MicroLED thermal management in GaN-on-Si backplanes for automotive clusters

AUG 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MicroLED Thermal Challenges in Automotive Displays

MicroLED displays have emerged as a promising technology for automotive clusters, offering superior brightness, contrast, and energy efficiency compared to traditional display technologies. However, the integration of MicroLED displays in automotive applications presents significant thermal management challenges, particularly when using GaN-on-Si backplanes.

The automotive environment imposes stringent requirements on display performance and reliability. MicroLED displays must maintain consistent performance across a wide range of temperatures, from extreme cold to intense heat, while also withstanding vibrations and other mechanical stresses. The thermal management of these displays is crucial to ensure optimal performance, longevity, and safety in automotive applications.

GaN-on-Si backplanes offer several advantages for MicroLED displays, including cost-effectiveness and scalability. However, they also introduce unique thermal challenges. The thermal conductivity of silicon is lower than that of other substrate materials, such as sapphire or SiC, which can lead to increased heat accumulation in the device. This heat buildup can affect the performance and reliability of the MicroLED display, potentially leading to color shifts, reduced brightness, and shortened lifespan.

One of the primary thermal challenges in MicroLED displays for automotive clusters is the high current density required to achieve the necessary brightness levels. This high current density generates significant heat, which must be efficiently dissipated to prevent thermal runaway and ensure stable operation. The compact nature of automotive clusters further complicates thermal management, as space constraints limit the implementation of traditional cooling solutions.

Another critical thermal challenge is the non-uniform heat distribution across the display. MicroLED displays in automotive clusters often have varying pixel densities and brightness levels in different areas, leading to localized hot spots. These temperature gradients can cause differential thermal expansion, potentially resulting in mechanical stress and display distortion.

The thermal interface between the MicroLED array and the GaN-on-Si backplane is also a critical area of concern. Ensuring efficient heat transfer from the active region to the substrate and ultimately to the heat sink is essential for maintaining optimal operating temperatures. Inadequate thermal management at this interface can lead to reduced efficiency and accelerated degradation of the MicroLED elements.

Furthermore, the automotive environment introduces additional thermal stresses, such as rapid temperature changes and prolonged exposure to high temperatures in parked vehicles. These conditions can exacerbate thermal management challenges and require innovative solutions to ensure the long-term reliability of MicroLED displays in automotive clusters.

Addressing these thermal challenges requires a multifaceted approach, combining advanced materials science, innovative thermal management techniques, and sophisticated system-level design. Researchers and engineers are exploring various strategies, including novel heat spreading materials, advanced thermal interface materials, and active cooling solutions tailored for the automotive environment.

The automotive environment imposes stringent requirements on display performance and reliability. MicroLED displays must maintain consistent performance across a wide range of temperatures, from extreme cold to intense heat, while also withstanding vibrations and other mechanical stresses. The thermal management of these displays is crucial to ensure optimal performance, longevity, and safety in automotive applications.

GaN-on-Si backplanes offer several advantages for MicroLED displays, including cost-effectiveness and scalability. However, they also introduce unique thermal challenges. The thermal conductivity of silicon is lower than that of other substrate materials, such as sapphire or SiC, which can lead to increased heat accumulation in the device. This heat buildup can affect the performance and reliability of the MicroLED display, potentially leading to color shifts, reduced brightness, and shortened lifespan.

One of the primary thermal challenges in MicroLED displays for automotive clusters is the high current density required to achieve the necessary brightness levels. This high current density generates significant heat, which must be efficiently dissipated to prevent thermal runaway and ensure stable operation. The compact nature of automotive clusters further complicates thermal management, as space constraints limit the implementation of traditional cooling solutions.

Another critical thermal challenge is the non-uniform heat distribution across the display. MicroLED displays in automotive clusters often have varying pixel densities and brightness levels in different areas, leading to localized hot spots. These temperature gradients can cause differential thermal expansion, potentially resulting in mechanical stress and display distortion.

The thermal interface between the MicroLED array and the GaN-on-Si backplane is also a critical area of concern. Ensuring efficient heat transfer from the active region to the substrate and ultimately to the heat sink is essential for maintaining optimal operating temperatures. Inadequate thermal management at this interface can lead to reduced efficiency and accelerated degradation of the MicroLED elements.

Furthermore, the automotive environment introduces additional thermal stresses, such as rapid temperature changes and prolonged exposure to high temperatures in parked vehicles. These conditions can exacerbate thermal management challenges and require innovative solutions to ensure the long-term reliability of MicroLED displays in automotive clusters.

Addressing these thermal challenges requires a multifaceted approach, combining advanced materials science, innovative thermal management techniques, and sophisticated system-level design. Researchers and engineers are exploring various strategies, including novel heat spreading materials, advanced thermal interface materials, and active cooling solutions tailored for the automotive environment.

