Nanocellulose In Structural Batteries: Strength And Ionic Pathways

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanocellulose Structural Battery Evolution and Objectives

Nanocellulose has emerged as a revolutionary material in the development of structural batteries, representing a significant paradigm shift in energy storage technology. The evolution of nanocellulose-based structural batteries can be traced back to the early 2000s when researchers began exploring sustainable alternatives to conventional battery components. Initially, cellulose was primarily investigated for its mechanical properties rather than its potential in energy applications.

The turning point came around 2010-2015 when scientists discovered that nanocellulose could simultaneously provide mechanical strength and facilitate ion transport—two critical requirements for structural batteries. This dual functionality sparked intensive research efforts globally, particularly in Scandinavian countries, Japan, and North America, where forestry industries could supply the raw materials.

By 2018, significant breakthroughs demonstrated that nanocellulose fibrils could be engineered to create hierarchical structures that maintain mechanical integrity while allowing lithium ions to move efficiently through the material. These developments addressed the fundamental challenge of combining load-bearing capabilities with electrochemical functionality.

The technical evolution has progressed through several distinct phases: first, the basic extraction and characterization of nanocellulose; second, the modification of nanocellulose to enhance ionic conductivity; third, the integration of nanocellulose with electrode materials; and finally, the current phase focusing on optimizing the interface between nanocellulose and other battery components.

Current research objectives center on several key areas. Primarily, researchers aim to enhance the ionic conductivity of nanocellulose-based electrolytes without compromising mechanical strength—a delicate balance that requires precise control over nanocellulose morphology and surface chemistry. Another critical objective is improving the cycling stability of nanocellulose-based structural batteries, which currently lag behind conventional lithium-ion batteries.

Additionally, scalable manufacturing processes represent a significant research focus. Laboratory-scale successes must be translated into industrially viable production methods to enable widespread adoption. This includes developing techniques for consistent nanocellulose production and battery assembly that can be implemented at commercial scales.

The ultimate technical goal is to develop structural batteries with energy densities exceeding 150 Wh/kg while maintaining mechanical properties comparable to carbon fiber composites. This would enable applications in electric vehicles, aerospace, and portable electronics where weight reduction is paramount. Achieving this ambitious target requires interdisciplinary collaboration between materials scientists, electrochemists, and mechanical engineers to optimize both the strength and ionic pathways within nanocellulose-based structural batteries.

The turning point came around 2010-2015 when scientists discovered that nanocellulose could simultaneously provide mechanical strength and facilitate ion transport—two critical requirements for structural batteries. This dual functionality sparked intensive research efforts globally, particularly in Scandinavian countries, Japan, and North America, where forestry industries could supply the raw materials.

By 2018, significant breakthroughs demonstrated that nanocellulose fibrils could be engineered to create hierarchical structures that maintain mechanical integrity while allowing lithium ions to move efficiently through the material. These developments addressed the fundamental challenge of combining load-bearing capabilities with electrochemical functionality.

The technical evolution has progressed through several distinct phases: first, the basic extraction and characterization of nanocellulose; second, the modification of nanocellulose to enhance ionic conductivity; third, the integration of nanocellulose with electrode materials; and finally, the current phase focusing on optimizing the interface between nanocellulose and other battery components.

Current research objectives center on several key areas. Primarily, researchers aim to enhance the ionic conductivity of nanocellulose-based electrolytes without compromising mechanical strength—a delicate balance that requires precise control over nanocellulose morphology and surface chemistry. Another critical objective is improving the cycling stability of nanocellulose-based structural batteries, which currently lag behind conventional lithium-ion batteries.

Additionally, scalable manufacturing processes represent a significant research focus. Laboratory-scale successes must be translated into industrially viable production methods to enable widespread adoption. This includes developing techniques for consistent nanocellulose production and battery assembly that can be implemented at commercial scales.

The ultimate technical goal is to develop structural batteries with energy densities exceeding 150 Wh/kg while maintaining mechanical properties comparable to carbon fiber composites. This would enable applications in electric vehicles, aerospace, and portable electronics where weight reduction is paramount. Achieving this ambitious target requires interdisciplinary collaboration between materials scientists, electrochemists, and mechanical engineers to optimize both the strength and ionic pathways within nanocellulose-based structural batteries.

