MicroLED driver IC topologies for ultra-high frame rate AR microdisplays

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MicroLED Driver IC Evolution and Objectives

MicroLED driver IC technology has undergone significant evolution since its inception, driven by the increasing demands of augmented reality (AR) microdisplays. The journey began with simple passive matrix drivers, which were adequate for low-resolution displays but lacked the sophistication required for high-performance AR applications.

As the industry progressed, active matrix drivers emerged, offering improved control and efficiency. These drivers allowed for individual pixel addressing, enhancing image quality and reducing power consumption. However, the pursuit of ultra-high frame rates for seamless AR experiences necessitated further advancements.

The next milestone in MicroLED driver IC evolution was the introduction of current-programmed pixel circuits. These circuits provided better uniformity and stability, addressing the challenges of brightness variations across the display. This development was crucial for achieving consistent image quality in AR microdisplays.

Recent years have seen a shift towards voltage-programmed pixel circuits, which offer faster programming times and reduced power consumption. This advancement has been instrumental in pushing frame rates higher while maintaining energy efficiency, a critical factor for wearable AR devices.

The latest frontier in MicroLED driver IC technology is the development of hybrid voltage-current programmed circuits. These innovative designs aim to combine the benefits of both voltage and current programming, offering unprecedented control over pixel behavior and enabling ultra-high frame rates.

The primary objective of current MicroLED driver IC research is to achieve frame rates exceeding 1000 Hz while maintaining high resolution and low power consumption. This goal is driven by the need to eliminate motion blur and reduce latency in AR applications, providing users with a more immersive and comfortable experience.

Another key objective is to miniaturize driver ICs further, allowing for more compact and lightweight AR devices. This miniaturization effort must be balanced with the need for increased functionality and performance, presenting a significant engineering challenge.

Improving color accuracy and expanding the color gamut are also critical objectives in MicroLED driver IC development. As AR applications become more sophisticated, the ability to render a wider range of colors with greater precision becomes increasingly important.

Looking ahead, the industry is setting ambitious targets for future MicroLED driver ICs. These include achieving frame rates of 10,000 Hz or higher, implementing advanced features such as eye-tracking and foveated rendering directly within the driver IC, and developing adaptive power management systems to optimize energy consumption based on displayed content and user behavior.

As the industry progressed, active matrix drivers emerged, offering improved control and efficiency. These drivers allowed for individual pixel addressing, enhancing image quality and reducing power consumption. However, the pursuit of ultra-high frame rates for seamless AR experiences necessitated further advancements.

The next milestone in MicroLED driver IC evolution was the introduction of current-programmed pixel circuits. These circuits provided better uniformity and stability, addressing the challenges of brightness variations across the display. This development was crucial for achieving consistent image quality in AR microdisplays.

Recent years have seen a shift towards voltage-programmed pixel circuits, which offer faster programming times and reduced power consumption. This advancement has been instrumental in pushing frame rates higher while maintaining energy efficiency, a critical factor for wearable AR devices.

The latest frontier in MicroLED driver IC technology is the development of hybrid voltage-current programmed circuits. These innovative designs aim to combine the benefits of both voltage and current programming, offering unprecedented control over pixel behavior and enabling ultra-high frame rates.

The primary objective of current MicroLED driver IC research is to achieve frame rates exceeding 1000 Hz while maintaining high resolution and low power consumption. This goal is driven by the need to eliminate motion blur and reduce latency in AR applications, providing users with a more immersive and comfortable experience.

Another key objective is to miniaturize driver ICs further, allowing for more compact and lightweight AR devices. This miniaturization effort must be balanced with the need for increased functionality and performance, presenting a significant engineering challenge.

Improving color accuracy and expanding the color gamut are also critical objectives in MicroLED driver IC development. As AR applications become more sophisticated, the ability to render a wider range of colors with greater precision becomes increasingly important.

Looking ahead, the industry is setting ambitious targets for future MicroLED driver ICs. These include achieving frame rates of 10,000 Hz or higher, implementing advanced features such as eye-tracking and foveated rendering directly within the driver IC, and developing adaptive power management systems to optimize energy consumption based on displayed content and user behavior.

