Modeling The Strengthening Effect Of Nanocellulose At Multiple Scales

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanocellulose Strengthening Mechanisms and Research Objectives

Nanocellulose has emerged as a revolutionary material in the field of sustainable composites due to its exceptional mechanical properties, biodegradability, and renewability. The strengthening effect of nanocellulose in composite materials has been observed across multiple scales, from nanoscale interactions to macroscale performance enhancements. Understanding these multi-scale strengthening mechanisms represents a critical frontier in materials science and engineering.

The evolution of nanocellulose technology has progressed significantly over the past two decades, transitioning from laboratory curiosity to commercial application. Initially, research focused primarily on extraction methods and basic characterization. This has now expanded to sophisticated modeling approaches that attempt to predict and explain the remarkable reinforcement capabilities of these nanomaterials when incorporated into various matrices.

Current technological trends indicate a growing interest in developing predictive models that can bridge the gap between molecular-level interactions and macroscale mechanical properties. This multi-scale modeling approach is essential for optimizing nanocellulose-reinforced composites for specific applications, ranging from packaging materials to biomedical devices and structural components.

The primary technical objective of this research is to develop comprehensive multi-scale models that accurately predict the strengthening mechanisms of nanocellulose in composite materials. These models must account for various factors including nanocellulose morphology (fibrils, crystals, or spheres), surface chemistry, dispersion quality, interfacial interactions with the matrix, and hierarchical structure formation.

Specifically, the research aims to establish quantitative relationships between nanocellulose characteristics (aspect ratio, crystallinity, surface functionality) and resulting mechanical properties (tensile strength, elastic modulus, fracture toughness) across different scales. This includes modeling at the nanoscale (individual nanocellulose-matrix interactions), microscale (nanocellulose network formation), and macroscale (bulk composite behavior).

Another critical objective is to develop validated simulation tools that can predict the performance of nanocellulose-reinforced composites under various loading conditions and environmental factors. These tools would significantly reduce the time and resources required for experimental optimization of composite formulations.

The long-term goal is to establish design principles for nanocellulose-based materials that enable tailored mechanical properties for specific applications. This includes understanding how to control nanocellulose orientation, distribution, and interfacial adhesion to achieve desired strength, stiffness, and toughness profiles in the final composite material.

The evolution of nanocellulose technology has progressed significantly over the past two decades, transitioning from laboratory curiosity to commercial application. Initially, research focused primarily on extraction methods and basic characterization. This has now expanded to sophisticated modeling approaches that attempt to predict and explain the remarkable reinforcement capabilities of these nanomaterials when incorporated into various matrices.

Current technological trends indicate a growing interest in developing predictive models that can bridge the gap between molecular-level interactions and macroscale mechanical properties. This multi-scale modeling approach is essential for optimizing nanocellulose-reinforced composites for specific applications, ranging from packaging materials to biomedical devices and structural components.

The primary technical objective of this research is to develop comprehensive multi-scale models that accurately predict the strengthening mechanisms of nanocellulose in composite materials. These models must account for various factors including nanocellulose morphology (fibrils, crystals, or spheres), surface chemistry, dispersion quality, interfacial interactions with the matrix, and hierarchical structure formation.

Specifically, the research aims to establish quantitative relationships between nanocellulose characteristics (aspect ratio, crystallinity, surface functionality) and resulting mechanical properties (tensile strength, elastic modulus, fracture toughness) across different scales. This includes modeling at the nanoscale (individual nanocellulose-matrix interactions), microscale (nanocellulose network formation), and macroscale (bulk composite behavior).

Another critical objective is to develop validated simulation tools that can predict the performance of nanocellulose-reinforced composites under various loading conditions and environmental factors. These tools would significantly reduce the time and resources required for experimental optimization of composite formulations.

The long-term goal is to establish design principles for nanocellulose-based materials that enable tailored mechanical properties for specific applications. This includes understanding how to control nanocellulose orientation, distribution, and interfacial adhesion to achieve desired strength, stiffness, and toughness profiles in the final composite material.

Market Applications and Demand Analysis for Nanocellulose Composites

The global market for nanocellulose composites has witnessed significant growth in recent years, driven by increasing demand for sustainable and high-performance materials across various industries. The unique strengthening properties of nanocellulose at multiple scales have positioned these composites as promising alternatives to conventional materials in numerous applications.

