MicroLED encapsulation and moisture ingress control for long-life wearable displays

AUG 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MicroLED Encapsulation Background and Objectives

MicroLED technology has emerged as a promising solution for next-generation displays, offering superior brightness, contrast, and energy efficiency compared to traditional LED and OLED technologies. The development of MicroLED displays for wearable devices has gained significant attention due to their potential to revolutionize the smartwatch and augmented reality (AR) markets. However, the miniaturization of LEDs to micro-scale dimensions presents unique challenges, particularly in terms of encapsulation and moisture protection.

The primary objective of this research is to explore and develop advanced encapsulation techniques for MicroLED displays, specifically tailored for long-life wearable applications. This involves investigating innovative materials and processes that can effectively protect the sensitive MicroLED components from environmental factors, with a particular focus on moisture ingress control.

Historically, LED encapsulation has evolved from simple epoxy resins to more sophisticated multi-layer structures. The transition to MicroLED technology necessitates a paradigm shift in encapsulation strategies due to the drastically reduced size of individual LED elements and the increased density of these elements in display panels. Traditional encapsulation methods often prove inadequate for MicroLED displays, especially in the context of wearable devices that are subjected to constant environmental stresses.

The technological trajectory in this field is moving towards ultra-thin, flexible, and highly impermeable encapsulation solutions. Recent advancements in atomic layer deposition (ALD) and chemical vapor deposition (CVD) techniques have opened new avenues for creating nanoscale barrier layers with exceptional moisture resistance. Additionally, the integration of novel 2D materials, such as graphene and hexagonal boron nitride, is being explored for their potential to provide atomically thin yet highly effective moisture barriers.

A critical aspect of this research is to address the unique requirements of wearable displays, including flexibility, durability, and long-term reliability under various environmental conditions. The encapsulation solution must not only protect against moisture but also maintain optical transparency, thermal stability, and mechanical flexibility. Furthermore, it should be compatible with existing MicroLED fabrication processes and scalable for mass production.

The successful development of advanced encapsulation techniques for MicroLED wearable displays is expected to significantly extend the lifespan of these devices, enhance their performance in diverse environments, and potentially enable new form factors and applications in the wearable technology sector. This research aims to contribute to the broader goal of establishing MicroLED technology as the dominant display solution for next-generation wearable devices, offering unparalleled visual quality and energy efficiency in compact, durable form factors.

The primary objective of this research is to explore and develop advanced encapsulation techniques for MicroLED displays, specifically tailored for long-life wearable applications. This involves investigating innovative materials and processes that can effectively protect the sensitive MicroLED components from environmental factors, with a particular focus on moisture ingress control.

Historically, LED encapsulation has evolved from simple epoxy resins to more sophisticated multi-layer structures. The transition to MicroLED technology necessitates a paradigm shift in encapsulation strategies due to the drastically reduced size of individual LED elements and the increased density of these elements in display panels. Traditional encapsulation methods often prove inadequate for MicroLED displays, especially in the context of wearable devices that are subjected to constant environmental stresses.

The technological trajectory in this field is moving towards ultra-thin, flexible, and highly impermeable encapsulation solutions. Recent advancements in atomic layer deposition (ALD) and chemical vapor deposition (CVD) techniques have opened new avenues for creating nanoscale barrier layers with exceptional moisture resistance. Additionally, the integration of novel 2D materials, such as graphene and hexagonal boron nitride, is being explored for their potential to provide atomically thin yet highly effective moisture barriers.

A critical aspect of this research is to address the unique requirements of wearable displays, including flexibility, durability, and long-term reliability under various environmental conditions. The encapsulation solution must not only protect against moisture but also maintain optical transparency, thermal stability, and mechanical flexibility. Furthermore, it should be compatible with existing MicroLED fabrication processes and scalable for mass production.

The successful development of advanced encapsulation techniques for MicroLED wearable displays is expected to significantly extend the lifespan of these devices, enhance their performance in diverse environments, and potentially enable new form factors and applications in the wearable technology sector. This research aims to contribute to the broader goal of establishing MicroLED technology as the dominant display solution for next-generation wearable devices, offering unparalleled visual quality and energy efficiency in compact, durable form factors.