AR Microdisplay Market Demand Analysis

The AR microdisplay market is experiencing rapid growth, driven by increasing demand for augmented reality applications across various industries. The market for AR microdisplays is expected to expand significantly in the coming years, with a particular focus on high-performance displays for next-generation AR devices.

One of the key drivers of market demand is the growing adoption of AR technology in enterprise and industrial applications. Companies are increasingly utilizing AR for tasks such as remote assistance, training, and maintenance, which require high-quality, high-resolution microdisplays. This trend is expected to continue as more businesses recognize the productivity and efficiency gains offered by AR solutions.

The consumer AR market is also showing promising growth potential, particularly in gaming, entertainment, and personal computing applications. As AR devices become more compact, lightweight, and capable, consumer interest in AR glasses and headsets is expected to rise, further driving demand for advanced microdisplays.

In the context of MicroLED driver IC topologies for ultra-high frame rate AR microdisplays, there is a growing need for displays that can deliver smooth, high-fidelity visual experiences. Ultra-high frame rates are crucial for reducing motion blur, minimizing latency, and enhancing overall user comfort in AR applications. This demand is pushing the development of innovative driver IC solutions capable of supporting these high refresh rates while maintaining power efficiency.

The automotive industry is emerging as another significant market for AR microdisplays, with increasing interest in heads-up displays (HUDs) and advanced driver assistance systems (ADAS). These applications require high-brightness, high-contrast displays that can operate reliably in various lighting conditions, further driving the need for advanced MicroLED technologies and driver ICs.

The healthcare sector is also contributing to the growth of the AR microdisplay market, with applications in surgical navigation, medical training, and patient care. These use cases demand high-resolution, low-latency displays that can provide accurate and timely information to medical professionals.

As the AR microdisplay market continues to evolve, there is a growing emphasis on reducing power consumption and improving efficiency. This trend is particularly relevant for battery-powered AR devices, where energy management is critical. Consequently, there is increasing demand for driver IC topologies that can balance high performance with low power consumption.

The market is also seeing a shift towards higher pixel densities and smaller form factors, driven by the need for more compact and lightweight AR devices. This trend is creating challenges for driver IC designers, who must develop solutions capable of addressing these requirements while maintaining high frame rates and image quality.

One of the key drivers of market demand is the growing adoption of AR technology in enterprise and industrial applications. Companies are increasingly utilizing AR for tasks such as remote assistance, training, and maintenance, which require high-quality, high-resolution microdisplays. This trend is expected to continue as more businesses recognize the productivity and efficiency gains offered by AR solutions.

The consumer AR market is also showing promising growth potential, particularly in gaming, entertainment, and personal computing applications. As AR devices become more compact, lightweight, and capable, consumer interest in AR glasses and headsets is expected to rise, further driving demand for advanced microdisplays.

In the context of MicroLED driver IC topologies for ultra-high frame rate AR microdisplays, there is a growing need for displays that can deliver smooth, high-fidelity visual experiences. Ultra-high frame rates are crucial for reducing motion blur, minimizing latency, and enhancing overall user comfort in AR applications. This demand is pushing the development of innovative driver IC solutions capable of supporting these high refresh rates while maintaining power efficiency.

The automotive industry is emerging as another significant market for AR microdisplays, with increasing interest in heads-up displays (HUDs) and advanced driver assistance systems (ADAS). These applications require high-brightness, high-contrast displays that can operate reliably in various lighting conditions, further driving the need for advanced MicroLED technologies and driver ICs.

The healthcare sector is also contributing to the growth of the AR microdisplay market, with applications in surgical navigation, medical training, and patient care. These use cases demand high-resolution, low-latency displays that can provide accurate and timely information to medical professionals.

As the AR microdisplay market continues to evolve, there is a growing emphasis on reducing power consumption and improving efficiency. This trend is particularly relevant for battery-powered AR devices, where energy management is critical. Consequently, there is increasing demand for driver IC topologies that can balance high performance with low power consumption.

The market is also seeing a shift towards higher pixel densities and smaller form factors, driven by the need for more compact and lightweight AR devices. This trend is creating challenges for driver IC designers, who must develop solutions capable of addressing these requirements while maintaining high frame rates and image quality.

