Functionalization Routes For Flame Retardancy In Nanocellulose Composites

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanocellulose Flame Retardancy Background and Objectives

Nanocellulose has emerged as a revolutionary biomaterial in the past two decades, offering exceptional mechanical properties, sustainability, and versatility across multiple industries. Derived from the most abundant biopolymer on Earth, cellulose, this nanoscale material represents a significant advancement in sustainable material science. However, like most cellulosic materials, nanocellulose exhibits high flammability, which severely restricts its application in sectors requiring flame-resistant properties, such as construction, automotive, and electronics.

The evolution of flame retardancy technologies for cellulosic materials has progressed from simple chemical treatments to sophisticated molecular engineering approaches. Early methods relied heavily on halogenated compounds, which, while effective, posed significant environmental and health concerns. The technological trajectory has since shifted toward more sustainable and environmentally benign solutions, particularly for nanocellulose-based materials.

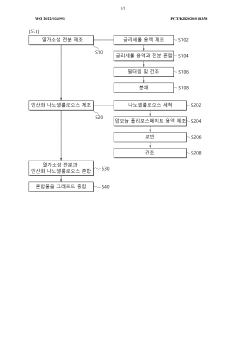

Current research focuses on developing functionalization routes that can impart flame retardancy to nanocellulose while preserving its inherent beneficial properties. These approaches include phosphorylation, silylation, layer-by-layer assembly techniques, and incorporation of inorganic nanoparticles. Each method presents unique advantages and challenges in terms of efficacy, processability, and environmental impact.

The primary objective of this technical research is to comprehensively evaluate existing functionalization routes for enhancing flame retardancy in nanocellulose composites. This includes assessing their effectiveness in reducing flammability, impact on mechanical properties, scalability for industrial applications, and environmental sustainability. Additionally, the research aims to identify promising novel approaches that could overcome current limitations.

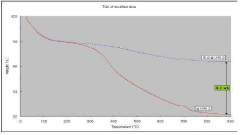

A critical goal is to establish a clear understanding of the structure-property relationships in flame-retardant nanocellulose composites. This involves investigating how different functionalization methods affect the thermal decomposition pathways, char formation mechanisms, and overall fire performance of these materials. Such insights are essential for designing next-generation flame-retardant nanocellulose composites with optimized properties.

Furthermore, this research seeks to explore synergistic combinations of different flame retardancy strategies that could potentially lead to superior fire performance with minimal impact on other material properties. The ultimate aim is to develop guidelines for tailoring flame-retardant nanocellulose composites for specific end-use applications, considering factors such as required flame retardancy level, mechanical performance, processing constraints, and regulatory compliance.

By addressing these objectives, this research will contribute to advancing the field of sustainable flame-retardant materials and expanding the application scope of nanocellulose-based composites in industries where fire safety is paramount.

The evolution of flame retardancy technologies for cellulosic materials has progressed from simple chemical treatments to sophisticated molecular engineering approaches. Early methods relied heavily on halogenated compounds, which, while effective, posed significant environmental and health concerns. The technological trajectory has since shifted toward more sustainable and environmentally benign solutions, particularly for nanocellulose-based materials.

Current research focuses on developing functionalization routes that can impart flame retardancy to nanocellulose while preserving its inherent beneficial properties. These approaches include phosphorylation, silylation, layer-by-layer assembly techniques, and incorporation of inorganic nanoparticles. Each method presents unique advantages and challenges in terms of efficacy, processability, and environmental impact.

The primary objective of this technical research is to comprehensively evaluate existing functionalization routes for enhancing flame retardancy in nanocellulose composites. This includes assessing their effectiveness in reducing flammability, impact on mechanical properties, scalability for industrial applications, and environmental sustainability. Additionally, the research aims to identify promising novel approaches that could overcome current limitations.

A critical goal is to establish a clear understanding of the structure-property relationships in flame-retardant nanocellulose composites. This involves investigating how different functionalization methods affect the thermal decomposition pathways, char formation mechanisms, and overall fire performance of these materials. Such insights are essential for designing next-generation flame-retardant nanocellulose composites with optimized properties.

Furthermore, this research seeks to explore synergistic combinations of different flame retardancy strategies that could potentially lead to superior fire performance with minimal impact on other material properties. The ultimate aim is to develop guidelines for tailoring flame-retardant nanocellulose composites for specific end-use applications, considering factors such as required flame retardancy level, mechanical performance, processing constraints, and regulatory compliance.

