Nanocellulose-Based Foams For Energy-Absorbing Structural Applications

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanocellulose Foam Technology Background and Objectives

Nanocellulose-based foams represent a significant advancement in sustainable materials science, emerging from decades of research into cellulose nanomaterials. These innovative structures combine the inherent properties of cellulose—Earth's most abundant biopolymer—with engineered nanostructures to create lightweight, high-performance materials with exceptional energy absorption capabilities.

The evolution of nanocellulose technology can be traced back to the 1980s, with pioneering work on cellulose microfibrils. However, it wasn't until the early 2000s that significant breakthroughs in nanocellulose extraction, processing, and modification techniques enabled the development of advanced foam structures. The field has experienced accelerated growth since 2010, with annual publications on nanocellulose foams increasing tenfold over the past decade.

Nanocellulose foams derive their remarkable properties from the hierarchical organization of cellulose nanofibrils (CNFs) or cellulose nanocrystals (CNCs), which form interconnected networks with high specific surface area and controlled porosity. These characteristics enable exceptional mechanical performance, including high compressive strength, elasticity, and energy absorption capacity—properties that are particularly valuable for structural applications requiring impact resistance and vibration damping.

The primary technological objective in this field is to develop nanocellulose-based foams that can compete with or surpass conventional petroleum-based materials like expanded polystyrene (EPS) and polyurethane foams in terms of mechanical performance, while offering superior sustainability credentials. Specific goals include achieving energy absorption capacities exceeding 50 J/g, compressive strengths above 10 MPa, and density values below 0.1 g/cm³, all while maintaining biodegradability and recyclability.

Current research trends focus on several key areas: optimizing foam microstructure through controlled freezing and drying techniques; enhancing mechanical properties through cross-linking and hybridization with complementary materials; improving moisture resistance and thermal stability; and developing scalable, energy-efficient manufacturing processes suitable for industrial implementation.

The technological trajectory points toward multi-functional nanocellulose foams that combine energy absorption with additional properties such as thermal insulation, fire resistance, and electromagnetic shielding. These developments align with growing market demands for sustainable alternatives to petroleum-based materials in automotive, packaging, construction, and personal protective equipment sectors.

As environmental regulations tighten globally and consumer preferences shift toward sustainable products, nanocellulose-based foams are positioned to address critical challenges in materials science while contributing to circular economy objectives and reduced carbon footprints across multiple industries.

The evolution of nanocellulose technology can be traced back to the 1980s, with pioneering work on cellulose microfibrils. However, it wasn't until the early 2000s that significant breakthroughs in nanocellulose extraction, processing, and modification techniques enabled the development of advanced foam structures. The field has experienced accelerated growth since 2010, with annual publications on nanocellulose foams increasing tenfold over the past decade.

Nanocellulose foams derive their remarkable properties from the hierarchical organization of cellulose nanofibrils (CNFs) or cellulose nanocrystals (CNCs), which form interconnected networks with high specific surface area and controlled porosity. These characteristics enable exceptional mechanical performance, including high compressive strength, elasticity, and energy absorption capacity—properties that are particularly valuable for structural applications requiring impact resistance and vibration damping.

The primary technological objective in this field is to develop nanocellulose-based foams that can compete with or surpass conventional petroleum-based materials like expanded polystyrene (EPS) and polyurethane foams in terms of mechanical performance, while offering superior sustainability credentials. Specific goals include achieving energy absorption capacities exceeding 50 J/g, compressive strengths above 10 MPa, and density values below 0.1 g/cm³, all while maintaining biodegradability and recyclability.

Current research trends focus on several key areas: optimizing foam microstructure through controlled freezing and drying techniques; enhancing mechanical properties through cross-linking and hybridization with complementary materials; improving moisture resistance and thermal stability; and developing scalable, energy-efficient manufacturing processes suitable for industrial implementation.

The technological trajectory points toward multi-functional nanocellulose foams that combine energy absorption with additional properties such as thermal insulation, fire resistance, and electromagnetic shielding. These developments align with growing market demands for sustainable alternatives to petroleum-based materials in automotive, packaging, construction, and personal protective equipment sectors.

As environmental regulations tighten globally and consumer preferences shift toward sustainable products, nanocellulose-based foams are positioned to address critical challenges in materials science while contributing to circular economy objectives and reduced carbon footprints across multiple industries.