MicroLED Driver IC Challenges for High Frame Rates

The development of MicroLED driver ICs for ultra-high frame rate AR microdisplays faces several significant challenges. One of the primary obstacles is the need for extremely fast switching speeds to support frame rates exceeding 1000 Hz. This requirement pushes the boundaries of current semiconductor technology and demands innovative circuit designs to achieve the necessary performance.

Power consumption is another critical challenge. As frame rates increase, so does the power required to drive the MicroLED pixels. This issue is particularly acute in AR applications, where battery life and heat dissipation are crucial factors. Engineers must develop sophisticated power management techniques and explore new materials to improve energy efficiency without compromising display quality.

The miniaturization of driver ICs presents a formidable challenge. AR microdisplays require ultra-compact form factors, necessitating the integration of complex circuitry into increasingly smaller chip areas. This miniaturization effort must balance performance requirements with thermal management concerns, as higher pixel densities and faster refresh rates generate more heat in a confined space.

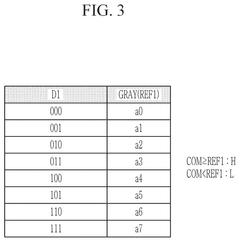

Uniformity and consistency across the display are paramount for high-quality AR experiences. Driver ICs must ensure precise control over each MicroLED pixel, compensating for variations in LED characteristics and maintaining color accuracy at high refresh rates. This demands advanced calibration techniques and feedback mechanisms integrated into the driver architecture.

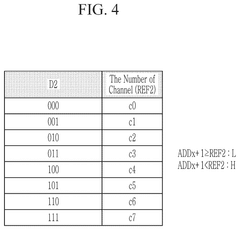

The challenge of addressing individual pixels at ultra-high frame rates requires innovative approaches to data transmission and processing. Traditional row-column addressing schemes may prove insufficient, leading to the exploration of new topologies such as multi-level addressing or parallel driving techniques to handle the massive data throughput required.

Electromagnetic interference (EMI) becomes a significant concern at high operating frequencies. Driver ICs must incorporate robust EMI shielding and noise reduction techniques to prevent signal degradation and ensure compliance with regulatory standards, all while maintaining the compact form factor required for AR devices.

Yield and manufacturability present ongoing challenges as the complexity of driver ICs increases. Achieving consistent performance across large production runs requires advanced process control and potentially new manufacturing techniques to ensure economic viability at scale.

Lastly, the integration of additional functionalities, such as sensing capabilities for eye-tracking or environmental awareness, adds another layer of complexity to driver IC design. Balancing these features with the primary display driving functions while maintaining ultra-high frame rates presents a multifaceted challenge for engineers in the field.

Power consumption is another critical challenge. As frame rates increase, so does the power required to drive the MicroLED pixels. This issue is particularly acute in AR applications, where battery life and heat dissipation are crucial factors. Engineers must develop sophisticated power management techniques and explore new materials to improve energy efficiency without compromising display quality.

The miniaturization of driver ICs presents a formidable challenge. AR microdisplays require ultra-compact form factors, necessitating the integration of complex circuitry into increasingly smaller chip areas. This miniaturization effort must balance performance requirements with thermal management concerns, as higher pixel densities and faster refresh rates generate more heat in a confined space.

Uniformity and consistency across the display are paramount for high-quality AR experiences. Driver ICs must ensure precise control over each MicroLED pixel, compensating for variations in LED characteristics and maintaining color accuracy at high refresh rates. This demands advanced calibration techniques and feedback mechanisms integrated into the driver architecture.

The challenge of addressing individual pixels at ultra-high frame rates requires innovative approaches to data transmission and processing. Traditional row-column addressing schemes may prove insufficient, leading to the exploration of new topologies such as multi-level addressing or parallel driving techniques to handle the massive data throughput required.

Electromagnetic interference (EMI) becomes a significant concern at high operating frequencies. Driver ICs must incorporate robust EMI shielding and noise reduction techniques to prevent signal degradation and ensure compliance with regulatory standards, all while maintaining the compact form factor required for AR devices.

Yield and manufacturability present ongoing challenges as the complexity of driver ICs increases. Achieving consistent performance across large production runs requires advanced process control and potentially new manufacturing techniques to ensure economic viability at scale.