By addressing these objectives, this research will contribute to advancing the field of sustainable flame-retardant materials and expanding the application scope of nanocellulose-based composites in industries where fire safety is paramount.

Market Analysis for Fire-Resistant Nanocellulose Materials

The global market for fire-resistant nanocellulose materials has been experiencing significant growth, driven by increasing safety regulations across industries and growing awareness of sustainable alternatives to traditional flame retardants. The current market size for flame-retardant materials is estimated at $7.5 billion globally, with nanocellulose-based solutions representing an emerging segment growing at approximately 14% annually.

Construction and building materials constitute the largest application segment, accounting for nearly 40% of the market demand. This sector's growth is propelled by stringent building codes and fire safety regulations, particularly in North America and Europe. The automotive industry follows as the second-largest consumer, where lightweight fire-resistant materials are sought to improve fuel efficiency while maintaining safety standards.

Electronics and electrical applications represent the fastest-growing segment with a 17% annual growth rate, as manufacturers seek non-toxic flame retardants for consumer electronics. This growth is particularly pronounced in Asia-Pacific markets, where electronics manufacturing continues to expand rapidly.

Geographically, North America currently leads the market with approximately 35% share, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is projected to overtake other regions by 2027, driven by rapid industrialization, construction booms in China and India, and increasing adoption of stringent safety standards.

Consumer preferences are shifting decisively toward environmentally friendly flame retardants, with 72% of surveyed industrial buyers expressing interest in bio-based alternatives to halogenated compounds. This trend aligns with regulatory movements, particularly in the European Union where the REACH regulation continues to restrict traditional flame retardants with adverse environmental profiles.

Price sensitivity remains a significant market constraint, with nanocellulose-based flame retardants currently commanding a 30-40% premium over conventional solutions. However, this gap is narrowing as production scales increase and functionalization techniques become more efficient.

Market forecasts indicate that the fire-resistant nanocellulose materials segment could reach $1.2 billion by 2028, representing a significant opportunity for early movers. The most promising growth is expected in applications requiring both flame retardancy and additional functional properties such as mechanical strength enhancement, transparency, or electrical conductivity—areas where functionalized nanocellulose composites excel compared to traditional flame retardants.

Construction and building materials constitute the largest application segment, accounting for nearly 40% of the market demand. This sector's growth is propelled by stringent building codes and fire safety regulations, particularly in North America and Europe. The automotive industry follows as the second-largest consumer, where lightweight fire-resistant materials are sought to improve fuel efficiency while maintaining safety standards.

Electronics and electrical applications represent the fastest-growing segment with a 17% annual growth rate, as manufacturers seek non-toxic flame retardants for consumer electronics. This growth is particularly pronounced in Asia-Pacific markets, where electronics manufacturing continues to expand rapidly.

Geographically, North America currently leads the market with approximately 35% share, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is projected to overtake other regions by 2027, driven by rapid industrialization, construction booms in China and India, and increasing adoption of stringent safety standards.

Consumer preferences are shifting decisively toward environmentally friendly flame retardants, with 72% of surveyed industrial buyers expressing interest in bio-based alternatives to halogenated compounds. This trend aligns with regulatory movements, particularly in the European Union where the REACH regulation continues to restrict traditional flame retardants with adverse environmental profiles.

Price sensitivity remains a significant market constraint, with nanocellulose-based flame retardants currently commanding a 30-40% premium over conventional solutions. However, this gap is narrowing as production scales increase and functionalization techniques become more efficient.

Market forecasts indicate that the fire-resistant nanocellulose materials segment could reach $1.2 billion by 2028, representing a significant opportunity for early movers. The most promising growth is expected in applications requiring both flame retardancy and additional functional properties such as mechanical strength enhancement, transparency, or electrical conductivity—areas where functionalized nanocellulose composites excel compared to traditional flame retardants.

Current Functionalization Techniques and Challenges

The functionalization of nanocellulose for flame retardancy applications currently employs several established techniques, each with distinct advantages and limitations. Chemical modification approaches dominate the field, with phosphorylation being particularly prominent. This process involves introducing phosphorus-containing groups onto the nanocellulose surface, creating a char-forming barrier during combustion. While effective, phosphorylation often requires harsh reaction conditions that can compromise the mechanical integrity of the nanocellulose structure.