Automotive Cluster Market Demand Analysis

The automotive cluster market is experiencing a significant shift towards advanced digital displays, driven by the increasing demand for connected and intelligent vehicles. This trend is particularly evident in the adoption of MicroLED technology, which offers superior brightness, contrast, and energy efficiency compared to traditional display technologies. The market for automotive clusters is projected to grow substantially in the coming years, with a strong focus on high-quality, customizable, and interactive displays.

Consumer preferences are evolving rapidly, with drivers expecting more sophisticated and informative dashboard displays. This has led to a surge in demand for larger, higher-resolution screens that can provide a wealth of information at a glance. MicroLED displays are well-positioned to meet these requirements, offering excellent visibility even in bright sunlight and the ability to display rich, vibrant colors.

The automotive industry's push towards electrification and autonomous driving is also fueling the demand for advanced cluster displays. Electric vehicles, in particular, require more comprehensive and intuitive interfaces to communicate complex information about battery status, range, and charging options. Similarly, as vehicles become more autonomous, the role of the instrument cluster is expanding to include more advanced driver assistance information and entertainment features.

Safety regulations and the need for improved driver awareness are additional factors driving the market demand for advanced automotive clusters. MicroLED displays can offer better visibility and faster response times, which are crucial for displaying critical safety information and warnings. The ability to present information in a clear, non-distracting manner is becoming increasingly important as vehicles incorporate more sensors and safety systems.

The automotive cluster market is also seeing a trend towards personalization and customization. Drivers are seeking displays that can be tailored to their preferences, with the ability to change layouts, color schemes, and information displayed. MicroLED technology's flexibility in terms of form factor and pixel arrangement makes it an ideal candidate for creating these customizable interfaces.

From a regional perspective, the demand for advanced automotive clusters is particularly strong in developed markets such as North America, Europe, and parts of Asia. However, emerging markets are also showing increased interest as consumer expectations rise and vehicle manufacturers seek to differentiate their products. The global nature of the automotive supply chain means that advancements in cluster technology are quickly disseminating across different markets.

In conclusion, the automotive cluster market is poised for significant growth, driven by technological advancements, changing consumer expectations, and evolving vehicle architectures. The adoption of MicroLED technology in GaN-on-Si backplanes for automotive clusters is well-aligned with these market trends, offering a promising solution to meet the demanding requirements of next-generation vehicles.

Consumer preferences are evolving rapidly, with drivers expecting more sophisticated and informative dashboard displays. This has led to a surge in demand for larger, higher-resolution screens that can provide a wealth of information at a glance. MicroLED displays are well-positioned to meet these requirements, offering excellent visibility even in bright sunlight and the ability to display rich, vibrant colors.

The automotive industry's push towards electrification and autonomous driving is also fueling the demand for advanced cluster displays. Electric vehicles, in particular, require more comprehensive and intuitive interfaces to communicate complex information about battery status, range, and charging options. Similarly, as vehicles become more autonomous, the role of the instrument cluster is expanding to include more advanced driver assistance information and entertainment features.

Safety regulations and the need for improved driver awareness are additional factors driving the market demand for advanced automotive clusters. MicroLED displays can offer better visibility and faster response times, which are crucial for displaying critical safety information and warnings. The ability to present information in a clear, non-distracting manner is becoming increasingly important as vehicles incorporate more sensors and safety systems.

The automotive cluster market is also seeing a trend towards personalization and customization. Drivers are seeking displays that can be tailored to their preferences, with the ability to change layouts, color schemes, and information displayed. MicroLED technology's flexibility in terms of form factor and pixel arrangement makes it an ideal candidate for creating these customizable interfaces.

From a regional perspective, the demand for advanced automotive clusters is particularly strong in developed markets such as North America, Europe, and parts of Asia. However, emerging markets are also showing increased interest as consumer expectations rise and vehicle manufacturers seek to differentiate their products. The global nature of the automotive supply chain means that advancements in cluster technology are quickly disseminating across different markets.

In conclusion, the automotive cluster market is poised for significant growth, driven by technological advancements, changing consumer expectations, and evolving vehicle architectures. The adoption of MicroLED technology in GaN-on-Si backplanes for automotive clusters is well-aligned with these market trends, offering a promising solution to meet the demanding requirements of next-generation vehicles.

GaN-on-Si Backplane Thermal Limitations

GaN-on-Si backplanes have emerged as a promising technology for MicroLED displays in automotive clusters. However, thermal management remains a critical challenge that limits their performance and reliability. The thermal limitations of GaN-on-Si backplanes stem from several factors, including the inherent properties of the materials and the high-power density of MicroLED devices.