Market Analysis for Durable Wearable Displays

The market for durable wearable displays, particularly those utilizing MicroLED technology with advanced encapsulation and moisture ingress control, is experiencing significant growth and transformation. This segment is driven by the increasing demand for long-lasting, high-performance wearable devices across various industries, including consumer electronics, healthcare, and industrial applications.

The global wearable display market is projected to expand rapidly in the coming years, with MicroLED displays emerging as a key technology. The need for durable displays in wearable devices stems from the growing consumer expectation for longer-lasting, more reliable products that can withstand daily wear and environmental factors. This demand is particularly strong in the smartwatch and fitness tracker segments, where devices are exposed to sweat, water, and frequent use.

In the healthcare sector, there is a rising demand for wearable displays in medical monitoring devices and augmented reality (AR) systems for surgical applications. These devices require displays that can maintain performance and integrity over extended periods, even in challenging environments. The industrial sector also shows increasing interest in durable wearable displays for applications such as heads-up displays in manufacturing and maintenance operations.

The market for MicroLED-based wearable displays is still in its early stages but is expected to grow significantly. This growth is driven by the technology's advantages in brightness, energy efficiency, and potential for miniaturization. However, the high cost of production and technical challenges in mass manufacturing currently limit widespread adoption.

Consumer preferences are shifting towards devices with longer lifespans and better durability, aligning well with the benefits offered by advanced encapsulation and moisture ingress control in MicroLED displays. This trend is likely to accelerate as environmental concerns and sustainability become more prominent factors in consumer purchasing decisions.

The Asia-Pacific region is expected to be a major growth driver for the durable wearable display market, with countries like China, South Korea, and Japan leading in both production and consumption. North America and Europe also represent significant markets, particularly for high-end wearable devices in consumer and professional applications.

Key challenges in the market include reducing production costs, improving yield rates in manufacturing, and addressing technical issues related to long-term reliability. Overcoming these challenges will be crucial for wider market penetration and adoption of MicroLED technology in wearable displays.

The global wearable display market is projected to expand rapidly in the coming years, with MicroLED displays emerging as a key technology. The need for durable displays in wearable devices stems from the growing consumer expectation for longer-lasting, more reliable products that can withstand daily wear and environmental factors. This demand is particularly strong in the smartwatch and fitness tracker segments, where devices are exposed to sweat, water, and frequent use.

In the healthcare sector, there is a rising demand for wearable displays in medical monitoring devices and augmented reality (AR) systems for surgical applications. These devices require displays that can maintain performance and integrity over extended periods, even in challenging environments. The industrial sector also shows increasing interest in durable wearable displays for applications such as heads-up displays in manufacturing and maintenance operations.

The market for MicroLED-based wearable displays is still in its early stages but is expected to grow significantly. This growth is driven by the technology's advantages in brightness, energy efficiency, and potential for miniaturization. However, the high cost of production and technical challenges in mass manufacturing currently limit widespread adoption.

Consumer preferences are shifting towards devices with longer lifespans and better durability, aligning well with the benefits offered by advanced encapsulation and moisture ingress control in MicroLED displays. This trend is likely to accelerate as environmental concerns and sustainability become more prominent factors in consumer purchasing decisions.

The Asia-Pacific region is expected to be a major growth driver for the durable wearable display market, with countries like China, South Korea, and Japan leading in both production and consumption. North America and Europe also represent significant markets, particularly for high-end wearable devices in consumer and professional applications.

Key challenges in the market include reducing production costs, improving yield rates in manufacturing, and addressing technical issues related to long-term reliability. Overcoming these challenges will be crucial for wider market penetration and adoption of MicroLED technology in wearable displays.

Current Challenges in MicroLED Moisture Protection

MicroLED technology has emerged as a promising solution for next-generation displays, particularly in wearable devices. However, the long-term reliability of these displays is significantly challenged by moisture ingress, which can lead to device degradation and failure. The current challenges in MicroLED moisture protection are multifaceted and require innovative solutions to ensure the longevity of wearable displays.