Layer-by-layer (LbL) assembly represents another significant functionalization route, wherein alternating layers of oppositely charged materials are deposited onto nanocellulose surfaces. This technique allows for precise control over coating thickness and composition, enabling tailored flame retardant properties. However, LbL processes are time-consuming and challenging to scale up for industrial applications, limiting their commercial viability despite excellent laboratory results.

Grafting techniques, including "grafting-to" and "grafting-from" approaches, have gained traction for introducing flame retardant moieties onto nanocellulose. These methods create covalent bonds between the nanocellulose substrate and flame retardant compounds, ensuring durability and wash resistance. The primary challenge with grafting lies in achieving uniform coverage across the nanocellulose surface while maintaining its desirable properties such as crystallinity and aspect ratio.

Sol-gel processing has emerged as a versatile technique for creating hybrid organic-inorganic flame retardant coatings on nanocellulose. This approach typically involves the hydrolysis and condensation of metal alkoxides to form a protective network. While sol-gel methods offer excellent thermal stability, controlling the hydrolysis rate and preventing agglomeration remain significant challenges that can affect the homogeneity of the final composite.

A major technical hurdle across all functionalization routes is balancing flame retardancy with the preservation of nanocellulose's inherent properties. Many current techniques significantly reduce the mechanical strength, transparency, or biodegradability of nanocellulose composites. Additionally, the hydrophilic nature of nanocellulose often leads to poor compatibility with hydrophobic polymer matrices, necessitating additional surface modifications that further complicate processing.

Scalability presents another critical challenge, as many laboratory-proven functionalization techniques involve complex multi-step processes that are difficult to implement in industrial settings. The use of environmentally harmful solvents and reagents in some functionalization routes also raises sustainability concerns, contradicting the eco-friendly nature of nanocellulose itself.

Recent research has begun exploring greener functionalization approaches, including enzyme-mediated modifications and the use of bio-based flame retardants. However, these emerging techniques currently suffer from lower efficiency compared to conventional methods, highlighting the need for continued innovation in this field.

Layer-by-layer (LbL) assembly represents another significant functionalization route, wherein alternating layers of oppositely charged materials are deposited onto nanocellulose surfaces. This technique allows for precise control over coating thickness and composition, enabling tailored flame retardant properties. However, LbL processes are time-consuming and challenging to scale up for industrial applications, limiting their commercial viability despite excellent laboratory results.

Grafting techniques, including "grafting-to" and "grafting-from" approaches, have gained traction for introducing flame retardant moieties onto nanocellulose. These methods create covalent bonds between the nanocellulose substrate and flame retardant compounds, ensuring durability and wash resistance. The primary challenge with grafting lies in achieving uniform coverage across the nanocellulose surface while maintaining its desirable properties such as crystallinity and aspect ratio.

Sol-gel processing has emerged as a versatile technique for creating hybrid organic-inorganic flame retardant coatings on nanocellulose. This approach typically involves the hydrolysis and condensation of metal alkoxides to form a protective network. While sol-gel methods offer excellent thermal stability, controlling the hydrolysis rate and preventing agglomeration remain significant challenges that can affect the homogeneity of the final composite.

A major technical hurdle across all functionalization routes is balancing flame retardancy with the preservation of nanocellulose's inherent properties. Many current techniques significantly reduce the mechanical strength, transparency, or biodegradability of nanocellulose composites. Additionally, the hydrophilic nature of nanocellulose often leads to poor compatibility with hydrophobic polymer matrices, necessitating additional surface modifications that further complicate processing.

Scalability presents another critical challenge, as many laboratory-proven functionalization techniques involve complex multi-step processes that are difficult to implement in industrial settings. The use of environmentally harmful solvents and reagents in some functionalization routes also raises sustainability concerns, contradicting the eco-friendly nature of nanocellulose itself.

Recent research has begun exploring greener functionalization approaches, including enzyme-mediated modifications and the use of bio-based flame retardants. However, these emerging techniques currently suffer from lower efficiency compared to conventional methods, highlighting the need for continued innovation in this field.