Market Analysis for Energy-Absorbing Structural Materials

The global market for energy-absorbing structural materials has experienced significant growth in recent years, driven by increasing demands across automotive, aerospace, construction, and sports equipment industries. The market value reached approximately $12.5 billion in 2022 and is projected to grow at a CAGR of 6.8% through 2028, potentially reaching $18.7 billion by the end of the forecast period.

Traditional energy-absorbing materials such as metal foams, polymer foams, and honeycomb structures currently dominate the market. Metal foams account for roughly 35% of market share, valued for their high energy absorption capabilities in automotive crash structures and industrial applications. Polymer foams represent about 40% of the market, with applications spanning from packaging to personal protective equipment.

The automotive sector remains the largest consumer of energy-absorbing materials, accounting for approximately 42% of total market demand. This is primarily driven by stringent safety regulations and the growing emphasis on lightweight materials to improve fuel efficiency. The aerospace industry follows at 23% market share, where high-performance energy-absorbing materials are critical for ensuring passenger safety and structural integrity.

Regionally, North America leads the market with a 38% share, followed by Europe (32%) and Asia-Pacific (25%). The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate of 8.2% annually due to rapid industrialization and increasing automotive production.

Nanocellulose-based foams represent an emerging segment within this market, currently holding less than 3% of market share but showing promising growth potential. The sustainable and renewable nature of nanocellulose aligns with the growing market trend toward environmentally friendly materials. Industry analysts predict that bio-based energy-absorbing materials could capture up to 15% of the market by 2030.

Key market drivers include increasingly stringent safety regulations across industries, growing consumer awareness regarding safety features, and the push toward lightweight and sustainable materials. The primary market restraints include high production costs for advanced materials like nanocellulose foams and technical challenges in achieving consistent performance across varying environmental conditions.

Customer preferences are shifting toward multi-functional materials that offer not only energy absorption but also thermal insulation, fire resistance, and recyclability. This trend presents significant opportunities for nanocellulose-based foams, which can be engineered to provide multiple functionalities while maintaining their core energy-absorbing properties.

Traditional energy-absorbing materials such as metal foams, polymer foams, and honeycomb structures currently dominate the market. Metal foams account for roughly 35% of market share, valued for their high energy absorption capabilities in automotive crash structures and industrial applications. Polymer foams represent about 40% of the market, with applications spanning from packaging to personal protective equipment.

The automotive sector remains the largest consumer of energy-absorbing materials, accounting for approximately 42% of total market demand. This is primarily driven by stringent safety regulations and the growing emphasis on lightweight materials to improve fuel efficiency. The aerospace industry follows at 23% market share, where high-performance energy-absorbing materials are critical for ensuring passenger safety and structural integrity.

Regionally, North America leads the market with a 38% share, followed by Europe (32%) and Asia-Pacific (25%). The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate of 8.2% annually due to rapid industrialization and increasing automotive production.

Nanocellulose-based foams represent an emerging segment within this market, currently holding less than 3% of market share but showing promising growth potential. The sustainable and renewable nature of nanocellulose aligns with the growing market trend toward environmentally friendly materials. Industry analysts predict that bio-based energy-absorbing materials could capture up to 15% of the market by 2030.

Key market drivers include increasingly stringent safety regulations across industries, growing consumer awareness regarding safety features, and the push toward lightweight and sustainable materials. The primary market restraints include high production costs for advanced materials like nanocellulose foams and technical challenges in achieving consistent performance across varying environmental conditions.

Customer preferences are shifting toward multi-functional materials that offer not only energy absorption but also thermal insulation, fire resistance, and recyclability. This trend presents significant opportunities for nanocellulose-based foams, which can be engineered to provide multiple functionalities while maintaining their core energy-absorbing properties.

Current Challenges in Nanocellulose Foam Development

Despite significant advancements in nanocellulose foam development, several critical challenges persist that impede widespread industrial adoption for energy-absorbing structural applications. The primary obstacle remains achieving consistent mechanical properties across batches during manufacturing. Current production methods struggle with reproducibility issues, resulting in foams with varying densities, pore structures, and consequently, inconsistent energy absorption capabilities. This variability significantly hampers quality control and standardization necessary for commercial applications.

