Muriatic Acid in the Treatment of Paint Manufacturing Wastewater

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Muriatic Acid Treatment Background and Objectives

Muriatic acid, also known as hydrochloric acid, has been a significant component in various industrial processes for decades. In the context of paint manufacturing wastewater treatment, its application has gained increasing attention due to its effectiveness and cost-efficiency. The evolution of this technology can be traced back to the early 20th century when industrial waste management became a pressing concern.

The paint manufacturing industry has long grappled with the challenge of treating wastewater contaminated with heavy metals, organic compounds, and other pollutants. Traditional treatment methods often proved inadequate in meeting stringent environmental regulations and sustainability goals. This led to the exploration of alternative treatment options, among which muriatic acid emerged as a promising solution.

The primary objective of utilizing muriatic acid in paint manufacturing wastewater treatment is to achieve efficient removal of contaminants while minimizing environmental impact and operational costs. Specifically, the technology aims to neutralize alkaline waste streams, precipitate heavy metals, and break down complex organic compounds into more manageable forms.

Over the years, the application of muriatic acid in this field has undergone significant refinement. Initial uses focused primarily on pH adjustment and basic metal precipitation. However, as understanding of chemical interactions deepened, more sophisticated treatment processes were developed. These advancements aimed to enhance removal efficiencies, reduce chemical consumption, and improve the overall quality of treated effluent.

The technological trajectory in this domain has been driven by several factors, including increasingly stringent environmental regulations, growing awareness of water scarcity, and the paint industry's pursuit of more sustainable production practices. As a result, research and development efforts have intensified, focusing on optimizing muriatic acid dosage, improving mixing and reaction kinetics, and developing novel treatment configurations.

Current technological goals in this field include achieving near-zero liquid discharge, recovering valuable resources from wastewater, and minimizing the generation of secondary waste streams. Additionally, there is a growing emphasis on integrating muriatic acid treatment with other advanced technologies such as membrane filtration, advanced oxidation processes, and electrochemical treatment methods.

As we look towards the future, the role of muriatic acid in paint manufacturing wastewater treatment is expected to evolve further. Emerging trends suggest a shift towards more targeted and precise application of the acid, potentially aided by real-time monitoring and control systems. The integration of artificial intelligence and machine learning algorithms may also play a crucial role in optimizing treatment processes and predicting treatment outcomes.

The paint manufacturing industry has long grappled with the challenge of treating wastewater contaminated with heavy metals, organic compounds, and other pollutants. Traditional treatment methods often proved inadequate in meeting stringent environmental regulations and sustainability goals. This led to the exploration of alternative treatment options, among which muriatic acid emerged as a promising solution.

The primary objective of utilizing muriatic acid in paint manufacturing wastewater treatment is to achieve efficient removal of contaminants while minimizing environmental impact and operational costs. Specifically, the technology aims to neutralize alkaline waste streams, precipitate heavy metals, and break down complex organic compounds into more manageable forms.

Over the years, the application of muriatic acid in this field has undergone significant refinement. Initial uses focused primarily on pH adjustment and basic metal precipitation. However, as understanding of chemical interactions deepened, more sophisticated treatment processes were developed. These advancements aimed to enhance removal efficiencies, reduce chemical consumption, and improve the overall quality of treated effluent.

The technological trajectory in this domain has been driven by several factors, including increasingly stringent environmental regulations, growing awareness of water scarcity, and the paint industry's pursuit of more sustainable production practices. As a result, research and development efforts have intensified, focusing on optimizing muriatic acid dosage, improving mixing and reaction kinetics, and developing novel treatment configurations.

Current technological goals in this field include achieving near-zero liquid discharge, recovering valuable resources from wastewater, and minimizing the generation of secondary waste streams. Additionally, there is a growing emphasis on integrating muriatic acid treatment with other advanced technologies such as membrane filtration, advanced oxidation processes, and electrochemical treatment methods.

