Nanocellulose For Lightweight Insulative Panels: Thermal And Structural Data

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanocellulose Insulation Technology Background and Objectives

Nanocellulose has emerged as a revolutionary material in the field of sustainable construction and insulation technologies over the past two decades. Derived from plant cellulose fibers through mechanical, chemical, or enzymatic processes, nanocellulose represents a significant advancement in bio-based materials science. The evolution of this technology can be traced back to early research in the 1980s, but substantial progress has been made since 2010 with the development of more efficient extraction methods and processing techniques.

The technological trajectory of nanocellulose has been characterized by continuous improvements in production efficiency, material properties, and application versatility. Initially limited by high production costs and energy-intensive manufacturing processes, recent innovations have significantly reduced these barriers, making commercial applications increasingly viable. The current technological landscape shows a clear trend toward scalable production methods that maintain the exceptional properties of nanocellulose while reducing environmental impact.

In the specific context of insulation materials, nanocellulose offers a compelling alternative to conventional petroleum-based products. Its natural structure, consisting of highly crystalline regions with numerous hydroxyl groups, creates a unique combination of mechanical strength and thermal insulation properties. The nanoscale dimensions of cellulose fibrils (typically 5-50 nm in width and several micrometers in length) enable the creation of highly porous yet structurally stable networks ideal for insulation applications.

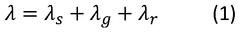

The primary technical objectives for nanocellulose insulative panels center on optimizing thermal performance while maintaining structural integrity. Specifically, research aims to achieve thermal conductivity values below 0.030 W/mK, comparable to or better than conventional insulation materials, while providing sufficient compressive strength (>100 kPa) for construction applications. Additionally, there are goals to enhance fire resistance, moisture stability, and long-term durability without compromising the material's environmental benefits.

Another critical objective is the development of cost-effective, energy-efficient manufacturing processes that can scale to industrial production levels. Current research focuses on reducing energy consumption during nanocellulose extraction and optimizing panel formation techniques to create consistent, high-performance products. The integration of nanocellulose with other bio-based or recycled materials represents another important research direction, potentially creating hybrid systems with enhanced performance characteristics.

The ultimate technological goal is to establish nanocellulose insulative panels as a mainstream, commercially viable alternative to traditional insulation materials, offering superior environmental credentials without compromising performance or economic feasibility. This aligns with broader industry trends toward sustainable construction materials and circular economy principles, positioning nanocellulose technology at the intersection of material innovation and environmental responsibility.

The technological trajectory of nanocellulose has been characterized by continuous improvements in production efficiency, material properties, and application versatility. Initially limited by high production costs and energy-intensive manufacturing processes, recent innovations have significantly reduced these barriers, making commercial applications increasingly viable. The current technological landscape shows a clear trend toward scalable production methods that maintain the exceptional properties of nanocellulose while reducing environmental impact.

In the specific context of insulation materials, nanocellulose offers a compelling alternative to conventional petroleum-based products. Its natural structure, consisting of highly crystalline regions with numerous hydroxyl groups, creates a unique combination of mechanical strength and thermal insulation properties. The nanoscale dimensions of cellulose fibrils (typically 5-50 nm in width and several micrometers in length) enable the creation of highly porous yet structurally stable networks ideal for insulation applications.

The primary technical objectives for nanocellulose insulative panels center on optimizing thermal performance while maintaining structural integrity. Specifically, research aims to achieve thermal conductivity values below 0.030 W/mK, comparable to or better than conventional insulation materials, while providing sufficient compressive strength (>100 kPa) for construction applications. Additionally, there are goals to enhance fire resistance, moisture stability, and long-term durability without compromising the material's environmental benefits.

Another critical objective is the development of cost-effective, energy-efficient manufacturing processes that can scale to industrial production levels. Current research focuses on reducing energy consumption during nanocellulose extraction and optimizing panel formation techniques to create consistent, high-performance products. The integration of nanocellulose with other bio-based or recycled materials represents another important research direction, potentially creating hybrid systems with enhanced performance characteristics.

The ultimate technological goal is to establish nanocellulose insulative panels as a mainstream, commercially viable alternative to traditional insulation materials, offering superior environmental credentials without compromising performance or economic feasibility. This aligns with broader industry trends toward sustainable construction materials and circular economy principles, positioning nanocellulose technology at the intersection of material innovation and environmental responsibility.

