. PWM modulation may struggle to maintain efficiency at the lower end of this range, potentially leading to increased power consumption. Current modulation, while potentially more efficient at lower brightness levels, may require more complex driver circuitry to maintain precise control over a wide current range.

The choice between PWM and current modulation also affects the design of power supply and driver circuits. PWM typically requires faster switching capabilities but can use simpler driver designs. Current modulation may allow for slower switching but necessitates more sophisticated current control circuitry. These differences can impact the overall power efficiency of the display system beyond just the LED power consumption.

Thermal management is another crucial factor influenced by the modulation technique. PWM's rapid switching can lead to increased electromagnetic interference (EMI) and potentially higher thermal loads due to switching losses. Current modulation may offer advantages in thermal management, particularly at lower brightness levels, potentially reducing the need for extensive cooling solutions.

In conclusion, the selection between PWM and current modulation for MicroLED displays involves a complex balance of power efficiency, color accuracy, and system design considerations. The optimal choice may depend on the specific application requirements, target market, and the particular characteristics of the MicroLED technology being employed.

PWM modulation operates by rapidly switching the LEDs on and off at a fixed current level, with the duty cycle determining the perceived brightness. This approach offers excellent linearity and precision in brightness control. However, PWM can be less power-efficient at lower brightness levels, as the LEDs are driven at full current during their on-time, regardless of the desired brightness.

In contrast, current modulation directly adjusts the current flowing through the LEDs to control brightness. This method can potentially offer better power efficiency, especially at lower brightness levels, as the current is reduced proportionally to the desired output. However, current modulation may face challenges in maintaining color accuracy across the full brightness range due to potential shifts in the LED's emission spectrum at different current levels.

The impact on power efficiency becomes particularly pronounced when considering HDR (High Dynamic Range) content. HDR displays require a wide range of brightness levels, from very low to very high. PWM modulation may struggle to maintain efficiency at the lower end of this range, potentially leading to increased power consumption. Current modulation, while potentially more efficient at lower brightness levels, may require more complex driver circuitry to maintain precise control over a wide current range.

The choice between PWM and current modulation also affects the design of power supply and driver circuits. PWM typically requires faster switching capabilities but can use simpler driver designs. Current modulation may allow for slower switching but necessitates more sophisticated current control circuitry. These differences can impact the overall power efficiency of the display system beyond just the LED power consumption.

Thermal management is another crucial factor influenced by the modulation technique. PWM's rapid switching can lead to increased electromagnetic interference (EMI) and potentially higher thermal loads due to switching losses. Current modulation may offer advantages in thermal management, particularly at lower brightness levels, potentially reducing the need for extensive cooling solutions.

In conclusion, the selection between PWM and current modulation for MicroLED displays involves a complex balance of power efficiency, color accuracy, and system design considerations. The optimal choice may depend on the specific application requirements, target market, and the particular characteristics of the MicroLED technology being employed.

Standardization Efforts for MicroLED Displays

The standardization efforts for MicroLED displays are gaining momentum as the technology matures and approaches widespread commercial adoption. Several industry organizations and consortia are working to establish common standards and specifications for MicroLED displays, aiming to ensure interoperability, quality, and consistency across different manufacturers and applications.

One of the key areas of focus for standardization is the color performance and accuracy of MicroLED displays. The International Committee for Display Metrology (ICDM) is developing measurement standards specifically tailored to MicroLED technology, addressing the unique challenges posed by the ultra-high brightness and wide color gamut capabilities of these displays. These standards will help ensure consistent color reproduction and calibration across different MicroLED implementations.

Another important aspect of standardization efforts is the development of common interfaces and protocols for driving MicroLED displays. The Video Electronics Standards Association (VESA) is working on extending its DisplayPort and Embedded DisplayPort (eDP) standards to accommodate the high data rates and unique requirements of MicroLED displays, particularly in the context of high dynamic range (HDR) content delivery.

The Society for Information Display (SID) has established a special interest group focused on MicroLED technology, which is actively working on defining terminology, measurement methods, and performance metrics specific to MicroLED displays. This effort aims to create a common language and set of benchmarks for the industry, facilitating comparisons between different MicroLED solutions and accelerating technology development.

In the realm of manufacturing and quality control, the IEEE is developing standards for MicroLED fabrication processes and testing procedures. These standards will help ensure consistency in production and enable more efficient supply chain management as the MicroLED ecosystem expands.

The International Electrotechnical Commission (IEC) is also contributing to MicroLED standardization efforts, particularly in the areas of safety and electromagnetic compatibility. As MicroLED displays find applications in automotive, aerospace, and medical fields, robust safety standards become increasingly critical.

While these standardization efforts are still in progress, they represent a crucial step towards the widespread adoption of MicroLED technology. By establishing common ground for manufacturers, developers, and end-users, these standards will help drive innovation, reduce costs, and ensure the long-term viability of MicroLED displays across various industries and applications.

One of the key areas of focus for standardization is the color performance and accuracy of MicroLED displays. The International Committee for Display Metrology (ICDM) is developing measurement standards specifically tailored to MicroLED technology, addressing the unique challenges posed by the ultra-high brightness and wide color gamut capabilities of these displays. These standards will help ensure consistent color reproduction and calibration across different MicroLED implementations.

Another important aspect of standardization efforts is the development of common interfaces and protocols for driving MicroLED displays. The Video Electronics Standards Association (VESA) is working on extending its DisplayPort and Embedded DisplayPort (eDP) standards to accommodate the high data rates and unique requirements of MicroLED displays, particularly in the context of high dynamic range (HDR) content delivery.

The Society for Information Display (SID) has established a special interest group focused on MicroLED technology, which is actively working on defining terminology, measurement methods, and performance metrics specific to MicroLED displays. This effort aims to create a common language and set of benchmarks for the industry, facilitating comparisons between different MicroLED solutions and accelerating technology development.

In the realm of manufacturing and quality control, the IEEE is developing standards for MicroLED fabrication processes and testing procedures. These standards will help ensure consistency in production and enable more efficient supply chain management as the MicroLED ecosystem expands.

The International Electrotechnical Commission (IEC) is also contributing to MicroLED standardization efforts, particularly in the areas of safety and electromagnetic compatibility. As MicroLED displays find applications in automotive, aerospace, and medical fields, robust safety standards become increasingly critical.

While these standardization efforts are still in progress, they represent a crucial step towards the widespread adoption of MicroLED technology. By establishing common ground for manufacturers, developers, and end-users, these standards will help drive innovation, reduce costs, and ensure the long-term viability of MicroLED displays across various industries and applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!