One of the primary thermal limitations is the relatively low thermal conductivity of silicon compared to other substrate materials like sapphire or silicon carbide. This characteristic restricts the efficient dissipation of heat generated by the MicroLED devices, leading to localized hot spots and potential thermal runaway. The thermal boundary resistance between the GaN layer and the silicon substrate further exacerbates this issue, impeding heat flow from the active region to the substrate.

The mismatch in coefficient of thermal expansion (CTE) between GaN and silicon introduces additional thermal stress during operation. As the temperature fluctuates, the differential expansion and contraction of these materials can lead to mechanical strain, potentially causing cracks, delamination, or other structural defects that compromise the device's reliability and performance.

High current densities required for MicroLED operation contribute significantly to heat generation. The small size of MicroLED pixels results in concentrated heat sources, making it challenging to distribute and dissipate heat effectively across the backplane. This localized heating can lead to non-uniform temperature distribution, affecting color consistency and overall display performance.

The thermal resistance of the entire device stack, including the GaN-on-Si backplane, MicroLED array, and any additional layers such as color conversion or encapsulation materials, compounds the thermal management challenge. Each interface and layer introduces thermal barriers that must be carefully considered in the overall thermal design.

Automotive environments present additional thermal challenges due to extreme temperature variations and prolonged exposure to high temperatures. The GaN-on-Si backplane must maintain stability and performance across a wide temperature range, typically from -40°C to 125°C for automotive applications. This requirement places further constraints on material selection and thermal management strategies.

The limited thermal budget available in automotive clusters restricts the implementation of active cooling solutions, necessitating innovative passive cooling approaches. This limitation makes it crucial to optimize the thermal design of the GaN-on-Si backplane and surrounding structures to maximize heat dissipation within the confined space of the automotive cluster.

Addressing these thermal limitations requires a multifaceted approach, including advanced materials engineering, novel heat spreading techniques, and optimized device architectures. Researchers and engineers are exploring various strategies, such as the integration of high thermal conductivity materials, implementation of through-silicon vias for vertical heat extraction, and development of advanced thermal interface materials to mitigate these challenges and unlock the full potential of GaN-on-Si backplanes for automotive MicroLED displays.

One of the primary thermal limitations is the relatively low thermal conductivity of silicon compared to other substrate materials like sapphire or silicon carbide. This characteristic restricts the efficient dissipation of heat generated by the MicroLED devices, leading to localized hot spots and potential thermal runaway. The thermal boundary resistance between the GaN layer and the silicon substrate further exacerbates this issue, impeding heat flow from the active region to the substrate.

The mismatch in coefficient of thermal expansion (CTE) between GaN and silicon introduces additional thermal stress during operation. As the temperature fluctuates, the differential expansion and contraction of these materials can lead to mechanical strain, potentially causing cracks, delamination, or other structural defects that compromise the device's reliability and performance.

High current densities required for MicroLED operation contribute significantly to heat generation. The small size of MicroLED pixels results in concentrated heat sources, making it challenging to distribute and dissipate heat effectively across the backplane. This localized heating can lead to non-uniform temperature distribution, affecting color consistency and overall display performance.

The thermal resistance of the entire device stack, including the GaN-on-Si backplane, MicroLED array, and any additional layers such as color conversion or encapsulation materials, compounds the thermal management challenge. Each interface and layer introduces thermal barriers that must be carefully considered in the overall thermal design.

Automotive environments present additional thermal challenges due to extreme temperature variations and prolonged exposure to high temperatures. The GaN-on-Si backplane must maintain stability and performance across a wide temperature range, typically from -40°C to 125°C for automotive applications. This requirement places further constraints on material selection and thermal management strategies.

The limited thermal budget available in automotive clusters restricts the implementation of active cooling solutions, necessitating innovative passive cooling approaches. This limitation makes it crucial to optimize the thermal design of the GaN-on-Si backplane and surrounding structures to maximize heat dissipation within the confined space of the automotive cluster.

Addressing these thermal limitations requires a multifaceted approach, including advanced materials engineering, novel heat spreading techniques, and optimized device architectures. Researchers and engineers are exploring various strategies, such as the integration of high thermal conductivity materials, implementation of through-silicon vias for vertical heat extraction, and development of advanced thermal interface materials to mitigate these challenges and unlock the full potential of GaN-on-Si backplanes for automotive MicroLED displays.