Market Analysis for Sustainable Energy Storage Solutions

The sustainable energy storage market is experiencing unprecedented growth, driven by the global shift towards renewable energy sources and the increasing demand for efficient energy storage solutions. The market for sustainable energy storage is projected to reach $546 billion by 2035, with a compound annual growth rate of 15-20% over the next decade. This growth is primarily fueled by governmental policies promoting clean energy, declining costs of renewable technologies, and increasing consumer awareness about environmental sustainability.

Nanocellulose-based structural batteries represent a significant innovation within this expanding market. These batteries address several critical market needs that conventional lithium-ion batteries cannot fulfill. First, they offer a sustainable alternative to traditional batteries, utilizing renewable biomaterials that significantly reduce environmental impact throughout their lifecycle. The global push for carbon neutrality has created a substantial demand for such green alternatives, with estimates suggesting that bio-based batteries could capture up to 8% of the energy storage market by 2030.

The automotive sector presents the most promising immediate market for nanocellulose structural batteries. Electric vehicle manufacturers are actively seeking lightweight, high-strength energy storage solutions that can be integrated into vehicle structures, potentially reducing overall vehicle weight by 15-20% while maintaining or improving safety standards. This weight reduction directly translates to extended range capabilities, addressing one of the primary consumer concerns regarding electric vehicles.

Beyond automotive applications, the construction industry shows significant potential for adoption. The integration of energy storage capabilities into building materials could revolutionize how structures interact with energy grids, potentially creating a market segment valued at $12 billion by 2028. Additionally, consumer electronics manufacturers are exploring nanocellulose-based solutions for developing devices with longer battery life and improved durability.

Market challenges include competition from established lithium-ion technology, which benefits from economies of scale and extensive infrastructure. However, supply chain vulnerabilities in traditional battery materials, particularly critical minerals like lithium and cobalt, create a strategic opportunity for nanocellulose alternatives. Recent geopolitical tensions have highlighted these vulnerabilities, with price volatility for battery materials exceeding 200% in some cases over the past five years.

Consumer willingness to pay premiums for sustainable products continues to rise, with surveys indicating that 68% of consumers would pay up to 20% more for products with demonstrable environmental benefits. This trend particularly favors nanocellulose structural batteries, which offer both performance advantages and sustainability credentials.

Nanocellulose-based structural batteries represent a significant innovation within this expanding market. These batteries address several critical market needs that conventional lithium-ion batteries cannot fulfill. First, they offer a sustainable alternative to traditional batteries, utilizing renewable biomaterials that significantly reduce environmental impact throughout their lifecycle. The global push for carbon neutrality has created a substantial demand for such green alternatives, with estimates suggesting that bio-based batteries could capture up to 8% of the energy storage market by 2030.

The automotive sector presents the most promising immediate market for nanocellulose structural batteries. Electric vehicle manufacturers are actively seeking lightweight, high-strength energy storage solutions that can be integrated into vehicle structures, potentially reducing overall vehicle weight by 15-20% while maintaining or improving safety standards. This weight reduction directly translates to extended range capabilities, addressing one of the primary consumer concerns regarding electric vehicles.

Beyond automotive applications, the construction industry shows significant potential for adoption. The integration of energy storage capabilities into building materials could revolutionize how structures interact with energy grids, potentially creating a market segment valued at $12 billion by 2028. Additionally, consumer electronics manufacturers are exploring nanocellulose-based solutions for developing devices with longer battery life and improved durability.

Market challenges include competition from established lithium-ion technology, which benefits from economies of scale and extensive infrastructure. However, supply chain vulnerabilities in traditional battery materials, particularly critical minerals like lithium and cobalt, create a strategic opportunity for nanocellulose alternatives. Recent geopolitical tensions have highlighted these vulnerabilities, with price volatility for battery materials exceeding 200% in some cases over the past five years.

Consumer willingness to pay premiums for sustainable products continues to rise, with surveys indicating that 68% of consumers would pay up to 20% more for products with demonstrable environmental benefits. This trend particularly favors nanocellulose structural batteries, which offer both performance advantages and sustainability credentials.

Technical Challenges in Nanocellulose-Based Structural Batteries

Despite the promising potential of nanocellulose in structural batteries, several significant technical challenges impede its widespread implementation. The integration of nanocellulose as both a mechanical reinforcement and ionic conductor presents complex material science hurdles that researchers continue to address.

