Quality Control Protocols For Consistent Nanocellulose-Based Material Production

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanocellulose Production Background and Objectives

Nanocellulose has emerged as a revolutionary biomaterial with exceptional properties, marking a significant advancement in sustainable material science over the past two decades. Derived from cellulose, the most abundant biopolymer on Earth, nanocellulose combines remarkable mechanical strength, high surface area, biodegradability, and renewability. The evolution of nanocellulose technology has progressed from initial laboratory discoveries in the 1980s to industrial-scale production methods in recent years, driven by growing environmental concerns and the search for petroleum-based material alternatives.

The development trajectory of nanocellulose has been characterized by three distinct phases: discovery and fundamental research (1980s-2000s), process optimization and scaling (2000s-2015), and the current commercialization and application expansion phase (2015-present). Each phase has contributed significantly to our understanding of nanocellulose properties and production methodologies, gradually transforming it from a laboratory curiosity to a commercially viable material.

Current technical objectives in nanocellulose production focus primarily on establishing robust quality control protocols to ensure consistent material properties across production batches. This consistency is crucial for industrial adoption, as variations in fiber dimensions, crystallinity, surface chemistry, and purity can significantly impact performance in end applications. The heterogeneity inherent in natural cellulose sources presents a fundamental challenge that must be addressed through standardized processing and characterization methods.

The primary technical goals for advancing nanocellulose production include developing real-time monitoring systems for production parameters, establishing industry-wide quality standards, reducing energy consumption in processing, and creating closed-loop production systems that minimize waste and environmental impact. Additionally, there is significant interest in developing hybrid production methods that combine mechanical, chemical, and enzymatic approaches to optimize both efficiency and material properties.

Looking forward, the field aims to achieve precise control over nanocellulose morphology and surface functionality to tailor materials for specific applications ranging from advanced composites to biomedical devices. This requires deeper understanding of structure-property relationships and the development of predictive models that can guide process optimization. The ultimate objective is to establish nanocellulose as a mainstream industrial material with well-defined, reproducible properties that can be consistently manufactured at competitive costs.

The convergence of nanotechnology, biotechnology, and materials science continues to drive innovation in this field, with increasing focus on developing sustainable production pathways that align with circular economy principles and reduced carbon footprints. This interdisciplinary approach is essential for realizing the full potential of nanocellulose as a next-generation sustainable material.

The development trajectory of nanocellulose has been characterized by three distinct phases: discovery and fundamental research (1980s-2000s), process optimization and scaling (2000s-2015), and the current commercialization and application expansion phase (2015-present). Each phase has contributed significantly to our understanding of nanocellulose properties and production methodologies, gradually transforming it from a laboratory curiosity to a commercially viable material.

Current technical objectives in nanocellulose production focus primarily on establishing robust quality control protocols to ensure consistent material properties across production batches. This consistency is crucial for industrial adoption, as variations in fiber dimensions, crystallinity, surface chemistry, and purity can significantly impact performance in end applications. The heterogeneity inherent in natural cellulose sources presents a fundamental challenge that must be addressed through standardized processing and characterization methods.

The primary technical goals for advancing nanocellulose production include developing real-time monitoring systems for production parameters, establishing industry-wide quality standards, reducing energy consumption in processing, and creating closed-loop production systems that minimize waste and environmental impact. Additionally, there is significant interest in developing hybrid production methods that combine mechanical, chemical, and enzymatic approaches to optimize both efficiency and material properties.

Looking forward, the field aims to achieve precise control over nanocellulose morphology and surface functionality to tailor materials for specific applications ranging from advanced composites to biomedical devices. This requires deeper understanding of structure-property relationships and the development of predictive models that can guide process optimization. The ultimate objective is to establish nanocellulose as a mainstream industrial material with well-defined, reproducible properties that can be consistently manufactured at competitive costs.

The convergence of nanotechnology, biotechnology, and materials science continues to drive innovation in this field, with increasing focus on developing sustainable production pathways that align with circular economy principles and reduced carbon footprints. This interdisciplinary approach is essential for realizing the full potential of nanocellulose as a next-generation sustainable material.