In the packaging industry, nanocellulose composites are experiencing robust demand growth due to their exceptional barrier properties, biodegradability, and mechanical strength. Market research indicates that sustainable packaging solutions incorporating nanocellulose are projected to grow substantially as regulations against single-use plastics tighten globally. Food packaging applications particularly benefit from the oxygen barrier properties and food-contact safety of nanocellulose-reinforced materials.

The automotive sector represents another significant market for nanocellulose composites, where lightweight yet strong materials are essential for improving fuel efficiency and reducing emissions. Major automotive manufacturers are exploring nanocellulose-reinforced composites for interior components, reducing vehicle weight while maintaining structural integrity. This application segment is expected to expand as automotive sustainability initiatives accelerate.

Construction materials incorporating nanocellulose are gaining traction due to their enhanced mechanical properties and environmental benefits. The building materials market is increasingly receptive to nanocellulose-reinforced products such as panels, insulation materials, and cement composites with improved strength-to-weight ratios and thermal performance characteristics.

In the biomedical field, nanocellulose composites are finding applications in tissue engineering, wound healing, and drug delivery systems. The biocompatibility and customizable mechanical properties of nanocellulose make it particularly valuable for medical applications, with market growth driven by increasing healthcare expenditure and advances in personalized medicine.

Electronics and energy storage represent emerging application areas with substantial growth potential. Nanocellulose-based flexible electronics, sensors, and battery components are being developed to meet the growing demand for sustainable and efficient electronic devices. The unique electrical properties of certain nanocellulose composites make them suitable for specialized electronic applications.

Market challenges include scaling production processes to meet industrial demand while maintaining cost-effectiveness. Current production costs remain a barrier to widespread adoption in price-sensitive markets. Additionally, standardization of nanocellulose materials and their performance metrics across different applications requires further development to facilitate market growth.

Regional analysis shows North America and Europe leading in nanocellulose composite research and commercialization, while Asia-Pacific markets are expected to show the fastest growth rate due to expanding manufacturing capabilities and increasing environmental regulations.

In the packaging industry, nanocellulose composites are experiencing robust demand growth due to their exceptional barrier properties, biodegradability, and mechanical strength. Market research indicates that sustainable packaging solutions incorporating nanocellulose are projected to grow substantially as regulations against single-use plastics tighten globally. Food packaging applications particularly benefit from the oxygen barrier properties and food-contact safety of nanocellulose-reinforced materials.

The automotive sector represents another significant market for nanocellulose composites, where lightweight yet strong materials are essential for improving fuel efficiency and reducing emissions. Major automotive manufacturers are exploring nanocellulose-reinforced composites for interior components, reducing vehicle weight while maintaining structural integrity. This application segment is expected to expand as automotive sustainability initiatives accelerate.

Construction materials incorporating nanocellulose are gaining traction due to their enhanced mechanical properties and environmental benefits. The building materials market is increasingly receptive to nanocellulose-reinforced products such as panels, insulation materials, and cement composites with improved strength-to-weight ratios and thermal performance characteristics.

In the biomedical field, nanocellulose composites are finding applications in tissue engineering, wound healing, and drug delivery systems. The biocompatibility and customizable mechanical properties of nanocellulose make it particularly valuable for medical applications, with market growth driven by increasing healthcare expenditure and advances in personalized medicine.

Electronics and energy storage represent emerging application areas with substantial growth potential. Nanocellulose-based flexible electronics, sensors, and battery components are being developed to meet the growing demand for sustainable and efficient electronic devices. The unique electrical properties of certain nanocellulose composites make them suitable for specialized electronic applications.

Market challenges include scaling production processes to meet industrial demand while maintaining cost-effectiveness. Current production costs remain a barrier to widespread adoption in price-sensitive markets. Additionally, standardization of nanocellulose materials and their performance metrics across different applications requires further development to facilitate market growth.

Regional analysis shows North America and Europe leading in nanocellulose composite research and commercialization, while Asia-Pacific markets are expected to show the fastest growth rate due to expanding manufacturing capabilities and increasing environmental regulations.