Current Functionalization Routes for Flame Retardancy

01 Phosphorus-based flame retardants for nanocellulose composites

Phosphorus-based compounds are effective flame retardants for nanocellulose composites. These compounds work by promoting char formation during combustion, which creates a protective barrier that limits oxygen access and heat transfer. The phosphorus compounds can be incorporated into the nanocellulose matrix through various methods including impregnation, coating, or chemical modification. This approach significantly improves the flame retardancy of nanocellulose-based materials while maintaining their mechanical properties.- Phosphorus-based flame retardants for nanocellulose composites: Phosphorus-based compounds are effective flame retardants for nanocellulose composites. These compounds work by promoting char formation during combustion, which creates a protective barrier that limits oxygen access and heat transfer. The phosphorus compounds can be incorporated into the nanocellulose matrix through various methods including impregnation, coating, or chemical modification. This approach significantly improves the flame retardancy of nanocellulose-based materials while maintaining their mechanical properties.

- Metal hydroxide additives for flame retardancy: Metal hydroxides, particularly aluminum hydroxide and magnesium hydroxide, can be incorporated into nanocellulose composites to enhance flame retardancy. These compounds work through an endothermic decomposition mechanism that absorbs heat and releases water vapor during combustion, cooling the material and diluting flammable gases. The combination of metal hydroxides with nanocellulose creates composites with improved fire resistance while maintaining the lightweight and renewable characteristics of cellulose-based materials.

- Surface modification of nanocellulose for flame retardancy: Chemical modification of nanocellulose surfaces can significantly enhance flame retardancy properties. Techniques include grafting flame-retardant molecules onto cellulose nanofibrils, layer-by-layer deposition of fire-resistant coatings, and sol-gel treatments. These modifications create a protective barrier that prevents the rapid decomposition of cellulose during fire exposure. Surface-modified nanocellulose can be incorporated into various polymer matrices to create flame-retardant composites with excellent mechanical properties and thermal stability.

- Synergistic flame retardant systems for nanocellulose: Combining multiple flame retardant mechanisms creates synergistic systems that provide superior protection for nanocellulose composites. These systems typically include char-forming agents, gas-phase inhibitors, and heat-absorbing compounds working together to suppress combustion through different pathways. The synergistic approach allows for lower overall flame retardant loading while achieving higher performance, which helps preserve the mechanical properties and biodegradability of nanocellulose-based materials.

- Bio-based and environmentally friendly flame retardants: Environmentally friendly flame retardants derived from renewable resources can be incorporated into nanocellulose composites. These include compounds extracted from plants, modified proteins, and other bio-based materials with inherent flame-retardant properties. The combination of bio-based flame retardants with nanocellulose creates fully renewable composite materials with reduced environmental impact and improved end-of-life disposal options, while still providing effective protection against fire hazards.

02 Metal hydroxide flame retardants in nanocellulose composites

Metal hydroxides, particularly aluminum hydroxide and magnesium hydroxide, serve as effective flame retardants in nanocellulose composites. These compounds work through an endothermic decomposition mechanism that absorbs heat and releases water vapor during combustion, cooling the material and diluting flammable gases. The incorporation of metal hydroxides into nanocellulose matrices creates fire-resistant materials with improved thermal stability. The synergistic effect between nanocellulose and metal hydroxides enhances the overall flame retardancy performance.Expand Specific Solutions03 Surface modification of nanocellulose for flame retardancy

Surface modification techniques can enhance the flame retardancy of nanocellulose composites. These methods involve chemically altering the surface of nanocellulose fibers to incorporate flame-retardant functionalities or to improve compatibility with other flame-retardant additives. Techniques include silylation, phosphorylation, and grafting with flame-retardant polymers. Surface-modified nanocellulose shows improved thermal stability, reduced flammability, and better dispersion in polymer matrices, resulting in enhanced flame-retardant properties of the final composite materials.Expand Specific Solutions04 Synergistic flame retardant systems for nanocellulose

Synergistic combinations of different flame retardants can significantly enhance the fire resistance of nanocellulose composites. These systems typically combine two or more flame retardants that work through different mechanisms, such as intumescent systems with char-forming agents, or halogen-free flame retardants with smoke suppressants. The synergistic effect results in improved flame retardancy at lower overall additive loadings, maintaining better mechanical properties while achieving higher fire protection standards. These combinations often include nitrogen-phosphorus systems or metal hydroxides with phosphorus compounds.Expand Specific Solutions05 Nanocellulose as char-forming agent in flame retardant composites