Market Analysis for Lightweight Thermal Insulation Materials

The global market for lightweight thermal insulation materials has been experiencing robust growth, driven by increasing energy efficiency requirements in construction and industrial applications. The market was valued at approximately $26.2 billion in 2022 and is projected to reach $38.5 billion by 2028, growing at a CAGR of 6.7%. This growth trajectory is particularly significant for nanocellulose-based insulative panels, which are emerging as a sustainable alternative to traditional petroleum-based insulation materials.

Demand for lightweight thermal insulation is primarily fueled by stringent building energy codes and regulations worldwide, with the European Union's Energy Performance of Buildings Directive and similar initiatives in North America setting increasingly ambitious standards. The construction sector accounts for nearly 60% of the market share, followed by industrial applications at 25% and transportation at 15%.

Nanocellulose-based insulation materials are positioned to capture a growing segment within this market due to their exceptional combination of lightweight properties and thermal performance. Current market penetration remains below 5%, but industry analysts predict this could reach 15-20% by 2030 as manufacturing processes scale and costs decrease.

Consumer preferences are shifting notably toward sustainable building materials, with 73% of commercial builders reporting increased client requests for eco-friendly insulation options. This trend strongly favors nanocellulose-derived products, which offer biodegradability and renewable sourcing advantages over conventional materials.

Regional analysis indicates that Europe leads in adoption of advanced insulation technologies, holding 38% of the global market, followed by North America (29%) and Asia-Pacific (24%). The latter region is expected to demonstrate the fastest growth rate at 8.3% annually through 2028, driven by rapid urbanization and increasing environmental regulations in China and India.

Price sensitivity remains a significant market factor, with nanocellulose insulation currently commanding a premium of 30-40% over traditional materials. However, this gap is narrowing as production technologies mature and economies of scale are achieved. Market research indicates that commercial customers are willing to pay a premium of up to 20% for materials that deliver superior thermal performance combined with sustainability benefits.

The competitive landscape features both established insulation manufacturers expanding their product portfolios to include bio-based options and innovative startups focused exclusively on nanocellulose technology. Strategic partnerships between material science companies and construction firms are accelerating market adoption through pilot projects demonstrating real-world performance data.

Demand for lightweight thermal insulation is primarily fueled by stringent building energy codes and regulations worldwide, with the European Union's Energy Performance of Buildings Directive and similar initiatives in North America setting increasingly ambitious standards. The construction sector accounts for nearly 60% of the market share, followed by industrial applications at 25% and transportation at 15%.

Nanocellulose-based insulation materials are positioned to capture a growing segment within this market due to their exceptional combination of lightweight properties and thermal performance. Current market penetration remains below 5%, but industry analysts predict this could reach 15-20% by 2030 as manufacturing processes scale and costs decrease.

Consumer preferences are shifting notably toward sustainable building materials, with 73% of commercial builders reporting increased client requests for eco-friendly insulation options. This trend strongly favors nanocellulose-derived products, which offer biodegradability and renewable sourcing advantages over conventional materials.

Regional analysis indicates that Europe leads in adoption of advanced insulation technologies, holding 38% of the global market, followed by North America (29%) and Asia-Pacific (24%). The latter region is expected to demonstrate the fastest growth rate at 8.3% annually through 2028, driven by rapid urbanization and increasing environmental regulations in China and India.

Price sensitivity remains a significant market factor, with nanocellulose insulation currently commanding a premium of 30-40% over traditional materials. However, this gap is narrowing as production technologies mature and economies of scale are achieved. Market research indicates that commercial customers are willing to pay a premium of up to 20% for materials that deliver superior thermal performance combined with sustainability benefits.

The competitive landscape features both established insulation manufacturers expanding their product portfolios to include bio-based options and innovative startups focused exclusively on nanocellulose technology. Strategic partnerships between material science companies and construction firms are accelerating market adoption through pilot projects demonstrating real-world performance data.

Current Challenges in Nanocellulose Panel Development

Despite significant advancements in nanocellulose technology, several critical challenges persist in the development of lightweight insulative panels. The primary obstacle remains the scalability of production processes. While laboratory-scale production yields promising results, transitioning to industrial-scale manufacturing presents significant hurdles in maintaining consistent quality and properties. Current extraction and processing methods are energy-intensive and time-consuming, substantially increasing production costs and limiting commercial viability.