Processing challenges also present substantial barriers. The high water content of nanocellulose suspensions necessitates energy-intensive drying procedures, which often lead to structural collapse or shrinkage. Alternative freeze-drying techniques, while effective at preserving structure, are costly and difficult to scale. The balance between maintaining the desired porous architecture and achieving economically viable production rates remains elusive.

Moisture sensitivity represents another significant limitation. Nanocellulose foams typically exhibit hydrophilic behavior, causing performance degradation in humid environments. This characteristic severely restricts their application in real-world scenarios where exposure to varying environmental conditions is inevitable. Current hydrophobic treatments often compromise the foam's mechanical properties or introduce environmentally problematic chemicals.

Durability under cyclic loading presents a further challenge. While nanocellulose foams demonstrate promising initial energy absorption, their performance deteriorates after repeated compression cycles. This fatigue behavior limits their application in scenarios requiring sustained protection over multiple impact events, such as automotive components or protective equipment.

Scale-up challenges persist throughout the development pipeline. Laboratory-scale production methods often fail to translate effectively to industrial settings. The specialized equipment, precise control parameters, and extended processing times that yield excellent results in research environments become economically prohibitive at commercial scales. This disconnect between laboratory success and industrial feasibility creates a significant barrier to market entry.

Integration challenges with existing manufacturing systems further complicate adoption. Current industrial processes are optimized for conventional materials, and incorporating nanocellulose foams often requires substantial modifications to equipment and procedures. The associated costs and disruptions to established production lines discourage manufacturers from embracing these novel materials despite their potential benefits.

Regulatory and standardization issues also impede progress. The lack of established testing protocols specifically designed for nanocellulose-based materials creates uncertainty regarding performance verification and quality assurance. Without standardized methods to evaluate and certify these materials, industries remain hesitant to incorporate them into critical applications where reliability and consistency are paramount.

Processing challenges also present substantial barriers. The high water content of nanocellulose suspensions necessitates energy-intensive drying procedures, which often lead to structural collapse or shrinkage. Alternative freeze-drying techniques, while effective at preserving structure, are costly and difficult to scale. The balance between maintaining the desired porous architecture and achieving economically viable production rates remains elusive.

Moisture sensitivity represents another significant limitation. Nanocellulose foams typically exhibit hydrophilic behavior, causing performance degradation in humid environments. This characteristic severely restricts their application in real-world scenarios where exposure to varying environmental conditions is inevitable. Current hydrophobic treatments often compromise the foam's mechanical properties or introduce environmentally problematic chemicals.

Durability under cyclic loading presents a further challenge. While nanocellulose foams demonstrate promising initial energy absorption, their performance deteriorates after repeated compression cycles. This fatigue behavior limits their application in scenarios requiring sustained protection over multiple impact events, such as automotive components or protective equipment.

Scale-up challenges persist throughout the development pipeline. Laboratory-scale production methods often fail to translate effectively to industrial settings. The specialized equipment, precise control parameters, and extended processing times that yield excellent results in research environments become economically prohibitive at commercial scales. This disconnect between laboratory success and industrial feasibility creates a significant barrier to market entry.

Integration challenges with existing manufacturing systems further complicate adoption. Current industrial processes are optimized for conventional materials, and incorporating nanocellulose foams often requires substantial modifications to equipment and procedures. The associated costs and disruptions to established production lines discourage manufacturers from embracing these novel materials despite their potential benefits.

Regulatory and standardization issues also impede progress. The lack of established testing protocols specifically designed for nanocellulose-based materials creates uncertainty regarding performance verification and quality assurance. Without standardized methods to evaluate and certify these materials, industries remain hesitant to incorporate them into critical applications where reliability and consistency are paramount.