Current Thermal Management Solutions

01 Thermal management in GaN-on-Si MicroLED backplanes

Effective thermal management is crucial for GaN-on-Si MicroLED backplanes to maintain optimal performance and longevity. This involves implementing heat dissipation techniques, such as using thermally conductive materials and designing efficient heat sinks. Advanced thermal management solutions can help prevent overheating, improve device reliability, and enhance overall performance of MicroLED displays.- Thermal management in GaN-on-Si MicroLED backplanes: Effective thermal management is crucial for GaN-on-Si MicroLED backplanes to maintain optimal performance and longevity. This involves implementing heat dissipation techniques, such as advanced packaging solutions and thermal interface materials, to efficiently remove heat generated during operation. Proper thermal management helps prevent performance degradation and extends the lifespan of MicroLED devices.

- Integration of heat sinks and cooling systems: Incorporating heat sinks and active cooling systems into MicroLED GaN-on-Si backplane designs can significantly improve thermal management. These components help dissipate heat more efficiently, reducing the overall operating temperature of the device. Advanced cooling solutions may include micro-channel heat sinks, thermoelectric coolers, or liquid cooling systems tailored for the unique requirements of MicroLED displays.

- Thermal simulation and modeling for MicroLED backplanes: Utilizing thermal simulation and modeling techniques is essential for optimizing the thermal management of MicroLED GaN-on-Si backplanes. These tools allow designers to predict heat distribution, identify hotspots, and evaluate the effectiveness of various cooling strategies before physical prototyping. Advanced thermal modeling can lead to more efficient and reliable MicroLED display designs.

- Novel materials for improved thermal conductivity: Developing and incorporating novel materials with enhanced thermal conductivity can significantly improve heat dissipation in MicroLED GaN-on-Si backplanes. This may include advanced composite materials, thermally conductive adhesives, or innovative substrate materials that facilitate better heat transfer while maintaining the electrical and optical properties required for MicroLED operation.

- Thermal management through backplane design optimization: Optimizing the design of GaN-on-Si backplanes can inherently improve thermal management in MicroLED displays. This may involve strategic placement of components, implementing thermal vias, or designing specialized heat spreading layers within the backplane structure. Careful consideration of the backplane layout and material selection can enhance overall thermal performance without compromising display quality or efficiency.

02 Integration of cooling systems in MicroLED backplanes

Incorporating cooling systems directly into MicroLED backplanes can significantly improve thermal management. This may include micro-channel cooling, thermoelectric coolers, or phase-change materials integrated within the backplane structure. Such cooling systems can efficiently remove heat from critical areas, ensuring stable operation of the MicroLED array.Expand Specific Solutions03 Substrate engineering for improved thermal conductivity

Optimizing the GaN-on-Si substrate structure can enhance thermal conductivity and heat dissipation. This may involve using advanced epitaxial growth techniques, implementing buffer layers, or developing novel substrate materials that offer better thermal properties while maintaining compatibility with GaN and Si technologies.Expand Specific Solutions04 Thermal simulation and modeling for MicroLED backplanes

Utilizing advanced thermal simulation and modeling techniques can help optimize the design of MicroLED GaN-on-Si backplanes for better heat management. These tools can predict hotspots, analyze heat flow patterns, and guide the development of more efficient thermal management strategies before physical prototyping.Expand Specific Solutions05 Novel packaging solutions for thermal management

Developing innovative packaging solutions can significantly improve thermal management in MicroLED GaN-on-Si backplanes. This may include advanced encapsulation techniques, the use of thermally conductive adhesives, or the integration of heat spreading layers within the package. These solutions aim to efficiently dissipate heat while protecting the sensitive MicroLED components.Expand Specific Solutions

Key Players in Automotive MicroLED Industry

The MicroLED thermal management in GaN-on-Si backplanes for automotive clusters is in an early development stage, with significant growth potential in the automotive display market. The technology is still maturing, with companies like BOE Technology, Sharp, and Japan Display leading research efforts. The market size is expanding as automakers increasingly adopt advanced display technologies. Technical challenges remain in heat dissipation and integration, but progress is being made by key players such as Lattice Power Jiangxi and eLux in GaN-on-Si and microLED assembly technologies. Collaboration between automotive and display manufacturers is driving innovation in this emerging field.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed an advanced thermal management solution for MicroLED displays in automotive clusters using GaN-on-Si backplanes. Their approach involves a multi-layered heat dissipation system, combining high thermal conductivity materials with innovative micro-channel cooling structures. The company has implemented a proprietary active cooling mechanism that utilizes miniaturized thermoelectric coolers integrated directly into the backplane[1]. This system allows for precise temperature control across the entire display surface, ensuring uniform performance and longevity of MicroLED pixels. BOE's solution also incorporates advanced thermal interface materials to maximize heat transfer efficiency between the GaN-on-Si backplane and the cooling system[3].

Strengths: Excellent thermal management, uniform pixel performance, and extended display lifespan. Weaknesses: Potentially higher production costs and increased system complexity.

Shenzhen China Star Optoelectronics Semicon Display Tech Co.