Lastly, the integration of additional functionalities, such as sensing capabilities for eye-tracking or environmental awareness, adds another layer of complexity to driver IC design. Balancing these features with the primary display driving functions while maintaining ultra-high frame rates presents a multifaceted challenge for engineers in the field.

Current MicroLED Driver IC Topologies

01 Frame rate control in MicroLED driver ICs

MicroLED driver ICs incorporate frame rate control mechanisms to optimize display performance. These mechanisms allow for adjustable refresh rates, which can enhance image quality, reduce power consumption, and minimize motion blur in MicroLED displays. Advanced driver ICs may include adaptive frame rate technologies that dynamically adjust the refresh rate based on content and viewing conditions.- Frame rate control in MicroLED driver ICs: MicroLED driver ICs incorporate frame rate control mechanisms to optimize display performance. These mechanisms allow for adjustable refresh rates, which can enhance image quality, reduce power consumption, and minimize motion blur in MicroLED displays. Advanced driver ICs may include adaptive frame rate technologies that dynamically adjust the refresh rate based on content and viewing conditions.

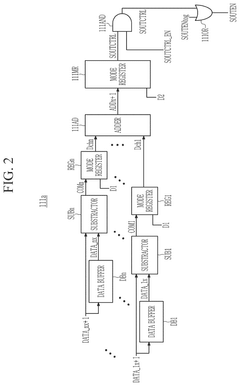

- High-speed data processing for MicroLED displays: MicroLED driver ICs employ high-speed data processing techniques to handle the large amounts of data required for high-resolution displays. These techniques may include parallel processing, advanced signal processing algorithms, and dedicated hardware accelerators. The goal is to ensure smooth frame transitions and maintain high frame rates even for complex, high-resolution MicroLED displays.

- Power management in MicroLED driver ICs: Efficient power management is crucial for MicroLED driver ICs to maintain high frame rates while minimizing energy consumption. This involves implementing advanced power-saving modes, voltage regulation techniques, and intelligent power distribution across the display. Driver ICs may also incorporate features to optimize power usage based on display content and ambient lighting conditions.

- Timing control and synchronization: MicroLED driver ICs utilize sophisticated timing control and synchronization mechanisms to ensure precise pixel activation and maintain consistent frame rates. This includes implementing advanced clock generation circuits, synchronization protocols, and timing adjustment techniques to compensate for variations in display size and resolution.

- Integration of image processing capabilities: Modern MicroLED driver ICs often integrate advanced image processing capabilities to enhance display quality and maintain high frame rates. These may include features such as motion compensation, color management, and dynamic contrast adjustment. By performing these operations directly within the driver IC, overall system performance and frame rate stability can be improved.

02 Integration of timing controllers in MicroLED driver ICs

MicroLED driver ICs often integrate timing controllers to manage frame rates and synchronization. These controllers coordinate the timing of pixel activation and deactivation, ensuring smooth frame transitions and precise control over the display's refresh rate. The integration of timing controllers within the driver IC can lead to improved performance and reduced system complexity.Expand Specific Solutions03 Power management for frame rate optimization

Driver ICs for MicroLEDs implement power management techniques to optimize frame rates while minimizing energy consumption. These may include dynamic power scaling based on display content, selective refresh of changed pixels, and intelligent backlight control. Such features allow for high frame rates when needed while conserving power during less demanding display tasks.Expand Specific Solutions04 High-speed data processing for increased frame rates

MicroLED driver ICs employ advanced data processing techniques to support high frame rates. This includes parallel processing architectures, high-bandwidth interfaces, and efficient data compression algorithms. These features enable the rapid transfer and processing of display data, allowing for smoother motion and reduced latency in high-refresh-rate MicroLED displays.Expand Specific Solutions05 Adaptive frame rate techniques for MicroLED displays

Driver ICs incorporate adaptive frame rate techniques to optimize display performance and power efficiency. These methods may include variable refresh rates, content-aware frame insertion, and motion estimation algorithms. By dynamically adjusting the frame rate based on the displayed content and user interactions, MicroLED displays can achieve an optimal balance between visual quality and power consumption.Expand Specific Solutions