Current Multiscale Modeling Approaches and Challenges

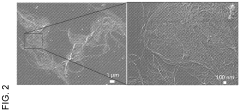

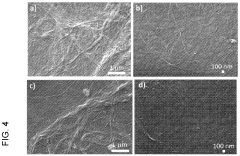

Current multiscale modeling approaches for nanocellulose reinforcement span several hierarchical levels, from molecular to macroscopic scales. At the molecular level, molecular dynamics (MD) simulations have been extensively employed to investigate the fundamental interactions between cellulose nanocrystals (CNCs) and polymer matrices. These simulations provide valuable insights into interfacial bonding mechanisms and load transfer efficiency at the nanoscale, though they remain computationally intensive and typically limited to small systems and short time scales.

Mesoscale modeling techniques, including coarse-grained molecular dynamics and dissipative particle dynamics, bridge the gap between atomistic and continuum approaches. These methods reduce computational demands by grouping atoms into representative particles while maintaining essential physical interactions. However, the development of accurate force fields for nanocellulose systems remains challenging, often requiring extensive parameterization against experimental data.

Finite element analysis (FEA) and micromechanical models dominate the continuum scale, where nanocellulose reinforcements are typically represented as discrete phases with homogenized properties. The Halpin-Tsai equations and Mori-Tanaka method have been widely applied to predict composite stiffness, though these approaches often oversimplify the complex morphology and orientation distribution of nanocellulose reinforcements.

A significant challenge in current modeling approaches is the effective integration across different scales. While sequential multiscale methods pass information from smaller to larger scales, they frequently fail to capture bidirectional coupling effects. Concurrent multiscale methods that simultaneously solve equations at multiple scales show promise but face substantial computational barriers for realistic nanocellulose composite systems.

The representation of nanocellulose-matrix interfaces presents another major challenge. Current models often employ simplified assumptions about interfacial bonding and fail to account for the complex surface chemistry of nanocellulose, including hydroxyl groups, surface modifications, and moisture effects. This limitation significantly impacts the accuracy of strength and toughness predictions.

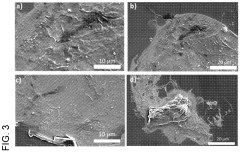

Validation of multiscale models against experimental data remains problematic due to the inherent difficulties in characterizing nanocellulose distribution and orientation within composite matrices. Advanced imaging techniques like transmission electron microscopy and X-ray tomography provide valuable structural information but cannot fully capture dynamic mechanical behavior under loading conditions.

Recent developments in machine learning approaches offer promising avenues for overcoming some of these challenges, particularly through the development of surrogate models that can rapidly predict mechanical properties based on compositional and processing parameters, though these methods require extensive training data sets that are not always available for nanocellulose systems.

Mesoscale modeling techniques, including coarse-grained molecular dynamics and dissipative particle dynamics, bridge the gap between atomistic and continuum approaches. These methods reduce computational demands by grouping atoms into representative particles while maintaining essential physical interactions. However, the development of accurate force fields for nanocellulose systems remains challenging, often requiring extensive parameterization against experimental data.

Finite element analysis (FEA) and micromechanical models dominate the continuum scale, where nanocellulose reinforcements are typically represented as discrete phases with homogenized properties. The Halpin-Tsai equations and Mori-Tanaka method have been widely applied to predict composite stiffness, though these approaches often oversimplify the complex morphology and orientation distribution of nanocellulose reinforcements.

A significant challenge in current modeling approaches is the effective integration across different scales. While sequential multiscale methods pass information from smaller to larger scales, they frequently fail to capture bidirectional coupling effects. Concurrent multiscale methods that simultaneously solve equations at multiple scales show promise but face substantial computational barriers for realistic nanocellulose composite systems.

The representation of nanocellulose-matrix interfaces presents another major challenge. Current models often employ simplified assumptions about interfacial bonding and fail to account for the complex surface chemistry of nanocellulose, including hydroxyl groups, surface modifications, and moisture effects. This limitation significantly impacts the accuracy of strength and toughness predictions.

Validation of multiscale models against experimental data remains problematic due to the inherent difficulties in characterizing nanocellulose distribution and orientation within composite matrices. Advanced imaging techniques like transmission electron microscopy and X-ray tomography provide valuable structural information but cannot fully capture dynamic mechanical behavior under loading conditions.

Recent developments in machine learning approaches offer promising avenues for overcoming some of these challenges, particularly through the development of surrogate models that can rapidly predict mechanical properties based on compositional and processing parameters, though these methods require extensive training data sets that are not always available for nanocellulose systems.