One of the primary challenges is the development of effective encapsulation materials and techniques. Traditional encapsulation methods used in OLED displays are often inadequate for MicroLEDs due to their unique structure and operating conditions. The nanoscale size of MicroLEDs makes them particularly susceptible to moisture penetration, necessitating the development of ultra-thin, highly impermeable barrier layers that can conform to the complex topography of MicroLED arrays without compromising their optical performance.

Another significant challenge lies in the integration of moisture barriers with other functional layers in the display stack. The moisture protection layer must be compatible with the underlying MicroLED structure and subsequent layers, such as color conversion materials and optical elements. This integration must be achieved without introducing additional stress or defects that could compromise the display's performance or lifetime.

The dynamic nature of wearable devices poses additional challenges for moisture protection. Frequent bending, stretching, and exposure to varying environmental conditions can lead to mechanical stress and potential failure points in the encapsulation layer. Developing flexible, durable moisture barriers that can withstand these mechanical stresses while maintaining their protective properties is a critical area of research.

Temperature fluctuations in wearable devices also present a significant challenge for moisture protection. The thermal cycling experienced during device operation can lead to expansion and contraction of materials, potentially creating pathways for moisture ingress. Addressing this issue requires the development of encapsulation materials with matched thermal expansion coefficients and stable properties across a wide temperature range.

Furthermore, the long-term stability of moisture barriers is a crucial concern. Over time, even small amounts of moisture penetration can accumulate and cause device degradation. Developing accelerated testing methods to accurately predict the long-term performance of moisture barriers in real-world conditions is essential for validating new protection strategies.

The miniaturization trend in wearable devices also presents challenges for moisture protection. As devices become thinner and more compact, the available space for protective layers decreases, necessitating the development of ultra-thin, highly effective moisture barriers that do not compromise the form factor of the final product.

Addressing these challenges requires a multidisciplinary approach, combining expertise in materials science, nanotechnology, and device engineering. Innovations in atomic layer deposition techniques, nanocomposite materials, and hybrid organic-inorganic barrier layers are among the promising avenues being explored to overcome the current limitations in MicroLED moisture protection for long-life wearable displays.

One of the primary challenges is the development of effective encapsulation materials and techniques. Traditional encapsulation methods used in OLED displays are often inadequate for MicroLEDs due to their unique structure and operating conditions. The nanoscale size of MicroLEDs makes them particularly susceptible to moisture penetration, necessitating the development of ultra-thin, highly impermeable barrier layers that can conform to the complex topography of MicroLED arrays without compromising their optical performance.

Another significant challenge lies in the integration of moisture barriers with other functional layers in the display stack. The moisture protection layer must be compatible with the underlying MicroLED structure and subsequent layers, such as color conversion materials and optical elements. This integration must be achieved without introducing additional stress or defects that could compromise the display's performance or lifetime.

The dynamic nature of wearable devices poses additional challenges for moisture protection. Frequent bending, stretching, and exposure to varying environmental conditions can lead to mechanical stress and potential failure points in the encapsulation layer. Developing flexible, durable moisture barriers that can withstand these mechanical stresses while maintaining their protective properties is a critical area of research.

Temperature fluctuations in wearable devices also present a significant challenge for moisture protection. The thermal cycling experienced during device operation can lead to expansion and contraction of materials, potentially creating pathways for moisture ingress. Addressing this issue requires the development of encapsulation materials with matched thermal expansion coefficients and stable properties across a wide temperature range.

Furthermore, the long-term stability of moisture barriers is a crucial concern. Over time, even small amounts of moisture penetration can accumulate and cause device degradation. Developing accelerated testing methods to accurately predict the long-term performance of moisture barriers in real-world conditions is essential for validating new protection strategies.

The miniaturization trend in wearable devices also presents challenges for moisture protection. As devices become thinner and more compact, the available space for protective layers decreases, necessitating the development of ultra-thin, highly effective moisture barriers that do not compromise the form factor of the final product.