As we look towards the future, the role of muriatic acid in paint manufacturing wastewater treatment is expected to evolve further. Emerging trends suggest a shift towards more targeted and precise application of the acid, potentially aided by real-time monitoring and control systems. The integration of artificial intelligence and machine learning algorithms may also play a crucial role in optimizing treatment processes and predicting treatment outcomes.

Paint Industry Wastewater Management Needs

The paint industry faces significant challenges in managing its wastewater, which contains a complex mixture of chemicals, pigments, and solvents. As environmental regulations become more stringent, there is an increasing need for effective and sustainable wastewater treatment solutions. The industry's wastewater typically includes high levels of suspended solids, heavy metals, organic compounds, and color, all of which require specialized treatment processes.

One of the primary concerns for paint manufacturers is the removal of toxic heavy metals such as lead, chromium, and cadmium from their wastewater. These metals, often present in pigments and additives, pose serious environmental and health risks if released untreated. Additionally, the high organic content in paint wastewater, including volatile organic compounds (VOCs) and various resins, demands advanced treatment technologies to meet discharge standards.

Color removal is another critical aspect of paint industry wastewater management. The intense pigmentation in the effluent not only affects the aesthetic quality of receiving water bodies but can also interfere with aquatic ecosystems by reducing light penetration. This necessitates the development and implementation of effective decolorization techniques as part of the overall treatment strategy.

The paint industry also faces challenges related to the variability of wastewater composition. Different production batches and product lines can result in significant fluctuations in wastewater characteristics, requiring flexible and adaptable treatment systems. This variability complicates the design of treatment plants and often necessitates the use of multiple treatment stages to ensure consistent compliance with environmental regulations.

Water reuse and recycling have become increasingly important for paint manufacturers seeking to reduce their environmental footprint and operational costs. There is a growing demand for technologies that can treat wastewater to a quality suitable for reuse in production processes or for non-potable applications within the facility. This approach not only conserves water resources but also helps companies meet sustainability goals and improve their corporate image.

The industry is also exploring innovative treatment methods to address emerging contaminants and microplastics that may be present in paint formulations. As awareness of these pollutants grows, there is a need for advanced treatment technologies capable of removing these microscopic particles and complex chemical compounds from wastewater streams.

One of the primary concerns for paint manufacturers is the removal of toxic heavy metals such as lead, chromium, and cadmium from their wastewater. These metals, often present in pigments and additives, pose serious environmental and health risks if released untreated. Additionally, the high organic content in paint wastewater, including volatile organic compounds (VOCs) and various resins, demands advanced treatment technologies to meet discharge standards.

Color removal is another critical aspect of paint industry wastewater management. The intense pigmentation in the effluent not only affects the aesthetic quality of receiving water bodies but can also interfere with aquatic ecosystems by reducing light penetration. This necessitates the development and implementation of effective decolorization techniques as part of the overall treatment strategy.

The paint industry also faces challenges related to the variability of wastewater composition. Different production batches and product lines can result in significant fluctuations in wastewater characteristics, requiring flexible and adaptable treatment systems. This variability complicates the design of treatment plants and often necessitates the use of multiple treatment stages to ensure consistent compliance with environmental regulations.

Water reuse and recycling have become increasingly important for paint manufacturers seeking to reduce their environmental footprint and operational costs. There is a growing demand for technologies that can treat wastewater to a quality suitable for reuse in production processes or for non-potable applications within the facility. This approach not only conserves water resources but also helps companies meet sustainability goals and improve their corporate image.

The industry is also exploring innovative treatment methods to address emerging contaminants and microplastics that may be present in paint formulations. As awareness of these pollutants grows, there is a need for advanced treatment technologies capable of removing these microscopic particles and complex chemical compounds from wastewater streams.