Technical Solution: Shenzhen China Star Optoelectronics has developed a novel thermal management approach for MicroLED displays in automotive applications using GaN-on-Si backplanes. Their solution incorporates a hierarchical heat spreading design, utilizing a combination of high thermal conductivity materials and optimized heat sink structures. The company has implemented a patented phase-change material (PCM) layer within the backplane structure, which absorbs and redistributes heat spikes during peak operation[2]. This PCM layer works in conjunction with a micro-fluidic cooling system that circulates a thermally efficient coolant through channels etched directly into the Si substrate[4]. The system is designed to maintain optimal operating temperatures even under extreme automotive environmental conditions.

Strengths: Effective heat redistribution, ability to handle thermal spikes, and robust performance in harsh environments. Weaknesses: Potential for increased manufacturing complexity and higher initial costs.

Innovations in GaN-on-Si Heat Dissipation

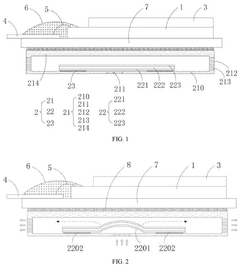

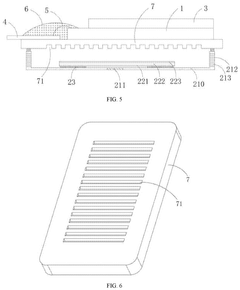

Display module

PatentPendingUS20250072293A1

Innovation

- A display module incorporating a silicon-based micro light emitting diode display panel and a heat dissipation device with a heat dissipation cavity and an electro-deformation member. The electro-deformation member, powered on, deforms to create a channel for external air to enter the heat dissipation cavity, enhancing air movement and temperature reduction.