Market Analysis for Nanocellulose-Based Materials

The global nanocellulose market has demonstrated remarkable growth potential, with a valuation of approximately $297 million in 2020 and projections indicating expansion to reach $783 million by 2025, representing a compound annual growth rate (CAGR) of 21.3%. This accelerated growth trajectory is primarily driven by increasing environmental concerns and the subsequent shift toward sustainable materials across various industries.

The packaging sector currently dominates the application landscape for nanocellulose-based materials, accounting for roughly 35% of the total market share. This dominance stems from the exceptional barrier properties, biodegradability, and mechanical strength that nanocellulose offers as an alternative to conventional plastic packaging. The food and beverage industry has been particularly receptive to these materials due to stringent regulations on plastic usage and growing consumer demand for eco-friendly packaging solutions.

Composite applications represent the fastest-growing segment, with a CAGR of approximately 24%, as automotive, aerospace, and construction industries increasingly incorporate nanocellulose to enhance material performance while reducing weight and environmental impact. The biomedical sector, though smaller in current market share (around 12%), shows promising growth potential due to nanocellulose's biocompatibility and unique structural properties suitable for tissue engineering and drug delivery systems.

Regionally, North America and Europe collectively account for over 60% of the global nanocellulose market, with established research infrastructure and supportive regulatory frameworks accelerating commercialization. However, Asia-Pacific is emerging as the fastest-growing region, with countries like Japan, China, and South Korea making significant investments in nanocellulose research and production facilities.

A critical market challenge remains the high production costs associated with consistent, high-quality nanocellulose manufacturing. Current production costs range from $4-10 per kilogram for cellulose nanofibrils (CNF) and $10-20 per kilogram for cellulose nanocrystals (CNC), significantly higher than conventional materials they aim to replace. This cost barrier underscores the urgent need for standardized quality control protocols to improve production efficiency and material consistency.

Consumer awareness and market education represent additional challenges, as many potential end-users remain unfamiliar with nanocellulose properties and applications. Industry surveys indicate that approximately 65% of potential industrial users cite concerns about material consistency and quality assurance as primary barriers to adoption, highlighting the direct connection between quality control protocols and market expansion.

The market outlook remains highly positive, with technological advancements in production methods and increasing regulatory pressure on conventional plastics expected to further accelerate adoption across multiple industries. Analysts predict that improvements in quality control and standardization could potentially reduce production costs by 30-40% within the next five years, significantly expanding market penetration.

The packaging sector currently dominates the application landscape for nanocellulose-based materials, accounting for roughly 35% of the total market share. This dominance stems from the exceptional barrier properties, biodegradability, and mechanical strength that nanocellulose offers as an alternative to conventional plastic packaging. The food and beverage industry has been particularly receptive to these materials due to stringent regulations on plastic usage and growing consumer demand for eco-friendly packaging solutions.

Composite applications represent the fastest-growing segment, with a CAGR of approximately 24%, as automotive, aerospace, and construction industries increasingly incorporate nanocellulose to enhance material performance while reducing weight and environmental impact. The biomedical sector, though smaller in current market share (around 12%), shows promising growth potential due to nanocellulose's biocompatibility and unique structural properties suitable for tissue engineering and drug delivery systems.

Regionally, North America and Europe collectively account for over 60% of the global nanocellulose market, with established research infrastructure and supportive regulatory frameworks accelerating commercialization. However, Asia-Pacific is emerging as the fastest-growing region, with countries like Japan, China, and South Korea making significant investments in nanocellulose research and production facilities.

A critical market challenge remains the high production costs associated with consistent, high-quality nanocellulose manufacturing. Current production costs range from $4-10 per kilogram for cellulose nanofibrils (CNF) and $10-20 per kilogram for cellulose nanocrystals (CNC), significantly higher than conventional materials they aim to replace. This cost barrier underscores the urgent need for standardized quality control protocols to improve production efficiency and material consistency.

Consumer awareness and market education represent additional challenges, as many potential end-users remain unfamiliar with nanocellulose properties and applications. Industry surveys indicate that approximately 65% of potential industrial users cite concerns about material consistency and quality assurance as primary barriers to adoption, highlighting the direct connection between quality control protocols and market expansion.

The market outlook remains highly positive, with technological advancements in production methods and increasing regulatory pressure on conventional plastics expected to further accelerate adoption across multiple industries. Analysts predict that improvements in quality control and standardization could potentially reduce production costs by 30-40% within the next five years, significantly expanding market penetration.