Current Challenges in Paint Wastewater Treatment

The treatment of paint manufacturing wastewater presents several significant challenges due to the complex nature of the effluent and the stringent environmental regulations governing its disposal. One of the primary difficulties is the high concentration of suspended solids, which can include pigments, resins, and other particulate matter. These solids not only contribute to turbidity but also carry adsorbed pollutants, making their removal crucial yet challenging.

Another major hurdle is the presence of volatile organic compounds (VOCs) and other toxic substances in paint wastewater. These compounds, which include solvents and additives, are often resistant to conventional treatment methods and pose significant environmental and health risks if not properly managed. Their removal requires specialized techniques that can be both energy-intensive and costly.

The variability in wastewater composition presents an additional challenge. Paint manufacturing processes can produce effluents with widely varying pH levels, chemical oxygen demand (COD), and pollutant concentrations, depending on the types of paints being produced and the specific manufacturing processes employed. This variability necessitates flexible and adaptable treatment systems capable of handling fluctuations in wastewater characteristics.

Heavy metals, such as lead, chromium, and cadmium, which may be present in certain paint formulations, pose a particular challenge in wastewater treatment. These metals are highly toxic even in small concentrations and require specialized removal techniques to meet increasingly strict discharge limits.

The high COD and biochemical oxygen demand (BOD) levels in paint wastewater are also problematic. These parameters indicate the presence of organic pollutants that can deplete oxygen in receiving water bodies, potentially leading to eutrophication and harm to aquatic ecosystems. Effective reduction of COD and BOD often requires a combination of physical, chemical, and biological treatment processes.

Furthermore, the presence of emulsified oils and greases in paint wastewater can interfere with many treatment processes, reducing their efficiency and potentially causing operational issues in treatment plants. Separating these substances from the water phase is essential but can be technically challenging.

Lastly, the management of sludge generated during the treatment process presents its own set of challenges. This sludge often contains concentrated levels of pollutants and may be classified as hazardous waste, requiring careful handling, treatment, and disposal to prevent secondary environmental contamination.

Another major hurdle is the presence of volatile organic compounds (VOCs) and other toxic substances in paint wastewater. These compounds, which include solvents and additives, are often resistant to conventional treatment methods and pose significant environmental and health risks if not properly managed. Their removal requires specialized techniques that can be both energy-intensive and costly.

The variability in wastewater composition presents an additional challenge. Paint manufacturing processes can produce effluents with widely varying pH levels, chemical oxygen demand (COD), and pollutant concentrations, depending on the types of paints being produced and the specific manufacturing processes employed. This variability necessitates flexible and adaptable treatment systems capable of handling fluctuations in wastewater characteristics.

Heavy metals, such as lead, chromium, and cadmium, which may be present in certain paint formulations, pose a particular challenge in wastewater treatment. These metals are highly toxic even in small concentrations and require specialized removal techniques to meet increasingly strict discharge limits.

The high COD and biochemical oxygen demand (BOD) levels in paint wastewater are also problematic. These parameters indicate the presence of organic pollutants that can deplete oxygen in receiving water bodies, potentially leading to eutrophication and harm to aquatic ecosystems. Effective reduction of COD and BOD often requires a combination of physical, chemical, and biological treatment processes.

Furthermore, the presence of emulsified oils and greases in paint wastewater can interfere with many treatment processes, reducing their efficiency and potentially causing operational issues in treatment plants. Separating these substances from the water phase is essential but can be technically challenging.

Lastly, the management of sludge generated during the treatment process presents its own set of challenges. This sludge often contains concentrated levels of pollutants and may be classified as hazardous waste, requiring careful handling, treatment, and disposal to prevent secondary environmental contamination.

Existing Muriatic Acid Treatment Processes

01 Surface treatment of metals

Muriatic acid is used for surface treatment of metals, particularly in the preparation of metal surfaces for coating or further processing. This treatment can involve cleaning, etching, or pickling of metal surfaces to remove oxides, scale, or other contaminants. The process improves adhesion for subsequent coatings or treatments and can enhance the overall quality of the metal surface.- Surface treatment of metals: Muriatic acid is used for surface treatment of metals, particularly in the preparation of metal surfaces for coating or further processing. This treatment helps to remove rust, scale, and other contaminants, improving the adhesion of subsequent coatings or treatments. The process often involves controlled application of the acid followed by thorough rinsing.