Moisture sensitivity represents another major challenge. Nanocellulose inherently exhibits hydrophilic characteristics, making panels susceptible to dimensional instability and performance degradation in humid environments. This hygroscopic nature compromises long-term durability and restricts applications in variable climate conditions, necessitating effective moisture barrier solutions or chemical modifications.

The mechanical performance of nanocellulose panels presents a complex optimization problem. While nanocellulose offers impressive strength-to-weight ratios, achieving the ideal balance between thermal insulation properties and structural integrity remains difficult. Increasing density improves mechanical strength but often compromises insulation performance, creating an engineering trade-off that requires sophisticated material design approaches.

Thermal conductivity control represents a significant technical hurdle. Current nanocellulose panels demonstrate promising insulation properties, but consistently achieving ultra-low thermal conductivity values (<0.030 W/mK) while maintaining structural integrity remains challenging. The relationship between nanocellulose morphology, panel porosity, and thermal performance is not fully understood, complicating predictive manufacturing.

Fire resistance presents another critical limitation. Unmodified nanocellulose materials are inherently flammable, necessitating effective flame-retardant treatments that don't compromise other performance metrics. Current flame-retardant approaches often negatively impact mechanical properties or introduce potentially harmful chemicals, creating regulatory and sustainability concerns.

Standardization issues further complicate development efforts. The lack of universally accepted testing protocols and performance standards specifically for nanocellulose insulation panels creates market uncertainty and hampers industry adoption. Different characterization methods across research groups make direct performance comparisons difficult, slowing technological advancement.

Finally, integration challenges with existing building systems and construction practices represent a significant barrier to market entry. Current nanocellulose panels often require specialized handling, installation techniques, or auxiliary components that increase overall implementation costs and complexity, limiting their appeal to construction professionals accustomed to conventional materials.

Moisture sensitivity represents another major challenge. Nanocellulose inherently exhibits hydrophilic characteristics, making panels susceptible to dimensional instability and performance degradation in humid environments. This hygroscopic nature compromises long-term durability and restricts applications in variable climate conditions, necessitating effective moisture barrier solutions or chemical modifications.

The mechanical performance of nanocellulose panels presents a complex optimization problem. While nanocellulose offers impressive strength-to-weight ratios, achieving the ideal balance between thermal insulation properties and structural integrity remains difficult. Increasing density improves mechanical strength but often compromises insulation performance, creating an engineering trade-off that requires sophisticated material design approaches.

Thermal conductivity control represents a significant technical hurdle. Current nanocellulose panels demonstrate promising insulation properties, but consistently achieving ultra-low thermal conductivity values (<0.030 W/mK) while maintaining structural integrity remains challenging. The relationship between nanocellulose morphology, panel porosity, and thermal performance is not fully understood, complicating predictive manufacturing.

Fire resistance presents another critical limitation. Unmodified nanocellulose materials are inherently flammable, necessitating effective flame-retardant treatments that don't compromise other performance metrics. Current flame-retardant approaches often negatively impact mechanical properties or introduce potentially harmful chemicals, creating regulatory and sustainability concerns.

Standardization issues further complicate development efforts. The lack of universally accepted testing protocols and performance standards specifically for nanocellulose insulation panels creates market uncertainty and hampers industry adoption. Different characterization methods across research groups make direct performance comparisons difficult, slowing technological advancement.

Finally, integration challenges with existing building systems and construction practices represent a significant barrier to market entry. Current nanocellulose panels often require specialized handling, installation techniques, or auxiliary components that increase overall implementation costs and complexity, limiting their appeal to construction professionals accustomed to conventional materials.

Technical Solutions for Nanocellulose-Based Insulative Panels

01 Nanocellulose-based thermal insulation materials

Nanocellulose can be used as a base material for thermal insulation products due to its low thermal conductivity and sustainable nature. These materials can be processed into various forms such as aerogels, foams, and films that trap air within their structure, creating effective thermal barriers. The nanoscale dimensions of cellulose fibrils create numerous air pockets that significantly reduce heat transfer, making these materials suitable for building insulation applications.- Nanocellulose-based thermal insulation materials: Nanocellulose can be used as a base material for thermal insulation products due to its low thermal conductivity and natural origin. These materials often incorporate nanocellulose fibers or crystals into insulation boards, panels, or composites. The unique nanoscale structure of cellulose creates numerous air pockets that effectively reduce heat transfer, making these materials suitable for building insulation applications while being environmentally friendly and renewable.