Current QC Challenges in Nanocellulose Manufacturing

The manufacturing of nanocellulose-based materials faces significant quality control challenges that impede consistent production at industrial scale. Current production processes exhibit considerable batch-to-batch variability, with fluctuations in fiber dimensions, crystallinity, and surface chemistry. These inconsistencies directly impact the mechanical, thermal, and barrier properties of the final materials, creating obstacles for commercial applications requiring reliable performance.

Dimensional characterization represents a primary challenge, as existing analytical techniques struggle to accurately measure the heterogeneous size distributions typical in nanocellulose suspensions. Conventional methods like dynamic light scattering often produce misleading results due to the high aspect ratio and aggregation tendencies of nanocellulose fibrils. Microscopy techniques provide valuable visualization but suffer from sampling limitations and preparation artifacts that can distort true morphological characteristics.

Surface chemistry characterization presents another significant hurdle. The complex, hierarchical structure of nanocellulose makes quantitative assessment of surface functional groups challenging. Current methods like titration and spectroscopy techniques often yield inconsistent results between laboratories, hampering standardization efforts. This variability directly affects downstream processing, as surface chemistry governs dispersion stability, rheological behavior, and compatibility with matrix materials in composites.

Process monitoring capabilities remain inadequate for real-time quality assessment during production. Most characterization methods require offline analysis with significant time delays, preventing immediate process adjustments. The lack of in-line monitoring tools suitable for high-solids suspensions and the harsh conditions of industrial processing environments further complicates quality control implementation.

Standardization gaps persist across the industry, with no universally accepted protocols for characterizing critical nanocellulose properties. Different research groups and manufacturers employ varied methodologies, making direct comparisons between materials from different sources nearly impossible. This fragmentation hinders technology transfer and slows commercial adoption of nanocellulose-based materials.

Scaling effects introduce additional complexities, as quality control protocols developed at laboratory scale often prove inadequate when translated to industrial production. Phenomena like shear-induced aggregation, heat transfer limitations, and mixing inefficiencies at larger scales can dramatically alter material properties, necessitating scale-specific quality control approaches.

Contamination detection and control represent persistent challenges, particularly for applications in food packaging, biomedical devices, and electronics. Current analytical methods lack sufficient sensitivity to detect trace contaminants that may compromise performance or safety, while filtration and purification processes add significant cost and complexity to manufacturing operations.

Dimensional characterization represents a primary challenge, as existing analytical techniques struggle to accurately measure the heterogeneous size distributions typical in nanocellulose suspensions. Conventional methods like dynamic light scattering often produce misleading results due to the high aspect ratio and aggregation tendencies of nanocellulose fibrils. Microscopy techniques provide valuable visualization but suffer from sampling limitations and preparation artifacts that can distort true morphological characteristics.

Surface chemistry characterization presents another significant hurdle. The complex, hierarchical structure of nanocellulose makes quantitative assessment of surface functional groups challenging. Current methods like titration and spectroscopy techniques often yield inconsistent results between laboratories, hampering standardization efforts. This variability directly affects downstream processing, as surface chemistry governs dispersion stability, rheological behavior, and compatibility with matrix materials in composites.

Process monitoring capabilities remain inadequate for real-time quality assessment during production. Most characterization methods require offline analysis with significant time delays, preventing immediate process adjustments. The lack of in-line monitoring tools suitable for high-solids suspensions and the harsh conditions of industrial processing environments further complicates quality control implementation.

Standardization gaps persist across the industry, with no universally accepted protocols for characterizing critical nanocellulose properties. Different research groups and manufacturers employ varied methodologies, making direct comparisons between materials from different sources nearly impossible. This fragmentation hinders technology transfer and slows commercial adoption of nanocellulose-based materials.

Scaling effects introduce additional complexities, as quality control protocols developed at laboratory scale often prove inadequate when translated to industrial production. Phenomena like shear-induced aggregation, heat transfer limitations, and mixing inefficiencies at larger scales can dramatically alter material properties, necessitating scale-specific quality control approaches.

Contamination detection and control represent persistent challenges, particularly for applications in food packaging, biomedical devices, and electronics. Current analytical methods lack sufficient sensitivity to detect trace contaminants that may compromise performance or safety, while filtration and purification processes add significant cost and complexity to manufacturing operations.