Addressing these challenges requires a multidisciplinary approach, combining expertise in materials science, nanotechnology, and device engineering. Innovations in atomic layer deposition techniques, nanocomposite materials, and hybrid organic-inorganic barrier layers are among the promising avenues being explored to overcome the current limitations in MicroLED moisture protection for long-life wearable displays.

Existing MicroLED Moisture Ingress Control Solutions

01 Moisture-resistant packaging for MicroLEDs

Developing specialized packaging techniques to protect MicroLEDs from moisture ingress. This includes using moisture-resistant materials and hermetic sealing methods to create a barrier against water vapor, ensuring the longevity and performance of the MicroLED devices.- Moisture-resistant packaging for MicroLEDs: Developing specialized packaging techniques to protect MicroLEDs from moisture ingress. This includes using moisture-resistant materials, hermetic sealing methods, and advanced encapsulation technologies to create a barrier against humidity and water vapor, thereby extending the lifespan and maintaining the performance of MicroLED devices.

- Moisture detection and monitoring systems: Implementing moisture detection and monitoring systems within MicroLED devices or their packaging. These systems can include sensors or indicators that detect the presence of moisture, allowing for early intervention or preventive measures to be taken before damage occurs to the MicroLED components.

- Desiccant integration in MicroLED assemblies: Incorporating desiccant materials into MicroLED assemblies or packaging to absorb any moisture that may penetrate the device. This approach helps maintain a dry environment within the MicroLED package, reducing the risk of moisture-related degradation and extending the operational life of the device.

- Surface treatment and coating technologies: Applying specialized surface treatments or coatings to MicroLED components to enhance their resistance to moisture. These treatments can include hydrophobic coatings, passivation layers, or other moisture-repelling materials that prevent water molecules from interacting with sensitive MicroLED structures.

- Moisture-resistant substrate and interconnect design: Developing moisture-resistant substrates and interconnect designs specifically for MicroLED applications. This involves using materials and structures that are inherently resistant to moisture ingress, as well as optimizing the layout and configuration of MicroLED arrays to minimize exposure to potential moisture sources.

02 Moisture detection systems for MicroLED displays

Implementing moisture detection systems within MicroLED displays to monitor and alert for potential moisture ingress. These systems can use various sensing technologies to detect the presence of moisture before it causes damage to the MicroLED components.Expand Specific Solutions03 Desiccant integration in MicroLED enclosures

Incorporating desiccant materials within MicroLED enclosures to absorb any moisture that may penetrate the packaging. This approach helps maintain a dry environment around the MicroLEDs, reducing the risk of moisture-related failures.Expand Specific Solutions04 Moisture-resistant coatings for MicroLEDs

Applying specialized moisture-resistant coatings directly to MicroLED components or the entire display surface. These coatings create an additional barrier against moisture ingress while maintaining the optical properties of the MicroLEDs.Expand Specific Solutions05 Environmental control systems for MicroLED manufacturing

Implementing advanced environmental control systems in MicroLED manufacturing facilities to minimize moisture exposure during production. This includes controlling humidity levels, using dry air or inert gas environments, and implementing stringent handling procedures to prevent moisture ingress before packaging.Expand Specific Solutions

Key Players in MicroLED and Encapsulation Industry

The research on MicroLED encapsulation and moisture ingress control for long-life wearable displays is in a nascent stage, with the market showing significant growth potential. The technology is still evolving, with major players like Samsung Display, LG Display, and BOE Technology Group leading the development. These companies are investing heavily in R&D to overcome challenges related to moisture protection and longevity. The market size is expected to expand rapidly as wearable technology gains traction across various industries. However, the technology's maturity is still relatively low, with companies like Applied Materials and Corning contributing to advancements in materials and manufacturing processes to improve MicroLED durability and performance in wearable applications.

BOE Technology Group Co., Ltd.