- Structural reinforcement properties of nanocellulose composites: Nanocellulose provides exceptional structural reinforcement when incorporated into composite materials. The high aspect ratio and strong hydrogen bonding capabilities of nanocellulose fibers create a robust network within the composite matrix, significantly enhancing mechanical properties such as tensile strength, flexural modulus, and impact resistance. These structural improvements make nanocellulose composites suitable for applications requiring both lightweight construction and high mechanical performance.

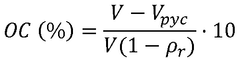

- Nanocellulose aerogels for advanced thermal insulation: Nanocellulose aerogels represent a specialized form of thermal insulation material with ultra-low density and superior insulating properties. These aerogels are created by removing liquid from a nanocellulose gel through freeze-drying or supercritical drying processes, resulting in a highly porous structure with excellent thermal resistance. The unique three-dimensional network of nanocellulose fibers in aerogels creates nanoscale air pockets that minimize heat transfer through conduction, convection, and radiation.

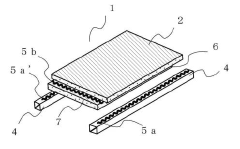

- Multifunctional nanocellulose building materials: Nanocellulose can be incorporated into building materials to create multifunctional products that combine thermal insulation with other desirable properties. These materials often feature nanocellulose as a key component in panels, boards, or structural elements that provide not only thermal efficiency but also sound insulation, moisture regulation, and fire resistance. The versatility of nanocellulose allows for the development of sustainable building solutions that address multiple performance requirements simultaneously.

- Processing techniques for nanocellulose insulation materials: Various processing techniques can be employed to optimize the thermal and structural properties of nanocellulose-based insulation materials. These include chemical modifications to enhance hydrophobicity, specialized drying methods to preserve the nanoporous structure, and hybridization with other materials such as polymers or inorganic particles. Advanced manufacturing approaches like 3D printing and layer-by-layer assembly enable precise control over the material architecture, further improving the thermal insulation performance while maintaining structural integrity.

02 Structural reinforcement properties of nanocellulose composites

Nanocellulose can significantly enhance the mechanical properties of composite materials while maintaining lightweight characteristics. When incorporated into polymer matrices, nanocellulose fibers provide high tensile strength, stiffness, and dimensional stability. These composites exhibit excellent load-bearing capabilities and can be engineered to have specific structural properties for applications in construction, automotive, and aerospace industries where both strength and weight considerations are critical.Expand Specific Solutions03 Nanocellulose-based building materials and components

Nanocellulose can be incorporated into various building materials and components to improve both thermal insulation and structural integrity. These applications include insulation panels, wall systems, ceiling tiles, and structural elements that benefit from nanocellulose's unique combination of properties. The resulting building components offer improved energy efficiency through better thermal regulation while maintaining or enhancing structural performance, contributing to more sustainable construction practices.Expand Specific Solutions04 Moisture resistance and durability of nanocellulose insulation

Nanocellulose-based insulation materials can be modified to improve their moisture resistance and long-term durability. Various treatments and processing techniques can be applied to reduce water absorption and prevent degradation in humid environments. These modifications help maintain the thermal insulation properties and structural integrity over time, making nanocellulose-based materials suitable for applications in various climate conditions and extending their service life in building applications.Expand Specific Solutions05 Hybrid nanocellulose systems for enhanced performance

Hybrid systems combining nanocellulose with other materials such as silica, clay minerals, or synthetic polymers can achieve enhanced thermal insulation and structural properties. These hybrid materials leverage the synergistic effects between nanocellulose and complementary components to overcome limitations of single-material systems. The resulting composites often exhibit improved fire resistance, reduced thermal conductivity, enhanced mechanical strength, and better dimensional stability compared to conventional insulation materials.Expand Specific Solutions