Nanocellulose itself can function as a char-forming agent in flame retardant systems. When exposed to heat, nanocellulose can form a carbonaceous char layer that acts as a physical barrier, protecting the underlying material from heat and oxygen. This property can be enhanced by combining nanocellulose with other flame retardants that promote char formation. The high surface area and network structure of nanocellulose contribute to the formation of a continuous and stable char layer, improving the overall flame retardancy of composite materials.Expand Specific Solutions

Leading Companies and Research Institutions in Nanocellulose Functionalization

The flame retardancy nanocellulose composites market is currently in a growth phase, with increasing demand driven by stringent fire safety regulations across industries. The global market size is estimated to reach approximately $350 million by 2027, growing at a CAGR of 8-10%. Technologically, the field is advancing rapidly but remains in mid-maturity, with significant R&D ongoing. Leading players include established chemical companies like Clariant, LG Chem, and FUJIFILM, alongside research-focused institutions such as VTT and academic powerhouses like South China University of Technology and Donghua University. These organizations are developing innovative functionalization routes through chemical modification, nanoparticle incorporation, and layer-by-layer assembly techniques to enhance flame retardancy while maintaining the sustainable benefits of nanocellulose.

Lenzing AG

Technical Solution: Lenzing AG has developed an integrated approach to flame retardancy in nanocellulose composites that builds upon their expertise in cellulosic fiber production. Their technology involves the incorporation of aluminum hydroxide nanoparticles directly into the cellulose nanofibrils during the mechanical fibrillation process, creating a homogeneous distribution of flame retardant throughout the material. This in-situ modification approach achieves flame retardant loading of 20-30% by weight while maintaining the nanofibrillar structure of cellulose. The company has also pioneered surface modification techniques using silane coupling agents with phosphorus-containing functional groups to enhance the interfacial compatibility between the inorganic flame retardants and the organic nanocellulose matrix. Their research demonstrates that this hybrid approach reduces peak heat release rate by up to 65% and increases char yield by over 40% compared to untreated nanocellulose. Lenzing has scaled this technology to pilot production levels, demonstrating its feasibility for commercial applications in packaging, construction, and automotive industries.

Strengths: Scalable production process compatible with existing manufacturing infrastructure; good flame retardant performance with reduced heat release; maintains processing characteristics of nanocellulose. Weaknesses: Higher loading levels required compared to some chemical modification approaches; potential for reduced transparency in thin films; increased density of the final composite material.

Chinese Academy of Sciences Guangzhou Chemical Co. Ltd.

Technical Solution: The company has developed phosphorus-based flame retardant systems specifically for nanocellulose composites. Their approach involves phosphorylation of cellulose nanofibrils (CNF) through reactive extrusion processes, creating covalent bonds between phosphorus compounds and hydroxyl groups on the nanocellulose surface. This chemical modification creates a char-forming protective layer during combustion that inhibits flame propagation. Their proprietary process achieves phosphorus content of 2-5% by weight, significantly reducing peak heat release rate by up to 70% compared to untreated nanocellulose. The company has also pioneered combination treatments using phosphorus with nitrogen-containing compounds for synergistic flame retardancy effects, enhancing the overall fire performance while maintaining the mechanical integrity of the nanocellulose composite structure.

Strengths: Excellent flame retardancy performance with significant reduction in heat release rate; maintains good mechanical properties of the composite; environmentally friendly compared to halogenated flame retardants. Weaknesses: The phosphorylation process may reduce some mechanical properties like tensile strength; higher production costs compared to conventional flame retardants; potential for increased moisture sensitivity in the treated composites.

Key Patents and Scientific Breakthroughs in Nanocellulose Flame Retardancy

Nanoparticles having Flame Retardancy and Method for Preparation Thereof

PatentInactiveKR1020080112840A

Innovation

- Surface-treating colloidal nanoparticles with a phosphorus-based compound to chemically bond it to the nanoparticle surface, forming a stable flame-retardant structure that maintains resin stability and enhances flame retardancy.

Phosphorylated nanocellulose-grafted thermoplastic starch and method for preparing sjavascript: document.forms[0].task.value='8024993'; dosubmit('gototask_8024993')ame

PatentWO2022034991A1

Innovation

- Thermoplastic starch is grafted with phosphorylated nanocellulose using microwave treatment, combining starch extracted from plants with glycerol and ammonium polyphosphate-treated nanocellulose to enhance thermal properties and durability while providing flame retardancy.