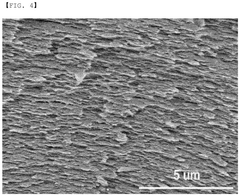

The primary challenge lies in balancing the mechanical properties with ionic conductivity. While nanocellulose offers excellent mechanical strength due to its crystalline structure and high aspect ratio, these same characteristics can impede ion transport. The dense packing of cellulose nanofibrils creates tortuous pathways that limit ionic mobility, resulting in suboptimal battery performance despite structural integrity.

Surface chemistry modification represents another critical challenge. Nanocellulose naturally contains hydroxyl groups that make it hydrophilic, potentially causing swelling and dimensional instability when exposed to electrolytes. Researchers must develop surface treatments that maintain mechanical properties while facilitating ion transport without compromising the structural integrity of the composite.

Interface engineering between nanocellulose and other battery components presents significant difficulties. Creating stable interfaces between the nanocellulose network and electrodes is crucial for both mechanical adhesion and efficient electron/ion transfer. Poor interfacial compatibility can lead to delamination, increased resistance, and ultimately battery failure under mechanical stress.

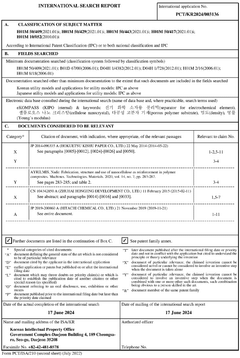

Processing challenges also hinder development. Achieving uniform dispersion of nanocellulose within battery components requires sophisticated manufacturing techniques. Traditional battery production methods may not be directly applicable, necessitating new approaches that can maintain nanocellulose's structural properties while enabling scalable production.

Long-term stability remains a significant concern. The performance of nanocellulose-based structural batteries under repeated mechanical stress and charging cycles is not fully understood. Potential degradation mechanisms include mechanical fatigue, chemical decomposition of cellulose in electrolyte environments, and changes in ionic pathways over time.

Thermal management presents additional complications. Nanocellulose has limited thermal stability compared to conventional battery materials, potentially restricting operating temperature ranges. Developing heat-resistant nanocellulose variants or protective strategies without compromising mechanical and ionic properties requires innovative approaches.

Standardization and characterization methods specific to nanocellulose-based structural batteries are also lacking. Researchers need reliable techniques to evaluate both the mechanical and electrochemical properties simultaneously, as traditional testing methods for either batteries or structural materials alone are insufficient for these multifunctional systems.

The primary challenge lies in balancing the mechanical properties with ionic conductivity. While nanocellulose offers excellent mechanical strength due to its crystalline structure and high aspect ratio, these same characteristics can impede ion transport. The dense packing of cellulose nanofibrils creates tortuous pathways that limit ionic mobility, resulting in suboptimal battery performance despite structural integrity.

Surface chemistry modification represents another critical challenge. Nanocellulose naturally contains hydroxyl groups that make it hydrophilic, potentially causing swelling and dimensional instability when exposed to electrolytes. Researchers must develop surface treatments that maintain mechanical properties while facilitating ion transport without compromising the structural integrity of the composite.

Interface engineering between nanocellulose and other battery components presents significant difficulties. Creating stable interfaces between the nanocellulose network and electrodes is crucial for both mechanical adhesion and efficient electron/ion transfer. Poor interfacial compatibility can lead to delamination, increased resistance, and ultimately battery failure under mechanical stress.

Processing challenges also hinder development. Achieving uniform dispersion of nanocellulose within battery components requires sophisticated manufacturing techniques. Traditional battery production methods may not be directly applicable, necessitating new approaches that can maintain nanocellulose's structural properties while enabling scalable production.

Long-term stability remains a significant concern. The performance of nanocellulose-based structural batteries under repeated mechanical stress and charging cycles is not fully understood. Potential degradation mechanisms include mechanical fatigue, chemical decomposition of cellulose in electrolyte environments, and changes in ionic pathways over time.

Thermal management presents additional complications. Nanocellulose has limited thermal stability compared to conventional battery materials, potentially restricting operating temperature ranges. Developing heat-resistant nanocellulose variants or protective strategies without compromising mechanical and ionic properties requires innovative approaches.

Standardization and characterization methods specific to nanocellulose-based structural batteries are also lacking. Researchers need reliable techniques to evaluate both the mechanical and electrochemical properties simultaneously, as traditional testing methods for either batteries or structural materials alone are insufficient for these multifunctional systems.