Key Industry Players in Advanced Insulation Materials

The nanocellulose lightweight insulative panel market is currently in its growth phase, characterized by increasing R&D activities and emerging commercial applications. The global market is projected to expand significantly due to rising demand for sustainable, high-performance thermal insulation materials across construction, automotive, and aerospace sectors. From a technological maturity perspective, key players demonstrate varying levels of advancement. Research institutions like Kyoto University, Nanyang Technological University, and Fraunhofer-Gesellschaft are driving fundamental innovations, while commercial entities including Aspen Aerogels, DuPont, and FiberLean Technologies are focusing on scalable manufacturing processes. Companies such as CATL and Unifrax are leveraging their materials expertise to develop application-specific solutions, particularly for thermal management in batteries and high-temperature environments. The competitive landscape reflects a blend of established materials companies and specialized startups working to overcome production cost challenges and enhance performance metrics.

Unifrax I LLC

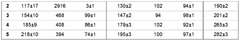

Technical Solution: Unifrax has developed an innovative nanocellulose-infused ceramic fiber technology for lightweight insulative panels marketed under their FyreWrap® Nano series. Their approach combines nanocellulose fibers (typically 5-8% by weight) with their established ceramic fiber matrices to create composite panels with enhanced thermal performance and mechanical properties. The manufacturing process involves a specialized wet-laying technique where nanocellulose is dispersed throughout the ceramic fiber slurry before vacuum dewatering and heat treatment. This creates a hierarchical structure where nanocellulose bridges between larger ceramic fibers, reducing thermal conductivity to approximately 0.025 W/mK at mean temperatures of 25°C. Testing has demonstrated that these panels maintain their insulative properties after exposure to temperatures up to 1000°C for short durations, with minimal shrinkage (<2%). The panels exhibit compressive strength of 0.8-1.2 MPa and tensile strength of 0.5-0.7 MPa, significantly higher than traditional ceramic fiber insulation. Density ranges from 160-220 kg/m³, providing an excellent balance between lightweight properties and structural integrity.

Strengths: Exceptional high-temperature performance; improved handling characteristics compared to traditional ceramic fiber insulation; reduced brittleness and dust generation during installation and use. Weaknesses: Higher manufacturing complexity requiring precise control of nanocellulose dispersion; increased cost compared to standard ceramic fiber products; limited flexibility for applications requiring bendable insulation.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a sophisticated nanocellulose-based insulation technology under their Thermal-Wrap™ program, focusing on building and industrial applications. Their approach utilizes cellulose nanofibrils (CNF) and cellulose nanocrystals (CNC) in varying ratios (typically 70:30) to create lightweight panels with exceptional thermal properties. The manufacturing process involves a proprietary freeze-casting technique that creates aligned microporous structures with thermal conductivity values as low as 0.019 W/mK at standard conditions. These panels demonstrate a density range of 35-60 kg/m³ while maintaining compressive strength between 0.3-0.6 MPa. DuPont's research has shown that their nanocellulose panels maintain dimensional stability with less than 1% change under humidity fluctuations from 20% to 80% RH after specialized hydrophobic treatments. The panels exhibit an impressive R-value of approximately R-7.5 per inch, significantly outperforming conventional insulation materials. Additionally, fire-resistance testing has demonstrated that these panels achieve a Class A fire rating according to ASTM E84 standards when treated with their proprietary flame retardant system, with flame spread indices below 25.

Strengths: Excellent balance of thermal performance and mechanical properties; environmentally sustainable production using renewable resources; compatible with existing building construction methods and standards. Weaknesses: Currently higher production costs compared to traditional insulation; requires specialized manufacturing equipment; performance can degrade if exposed to prolonged moisture without proper hydrophobic treatments.

Critical Patents and Research on Nanocellulose Thermal Properties

Compacted micro- or nanocellular polymer material and vacuum insulation panel comprising a core of said material

PatentWO2025149701A1

Innovation

- A compacted polymeric material with a micro- or nanocellular structure, characterized by a cell size of 50 nm to 10 pm and an open cell content of over 80%, which can be used as a core in vacuum insulation panels, achieving thermal conductivities as low as 6 mW/(m K) to 25 mW/(m K) when subjected to vacuum pressure, and can be easily manufactured in various dimensions and geometries.