- Cleaning and etching of concrete and masonry: Muriatic acid is employed in the cleaning and etching of concrete and masonry surfaces. It effectively removes efflorescence, mortar residues, and stains from these materials. The treatment process typically involves diluting the acid, applying it to the surface, allowing it to react, and then neutralizing and rinsing thoroughly.

- pH adjustment in water treatment: Muriatic acid is utilized in water treatment processes for pH adjustment. It helps to lower the pH of water in various applications, including swimming pool maintenance, industrial water treatment, and wastewater management. Proper dosing and monitoring are crucial to achieve the desired pH levels without causing adverse effects.

- Chemical synthesis and processing: In chemical synthesis and processing, muriatic acid serves as a key reagent or catalyst. It is used in the production of various chemicals, pharmaceuticals, and materials. The acid's strong proton-donating properties make it valuable in reactions such as hydrolysis, dehydration, and chlorination.

- Extraction and purification of minerals: Muriatic acid is employed in the extraction and purification of minerals from ores and other sources. It can dissolve certain minerals, allowing for their separation and recovery. This process is particularly useful in the mining and metallurgical industries for obtaining pure metals or compounds from raw materials.

02 Cleaning and descaling applications

Muriatic acid is employed in various cleaning and descaling applications, particularly in industrial settings. It is effective in removing mineral deposits, rust, and other stubborn stains from surfaces. This acid treatment is commonly used for cleaning swimming pools, removing scale from boilers and heat exchangers, and general maintenance of industrial equipment.Expand Specific Solutions03 pH adjustment in water treatment

Muriatic acid is utilized for pH adjustment in water treatment processes. It can be added to water systems to lower the pH, which is crucial in various industrial and municipal water treatment applications. This pH adjustment can help in controlling corrosion, improving water quality, and optimizing the effectiveness of other treatment chemicals.Expand Specific Solutions04 Chemical synthesis and processing

Muriatic acid plays a role in various chemical synthesis and processing applications. It is used as a reagent or catalyst in the production of organic and inorganic compounds. The acid treatment can facilitate reactions, aid in extraction processes, or serve as a key component in the manufacture of chemicals and pharmaceutical products.Expand Specific Solutions05 Soil and agricultural applications

Muriatic acid finds applications in soil treatment and agriculture. It can be used to adjust soil pH, particularly in alkaline soils, to improve nutrient availability for plants. The acid treatment may also be employed in the preparation of certain fertilizers or in the treatment of agricultural waste. However, careful application is necessary to avoid negative environmental impacts.Expand Specific Solutions

Key Players in Industrial Wastewater Treatment Sector

The treatment of paint manufacturing wastewater using muriatic acid is in a mature stage of development, with a growing market driven by increasing environmental regulations and sustainability initiatives. The global paint and coatings market, which directly impacts this sector, is projected to reach $235.06 billion by 2028, indicating significant potential for wastewater treatment solutions. Key players in this field include BASF Corp., China Petroleum & Chemical Corp., and Ecolab USA, Inc., who have established strong positions through their expertise in chemical manufacturing and water treatment technologies. These companies are continuously innovating to improve efficiency and reduce environmental impact, reflecting the industry's focus on sustainable practices and regulatory compliance.

BASF Corp.

Technical Solution: BASF Corp. has developed an advanced treatment system for paint manufacturing wastewater using muriatic acid. Their process involves a multi-stage approach, starting with pH adjustment using muriatic acid to optimize coagulation and flocculation [1]. This is followed by advanced oxidation processes (AOPs) to break down complex organic compounds. The system incorporates a specialized membrane filtration technology that can handle high Total Dissolved Solids (TDS) levels typical in paint wastewater [3]. BASF's solution also includes a proprietary chemical formulation that enhances the removal of heavy metals and pigments, achieving up to 99% removal efficiency for certain contaminants [5].