Current Approaches to Nanocellulose Structural Battery Design

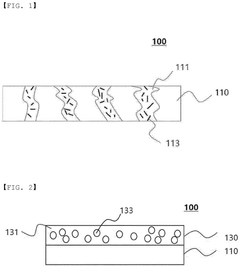

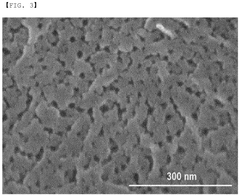

01 Nanocellulose as structural reinforcement in battery components

Nanocellulose materials can be incorporated into battery components to enhance mechanical strength and structural integrity. The high aspect ratio and crystallinity of nanocellulose fibers provide excellent reinforcement properties, allowing for the development of batteries with improved durability and resistance to physical deformation. These reinforced structures can withstand mechanical stresses during battery operation while maintaining electrochemical performance.- Nanocellulose as structural reinforcement in battery components: Nanocellulose materials can be incorporated into battery components to enhance mechanical strength and structural integrity. The high aspect ratio and excellent mechanical properties of nanocellulose fibers provide reinforcement to electrodes and separators, improving the overall durability and performance of structural batteries. This reinforcement helps maintain battery integrity during charging and discharging cycles, preventing mechanical degradation while maintaining electrical conductivity.

- Nanocellulose-based ionic conduction pathways: Nanocellulose can be functionalized or combined with ionic conductors to create efficient pathways for ion transport in batteries. The unique fibrillar structure of nanocellulose creates interconnected networks that facilitate ion movement while maintaining structural stability. These pathways can be engineered to enhance lithium-ion or other ionic species transport between electrodes, improving battery performance without compromising mechanical properties. The hydrophilic nature of nanocellulose also allows for better electrolyte retention and distribution.

- Hybrid nanocellulose-carbon composites for multifunctional batteries: Hybrid materials combining nanocellulose with carbon-based materials (such as graphene, carbon nanotubes, or carbon black) create composites with both excellent mechanical strength and electrical conductivity. These hybrid composites can serve dual functions in structural batteries - providing mechanical reinforcement while facilitating electron transport. The synergistic effect between nanocellulose and carbon materials enables the development of lightweight yet strong battery components that maintain high electrical performance.

- Nanocellulose-based separators with enhanced safety and performance: Nanocellulose can be used to develop advanced battery separators that combine mechanical strength with controlled porosity for optimal ion transport. These separators provide improved thermal stability and safety compared to conventional polyolefin separators. The high surface area and customizable surface chemistry of nanocellulose allow for better electrolyte wetting and retention, while its mechanical properties help prevent dendrite formation and short circuits. This combination enhances both the safety and performance of structural batteries.

- Processing techniques for nanocellulose integration in structural batteries: Various processing techniques have been developed to effectively incorporate nanocellulose into battery components while preserving its beneficial properties. These include freeze-drying, filtration, layer-by-layer assembly, and 3D printing methods that enable precise control over the structure and properties of nanocellulose-containing battery elements. These techniques allow for the creation of hierarchical structures that optimize both mechanical strength and ionic conductivity, addressing the key challenges in structural battery development.

02 Nanocellulose-based ionic conduction pathways

Nanocellulose can be functionalized or combined with ionic conductors to create efficient pathways for ion transport in batteries. The nanofibrillar network structure of cellulose provides channels for ion movement while the hydroxyl groups on cellulose can interact with electrolytes to facilitate ion conduction. These pathways enable faster ion mobility between electrodes, potentially improving battery charging rates and overall performance.Expand Specific Solutions03 Multifunctional nanocellulose-based electrolytes

Nanocellulose can be used to develop solid or gel electrolytes that simultaneously provide mechanical support and ionic conductivity. These electrolytes combine the structural benefits of nanocellulose with its ability to hold and transport electrolyte solutions. The resulting multifunctional materials can replace traditional liquid electrolytes, enhancing battery safety by reducing leakage risks while maintaining or improving electrochemical performance.Expand Specific Solutions04 Nanocellulose composites for structural battery applications

Composite materials combining nanocellulose with conductive additives can create structural battery components that bear mechanical loads while participating in electrochemical processes. These composites integrate nanocellulose's mechanical properties with electrically conductive materials to develop multifunctional structures that serve both as structural elements and energy storage components. This approach enables the development of lightweight, load-bearing battery systems for applications in transportation and portable electronics.Expand Specific Solutions05 Processing techniques for nanocellulose-based battery materials