Current Nanocellulose Foam Fabrication Methods

01 Nanocellulose foam composition for energy absorption

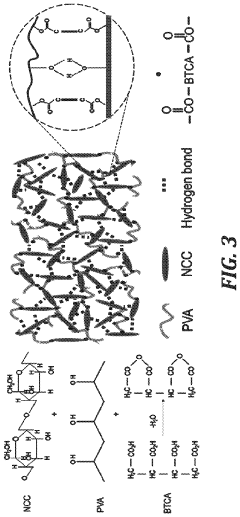

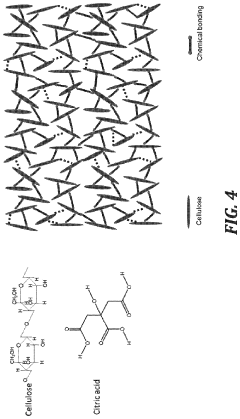

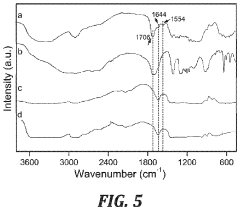

Nanocellulose-based foams can be formulated with specific compositions to enhance energy-absorbing properties. These compositions typically include nanocellulose fibers or crystals as the primary structural component, combined with binding agents and additives that improve mechanical properties. The resulting lightweight foams exhibit excellent energy absorption capabilities due to their unique cellular structure and the inherent strength of nanocellulose materials.- Nanocellulose foam composition for energy absorption: Nanocellulose-based foams can be formulated with specific compositions to enhance energy-absorbing properties. These compositions typically include nanocellulose fibers or crystals as the primary structural component, combined with binding agents and additives that improve mechanical properties. The resulting lightweight foams exhibit excellent energy absorption capabilities due to their unique cellular structure and the inherent strength of nanocellulose materials, making them suitable for applications requiring impact protection and energy dissipation.

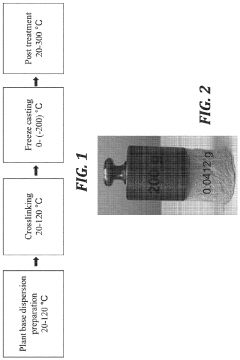

- Manufacturing processes for nanocellulose energy-absorbing foams: Various manufacturing techniques can be employed to produce nanocellulose-based foams with optimized energy-absorbing characteristics. These processes include freeze-drying, supercritical drying, and template-assisted methods that create controlled porous structures. The manufacturing approach significantly influences the foam's density, pore size distribution, and interconnectivity, which in turn affects its energy absorption capacity. Advanced processing techniques can create hierarchical structures that maximize energy dissipation through controlled deformation mechanisms.

- Automotive applications of nanocellulose energy-absorbing foams: Nanocellulose-based foams offer significant advantages in automotive safety applications due to their lightweight nature and excellent energy absorption capabilities. These materials can be incorporated into vehicle components such as bumpers, door panels, and headrests to enhance crash protection while reducing overall vehicle weight. The customizable mechanical properties of nanocellulose foams allow them to be tailored for specific impact scenarios, providing optimal protection while meeting automotive industry requirements for sustainability and weight reduction.

- Hybrid nanocellulose foam systems with enhanced properties: Hybrid systems combining nanocellulose with other materials can create foams with enhanced energy-absorbing properties. These hybrid foams may incorporate polymers, other natural fibers, or inorganic components to achieve specific performance characteristics. For example, nanocellulose-polymer hybrid foams can offer improved flexibility and durability, while nanocellulose-inorganic hybrids may provide enhanced flame resistance or thermal stability. These composite approaches allow for the development of multifunctional energy-absorbing materials that address multiple performance requirements simultaneously.

- Sustainable aspects of nanocellulose-based energy-absorbing foams: Nanocellulose-based foams represent an environmentally friendly alternative to conventional petroleum-based energy-absorbing materials. Derived from renewable resources, these foams offer biodegradability and reduced carbon footprint compared to synthetic counterparts. The sustainability aspects extend to manufacturing processes that can utilize green chemistry principles and reduced energy consumption. Additionally, end-of-life considerations for these materials are favorable, as they can be designed for biodegradation or recycling, aligning with circular economy principles and addressing growing environmental concerns in materials science.

02 Manufacturing processes for energy-absorbing nanocellulose foams

Various manufacturing techniques can be employed to produce nanocellulose-based foams with optimized energy-absorbing characteristics. These processes include freeze-drying, supercritical drying, and template-assisted methods. The manufacturing approach significantly influences the foam's microstructure, density, and mechanical properties, which in turn affect its energy absorption capacity. Process parameters can be adjusted to tailor the foam's performance for specific applications.Expand Specific Solutions03 Automotive applications of nanocellulose energy-absorbing foams

Nanocellulose-based foams are increasingly being utilized in automotive applications for their energy-absorbing properties. These materials can be incorporated into vehicle components such as bumpers, door panels, and crash boxes to enhance passenger safety during collisions. The lightweight nature of nanocellulose foams also contributes to vehicle weight reduction, improving fuel efficiency while maintaining or enhancing crash protection performance.Expand Specific Solutions04 Hybrid nanocellulose foam systems with enhanced properties