Established QC Protocols for Nanocellulose Production

01 Nanocellulose consistency control methods

Various methods can be employed to control the consistency of nanocellulose-based materials. These include mechanical processing techniques such as homogenization, microfluidization, and high-pressure homogenization that can adjust the fibril dimensions and network structure. Chemical treatments can also be used to modify surface properties and rheological behavior, resulting in more consistent nanocellulose materials with predictable performance characteristics.- Nanocellulose consistency control methods: Various methods can be employed to control the consistency of nanocellulose-based materials. These include mechanical processing techniques such as homogenization, microfluidization, and high-pressure homogenization that can adjust the fibril dimensions and network structure. Chemical treatments can also be used to modify surface properties and rheological behavior, resulting in more consistent nanocellulose suspensions with predictable flow properties.

- Rheological properties of nanocellulose materials: Nanocellulose-based materials exhibit unique rheological properties that affect their consistency. These materials typically show shear-thinning behavior, thixotropy, and yield stress characteristics. The concentration of nanocellulose fibrils, aspect ratio, surface charge, and network formation all contribute to the final consistency of the material. Understanding these properties is crucial for formulating nanocellulose materials with desired flow and application characteristics.

- Additives for modifying nanocellulose consistency: Various additives can be incorporated into nanocellulose formulations to modify their consistency. These include polymeric binders, plasticizers, cross-linking agents, and surfactants. The addition of these components can help adjust viscosity, improve dispersion stability, enhance film-forming properties, and provide better control over the final material consistency. Careful selection of additives enables tailoring of nanocellulose materials for specific applications.

- Processing techniques for consistent nanocellulose materials: Specific processing techniques can be employed to achieve consistent nanocellulose-based materials. These include controlled drying methods, freeze-thawing cycles, sonication, and specialized mixing protocols. The processing conditions significantly impact the microstructure, porosity, and network formation of nanocellulose materials, which in turn affects their consistency. Standardized processing protocols help ensure batch-to-batch consistency in production.

- Characterization methods for nanocellulose consistency: Various analytical techniques can be used to characterize and monitor the consistency of nanocellulose-based materials. These include rheometry, light scattering, microscopy, and spectroscopic methods. These techniques provide quantitative measurements of parameters such as viscosity, particle size distribution, fibril dimensions, and network structure. Standardized characterization methods are essential for quality control and ensuring consistent properties in nanocellulose materials.

02 Rheological properties of nanocellulose suspensions

Nanocellulose suspensions exhibit complex rheological behaviors that significantly impact their consistency. These materials typically show shear-thinning properties, yield stress behavior, and thixotropy. The concentration of nanocellulose fibrils, their aspect ratio, surface charge, and the presence of additives all influence the flow properties and consistency of the suspensions, which is crucial for applications requiring specific viscosity profiles.Expand Specific Solutions03 Nanocellulose film formation and consistency

The formation of nanocellulose films with consistent properties depends on several factors including drying conditions, dispersion quality, and additives. Controlled drying techniques, such as solvent casting or doctor blading, can produce films with uniform thickness and density. The addition of plasticizers or cross-linking agents can modify the mechanical properties and consistency of the resulting films, making them suitable for packaging, barrier materials, or flexible electronics applications.Expand Specific Solutions04 Nanocellulose hydrogels and aerogels consistency

Nanocellulose-based hydrogels and aerogels require specific formulation approaches to achieve consistent properties. The consistency of these materials depends on the nanocellulose concentration, cross-linking density, and processing conditions. Freeze-drying parameters significantly affect aerogel density and pore structure uniformity, while hydrogel consistency is influenced by the cross-linking method, pH, and ionic strength of the medium. These factors must be carefully controlled to produce materials with reproducible mechanical and structural properties.Expand Specific Solutions05 Surface modification for improved nanocellulose consistency