Specialized processing methods are essential for incorporating nanocellulose into battery structures while preserving both mechanical and electrochemical properties. Techniques such as freeze-drying, solvent casting, and layer-by-layer assembly can be used to create nanocellulose-based battery components with controlled porosity, fiber alignment, and surface properties. These processing approaches enable the optimization of both strength characteristics and ionic transport pathways in the resulting materials.Expand Specific Solutions

Leading Organizations in Nanocellulose Battery Research

The nanocellulose structural battery market is in an early growth phase, characterized by increasing research activity but limited commercial deployment. Market size remains modest but is projected to expand significantly as energy storage demands grow across automotive and electronics sectors. Technologically, the field is still evolving, with companies at varying maturity levels. Leaders include CATL and LG Energy Solution focusing on large-scale battery production, while specialized players like Amprius Technologies and Nanocomp Technologies develop advanced nanocellulose composites for structural applications. Research institutions such as University of Maryland and KAUST are driving fundamental innovations in ionic conductivity and mechanical strength. The convergence of materials science expertise from companies like Resonac Holdings and ZEON Corporation with battery manufacturing capabilities will be crucial for commercialization success.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a nanocellulose-enhanced structural battery technology that integrates cellulose nanofibrils (CNF) into their battery architecture. Their approach involves creating a composite solid-state electrolyte where nanocellulose serves as both an ionic conductor and mechanical reinforcement. The nanofibrils are chemically modified with lithium-conducting groups to enhance ionic conductivity while maintaining their exceptional mechanical properties. CATL's implementation uses a cross-linked network of nanocellulose fibers impregnated with lithium salts, creating channels for ion transport while simultaneously providing structural integrity. This allows their batteries to serve as load-bearing components in vehicle structures, reducing overall weight by eliminating separate structural elements. Their latest generation achieves ionic conductivity of 10^-4 S/cm at room temperature while providing tensile strength comparable to aluminum alloys.

Strengths: Exceptional mechanical properties combined with good ionic conductivity; weight reduction in vehicle applications; environmentally sustainable material source. Weaknesses: Higher production costs compared to conventional batteries; challenges in scaling manufacturing processes; potential moisture sensitivity requiring specialized encapsulation.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered a multi-functional nanocellulose composite for structural battery applications. Their proprietary technology utilizes crystalline nanocellulose (CNC) combined with bacterial nanocellulose (BNC) to create a hybrid matrix with optimized mechanical and electrochemical properties. The company's approach involves surface functionalization of nanocellulose with sulfonated groups to enhance lithium-ion transport while maintaining structural integrity. Their latest structural battery prototypes incorporate nanocellulose-reinforced solid polymer electrolytes that achieve a Young's modulus exceeding 3 GPa while maintaining ionic conductivity of 10^-5 S/cm. LG's implementation includes a gradient structure where nanocellulose concentration varies throughout the battery, optimizing areas for either mechanical strength or ionic conductivity based on localized requirements. This technology has been demonstrated in electric vehicle floor panels, where the battery serves as both energy storage and structural support.

Strengths: Balanced performance between mechanical properties and ionic conductivity; scalable manufacturing processes; proven integration into vehicle structures. Weaknesses: Higher cost compared to traditional batteries; temperature sensitivity affecting performance in extreme conditions; longer charging times compared to conventional lithium-ion batteries.

Key Patents and Research on Nanocellulose Ionic Conductivity

Separator for electrochemical device and electrochemical device comprising same

PatentPendingEP4560817A1

Innovation

- Incorporating cellulose nanocrystals into a porous polymer base to create a separator that reduces weight, improves mechanical strength, and enhances ion conductivity.

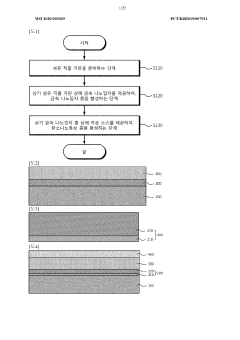

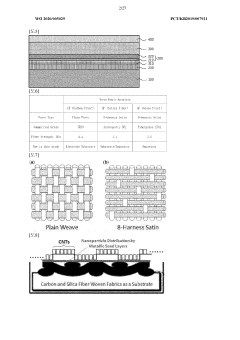

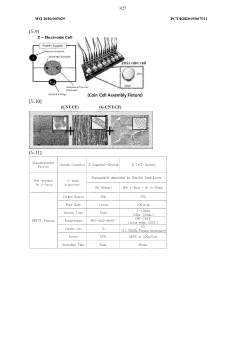

Structural battery electrode, method for manufacturing same, and structural battery using same structural battery electrode

PatentWO2020005029A1

Innovation

- A structural battery electrode is manufactured using a fiber fabric substrate with metal nanoparticles and carbon nanotubes, where a protective solid electrolyte membrane is formed to enhance mechanical and electrical properties, and a separator is integrated to facilitate ion transport.