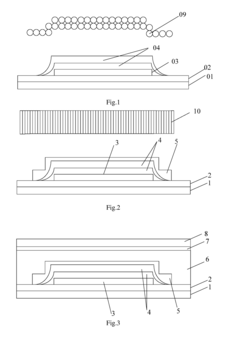

Technical Solution: BOE has developed a comprehensive MicroLED encapsulation solution for wearable displays, focusing on ultra-thin and flexible designs. Their approach utilizes a multi-layer barrier film structure, incorporating alternating inorganic and organic layers to achieve high moisture resistance[9]. BOE's inorganic layers are typically deposited using atomic layer deposition (ALD) for precise thickness control, while organic layers are applied via inkjet printing for cost-effective large-area coverage[10]. To enhance long-term reliability, BOE has implemented a proprietary "self-healing" polymer layer that can repair minor defects in the encapsulation structure[11]. Additionally, the company has developed a novel edge sealing technique using laser-assisted bonding, which creates a hermetic seal around the display perimeter without compromising flexibility[12].

Strengths: Ultra-thin and flexible encapsulation design, innovative "self-healing" polymer layer, and advanced edge sealing technique. Weaknesses: Potential challenges in maintaining consistent barrier performance over large areas and under repeated flexing.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display has developed advanced MicroLED encapsulation techniques for wearable displays, focusing on thin-film encapsulation (TFE) technology. Their approach utilizes a multi-layer structure combining inorganic and organic materials to create an effective moisture barrier[1]. The company has implemented atomic layer deposition (ALD) for precise control of inorganic layer thickness, typically using materials like Al2O3 and SiO2[2]. To enhance moisture resistance, they've incorporated fluorinated organic layers, which have shown superior water vapor transmission rates (WVTR) compared to traditional organic materials[3]. Samsung's encapsulation process also includes a final passivation layer to protect against mechanical stress and environmental factors, crucial for wearable applications[4].

Strengths: Advanced thin-film encapsulation technology, precise layer control through ALD, and use of fluorinated organic materials for enhanced moisture resistance. Weaknesses: Potential complexity in manufacturing process and higher production costs compared to traditional encapsulation methods.

Innovative Encapsulation Materials and Techniques

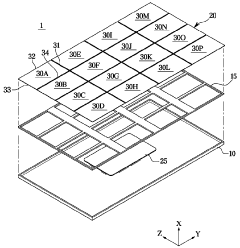

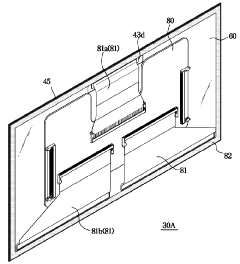

Display device comprising display module, and manufacturing method therefor

PatentWO2023163350A1

Innovation

- A display device and manufacturing method featuring a microLED panel with a moisture-proof design, including a substrate with inorganic light emitting elements, a TFT layer, and a sealing structure that prevents moisture penetration using a water-repellent material and a metal plate, ensuring reliable operation in large formats.

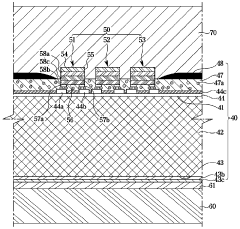

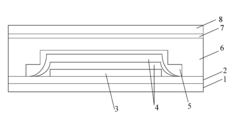

Encapsulation structure, method for encapsulating organic light-emitting diode device, and flexible display device

PatentActiveUS20170084869A1

Innovation

- An encapsulation structure featuring a flexible substrate with a thin film encapsulation layer composed of alternately arranged inorganic and organic polymer films, topped with a second inorganic film having a nanowire structure, which acts as a hydrophobic barrier to prevent moisture ingress, and optionally includes a barrier layer for enhanced protection.

Environmental Impact of Encapsulation Materials

The environmental impact of encapsulation materials used in MicroLED displays for wearable devices is a critical consideration in the development of long-life, sustainable technology. These materials play a crucial role in protecting the sensitive MicroLED components from moisture and other environmental factors, but their production, use, and disposal can have significant ecological implications.

Traditional encapsulation materials often include various polymers and inorganic compounds, which may pose environmental challenges throughout their lifecycle. The production of these materials typically involves energy-intensive processes and the use of potentially harmful chemicals. For instance, the synthesis of certain polymers used in encapsulation can release volatile organic compounds (VOCs) and greenhouse gases, contributing to air pollution and climate change.