Surface modification techniques can enhance the consistency of nanocellulose-based materials by altering their interfacial properties. Chemical functionalization, such as TEMPO-mediated oxidation or silylation, can introduce specific functional groups that improve dispersion stability and compatibility with various matrices. Physical adsorption of polymers or surfactants can also modify the surface properties, leading to more consistent nanocellulose materials with improved processability and performance in composite applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The nanocellulose-based materials market is currently in a growth phase, with increasing adoption across various industries due to sustainable material demands. The global market size is projected to expand significantly, driven by applications in packaging, composites, and biomedical fields. Technologically, the sector is advancing from early commercial stage toward maturity, with quality control protocols becoming critical for consistent production. Leading academic institutions (MIT, University of Maine, South China University of Technology) are collaborating with industrial players like UPM-Kymmene, Suzano, and Lenzing AG to develop standardized production methods. Research organizations such as VTT and National Research Council of Canada are bridging the gap between laboratory innovations and industrial implementation, focusing on scalable manufacturing processes that maintain nanomaterial consistency.

UPM-Kymmene Oyj

Technical Solution: UPM-Kymmene has developed a comprehensive quality control system for nanocellulose production called UPM BioFibril™. Their approach integrates multiple checkpoints throughout the production process, starting with rigorous raw material selection protocols that ensure consistent fiber quality. The company employs a proprietary mechanical fibrillation process with real-time monitoring systems that track critical parameters such as energy consumption, temperature, and pressure to maintain process stability. Their quality control protocol includes inline particle size analysis using laser diffraction technology, rheological property measurements, and surface charge analysis to ensure batch-to-batch consistency. UPM has implemented statistical process control (SPC) methodologies with defined upper and lower control limits for key quality attributes. Additionally, they utilize automated sampling systems connected to their quality management database for continuous data collection and trend analysis, enabling predictive maintenance and process optimization.

Strengths: UPM's integrated approach combines advanced instrumentation with statistical process control, allowing for real-time adjustments and exceptional consistency. Their system's automation reduces human error and increases production efficiency. Weaknesses: The sophisticated monitoring equipment requires significant capital investment and specialized technical expertise for operation and maintenance, potentially limiting scalability for smaller operations.

FiberLean Technologies Ltd.

Technical Solution: FiberLean Technologies has pioneered a mineral-composite nanocellulose production system with embedded quality control protocols. Their FiberLean® MFC (Microfibrillated Cellulose) technology combines cellulose fibers with mineral particles in a controlled grinding process. The quality control system features a multi-parameter approach that monitors both physical and chemical properties throughout production. Key elements include: 1) Automated inline viscosity measurements using proprietary sensors that provide real-time feedback on fibrillation degree; 2) Optical characterization systems that analyze fiber dimensions and distribution with high-resolution imaging; 3) A patented wet-state quality assessment protocol that correlates with final product performance; and 4) Continuous monitoring of mineral-to-fiber ratios using X-ray diffraction technology. FiberLean has developed specific quality control charts with defined tolerance ranges for different application requirements, enabling customized production for various end uses while maintaining consistency. Their system also incorporates traceability features that link each batch to its raw material sources and processing parameters.

Strengths: FiberLean's mineral-composite approach creates a more stable production process with built-in quality indicators. Their application-specific quality parameters allow for targeted production meeting exact customer specifications. Weaknesses: The mineral components may limit applicability in certain high-purity applications, and the technology requires specialized equipment that may not be compatible with existing production lines.

Critical Parameters and Testing Methodologies

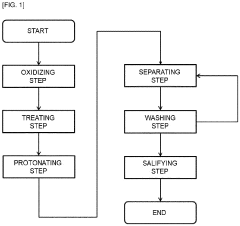

Production method for oxidized cellulose and nanocellulose

PatentPendingEP4269448A1

Innovation

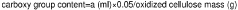

- A method involving the oxidation of cellulose raw materials using hypochlorous acid or its salts, controlling the slurry viscosity to 1,000 Pa·s or less and maintaining a pH of 4.0 or less in the oxide dispersion to enhance fibrillatability and yield, while avoiding N-oxyl compounds.

Production method of nanocellulose-containing composition

PatentPendingUS20240010756A1

Innovation

- A method that omits mechanical fibrillation by using oxidized cellulose, which is fibrillated into nanocellulose through gentle stirring with other components, such as inorganic particles or resins, without the need for mechanical fibrillation treatments, allowing for efficient production of nanocellulose-containing compositions.