Strengths: High removal efficiency for complex contaminants, ability to handle high TDS levels, and integration of advanced oxidation processes. Weaknesses: Potentially high operational costs due to chemical consumption and energy-intensive processes.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. has implemented an innovative muriatic acid-based treatment system for paint manufacturing wastewater. Their approach utilizes a combination of chemical precipitation and electrocoagulation, with muriatic acid playing a crucial role in pH control and metal ion removal [2]. The process incorporates a novel fluidized bed reactor design that enhances mixing and reaction efficiency. Additionally, they have developed a regeneration system that recovers and reuses muriatic acid, reducing chemical consumption by up to 40% [4]. The treatment train also includes an advanced biological treatment stage optimized for the degradation of paint-specific organic compounds.

Strengths: Efficient metal removal, reduced chemical consumption through acid regeneration, and effective biological treatment for organic compounds. Weaknesses: Complex system design may require specialized maintenance and operation.

Innovations in Muriatic Acid Wastewater Treatment

Treating Agent For Acidic Waste Liquid Treatment, and Treatment Process Using The Same

PatentInactiveKR1020130010666A

Innovation

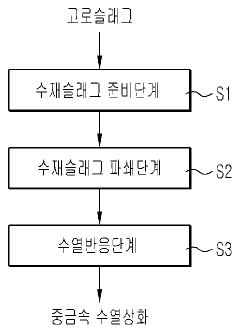

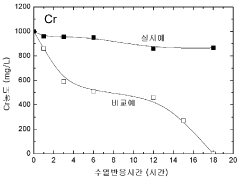

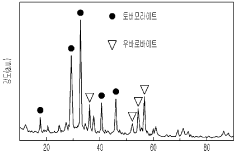

- A method involving the use of water-cooled blast furnace slag, a by-product of the ironmaking process, is crushed to 100 μm or less and subjected to a hydrothermal reaction with acidic waste liquids in an autoclave, forming stable hydrothermal phases like tobermorite and uvovalite to fix heavy metals, eliminating the need for additional reducing agents.

Reduction treatment method of waste water

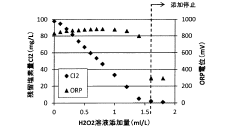

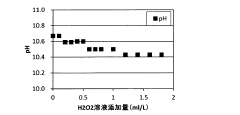

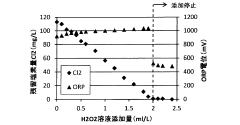

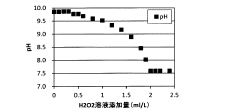

PatentActiveJP2018167238A

Innovation

- A wastewater treatment method using hydrogen peroxide solution is applied, with the optimal amount determined by measuring oxidation-reduction potential, to remove hypochlorous acid without increasing sulfate ion concentration.

Environmental Regulations for Paint Industry Effluents

The paint manufacturing industry is subject to stringent environmental regulations due to the potential hazards associated with its effluents. These regulations are designed to protect water resources, ecosystems, and public health from the harmful effects of paint manufacturing wastewater. In the United States, the Environmental Protection Agency (EPA) sets and enforces national standards for paint industry effluents under the Clean Water Act.

The National Pollutant Discharge Elimination System (NPDES) permit program is a key component of these regulations. Paint manufacturers are required to obtain NPDES permits, which specify limits on the discharge of pollutants and mandate the implementation of best management practices to minimize environmental impact. These permits often include requirements for regular monitoring, reporting, and treatment of wastewater before discharge.

Specific pollutants of concern in paint manufacturing wastewater include heavy metals, volatile organic compounds (VOCs), and suspended solids. The EPA has established effluent limitation guidelines (ELGs) for the paint and ink formulating industry, which set technology-based standards for wastewater treatment. These guidelines typically require the use of best practicable control technology (BPT) or best available technology economically achievable (BAT) to reduce pollutant loads.