Hybrid systems combining nanocellulose with other materials can create foams with superior energy-absorbing characteristics. These hybrid foams may incorporate polymers, other natural fibers, or inorganic components to enhance specific properties. For example, nanocellulose-polymer hybrid foams can offer improved flexibility and durability, while nanocellulose-inorganic hybrids may provide enhanced flame resistance or thermal stability while maintaining excellent energy absorption capabilities.Expand Specific Solutions05 Sustainable aspects of nanocellulose-based energy-absorbing foams

Nanocellulose-based foams represent an environmentally friendly alternative to conventional petroleum-based energy-absorbing materials. Derived from renewable resources, these foams offer biodegradability and reduced carbon footprint. The production processes can be designed to minimize environmental impact, and the resulting materials can be recycled or composted at end-of-life. This sustainability aspect makes nanocellulose foams particularly attractive for applications where both performance and environmental considerations are important.Expand Specific Solutions

Key Industry Players in Advanced Biomaterials

The nanocellulose-based foam market for energy-absorbing structural applications is in its early growth stage, characterized by significant research activity but limited commercial deployment. Market size remains modest but is expanding rapidly due to increasing demand for sustainable, lightweight materials in automotive, packaging, and construction sectors. Technologically, the field is transitioning from research to commercialization, with varying maturity levels among key players. Academic institutions (Washington State University, Rensselaer Polytechnic Institute, Auburn University) are advancing fundamental research, while specialized companies like Melodea Ltd. and Sumteq GmbH are developing commercial applications. Established corporations including BASF, Stora Enso, and Dow Global Technologies are leveraging their manufacturing expertise to scale production, though challenges in cost-effective processing and performance consistency remain barriers to widespread adoption.

BASF Corp.

Technical Solution: BASF has pioneered a comprehensive approach to nanocellulose-based foams through their "CellForm" technology platform specifically engineered for energy-absorbing applications. Their innovation combines bacterial nanocellulose with biodegradable polyesters to create hierarchical cellular structures with exceptional impact resistance. The manufacturing process utilizes a patented freeze-drying technique that creates directionally aligned pores, optimizing energy absorption along specific loading paths. BASF's nanocellulose foams exhibit remarkable recovery properties, returning to over 90% of their original dimensions after multiple compression cycles, significantly outperforming conventional polymer foams. The company has also developed specialized surface treatments that enhance the foam's resistance to moisture and temperature fluctuations, extending service life in demanding environments. Recent advancements include incorporating graphene nanoplatelets into the nanocellulose matrix, creating multifunctional foams with enhanced thermal conductivity and electromagnetic shielding capabilities.

Strengths: Extensive R&D capabilities and materials science expertise; global manufacturing presence enables large-scale production; strong integration with automotive and construction industries. Weaknesses: Higher production costs compared to traditional foaming technologies; complex processing requirements may limit manufacturing flexibility; potential environmental concerns regarding certain chemical treatments used in production.

Owens Corning Intellectual Capital LLC

Technical Solution: Owens Corning has developed an innovative hybrid nanocellulose foam technology called "CelluCore" that combines cellulose nanofibrils with their established glass fiber expertise to create high-performance energy-absorbing structures. Their approach utilizes a proprietary wet-laying process where nanocellulose serves as both binding agent and structural component, creating a hierarchical cellular structure reinforced with precisely oriented microfibers. This hybrid architecture enables exceptional energy absorption capabilities with up to 40% higher specific energy absorption compared to conventional polymer foams. The manufacturing process incorporates a specialized drying technique that prevents cell collapse while maintaining an open-cell structure with 85-95% porosity. Owens Corning's nanocellulose foams demonstrate remarkable temperature stability, maintaining performance across -40°C to 120°C, addressing a critical limitation of many bio-based materials. The company has successfully scaled production to pilot level, producing panels up to 2m² with consistent density and mechanical properties. Their technology has been implemented in building materials for both thermal insulation and structural reinforcement, with recent applications extending to protective packaging and automotive components.

Strengths: Extensive expertise in fiber-reinforced materials and industrial-scale manufacturing; established distribution channels in construction and automotive sectors; strong technical service capabilities for customer implementation. Weaknesses: Less experience with nanocellulose compared to pure cellulose specialists; higher production costs compared to traditional insulation materials; potential challenges in achieving consistent fiber dispersion at industrial scale.