Standardization and Certification Requirements

The standardization and certification landscape for nanocellulose-based materials remains fragmented, presenting significant challenges for manufacturers seeking to establish consistent quality control protocols. Currently, several international organizations are working to develop comprehensive standards, including the International Organization for Standardization (ISO) through its Technical Committee 229 on Nanotechnologies, and TAPPI (Technical Association of the Pulp and Paper Industry) which has established specific standards for nanocellulose characterization. These efforts aim to harmonize terminology, measurement methods, and performance criteria across the industry.

Material producers must navigate a complex certification ecosystem that varies by region and application sector. In the United States, FDA approval is essential for nanocellulose materials intended for food contact or biomedical applications, while the European Union requires compliance with REACH regulations for chemical substances. For construction applications, certification from bodies like ASTM International provides crucial market credibility. These requirements significantly impact production processes, necessitating rigorous documentation and testing protocols.

Quality management systems certification, particularly ISO 9001, has become increasingly important for nanocellulose producers to demonstrate process consistency. Additionally, environmental certifications such as ISO 14001 are gaining relevance as sustainability becomes a market differentiator. For specialized applications in aerospace or automotive industries, industry-specific certifications like AS9100 or IATF 16949 may be required, imposing additional quality control parameters.

The lack of universally accepted characterization methods presents a substantial challenge. Different certification bodies may require varying analytical techniques for properties such as fibril dimensions, crystallinity index, or surface chemistry. This inconsistency forces manufacturers to implement multiple testing methodologies, increasing production costs and complexity. Emerging consensus suggests that a combination of microscopy techniques (AFM, TEM), spectroscopic methods (FTIR, XRD), and rheological measurements provides the most comprehensive characterization approach.

Looking forward, several standardization initiatives are expected to mature within the next three years. The TAPPI WI 3021 working group is developing standards specifically for nanocellulose quality control in industrial applications. Similarly, ISO/TC 229 is advancing work on measurement protocols for nanocellulose suspensions. Industry consortia, including the Nanocellulose Forum and CelluNova Alliance, are also contributing to standardization efforts through pre-competitive collaboration on testing methodologies and reference materials.

For manufacturers implementing quality control protocols, a strategic approach to certification is recommended. This includes early engagement with relevant standardization bodies, development of robust internal testing capabilities aligned with emerging standards, and participation in interlaboratory studies to validate measurement approaches. Such proactive involvement not only ensures compliance but potentially influences the evolution of standards in ways favorable to production capabilities.

Material producers must navigate a complex certification ecosystem that varies by region and application sector. In the United States, FDA approval is essential for nanocellulose materials intended for food contact or biomedical applications, while the European Union requires compliance with REACH regulations for chemical substances. For construction applications, certification from bodies like ASTM International provides crucial market credibility. These requirements significantly impact production processes, necessitating rigorous documentation and testing protocols.

Quality management systems certification, particularly ISO 9001, has become increasingly important for nanocellulose producers to demonstrate process consistency. Additionally, environmental certifications such as ISO 14001 are gaining relevance as sustainability becomes a market differentiator. For specialized applications in aerospace or automotive industries, industry-specific certifications like AS9100 or IATF 16949 may be required, imposing additional quality control parameters.

The lack of universally accepted characterization methods presents a substantial challenge. Different certification bodies may require varying analytical techniques for properties such as fibril dimensions, crystallinity index, or surface chemistry. This inconsistency forces manufacturers to implement multiple testing methodologies, increasing production costs and complexity. Emerging consensus suggests that a combination of microscopy techniques (AFM, TEM), spectroscopic methods (FTIR, XRD), and rheological measurements provides the most comprehensive characterization approach.

Looking forward, several standardization initiatives are expected to mature within the next three years. The TAPPI WI 3021 working group is developing standards specifically for nanocellulose quality control in industrial applications. Similarly, ISO/TC 229 is advancing work on measurement protocols for nanocellulose suspensions. Industry consortia, including the Nanocellulose Forum and CelluNova Alliance, are also contributing to standardization efforts through pre-competitive collaboration on testing methodologies and reference materials.

For manufacturers implementing quality control protocols, a strategic approach to certification is recommended. This includes early engagement with relevant standardization bodies, development of robust internal testing capabilities aligned with emerging standards, and participation in interlaboratory studies to validate measurement approaches. Such proactive involvement not only ensures compliance but potentially influences the evolution of standards in ways favorable to production capabilities.