During the operational life of wearable displays, the environmental impact of encapsulation materials is generally minimal. However, the durability and effectiveness of these materials directly influence the lifespan of the device. Inadequate encapsulation can lead to premature device failure, resulting in electronic waste and the need for replacement, which in turn increases the overall environmental footprint of the product.

The end-of-life phase presents significant environmental concerns. Many encapsulation materials are not biodegradable and can persist in the environment for extended periods. When wearable displays are discarded, these materials may leach harmful substances into soil and water systems. Additionally, the complex nature of MicroLED displays, with their tightly integrated components, can make recycling and material recovery challenging.

Recent research has focused on developing more environmentally friendly encapsulation solutions. Bio-based polymers and recyclable inorganic materials are being explored as alternatives to traditional petrochemical-based encapsulants. These materials aim to reduce the carbon footprint of production and improve end-of-life recyclability. Some innovative approaches include the use of self-healing materials that can extend device lifespan and reduce the need for premature replacement.

The environmental impact of encapsulation materials also extends to the energy efficiency of the final product. Advanced encapsulation techniques that provide better thermal management can improve the overall energy efficiency of wearable displays, reducing power consumption and extending battery life. This indirect environmental benefit can be significant over the lifetime of the device.

As the demand for wearable displays grows, the importance of sustainable encapsulation solutions becomes increasingly apparent. Manufacturers and researchers are now prioritizing the development of materials that not only provide excellent moisture ingress control but also align with circular economy principles. This shift towards eco-friendly encapsulation is driven by both environmental regulations and consumer demand for more sustainable electronic products.

Traditional encapsulation materials often include various polymers and inorganic compounds, which may pose environmental challenges throughout their lifecycle. The production of these materials typically involves energy-intensive processes and the use of potentially harmful chemicals. For instance, the synthesis of certain polymers used in encapsulation can release volatile organic compounds (VOCs) and greenhouse gases, contributing to air pollution and climate change.

During the operational life of wearable displays, the environmental impact of encapsulation materials is generally minimal. However, the durability and effectiveness of these materials directly influence the lifespan of the device. Inadequate encapsulation can lead to premature device failure, resulting in electronic waste and the need for replacement, which in turn increases the overall environmental footprint of the product.

The end-of-life phase presents significant environmental concerns. Many encapsulation materials are not biodegradable and can persist in the environment for extended periods. When wearable displays are discarded, these materials may leach harmful substances into soil and water systems. Additionally, the complex nature of MicroLED displays, with their tightly integrated components, can make recycling and material recovery challenging.

Recent research has focused on developing more environmentally friendly encapsulation solutions. Bio-based polymers and recyclable inorganic materials are being explored as alternatives to traditional petrochemical-based encapsulants. These materials aim to reduce the carbon footprint of production and improve end-of-life recyclability. Some innovative approaches include the use of self-healing materials that can extend device lifespan and reduce the need for premature replacement.

The environmental impact of encapsulation materials also extends to the energy efficiency of the final product. Advanced encapsulation techniques that provide better thermal management can improve the overall energy efficiency of wearable displays, reducing power consumption and extending battery life. This indirect environmental benefit can be significant over the lifetime of the device.

As the demand for wearable displays grows, the importance of sustainable encapsulation solutions becomes increasingly apparent. Manufacturers and researchers are now prioritizing the development of materials that not only provide excellent moisture ingress control but also align with circular economy principles. This shift towards eco-friendly encapsulation is driven by both environmental regulations and consumer demand for more sustainable electronic products.

Reliability Testing Standards for Wearable Displays

Reliability testing standards for wearable displays are crucial in ensuring the longevity and performance of MicroLED-based devices, particularly in the context of encapsulation and moisture ingress control. These standards encompass a range of rigorous tests designed to simulate real-world conditions and assess the durability of wearable displays.