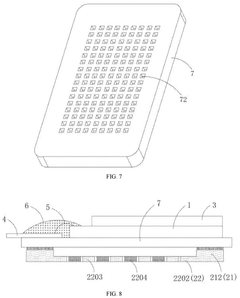

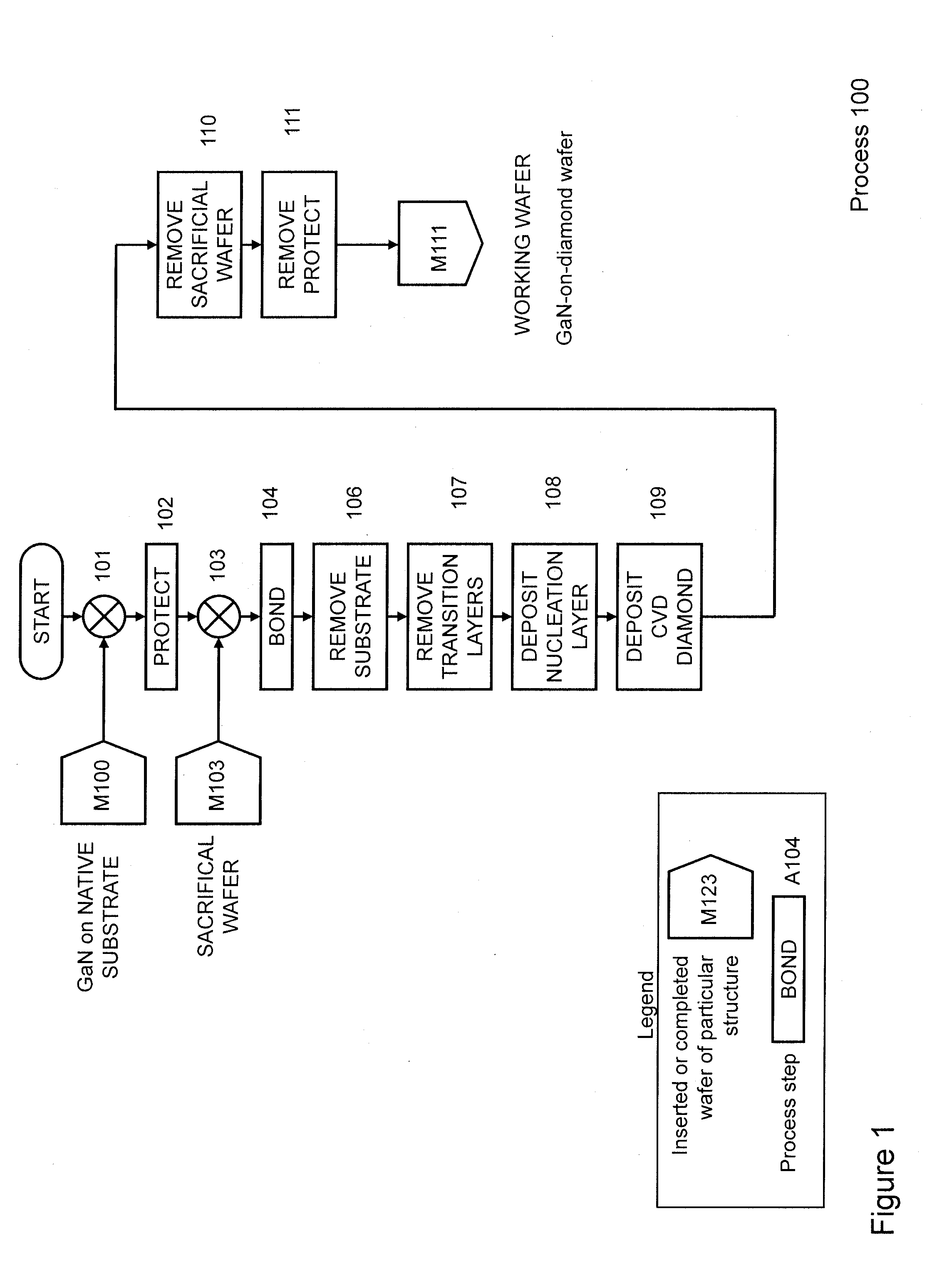

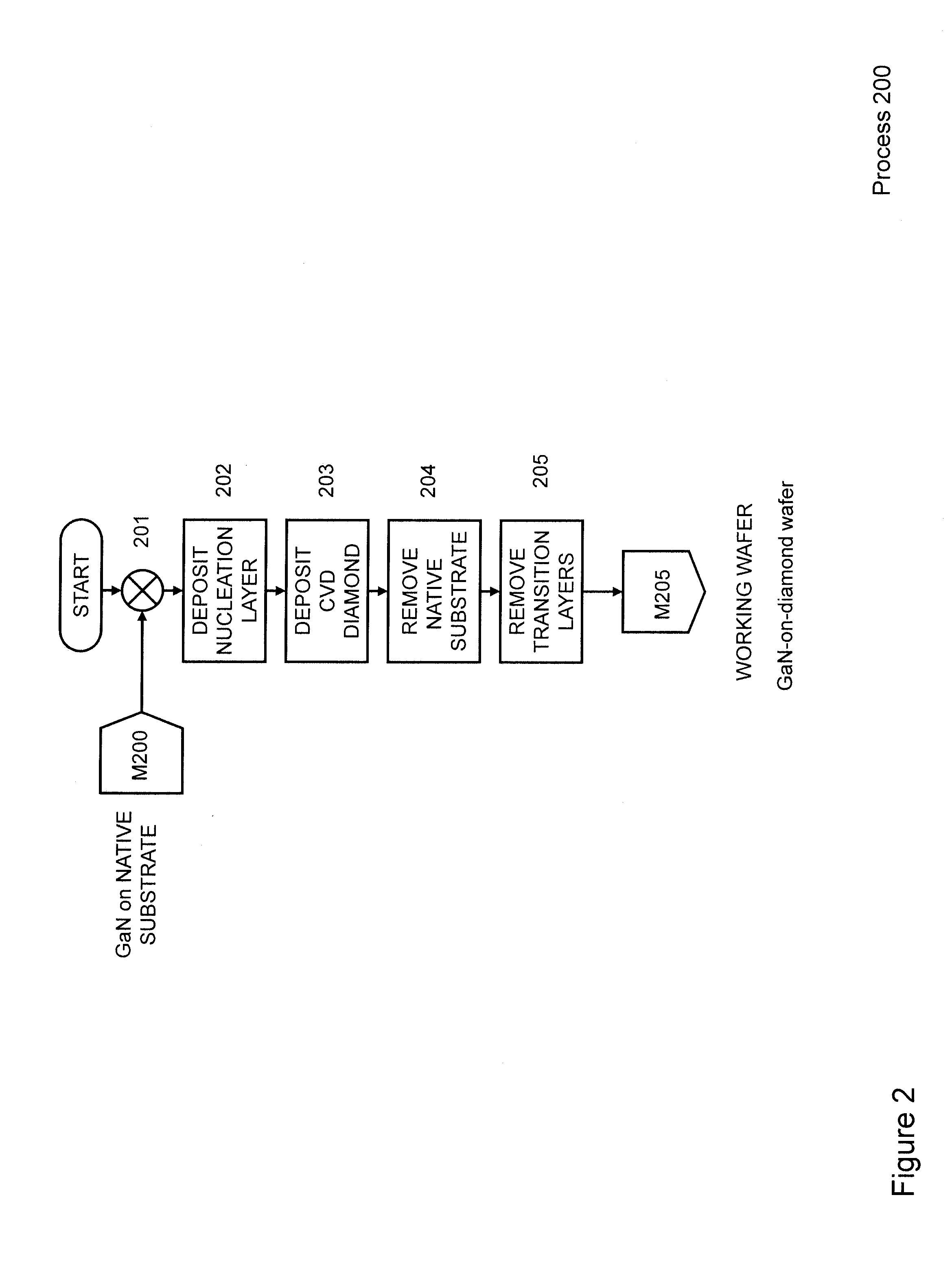

Gallium-nitride-on-diamond wafers and devices, and methods of manufacture

PatentActiveUS20140141595A1

Innovation

- The integration of GaN with CVD diamond to form free-standing GaN-on-diamond substrates, which reduces thermal resistance, improves epilayer quality, and allows for flat wafers with front-to-back connections without through holes, enabling microstrip transmission lines and standard processing techniques.

Automotive Safety Standards for Displays

Automotive safety standards for displays play a crucial role in ensuring the reliability and performance of visual interfaces in vehicles, particularly for critical components like MicroLED displays in automotive clusters. These standards are designed to address various aspects of display performance, durability, and safety in the challenging automotive environment.

The primary regulatory framework governing automotive displays is the ISO 26262 standard, which focuses on functional safety for road vehicles. This standard outlines the requirements for electronic and electrical systems, including display technologies. It emphasizes the importance of risk assessment, fault tolerance, and system reliability throughout the entire product lifecycle.

In addition to ISO 26262, the automotive industry also adheres to specific display-related standards. The Society of Automotive Engineers (SAE) has developed standards such as SAE J1757-1, which provides guidelines for optical performance and environmental requirements for electronic displays in automotive applications. This standard addresses issues like luminance, contrast ratio, color gamut, and viewing angle, all of which are critical for MicroLED displays in automotive clusters.

Thermal management, a key concern for MicroLED displays using GaN-on-Si backplanes, is addressed in various automotive standards. The AEC-Q100 standard, developed by the Automotive Electronics Council, defines stress test qualifications for integrated circuits in automotive applications. This standard includes temperature cycling tests and thermal shock tests, which are particularly relevant for assessing the thermal performance and reliability of MicroLED displays.

Electromagnetic compatibility (EMC) is another crucial aspect covered by automotive safety standards. The CISPR 25 standard specifically addresses radio disturbance characteristics for protection of receivers used in vehicles. MicroLED displays must comply with these EMC requirements to ensure they do not interfere with other electronic systems in the vehicle.