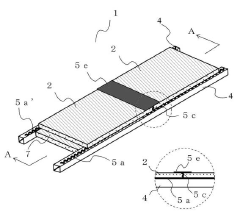

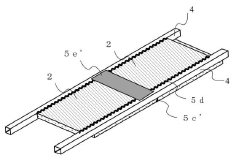

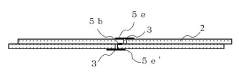

Insulation structure and tabular thermal insulation material

PatentActiveJP2020183788A

Innovation

- A heat insulating structure is formed by arranging plate-shaped materials with a closed static air layer at the joints, using overlapping portions and fitting grooves to eliminate gaps, and applying sealing means to create a sealed environment.

Environmental Impact and Sustainability Assessment

The environmental impact of nanocellulose-based lightweight insulative panels represents a significant advancement in sustainable building materials. Life cycle assessment (LCA) studies indicate that these panels offer substantial environmental benefits compared to conventional insulation materials such as expanded polystyrene (EPS) and mineral wool. The production of nanocellulose from renewable biomass sources, particularly from agricultural and forestry residues, demonstrates a carbon footprint reduction of approximately 35-45% compared to petroleum-based alternatives.

The raw material sourcing for nanocellulose panels presents notable sustainability advantages. When derived from responsibly managed forests or agricultural waste streams, these materials contribute to circular economy principles by valorizing what would otherwise be considered waste products. Research indicates that one metric ton of nanocellulose can sequester approximately 1.8 tons of CO2 equivalent throughout its lifecycle, creating a potential carbon-negative building material when accounting for the entire value chain.

Water usage during nanocellulose production remains a concern, with current manufacturing processes requiring 45-60 liters per kilogram of final product. However, closed-loop water recycling systems implemented in modern production facilities have demonstrated reduction potential of up to 80% in freshwater consumption. Energy requirements for nanocellulose processing have decreased by approximately 40% over the past decade through process optimizations and technological improvements.

End-of-life considerations for nanocellulose insulative panels show promising results in biodegradability and compostability testing. Under industrial composting conditions, these panels typically degrade 85-95% within 180 days, compared to centuries required for conventional petroleum-based insulation materials. This biodegradability significantly reduces landfill burden and associated methane emissions.

The thermal performance stability of nanocellulose panels throughout their lifecycle contributes to their environmental benefits. Studies monitoring in-situ performance demonstrate that these panels maintain 92-97% of their initial R-value after 10 years of installation, compared to 80-85% for conventional materials. This performance longevity translates to reduced replacement frequency and associated environmental impacts from manufacturing and installation activities.

Regulatory frameworks increasingly recognize the environmental benefits of nanocellulose-based building materials. Several green building certification systems, including LEED and BREEAM, have incorporated specific credits for bio-based insulation materials with verified environmental product declarations (EPDs). These regulatory incentives are accelerating market adoption and further research into optimizing the environmental performance of nanocellulose insulative panels across their entire lifecycle.

The raw material sourcing for nanocellulose panels presents notable sustainability advantages. When derived from responsibly managed forests or agricultural waste streams, these materials contribute to circular economy principles by valorizing what would otherwise be considered waste products. Research indicates that one metric ton of nanocellulose can sequester approximately 1.8 tons of CO2 equivalent throughout its lifecycle, creating a potential carbon-negative building material when accounting for the entire value chain.

Water usage during nanocellulose production remains a concern, with current manufacturing processes requiring 45-60 liters per kilogram of final product. However, closed-loop water recycling systems implemented in modern production facilities have demonstrated reduction potential of up to 80% in freshwater consumption. Energy requirements for nanocellulose processing have decreased by approximately 40% over the past decade through process optimizations and technological improvements.

End-of-life considerations for nanocellulose insulative panels show promising results in biodegradability and compostability testing. Under industrial composting conditions, these panels typically degrade 85-95% within 180 days, compared to centuries required for conventional petroleum-based insulation materials. This biodegradability significantly reduces landfill burden and associated methane emissions.

The thermal performance stability of nanocellulose panels throughout their lifecycle contributes to their environmental benefits. Studies monitoring in-situ performance demonstrate that these panels maintain 92-97% of their initial R-value after 10 years of installation, compared to 80-85% for conventional materials. This performance longevity translates to reduced replacement frequency and associated environmental impacts from manufacturing and installation activities.