Key Players in MicroLED Driver IC Industry

The MicroLED driver IC market for ultra-high frame rate AR microdisplays is in an early growth stage, characterized by rapid technological advancements and increasing market potential. The global AR market is projected to expand significantly, driving demand for high-performance microdisplays. Companies like BOE Technology, Huawei, and Samsung Display are investing heavily in MicroLED technology, indicating its growing importance. However, the technology is still evolving, with challenges in miniaturization and power efficiency. Emerging players like Jade Bird Display and AuroraTech are pushing innovation, while established semiconductor firms like SMIC and OSRAM Opto Semiconductors are leveraging their expertise to develop advanced driver ICs for this application.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed a cutting-edge MicroLED driver IC topology for ultra-high frame rate AR microdisplays. Their solution employs a multi-level pulse amplitude modulation (PAM) scheme, allowing for faster data transmission and reduced power consumption[2]. Huawei's driver ICs incorporate an advanced timing controller (T-CON) that supports frame rates up to 300Hz, significantly reducing motion artifacts in AR applications[4]. The company has also implemented a novel pixel compensation algorithm that ensures uniform brightness across the display, even at high refresh rates. Huawei's driver topology includes an integrated charge pump circuit, enabling efficient voltage boosting for MicroLED operation while maintaining a compact form factor suitable for AR glasses[6].

Strengths: Ultra-high frame rates up to 300Hz, efficient power management, and uniform brightness. Weaknesses: Potential compatibility issues with non-Huawei AR platforms and higher initial development costs.

Jade Bird Display (Shanghai) Ltd.

Technical Solution: Jade Bird Display has developed advanced MicroLED driver IC topologies for ultra-high frame rate AR microdisplays. Their solution incorporates a high-speed, low-power CMOS backplane with integrated drivers capable of achieving frame rates up to 240Hz[1]. The company utilizes a proprietary pixel circuit design that enables fast switching times and reduced motion blur. Their driver ICs feature adaptive power management, dynamically adjusting voltage levels based on display content to optimize power consumption[3]. Additionally, Jade Bird Display has implemented a novel charge-sharing technique that significantly reduces the power required for pixel transitions, crucial for battery-powered AR devices[5].

Strengths: High frame rates up to 240Hz, low power consumption, and reduced motion blur. Weaknesses: Potential heat dissipation challenges in compact AR devices and higher production costs compared to traditional display technologies.

Innovative MicroLED Driver IC Designs

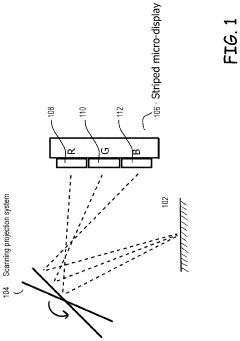

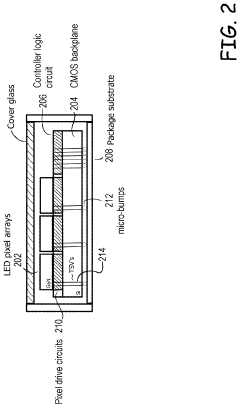

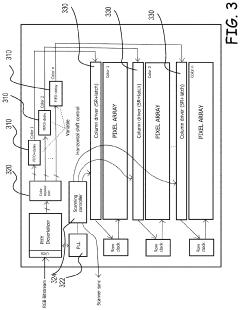

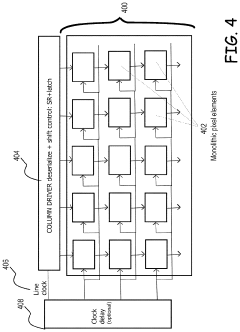

Display driver IC (DDIC) backplane for scanning microled array

PatentActiveUS20210225268A1

Innovation

- A tri-linear microdisplay architecture is used within a 1D-scanning display system, where each stripe consists of multiple rows of pixels, with a display driver configured to present time-shifted sub-bands and achieve grayscale illumination through distributed pulse width modulation, reducing the effect of physical LED non-uniformity and pixel blur, and utilizing a fast switch with high drive current to maintain performance over the device's life.

Display driver integrated circuit and display device including the same

PatentPendingUS20250095541A1

Innovation

- The display driver integrated circuit selectively performs high-rate driving and improves EMI characteristics by toggling an output enable signal based on change values in image data, allowing for efficient power management and reduced electromagnetic interference.