The automotive industry also places significant emphasis on optical safety. Standards like ISO 15008 specify ergonomic aspects of transport information and control systems, including requirements for in-vehicle visual presentation. This standard is particularly relevant for MicroLED displays in automotive clusters, as it addresses issues such as legibility, glare, and driver distraction.

As MicroLED technology continues to evolve, automotive safety standards are likely to adapt and incorporate new requirements specific to this display technology. Future standards may address unique aspects of MicroLED displays, such as pixel redundancy, color stability over time, and long-term reliability under automotive conditions. Compliance with these evolving standards will be crucial for the successful implementation of MicroLED displays in automotive applications, particularly in safety-critical systems like instrument clusters.

The primary regulatory framework governing automotive displays is the ISO 26262 standard, which focuses on functional safety for road vehicles. This standard outlines the requirements for electronic and electrical systems, including display technologies. It emphasizes the importance of risk assessment, fault tolerance, and system reliability throughout the entire product lifecycle.

In addition to ISO 26262, the automotive industry also adheres to specific display-related standards. The Society of Automotive Engineers (SAE) has developed standards such as SAE J1757-1, which provides guidelines for optical performance and environmental requirements for electronic displays in automotive applications. This standard addresses issues like luminance, contrast ratio, color gamut, and viewing angle, all of which are critical for MicroLED displays in automotive clusters.

Thermal management, a key concern for MicroLED displays using GaN-on-Si backplanes, is addressed in various automotive standards. The AEC-Q100 standard, developed by the Automotive Electronics Council, defines stress test qualifications for integrated circuits in automotive applications. This standard includes temperature cycling tests and thermal shock tests, which are particularly relevant for assessing the thermal performance and reliability of MicroLED displays.

Electromagnetic compatibility (EMC) is another crucial aspect covered by automotive safety standards. The CISPR 25 standard specifically addresses radio disturbance characteristics for protection of receivers used in vehicles. MicroLED displays must comply with these EMC requirements to ensure they do not interfere with other electronic systems in the vehicle.

The automotive industry also places significant emphasis on optical safety. Standards like ISO 15008 specify ergonomic aspects of transport information and control systems, including requirements for in-vehicle visual presentation. This standard is particularly relevant for MicroLED displays in automotive clusters, as it addresses issues such as legibility, glare, and driver distraction.