In addition to federal regulations, many states and local jurisdictions have implemented their own, often more stringent, requirements for paint industry effluents. These may include lower discharge limits, additional treatment requirements, or zero-discharge policies in environmentally sensitive areas. Compliance with these multi-tiered regulations requires paint manufacturers to invest in advanced wastewater treatment technologies and implement comprehensive environmental management systems.

The use of muriatic acid (hydrochloric acid) in the treatment of paint manufacturing wastewater must be carefully managed to comply with these regulations. While it can be effective in pH adjustment and metal precipitation, its use is subject to strict controls to prevent the release of acidic effluents or the formation of harmful byproducts. Manufacturers must ensure that any treatment process using muriatic acid is designed to meet all applicable discharge standards and does not introduce new environmental risks.

Globally, similar regulatory frameworks exist in many countries, with the European Union's Water Framework Directive and Industrial Emissions Directive setting comparable standards for paint industry effluents. International agreements, such as the Stockholm Convention on Persistent Organic Pollutants, also influence regulations by targeting specific hazardous substances used in paint formulations.

As environmental concerns continue to grow, regulations for paint industry effluents are likely to become increasingly stringent. Future trends may include stricter limits on emerging contaminants, requirements for water reuse and recycling, and the promotion of cleaner production technologies to minimize wastewater generation at the source.

The National Pollutant Discharge Elimination System (NPDES) permit program is a key component of these regulations. Paint manufacturers are required to obtain NPDES permits, which specify limits on the discharge of pollutants and mandate the implementation of best management practices to minimize environmental impact. These permits often include requirements for regular monitoring, reporting, and treatment of wastewater before discharge.

Specific pollutants of concern in paint manufacturing wastewater include heavy metals, volatile organic compounds (VOCs), and suspended solids. The EPA has established effluent limitation guidelines (ELGs) for the paint and ink formulating industry, which set technology-based standards for wastewater treatment. These guidelines typically require the use of best practicable control technology (BPT) or best available technology economically achievable (BAT) to reduce pollutant loads.

In addition to federal regulations, many states and local jurisdictions have implemented their own, often more stringent, requirements for paint industry effluents. These may include lower discharge limits, additional treatment requirements, or zero-discharge policies in environmentally sensitive areas. Compliance with these multi-tiered regulations requires paint manufacturers to invest in advanced wastewater treatment technologies and implement comprehensive environmental management systems.

The use of muriatic acid (hydrochloric acid) in the treatment of paint manufacturing wastewater must be carefully managed to comply with these regulations. While it can be effective in pH adjustment and metal precipitation, its use is subject to strict controls to prevent the release of acidic effluents or the formation of harmful byproducts. Manufacturers must ensure that any treatment process using muriatic acid is designed to meet all applicable discharge standards and does not introduce new environmental risks.

Globally, similar regulatory frameworks exist in many countries, with the European Union's Water Framework Directive and Industrial Emissions Directive setting comparable standards for paint industry effluents. International agreements, such as the Stockholm Convention on Persistent Organic Pollutants, also influence regulations by targeting specific hazardous substances used in paint formulations.

As environmental concerns continue to grow, regulations for paint industry effluents are likely to become increasingly stringent. Future trends may include stricter limits on emerging contaminants, requirements for water reuse and recycling, and the promotion of cleaner production technologies to minimize wastewater generation at the source.

Cost-Benefit Analysis of Muriatic Acid Treatment

The cost-benefit analysis of muriatic acid treatment in paint manufacturing wastewater management is a critical consideration for industry stakeholders. This analysis encompasses both the direct financial implications and the broader environmental and operational impacts of implementing this treatment method.