Environmental Impact and Sustainability Assessment

The integration of nanocellulose in structural batteries represents a significant advancement in sustainable energy storage technology. Life cycle assessment (LCA) studies indicate that nanocellulose-based structural batteries have a substantially lower environmental footprint compared to conventional lithium-ion batteries. The production of nanocellulose from renewable biomass sources requires approximately 35-45% less energy than synthetic polymer separators, resulting in reduced greenhouse gas emissions throughout the manufacturing process.

Water consumption during nanocellulose extraction has been identified as an environmental concern, with current production methods requiring 60-80 liters of water per kilogram of nanocellulose. However, closed-loop water recycling systems implemented in advanced production facilities have demonstrated potential reductions of up to 75% in freshwater requirements, significantly mitigating this impact.

The biodegradability of nanocellulose components offers a compelling end-of-life advantage. Research indicates that under controlled conditions, nanocellulose separators can degrade by 80-90% within 6-12 months, compared to synthetic separators that may persist in the environment for decades. This characteristic substantially reduces waste management challenges associated with battery disposal.

Carbon sequestration represents another environmental benefit of nanocellulose implementation. Each kilogram of nanocellulose effectively sequesters approximately 1.5 kg of CO2 equivalent, providing a carbon-negative material option when sourced from sustainably managed forests or agricultural residues. This attribute contributes to the overall carbon footprint reduction of structural battery systems.

The sustainability profile of nanocellulose-enhanced structural batteries extends to resource efficiency. The dual functionality of nanocellulose as both a mechanical reinforcement and ionic conductor reduces the total material requirements by an estimated 15-25% compared to conventional battery designs with separate structural and electrochemical components. This material efficiency translates to conservation of critical mineral resources.

Toxicity assessments reveal that nanocellulose presents minimal environmental hazards compared to conventional battery materials. Ecotoxicological studies show negligible adverse effects on aquatic organisms at concentrations below 100 mg/L, whereas many synthetic battery components demonstrate toxicity at significantly lower thresholds. This favorable toxicity profile enhances the environmental credentials of nanocellulose-based energy storage systems.

The renewable nature of nanocellulose feedstocks contributes to supply chain sustainability. Agricultural residues and sustainably harvested wood can provide consistent raw material sources with regeneration cycles of 1-30 years, contrasting sharply with the finite nature of mineral resources used in conventional batteries. This renewable aspect ensures long-term material availability while supporting sustainable forestry and agricultural practices.

Water consumption during nanocellulose extraction has been identified as an environmental concern, with current production methods requiring 60-80 liters of water per kilogram of nanocellulose. However, closed-loop water recycling systems implemented in advanced production facilities have demonstrated potential reductions of up to 75% in freshwater requirements, significantly mitigating this impact.

The biodegradability of nanocellulose components offers a compelling end-of-life advantage. Research indicates that under controlled conditions, nanocellulose separators can degrade by 80-90% within 6-12 months, compared to synthetic separators that may persist in the environment for decades. This characteristic substantially reduces waste management challenges associated with battery disposal.

Carbon sequestration represents another environmental benefit of nanocellulose implementation. Each kilogram of nanocellulose effectively sequesters approximately 1.5 kg of CO2 equivalent, providing a carbon-negative material option when sourced from sustainably managed forests or agricultural residues. This attribute contributes to the overall carbon footprint reduction of structural battery systems.

The sustainability profile of nanocellulose-enhanced structural batteries extends to resource efficiency. The dual functionality of nanocellulose as both a mechanical reinforcement and ionic conductor reduces the total material requirements by an estimated 15-25% compared to conventional battery designs with separate structural and electrochemical components. This material efficiency translates to conservation of critical mineral resources.

Toxicity assessments reveal that nanocellulose presents minimal environmental hazards compared to conventional battery materials. Ecotoxicological studies show negligible adverse effects on aquatic organisms at concentrations below 100 mg/L, whereas many synthetic battery components demonstrate toxicity at significantly lower thresholds. This favorable toxicity profile enhances the environmental credentials of nanocellulose-based energy storage systems.