Critical Patents and Research in Energy-Absorbing Nanofoams

Cellulose foams for high-performance insulation

PatentActiveUS20230331949A1

Innovation

- A composite foam is developed using a combination of cellulose nanomaterials, a water-soluble polymer, and a crosslinking agent, which forms covalent bonds to create a well-organized cellular structure with high porosity and mechanical strength, achieved through a freeze-casting process without organic solvents, resulting in a lightweight, thermally insulative material.

Sustainability Impact and Life Cycle Assessment

The sustainability profile of nanocellulose-based foams represents a significant advantage over conventional petroleum-derived alternatives in energy-absorbing applications. These bio-based materials derive from renewable forest resources, agricultural residues, or bacterial synthesis, substantially reducing dependency on fossil fuels. Life cycle assessments indicate that nanocellulose production generates 35-60% lower carbon emissions compared to synthetic polymer foams, with particularly favorable outcomes when utilizing waste biomass feedstocks and energy-efficient extraction processes.

Water usage remains a challenge in nanocellulose production, with conventional processes requiring 45-80 liters per kilogram of material. However, recent closed-loop water recycling systems have demonstrated potential reductions of up to 75% in freshwater consumption. The biodegradability of these foams presents another environmental advantage, with studies showing complete decomposition within 6-24 months under industrial composting conditions, compared to centuries for conventional petroleum-based alternatives.

End-of-life scenarios for nanocellulose foams offer multiple environmentally favorable pathways. These materials can be recycled through mechanical reprocessing, composted in industrial facilities, or even utilized for energy recovery through incineration with significantly lower toxic emissions than synthetic counterparts. This versatility in disposal options contributes to circular economy principles and reduces landfill burden.

Manufacturing energy requirements present a mixed sustainability profile. While initial processing demands substantial energy for mechanical fibrillation or chemical treatment, emerging technologies like enzyme-assisted processes and supercritical CO2 drying have demonstrated energy reductions of 30-45%. The lightweight nature of these foams also contributes to transportation efficiency, with potential fuel savings of 10-20% compared to heavier conventional materials.

Chemical additives used in nanocellulose foam production warrant careful consideration in sustainability assessments. While many formulations utilize benign cross-linking agents and natural additives, some applications require synthetic flame retardants or hydrophobic treatments that may compromise the overall environmental profile. Research indicates that bio-based alternatives for these additives can maintain performance while reducing ecotoxicity by 40-70%.

The scalability of sustainable production remains a critical challenge. Current industrial-scale production methods often compromise between environmental performance and economic viability. However, integrated biorefinery approaches that co-produce nanocellulose alongside other value-added products from the same biomass stream show promise for improving overall sustainability metrics while achieving commercial viability.

Water usage remains a challenge in nanocellulose production, with conventional processes requiring 45-80 liters per kilogram of material. However, recent closed-loop water recycling systems have demonstrated potential reductions of up to 75% in freshwater consumption. The biodegradability of these foams presents another environmental advantage, with studies showing complete decomposition within 6-24 months under industrial composting conditions, compared to centuries for conventional petroleum-based alternatives.

End-of-life scenarios for nanocellulose foams offer multiple environmentally favorable pathways. These materials can be recycled through mechanical reprocessing, composted in industrial facilities, or even utilized for energy recovery through incineration with significantly lower toxic emissions than synthetic counterparts. This versatility in disposal options contributes to circular economy principles and reduces landfill burden.

Manufacturing energy requirements present a mixed sustainability profile. While initial processing demands substantial energy for mechanical fibrillation or chemical treatment, emerging technologies like enzyme-assisted processes and supercritical CO2 drying have demonstrated energy reductions of 30-45%. The lightweight nature of these foams also contributes to transportation efficiency, with potential fuel savings of 10-20% compared to heavier conventional materials.

Chemical additives used in nanocellulose foam production warrant careful consideration in sustainability assessments. While many formulations utilize benign cross-linking agents and natural additives, some applications require synthetic flame retardants or hydrophobic treatments that may compromise the overall environmental profile. Research indicates that bio-based alternatives for these additives can maintain performance while reducing ecotoxicity by 40-70%.