Environmental Impact and Toxicity Assessment

The environmental impact and toxicity assessment of flame retardant nanocellulose composites represents a critical dimension in evaluating their sustainability and safety profiles. As these materials gain prominence in various applications, understanding their ecological footprint throughout their lifecycle becomes increasingly important for regulatory compliance and market acceptance.

Flame retardant chemicals traditionally used in polymeric materials have raised significant environmental concerns, particularly halogenated compounds which can persist in the environment and bioaccumulate in living organisms. The functionalization routes employed for nanocellulose flame retardancy present varying degrees of environmental impact, with phosphorus-based treatments generally showing lower environmental persistence compared to halogenated alternatives.

Life cycle assessment (LCA) studies indicate that the environmental footprint of functionalized nanocellulose composites is influenced by multiple factors: raw material sourcing, chemical modification processes, energy consumption during manufacturing, and end-of-life disposal options. Notably, nanocellulose derived from agricultural waste or sustainable forestry practices demonstrates a substantially reduced carbon footprint compared to synthetic flame retardants.

The release of nanoparticles during the use phase or after disposal represents a particular concern. Recent studies have investigated the potential for nanocellulose particles to be released from composite materials through weathering, abrasion, or degradation processes. The environmental fate of these particles, especially when functionalized with flame retardant chemicals, remains incompletely understood and requires further investigation.

Toxicological assessments of functionalized nanocellulose materials have yielded varying results depending on the specific chemical modifications employed. Phosphorus-nitrogen synergistic systems generally exhibit lower mammalian toxicity compared to halogenated alternatives. However, the potential for these materials to cause respiratory irritation or cellular damage when in nanoparticulate form necessitates careful evaluation, particularly in occupational settings where exposure may be heightened.

Aquatic toxicity testing has revealed that certain flame retardant chemicals used in nanocellulose functionalization can adversely affect aquatic organisms if leached into water bodies. The persistence of these compounds in aquatic environments varies significantly based on their chemical structure, with some phosphorus-based compounds showing relatively rapid degradation while others demonstrate concerning persistence.

Regulatory frameworks worldwide are increasingly addressing the environmental and health implications of nanomaterials, including functionalized nanocellulose. The European Union's REACH regulation and the US EPA's significant new use rules (SNURs) have particular relevance for flame retardant nanocomposites, requiring manufacturers to provide comprehensive safety data before market introduction.

Flame retardant chemicals traditionally used in polymeric materials have raised significant environmental concerns, particularly halogenated compounds which can persist in the environment and bioaccumulate in living organisms. The functionalization routes employed for nanocellulose flame retardancy present varying degrees of environmental impact, with phosphorus-based treatments generally showing lower environmental persistence compared to halogenated alternatives.

Life cycle assessment (LCA) studies indicate that the environmental footprint of functionalized nanocellulose composites is influenced by multiple factors: raw material sourcing, chemical modification processes, energy consumption during manufacturing, and end-of-life disposal options. Notably, nanocellulose derived from agricultural waste or sustainable forestry practices demonstrates a substantially reduced carbon footprint compared to synthetic flame retardants.

The release of nanoparticles during the use phase or after disposal represents a particular concern. Recent studies have investigated the potential for nanocellulose particles to be released from composite materials through weathering, abrasion, or degradation processes. The environmental fate of these particles, especially when functionalized with flame retardant chemicals, remains incompletely understood and requires further investigation.

Toxicological assessments of functionalized nanocellulose materials have yielded varying results depending on the specific chemical modifications employed. Phosphorus-nitrogen synergistic systems generally exhibit lower mammalian toxicity compared to halogenated alternatives. However, the potential for these materials to cause respiratory irritation or cellular damage when in nanoparticulate form necessitates careful evaluation, particularly in occupational settings where exposure may be heightened.

Aquatic toxicity testing has revealed that certain flame retardant chemicals used in nanocellulose functionalization can adversely affect aquatic organisms if leached into water bodies. The persistence of these compounds in aquatic environments varies significantly based on their chemical structure, with some phosphorus-based compounds showing relatively rapid degradation while others demonstrate concerning persistence.