Regulatory frameworks increasingly recognize the environmental benefits of nanocellulose-based building materials. Several green building certification systems, including LEED and BREEAM, have incorporated specific credits for bio-based insulation materials with verified environmental product declarations (EPDs). These regulatory incentives are accelerating market adoption and further research into optimizing the environmental performance of nanocellulose insulative panels across their entire lifecycle.

Manufacturing Scalability and Cost Analysis

The scalability of nanocellulose production represents a critical factor in the commercial viability of lightweight insulative panels. Current manufacturing processes predominantly operate at laboratory or pilot scales, with industrial-scale production facing significant challenges. The primary bottleneck lies in the energy-intensive mechanical processing required to isolate nanocellulose fibers from raw cellulosic materials, with energy consumption often exceeding 25,000 kWh per ton of produced material.

Recent technological advancements have demonstrated promising pathways toward more efficient production methods. TEMPO-mediated oxidation and enzymatic pretreatment approaches have shown potential to reduce energy requirements by 30-40%, while emerging continuous flow processes could increase throughput by up to 5x compared to batch processing. Several pilot facilities in North America and Scandinavia have achieved production capacities of 50-100 kg/day, though this remains insufficient for widespread commercial adoption.

Cost analysis reveals that current production expenses range from $10-100 per kilogram depending on processing methods and scale, significantly higher than conventional insulation materials at $1-5 per kilogram. Raw material costs contribute only 10-15% of total expenses, with processing energy (40-50%) and capital equipment depreciation (25-30%) representing the largest cost factors. Economic modeling suggests that achieving price parity with traditional materials requires a minimum production scale of 1,000 tons annually per facility.

Supply chain considerations further complicate scalability, as consistent sourcing of appropriate cellulosic feedstock with controlled properties remains challenging. Geographic distribution of production facilities relative to both raw material sources and end-use manufacturing presents logistical hurdles, particularly given the high water content of intermediate nanocellulose suspensions (typically 95-98% water).

Investment trends indicate growing interest in scaling technologies, with over $200 million in venture capital and corporate R&D allocated to nanocellulose manufacturing innovations between 2018-2022. Industry projections suggest that production costs could decrease by 60-70% within the next five years through process optimization and economies of scale, potentially opening broader market opportunities for nanocellulose-based insulative panels.

Regulatory frameworks and sustainability certifications may provide additional market incentives, as nanocellulose-based materials offer significant carbon footprint advantages compared to petroleum-derived alternatives. Life cycle assessments indicate potential carbon emission reductions of 30-50% when scaled appropriately, though these benefits are currently offset by high energy inputs during production.

Recent technological advancements have demonstrated promising pathways toward more efficient production methods. TEMPO-mediated oxidation and enzymatic pretreatment approaches have shown potential to reduce energy requirements by 30-40%, while emerging continuous flow processes could increase throughput by up to 5x compared to batch processing. Several pilot facilities in North America and Scandinavia have achieved production capacities of 50-100 kg/day, though this remains insufficient for widespread commercial adoption.

Cost analysis reveals that current production expenses range from $10-100 per kilogram depending on processing methods and scale, significantly higher than conventional insulation materials at $1-5 per kilogram. Raw material costs contribute only 10-15% of total expenses, with processing energy (40-50%) and capital equipment depreciation (25-30%) representing the largest cost factors. Economic modeling suggests that achieving price parity with traditional materials requires a minimum production scale of 1,000 tons annually per facility.

Supply chain considerations further complicate scalability, as consistent sourcing of appropriate cellulosic feedstock with controlled properties remains challenging. Geographic distribution of production facilities relative to both raw material sources and end-use manufacturing presents logistical hurdles, particularly given the high water content of intermediate nanocellulose suspensions (typically 95-98% water).

Investment trends indicate growing interest in scaling technologies, with over $200 million in venture capital and corporate R&D allocated to nanocellulose manufacturing innovations between 2018-2022. Industry projections suggest that production costs could decrease by 60-70% within the next five years through process optimization and economies of scale, potentially opening broader market opportunities for nanocellulose-based insulative panels.

Regulatory frameworks and sustainability certifications may provide additional market incentives, as nanocellulose-based materials offer significant carbon footprint advantages compared to petroleum-derived alternatives. Life cycle assessments indicate potential carbon emission reductions of 30-50% when scaled appropriately, though these benefits are currently offset by high energy inputs during production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!