One of the primary reliability testing standards focuses on environmental stress testing. This includes temperature cycling tests, where displays are subjected to extreme temperature variations to evaluate their resistance to thermal expansion and contraction. Humidity tests are equally important, exposing devices to high moisture levels to assess the effectiveness of encapsulation techniques in preventing moisture ingress.

Mechanical stress testing forms another critical component of reliability standards. Drop tests and vibration tests are conducted to simulate the daily wear and tear experienced by wearable devices. These tests help evaluate the robustness of the MicroLED encapsulation and its ability to maintain integrity under physical stress.

Accelerated life testing is a key methodology employed in reliability standards. This involves subjecting displays to intensified conditions that simulate long-term use in a compressed timeframe. For MicroLED wearable displays, this may include extended operation under varying environmental conditions to assess the long-term effectiveness of moisture barriers and encapsulation techniques.

Optical performance testing is integral to reliability standards for wearable displays. This includes evaluating color stability, brightness uniformity, and contrast ratio over time. These tests are particularly relevant for MicroLED displays, as they help assess the impact of moisture ingress and encapsulation quality on the optical characteristics of the display.

Specific to moisture ingress control, permeation testing is a critical standard. This involves measuring the rate of moisture penetration through the encapsulation layers using specialized equipment. The results of these tests are crucial in validating the effectiveness of moisture barrier technologies employed in MicroLED wearable displays.

Reliability standards also incorporate accelerated weathering tests, which expose displays to simulated outdoor conditions, including UV radiation, temperature fluctuations, and moisture. These tests are particularly relevant for wearable displays that may be used in various outdoor environments.

Electrical stress testing is another important aspect of reliability standards. This includes evaluating the display's performance under various voltage and current conditions, as well as assessing the impact of electrostatic discharge (ESD) on the device's longevity and functionality.

In conclusion, reliability testing standards for wearable displays encompass a comprehensive suite of tests designed to evaluate the robustness, longevity, and performance of MicroLED displays under various environmental and operational conditions. These standards are crucial in advancing the development of long-life wearable displays with effective encapsulation and moisture ingress control.

One of the primary reliability testing standards focuses on environmental stress testing. This includes temperature cycling tests, where displays are subjected to extreme temperature variations to evaluate their resistance to thermal expansion and contraction. Humidity tests are equally important, exposing devices to high moisture levels to assess the effectiveness of encapsulation techniques in preventing moisture ingress.

Mechanical stress testing forms another critical component of reliability standards. Drop tests and vibration tests are conducted to simulate the daily wear and tear experienced by wearable devices. These tests help evaluate the robustness of the MicroLED encapsulation and its ability to maintain integrity under physical stress.

Accelerated life testing is a key methodology employed in reliability standards. This involves subjecting displays to intensified conditions that simulate long-term use in a compressed timeframe. For MicroLED wearable displays, this may include extended operation under varying environmental conditions to assess the long-term effectiveness of moisture barriers and encapsulation techniques.

Optical performance testing is integral to reliability standards for wearable displays. This includes evaluating color stability, brightness uniformity, and contrast ratio over time. These tests are particularly relevant for MicroLED displays, as they help assess the impact of moisture ingress and encapsulation quality on the optical characteristics of the display.

Specific to moisture ingress control, permeation testing is a critical standard. This involves measuring the rate of moisture penetration through the encapsulation layers using specialized equipment. The results of these tests are crucial in validating the effectiveness of moisture barrier technologies employed in MicroLED wearable displays.

Reliability standards also incorporate accelerated weathering tests, which expose displays to simulated outdoor conditions, including UV radiation, temperature fluctuations, and moisture. These tests are particularly relevant for wearable displays that may be used in various outdoor environments.

Electrical stress testing is another important aspect of reliability standards. This includes evaluating the display's performance under various voltage and current conditions, as well as assessing the impact of electrostatic discharge (ESD) on the device's longevity and functionality.

In conclusion, reliability testing standards for wearable displays encompass a comprehensive suite of tests designed to evaluate the robustness, longevity, and performance of MicroLED displays under various environmental and operational conditions. These standards are crucial in advancing the development of long-life wearable displays with effective encapsulation and moisture ingress control.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!