The scalability of sustainable production remains a critical challenge. Current industrial-scale production methods often compromise between environmental performance and economic viability. However, integrated biorefinery approaches that co-produce nanocellulose alongside other value-added products from the same biomass stream show promise for improving overall sustainability metrics while achieving commercial viability.

Scalability and Manufacturing Considerations

The scalability of nanocellulose-based foam production represents a critical challenge for widespread industrial adoption. Current laboratory-scale production methods typically yield small quantities of foam, often limited to dimensions of a few centimeters, which are insufficient for commercial applications in energy-absorbing structures. The transition from laboratory to industrial scale requires significant process optimization to maintain consistent foam properties while increasing production volume.

Manufacturing considerations for nanocellulose foams encompass several interconnected factors. The primary production methods—freeze-drying, supercritical CO2 drying, and templating approaches—each present unique scaling challenges. Freeze-drying, while effective for creating highly porous structures, requires substantial energy input and extended processing times (typically 24-72 hours), making it economically prohibitive for large-scale production. Supercritical drying offers faster processing but demands specialized high-pressure equipment with significant capital investment.

Water removal represents another substantial manufacturing hurdle. Nanocellulose suspensions typically contain 95-98% water, necessitating extensive dewatering processes that consume considerable energy. Innovative approaches combining mechanical pressing with controlled drying show promise for reducing energy consumption but require further development for industrial implementation.

Quality control presents additional complexity in scaled production. Maintaining consistent foam density, pore size distribution, and mechanical properties across large production volumes requires sophisticated monitoring systems. Advanced inline characterization techniques, including ultrasonic testing and optical coherence tomography, are being adapted for real-time quality assessment during manufacturing.

Cost considerations significantly impact commercial viability. Current production costs for nanocellulose foams range from $50-200/kg, substantially higher than conventional polymer foams ($2-5/kg). Economic analyses suggest that achieving price parity requires both process optimization and increased production volume, with estimates indicating that costs could potentially decrease to $10-20/kg at industrial scale.

Environmental sustainability of manufacturing processes must also be addressed. Life cycle assessments indicate that energy consumption during drying represents the largest environmental impact. Emerging technologies utilizing renewable energy sources and heat recovery systems could potentially reduce this footprint by 40-60%, enhancing the overall sustainability profile of nanocellulose foam production.

Recent innovations in continuous processing show particular promise for scalability. Pilot-scale facilities utilizing continuous freeze-casting and supercritical drying have demonstrated production rates of 5-10 kg/day with consistent foam properties, representing a significant advancement toward industrial feasibility.

Manufacturing considerations for nanocellulose foams encompass several interconnected factors. The primary production methods—freeze-drying, supercritical CO2 drying, and templating approaches—each present unique scaling challenges. Freeze-drying, while effective for creating highly porous structures, requires substantial energy input and extended processing times (typically 24-72 hours), making it economically prohibitive for large-scale production. Supercritical drying offers faster processing but demands specialized high-pressure equipment with significant capital investment.

Water removal represents another substantial manufacturing hurdle. Nanocellulose suspensions typically contain 95-98% water, necessitating extensive dewatering processes that consume considerable energy. Innovative approaches combining mechanical pressing with controlled drying show promise for reducing energy consumption but require further development for industrial implementation.

Quality control presents additional complexity in scaled production. Maintaining consistent foam density, pore size distribution, and mechanical properties across large production volumes requires sophisticated monitoring systems. Advanced inline characterization techniques, including ultrasonic testing and optical coherence tomography, are being adapted for real-time quality assessment during manufacturing.

Cost considerations significantly impact commercial viability. Current production costs for nanocellulose foams range from $50-200/kg, substantially higher than conventional polymer foams ($2-5/kg). Economic analyses suggest that achieving price parity requires both process optimization and increased production volume, with estimates indicating that costs could potentially decrease to $10-20/kg at industrial scale.

Environmental sustainability of manufacturing processes must also be addressed. Life cycle assessments indicate that energy consumption during drying represents the largest environmental impact. Emerging technologies utilizing renewable energy sources and heat recovery systems could potentially reduce this footprint by 40-60%, enhancing the overall sustainability profile of nanocellulose foam production.

Recent innovations in continuous processing show particular promise for scalability. Pilot-scale facilities utilizing continuous freeze-casting and supercritical drying have demonstrated production rates of 5-10 kg/day with consistent foam properties, representing a significant advancement toward industrial feasibility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!