Thermal Management in High-Speed Driver ICs

Thermal management is a critical aspect of high-speed driver ICs for MicroLED displays in AR applications. As frame rates increase to ultra-high levels, the power consumption and heat generation of driver ICs become significant challenges that must be addressed to ensure reliable operation and optimal performance.

The primary sources of heat in MicroLED driver ICs are the switching transistors and current sources that control individual pixels. As frame rates increase, these components must switch more frequently, leading to higher dynamic power consumption and heat generation. Additionally, the compact form factor of AR devices limits the available space for heat dissipation, exacerbating the thermal management challenge.

To address these issues, several thermal management strategies have been developed for high-speed driver ICs. One approach is to optimize the IC layout to improve heat spreading. This involves carefully arranging heat-generating components and incorporating thermal vias to efficiently conduct heat away from critical areas. Advanced packaging techniques, such as flip-chip bonding, can also enhance thermal performance by providing a more direct path for heat dissipation.

Another strategy is to implement dynamic power management techniques within the driver IC. This may include adaptive voltage scaling, where the supply voltage is adjusted based on the current operating conditions, and selective pixel activation, which reduces power consumption by only driving the necessary pixels for a given frame. These techniques can significantly reduce overall power consumption and heat generation, particularly in AR applications where the displayed content may not always occupy the entire field of view.

Advanced cooling solutions are also being explored to improve thermal management in high-speed driver ICs. These include the use of high thermal conductivity materials, such as diamond or graphene, as heat spreaders or substrates. Micro-fluidic cooling channels integrated into the IC package or display substrate have shown promise in efficiently removing heat from localized hot spots.

Furthermore, thermal-aware circuit design techniques are being employed to optimize the performance of driver ICs under varying thermal conditions. This includes the implementation of on-chip temperature sensors and adaptive biasing circuits that can adjust the operating parameters of the IC based on real-time temperature measurements. Such techniques help maintain consistent performance and reliability across a wide range of operating temperatures.

As MicroLED displays for AR applications continue to push the boundaries of frame rates and pixel densities, innovative thermal management solutions will play an increasingly crucial role in enabling the next generation of high-performance driver ICs. The development of these solutions requires a multidisciplinary approach, combining expertise in IC design, materials science, and thermal engineering to address the complex challenges posed by ultra-high frame rate MicroLED displays in compact AR form factors.

The primary sources of heat in MicroLED driver ICs are the switching transistors and current sources that control individual pixels. As frame rates increase, these components must switch more frequently, leading to higher dynamic power consumption and heat generation. Additionally, the compact form factor of AR devices limits the available space for heat dissipation, exacerbating the thermal management challenge.

To address these issues, several thermal management strategies have been developed for high-speed driver ICs. One approach is to optimize the IC layout to improve heat spreading. This involves carefully arranging heat-generating components and incorporating thermal vias to efficiently conduct heat away from critical areas. Advanced packaging techniques, such as flip-chip bonding, can also enhance thermal performance by providing a more direct path for heat dissipation.

Another strategy is to implement dynamic power management techniques within the driver IC. This may include adaptive voltage scaling, where the supply voltage is adjusted based on the current operating conditions, and selective pixel activation, which reduces power consumption by only driving the necessary pixels for a given frame. These techniques can significantly reduce overall power consumption and heat generation, particularly in AR applications where the displayed content may not always occupy the entire field of view.

Advanced cooling solutions are also being explored to improve thermal management in high-speed driver ICs. These include the use of high thermal conductivity materials, such as diamond or graphene, as heat spreaders or substrates. Micro-fluidic cooling channels integrated into the IC package or display substrate have shown promise in efficiently removing heat from localized hot spots.

Furthermore, thermal-aware circuit design techniques are being employed to optimize the performance of driver ICs under varying thermal conditions. This includes the implementation of on-chip temperature sensors and adaptive biasing circuits that can adjust the operating parameters of the IC based on real-time temperature measurements. Such techniques help maintain consistent performance and reliability across a wide range of operating temperatures.