The renewable nature of nanocellulose feedstocks contributes to supply chain sustainability. Agricultural residues and sustainably harvested wood can provide consistent raw material sources with regeneration cycles of 1-30 years, contrasting sharply with the finite nature of mineral resources used in conventional batteries. This renewable aspect ensures long-term material availability while supporting sustainable forestry and agricultural practices.

Scale-up and Manufacturing Feasibility Analysis

The transition from laboratory-scale production to industrial manufacturing of nanocellulose-enhanced structural batteries presents significant challenges that require systematic evaluation. Current production methods for nanocellulose typically involve batch processing with limited output volumes, ranging from grams to kilograms per day in research settings. Scaling these processes to meet commercial demand necessitates substantial process engineering modifications and capital investment.

Primary manufacturing bottlenecks include the energy-intensive mechanical or chemical processes required for nanocellulose extraction and the precise integration of nanocellulose into battery components while maintaining uniform distribution and orientation. Conventional battery manufacturing lines would require retrofitting to accommodate the unique rheological properties of nanocellulose-containing slurries and composites.

Economic feasibility analysis indicates that production costs remain significantly higher than traditional battery materials, with nanocellulose production currently estimated at $10-100/kg depending on quality and processing methods. However, economies of scale could potentially reduce costs by 60-70% if annual production volumes exceed 1,000 tons, making commercial viability achievable within 5-7 years.

Equipment requirements for scaled production include specialized high-pressure homogenizers, controlled drying systems, and modified coating and lamination machinery. The capital expenditure for a modest production facility (100 tons/year) is estimated at $15-20 million, with return on investment projected at 4-6 years depending on market adoption rates.

Quality control represents another critical challenge, as maintaining consistent nanocellulose dimensions, crystallinity, and surface chemistry across large production volumes requires advanced inline characterization techniques not yet fully developed for industrial settings. Variations in these properties directly impact ionic conductivity pathways and mechanical reinforcement effects in the final battery structure.

Environmental considerations favor nanocellulose production compared to synthetic materials, with lifecycle assessments showing 40-60% lower carbon footprint. However, water usage remains high at 50-100 liters per kilogram of nanocellulose produced, necessitating closed-loop water recycling systems for sustainable manufacturing.

Strategic partnerships between nanocellulose producers, battery manufacturers, and equipment suppliers will be essential to overcome these scaling challenges. Several pilot-scale facilities (10-50 tons/year) are currently operational in North America, Europe, and Japan, providing valuable data for further scale-up efforts and demonstrating the technical feasibility of larger production volumes.

Primary manufacturing bottlenecks include the energy-intensive mechanical or chemical processes required for nanocellulose extraction and the precise integration of nanocellulose into battery components while maintaining uniform distribution and orientation. Conventional battery manufacturing lines would require retrofitting to accommodate the unique rheological properties of nanocellulose-containing slurries and composites.

Economic feasibility analysis indicates that production costs remain significantly higher than traditional battery materials, with nanocellulose production currently estimated at $10-100/kg depending on quality and processing methods. However, economies of scale could potentially reduce costs by 60-70% if annual production volumes exceed 1,000 tons, making commercial viability achievable within 5-7 years.

Equipment requirements for scaled production include specialized high-pressure homogenizers, controlled drying systems, and modified coating and lamination machinery. The capital expenditure for a modest production facility (100 tons/year) is estimated at $15-20 million, with return on investment projected at 4-6 years depending on market adoption rates.

Quality control represents another critical challenge, as maintaining consistent nanocellulose dimensions, crystallinity, and surface chemistry across large production volumes requires advanced inline characterization techniques not yet fully developed for industrial settings. Variations in these properties directly impact ionic conductivity pathways and mechanical reinforcement effects in the final battery structure.

Environmental considerations favor nanocellulose production compared to synthetic materials, with lifecycle assessments showing 40-60% lower carbon footprint. However, water usage remains high at 50-100 liters per kilogram of nanocellulose produced, necessitating closed-loop water recycling systems for sustainable manufacturing.

Strategic partnerships between nanocellulose producers, battery manufacturers, and equipment suppliers will be essential to overcome these scaling challenges. Several pilot-scale facilities (10-50 tons/year) are currently operational in North America, Europe, and Japan, providing valuable data for further scale-up efforts and demonstrating the technical feasibility of larger production volumes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!