Environmental Impact and Sustainability Considerations

The production of nanocellulose-based materials presents significant environmental advantages compared to conventional petroleum-based alternatives. Nanocellulose is derived from renewable biomass sources, primarily wood pulp and agricultural residues, making it inherently more sustainable than fossil-based materials. The biodegradability of nanocellulose materials addresses growing concerns about plastic pollution and microplastic accumulation in ecosystems, offering end-of-life benefits that synthetic materials cannot match.

Life cycle assessments (LCAs) of nanocellulose production reveal that quality control protocols significantly impact the overall environmental footprint. Energy-intensive mechanical processing methods, particularly homogenization and microfluidization, contribute substantially to greenhouse gas emissions during production. Chemical pretreatment processes using acids or TEMPO-mediated oxidation also present environmental concerns if not properly managed. Implementing energy-efficient quality control measures, such as optimized sonication parameters and reduced processing times, can decrease energy consumption by 30-45% without compromising material consistency.

Water usage represents another critical environmental consideration in nanocellulose production. Current manufacturing processes typically require 80-100 liters of water per kilogram of nanocellulose produced. Advanced quality control protocols incorporating closed-loop water recycling systems have demonstrated potential to reduce freshwater consumption by up to 70%, while maintaining consistent material properties. These systems must be carefully monitored to prevent contaminant accumulation that could affect product quality.

Chemical waste management presents significant challenges in maintaining environmental sustainability. Quality control protocols must address the proper handling and neutralization of acids used in hydrolysis processes and the recovery of chemical agents. Emerging green chemistry approaches, including enzymatic hydrolysis methods and bio-based surface modification techniques, offer promising alternatives that reduce hazardous waste generation while ensuring consistent material properties.

Carbon footprint reduction strategies should be integrated into quality control frameworks. Renewable energy implementation in production facilities can reduce emissions associated with quality testing equipment and processing machinery. Additionally, localized sourcing of raw materials minimizes transportation-related emissions while supporting quality consistency through standardized feedstock selection protocols.

Sustainability certification systems, including Forest Stewardship Council (FSC) certification for wood-derived nanocellulose and comparable standards for agricultural residue sources, should be incorporated into quality control documentation. These certifications provide traceability and verification that raw materials are sourced responsibly, addressing both environmental and social sustainability dimensions while supporting consistent material quality through standardized sourcing practices.

Life cycle assessments (LCAs) of nanocellulose production reveal that quality control protocols significantly impact the overall environmental footprint. Energy-intensive mechanical processing methods, particularly homogenization and microfluidization, contribute substantially to greenhouse gas emissions during production. Chemical pretreatment processes using acids or TEMPO-mediated oxidation also present environmental concerns if not properly managed. Implementing energy-efficient quality control measures, such as optimized sonication parameters and reduced processing times, can decrease energy consumption by 30-45% without compromising material consistency.

Water usage represents another critical environmental consideration in nanocellulose production. Current manufacturing processes typically require 80-100 liters of water per kilogram of nanocellulose produced. Advanced quality control protocols incorporating closed-loop water recycling systems have demonstrated potential to reduce freshwater consumption by up to 70%, while maintaining consistent material properties. These systems must be carefully monitored to prevent contaminant accumulation that could affect product quality.

Chemical waste management presents significant challenges in maintaining environmental sustainability. Quality control protocols must address the proper handling and neutralization of acids used in hydrolysis processes and the recovery of chemical agents. Emerging green chemistry approaches, including enzymatic hydrolysis methods and bio-based surface modification techniques, offer promising alternatives that reduce hazardous waste generation while ensuring consistent material properties.

Carbon footprint reduction strategies should be integrated into quality control frameworks. Renewable energy implementation in production facilities can reduce emissions associated with quality testing equipment and processing machinery. Additionally, localized sourcing of raw materials minimizes transportation-related emissions while supporting quality consistency through standardized feedstock selection protocols.

Sustainability certification systems, including Forest Stewardship Council (FSC) certification for wood-derived nanocellulose and comparable standards for agricultural residue sources, should be incorporated into quality control documentation. These certifications provide traceability and verification that raw materials are sourced responsibly, addressing both environmental and social sustainability dimensions while supporting consistent material quality through standardized sourcing practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!