As MicroLED displays for AR applications continue to push the boundaries of frame rates and pixel densities, innovative thermal management solutions will play an increasingly crucial role in enabling the next generation of high-performance driver ICs. The development of these solutions requires a multidisciplinary approach, combining expertise in IC design, materials science, and thermal engineering to address the complex challenges posed by ultra-high frame rate MicroLED displays in compact AR form factors.

Power Efficiency Optimization Strategies

Power efficiency optimization is a critical aspect of MicroLED driver IC design for ultra-high frame rate AR microdisplays. As these displays demand increasingly higher refresh rates to enhance user experience and reduce motion blur, the power consumption of driver ICs becomes a significant concern. Several strategies can be employed to optimize power efficiency in this context.

One primary approach involves the implementation of advanced power management techniques within the driver IC. This includes dynamic voltage scaling, where the supply voltage is adjusted based on the display content and frame rate requirements. By reducing the voltage during less demanding scenarios, overall power consumption can be significantly decreased without compromising performance.

Another effective strategy is the use of low-power design techniques at the circuit level. This encompasses the adoption of sub-threshold or near-threshold voltage operation for certain circuit blocks, allowing for reduced power consumption while maintaining functionality. Additionally, implementing power gating techniques can help isolate unused portions of the driver IC, further minimizing static power dissipation.

Optimizing the data transmission and processing within the driver IC is also crucial for power efficiency. Employing advanced compression algorithms for display data can reduce the amount of information that needs to be processed and transmitted, thereby lowering power requirements. Furthermore, implementing intelligent refresh mechanisms that update only the changing portions of the display can substantially reduce unnecessary power consumption.

The integration of energy-efficient memory technologies, such as embedded MRAM or RRAM, can contribute to power savings in the driver IC. These non-volatile memory solutions offer lower power consumption compared to traditional SRAM, especially in standby modes, while providing fast access times suitable for high frame rate operations.

Thermal management plays a vital role in power efficiency optimization. Implementing efficient heat dissipation techniques within the driver IC design can help maintain optimal operating temperatures, reducing power losses due to thermal effects and improving overall efficiency. This may include the use of advanced packaging technologies and thermal-aware layout strategies.

Lastly, the adoption of advanced process nodes and semiconductor technologies can significantly enhance power efficiency. Moving to smaller process nodes typically results in reduced power consumption due to lower parasitic capacitances and improved transistor characteristics. Additionally, exploring novel semiconductor materials, such as GaN or SiC, for specific driver IC components may offer superior power efficiency in high-frequency switching applications.

One primary approach involves the implementation of advanced power management techniques within the driver IC. This includes dynamic voltage scaling, where the supply voltage is adjusted based on the display content and frame rate requirements. By reducing the voltage during less demanding scenarios, overall power consumption can be significantly decreased without compromising performance.

Another effective strategy is the use of low-power design techniques at the circuit level. This encompasses the adoption of sub-threshold or near-threshold voltage operation for certain circuit blocks, allowing for reduced power consumption while maintaining functionality. Additionally, implementing power gating techniques can help isolate unused portions of the driver IC, further minimizing static power dissipation.

Optimizing the data transmission and processing within the driver IC is also crucial for power efficiency. Employing advanced compression algorithms for display data can reduce the amount of information that needs to be processed and transmitted, thereby lowering power requirements. Furthermore, implementing intelligent refresh mechanisms that update only the changing portions of the display can substantially reduce unnecessary power consumption.

The integration of energy-efficient memory technologies, such as embedded MRAM or RRAM, can contribute to power savings in the driver IC. These non-volatile memory solutions offer lower power consumption compared to traditional SRAM, especially in standby modes, while providing fast access times suitable for high frame rate operations.

Thermal management plays a vital role in power efficiency optimization. Implementing efficient heat dissipation techniques within the driver IC design can help maintain optimal operating temperatures, reducing power losses due to thermal effects and improving overall efficiency. This may include the use of advanced packaging technologies and thermal-aware layout strategies.

Lastly, the adoption of advanced process nodes and semiconductor technologies can significantly enhance power efficiency. Moving to smaller process nodes typically results in reduced power consumption due to lower parasitic capacitances and improved transistor characteristics. Additionally, exploring novel semiconductor materials, such as GaN or SiC, for specific driver IC components may offer superior power efficiency in high-frequency switching applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!