Regulatory frameworks worldwide are increasingly addressing the environmental and health implications of nanomaterials, including functionalized nanocellulose. The European Union's REACH regulation and the US EPA's significant new use rules (SNURs) have particular relevance for flame retardant nanocomposites, requiring manufacturers to provide comprehensive safety data before market introduction.

Scalability and Industrial Implementation Considerations

The scalability of functionalization routes for flame retardant nanocellulose composites represents a critical consideration for industrial adoption. Current laboratory-scale processes often employ methods that are challenging to scale up, such as solvent-intensive chemical modifications or time-consuming layer-by-layer assembly techniques. These approaches, while effective in controlled environments, face significant barriers when transitioning to industrial production volumes.

Production scale-up requires consideration of several key factors. Processing time presents a major challenge, as many functionalization methods involve multiple reaction steps and lengthy drying periods. For instance, phosphorylation treatments typically require reaction times of 2-4 hours, followed by neutralization and washing steps that further extend processing duration. Such timeframes are incompatible with continuous manufacturing processes demanded by industry.

Equipment compatibility also poses substantial challenges. Many functionalization routes utilize specialized laboratory equipment that lacks industrial equivalents or requires significant modification for large-scale implementation. The transition from batch processing to continuous flow systems necessitates redesigning reaction parameters and often results in different product characteristics.

Environmental and economic considerations further complicate industrial implementation. Solvent recovery systems must be integrated to address both cost and environmental concerns associated with chemical functionalization routes. Water-based approaches offer more sustainable alternatives but frequently result in longer processing times and potential quality inconsistencies in scaled production.

Regulatory compliance adds another layer of complexity. Many flame retardant chemicals face increasing scrutiny regarding toxicity and environmental persistence. Phosphorus-based treatments generally offer better regulatory prospects than halogenated alternatives, but manufacturers must still navigate evolving compliance landscapes across different markets and jurisdictions.

Recent innovations show promise for overcoming these challenges. Spray-drying techniques for phosphorus-based functionalization demonstrate potential for continuous processing, while reactive extrusion methods enable solvent-free modification of nanocellulose during composite formation. Additionally, supercritical CO2 processing offers an environmentally friendly alternative that facilitates uniform chemical distribution without water or organic solvents.

Cost-benefit analysis indicates that while initial capital investment for specialized equipment remains high, operational efficiencies can be achieved through process optimization. The premium pricing of flame retardant composites in high-value applications such as automotive and aerospace components can offset these costs, though price sensitivity in construction and packaging markets presents ongoing challenges for widespread adoption.

Production scale-up requires consideration of several key factors. Processing time presents a major challenge, as many functionalization methods involve multiple reaction steps and lengthy drying periods. For instance, phosphorylation treatments typically require reaction times of 2-4 hours, followed by neutralization and washing steps that further extend processing duration. Such timeframes are incompatible with continuous manufacturing processes demanded by industry.

Equipment compatibility also poses substantial challenges. Many functionalization routes utilize specialized laboratory equipment that lacks industrial equivalents or requires significant modification for large-scale implementation. The transition from batch processing to continuous flow systems necessitates redesigning reaction parameters and often results in different product characteristics.

Environmental and economic considerations further complicate industrial implementation. Solvent recovery systems must be integrated to address both cost and environmental concerns associated with chemical functionalization routes. Water-based approaches offer more sustainable alternatives but frequently result in longer processing times and potential quality inconsistencies in scaled production.

Regulatory compliance adds another layer of complexity. Many flame retardant chemicals face increasing scrutiny regarding toxicity and environmental persistence. Phosphorus-based treatments generally offer better regulatory prospects than halogenated alternatives, but manufacturers must still navigate evolving compliance landscapes across different markets and jurisdictions.

Recent innovations show promise for overcoming these challenges. Spray-drying techniques for phosphorus-based functionalization demonstrate potential for continuous processing, while reactive extrusion methods enable solvent-free modification of nanocellulose during composite formation. Additionally, supercritical CO2 processing offers an environmentally friendly alternative that facilitates uniform chemical distribution without water or organic solvents.

Cost-benefit analysis indicates that while initial capital investment for specialized equipment remains high, operational efficiencies can be achieved through process optimization. The premium pricing of flame retardant composites in high-value applications such as automotive and aerospace components can offset these costs, though price sensitivity in construction and packaging markets presents ongoing challenges for widespread adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!