As MicroLED technology continues to evolve, automotive safety standards are likely to adapt and incorporate new requirements specific to this display technology. Future standards may address unique aspects of MicroLED displays, such as pixel redundancy, color stability over time, and long-term reliability under automotive conditions. Compliance with these evolving standards will be crucial for the successful implementation of MicroLED displays in automotive applications, particularly in safety-critical systems like instrument clusters.

Environmental Impact of Cooling Technologies

The environmental impact of cooling technologies used in MicroLED thermal management for GaN-on-Si backplanes in automotive clusters is a critical consideration in the development and implementation of these advanced display systems. As the automotive industry increasingly adopts MicroLED technology for its superior brightness, contrast, and energy efficiency, the environmental implications of the associated thermal management solutions must be carefully evaluated.

Traditional cooling methods, such as forced air cooling and liquid cooling, often rely on energy-intensive processes that contribute to increased power consumption and, consequently, higher carbon emissions. In the context of automotive applications, this can lead to reduced fuel efficiency or decreased range in electric vehicles. Moreover, the production and disposal of cooling components, including heat sinks, fans, and liquid coolants, can have significant environmental impacts throughout their lifecycle.

Advanced thermal management solutions for MicroLED displays are exploring more environmentally friendly approaches. Passive cooling techniques, such as the use of thermally conductive materials and optimized heat spreading designs, can reduce the need for active cooling components. These passive solutions not only minimize energy consumption but also reduce the overall environmental footprint associated with manufacturing and end-of-life disposal.

Emerging technologies in thermal management are focusing on sustainable materials and processes. For instance, the development of bio-based thermal interface materials and recyclable heat spreaders can significantly reduce the environmental impact of cooling systems. Additionally, the integration of phase-change materials (PCMs) for thermal energy storage offers a promising avenue for efficient and environmentally conscious thermal management in automotive MicroLED displays.

The use of advanced simulation and modeling tools in the design phase of MicroLED thermal management systems allows for optimization of cooling strategies, potentially reducing material usage and improving overall system efficiency. This approach can lead to more environmentally friendly designs that minimize waste and energy consumption throughout the product lifecycle.

Furthermore, the environmental impact of cooling technologies extends beyond the immediate automotive application. The manufacturing processes for GaN-on-Si backplanes and associated cooling components must also be considered. Efforts to reduce water usage, minimize hazardous waste generation, and implement energy-efficient production methods are crucial in mitigating the overall environmental impact of these technologies.

As the automotive industry continues to evolve towards more sustainable practices, the environmental considerations of MicroLED thermal management will play an increasingly important role in technology selection and implementation. Balancing performance requirements with environmental responsibility will be key to the successful adoption of MicroLED displays in automotive clusters, ensuring that the benefits of this advanced technology do not come at the cost of increased environmental burden.

Traditional cooling methods, such as forced air cooling and liquid cooling, often rely on energy-intensive processes that contribute to increased power consumption and, consequently, higher carbon emissions. In the context of automotive applications, this can lead to reduced fuel efficiency or decreased range in electric vehicles. Moreover, the production and disposal of cooling components, including heat sinks, fans, and liquid coolants, can have significant environmental impacts throughout their lifecycle.

Advanced thermal management solutions for MicroLED displays are exploring more environmentally friendly approaches. Passive cooling techniques, such as the use of thermally conductive materials and optimized heat spreading designs, can reduce the need for active cooling components. These passive solutions not only minimize energy consumption but also reduce the overall environmental footprint associated with manufacturing and end-of-life disposal.

Emerging technologies in thermal management are focusing on sustainable materials and processes. For instance, the development of bio-based thermal interface materials and recyclable heat spreaders can significantly reduce the environmental impact of cooling systems. Additionally, the integration of phase-change materials (PCMs) for thermal energy storage offers a promising avenue for efficient and environmentally conscious thermal management in automotive MicroLED displays.

The use of advanced simulation and modeling tools in the design phase of MicroLED thermal management systems allows for optimization of cooling strategies, potentially reducing material usage and improving overall system efficiency. This approach can lead to more environmentally friendly designs that minimize waste and energy consumption throughout the product lifecycle.

Furthermore, the environmental impact of cooling technologies extends beyond the immediate automotive application. The manufacturing processes for GaN-on-Si backplanes and associated cooling components must also be considered. Efforts to reduce water usage, minimize hazardous waste generation, and implement energy-efficient production methods are crucial in mitigating the overall environmental impact of these technologies.

As the automotive industry continues to evolve towards more sustainable practices, the environmental considerations of MicroLED thermal management will play an increasingly important role in technology selection and implementation. Balancing performance requirements with environmental responsibility will be key to the successful adoption of MicroLED displays in automotive clusters, ensuring that the benefits of this advanced technology do not come at the cost of increased environmental burden.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!