From a cost perspective, muriatic acid treatment typically involves lower initial capital expenditure compared to more advanced treatment technologies. The primary expenses include the acid itself, storage and handling equipment, and safety measures. Operational costs are generally moderate, with the main ongoing expenses being the replenishment of acid and maintenance of treatment systems.

However, the benefits of muriatic acid treatment can be substantial. It effectively neutralizes alkaline wastewater, a common characteristic of paint manufacturing effluents. This pH adjustment is crucial for meeting regulatory discharge standards and avoiding potential fines or penalties. The treatment also aids in the removal of suspended solids and certain heavy metals, improving overall effluent quality.

Another significant benefit is the potential for water reuse within the manufacturing process. By effectively treating wastewater, companies can reduce their freshwater consumption, leading to long-term cost savings and improved environmental sustainability. This aspect is particularly valuable in regions facing water scarcity or stringent water use regulations.

The treatment process can also lead to reduced sludge production compared to some alternative methods. This results in lower disposal costs and a smaller environmental footprint. Additionally, the relatively simple nature of muriatic acid treatment often translates to lower labor costs and reduced need for specialized operator training.

However, it's important to consider potential drawbacks. The corrosive nature of muriatic acid necessitates investment in corrosion-resistant equipment and stringent safety protocols. There may also be additional costs associated with neutralizing the treated wastewater before discharge, depending on local regulations.

Long-term environmental considerations should also factor into the cost-benefit analysis. While effective in the short term, the use of strong acids in wastewater treatment may have cumulative environmental impacts that could lead to future remediation costs or regulatory challenges.

In conclusion, the cost-benefit analysis of muriatic acid treatment in paint manufacturing wastewater generally favors its implementation, particularly for small to medium-sized operations. The relatively low initial and operational costs, combined with effective pH control and potential for water reuse, often outweigh the associated risks and limitations. However, each facility must conduct a thorough analysis based on its specific operational context, regulatory environment, and long-term sustainability goals to determine the most appropriate treatment strategy.

From a cost perspective, muriatic acid treatment typically involves lower initial capital expenditure compared to more advanced treatment technologies. The primary expenses include the acid itself, storage and handling equipment, and safety measures. Operational costs are generally moderate, with the main ongoing expenses being the replenishment of acid and maintenance of treatment systems.

However, the benefits of muriatic acid treatment can be substantial. It effectively neutralizes alkaline wastewater, a common characteristic of paint manufacturing effluents. This pH adjustment is crucial for meeting regulatory discharge standards and avoiding potential fines or penalties. The treatment also aids in the removal of suspended solids and certain heavy metals, improving overall effluent quality.

Another significant benefit is the potential for water reuse within the manufacturing process. By effectively treating wastewater, companies can reduce their freshwater consumption, leading to long-term cost savings and improved environmental sustainability. This aspect is particularly valuable in regions facing water scarcity or stringent water use regulations.

The treatment process can also lead to reduced sludge production compared to some alternative methods. This results in lower disposal costs and a smaller environmental footprint. Additionally, the relatively simple nature of muriatic acid treatment often translates to lower labor costs and reduced need for specialized operator training.

However, it's important to consider potential drawbacks. The corrosive nature of muriatic acid necessitates investment in corrosion-resistant equipment and stringent safety protocols. There may also be additional costs associated with neutralizing the treated wastewater before discharge, depending on local regulations.

Long-term environmental considerations should also factor into the cost-benefit analysis. While effective in the short term, the use of strong acids in wastewater treatment may have cumulative environmental impacts that could lead to future remediation costs or regulatory challenges.

In conclusion, the cost-benefit analysis of muriatic acid treatment in paint manufacturing wastewater generally favors its implementation, particularly for small to medium-sized operations. The relatively low initial and operational costs, combined with effective pH control and potential for water reuse, often outweigh the associated risks and limitations. However, each facility must conduct a thorough analysis based on its specific operational context, regulatory environment, and long-term sustainability goals to determine the most appropriate treatment strategy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!