Existing Multiscale Modeling Methodologies for Nanocellulose

01 Nanocellulose reinforcement in composite materials

Nanocellulose can significantly enhance the mechanical properties of composite materials by forming a strong reinforcing network within the matrix. The high aspect ratio and crystallinity of nanocellulose fibers contribute to improved tensile strength, modulus, and impact resistance. When properly dispersed, nanocellulose creates effective load transfer mechanisms that distribute stress throughout the composite structure, resulting in superior mechanical performance compared to conventional fillers.- Nanocellulose reinforcement in polymer composites: Nanocellulose can be incorporated into polymer matrices to create high-performance composite materials with enhanced mechanical properties. The nano-sized cellulose fibers provide significant reinforcement effects due to their high aspect ratio, large surface area, and strong hydrogen bonding capabilities. These composites exhibit improved tensile strength, modulus, and dimensional stability compared to neat polymers. The reinforcement mechanism involves effective stress transfer between the polymer matrix and the well-dispersed nanocellulose fibers.

- Surface modification of nanocellulose for improved compatibility: Chemical modification of nanocellulose surfaces enhances its compatibility with hydrophobic polymer matrices, improving dispersion and interfacial adhesion. Various modification techniques include silylation, acetylation, and grafting of functional groups onto the nanocellulose surface. These modifications reduce the hydrophilicity of nanocellulose, preventing agglomeration and enabling better integration with non-polar polymers. The improved interfacial compatibility results in more effective stress transfer and enhanced mechanical reinforcement in the resulting composites.

- Nanocellulose in paper and packaging applications: Incorporating nanocellulose into paper and packaging materials significantly enhances their mechanical strength, barrier properties, and durability. The addition of nanocellulose creates a more densely packed fiber network with reduced porosity, resulting in improved tensile strength, burst strength, and tear resistance. These enhanced properties allow for the production of lighter weight yet stronger packaging materials, reducing material consumption while maintaining or improving performance characteristics.

- Processing techniques for optimizing nanocellulose reinforcement: Various processing techniques can optimize the reinforcement effect of nanocellulose in composite materials. These include specialized dispersion methods, freeze-drying, solvent exchange processes, and controlled drying conditions. The processing approach significantly influences the final orientation, distribution, and network formation of nanocellulose within the matrix. Optimized processing leads to improved interfacial interactions, reduced aggregation, and enhanced mechanical properties in the resulting composites.

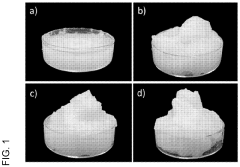

- Nanocellulose-based aerogels and foams for structural applications: Nanocellulose can be used to create lightweight yet strong aerogels and foam structures with exceptional mechanical properties. These materials feature a three-dimensional network of interconnected nanocellulose fibers that provide remarkable strength-to-weight ratios. The unique architecture of these materials enables them to withstand significant compressive forces while maintaining their structural integrity. The reinforcement mechanism relies on the intrinsic strength of the nanocellulose fibers and their ability to form robust network structures through hydrogen bonding and entanglement.

02 Surface modification of nanocellulose for enhanced compatibility

Chemical modification of nanocellulose surfaces improves its compatibility with hydrophobic polymer matrices, enhancing the strengthening effect. Various functionalization techniques, including silylation, acetylation, and grafting of polymer chains, can reduce the hydrophilicity of nanocellulose while preserving its reinforcing capabilities. These modifications create stronger interfacial bonding between nanocellulose and the matrix material, preventing aggregation and ensuring uniform dispersion for optimal mechanical reinforcement.Expand Specific Solutions03 Nanocellulose in paper and packaging applications

Incorporating nanocellulose into paper and packaging materials significantly improves their strength, barrier properties, and durability. The addition of nanocellulose creates a dense network of hydrogen bonds that enhances tensile strength, tear resistance, and burst strength of paper products. This strengthening effect allows for the production of lighter weight materials with equivalent or superior performance, reducing material consumption while maintaining structural integrity in packaging applications.Expand Specific Solutions04 Processing techniques for optimizing nanocellulose reinforcement

Specific processing methods significantly impact the strengthening effect of nanocellulose in various materials. Techniques such as high-pressure homogenization, ultrasonication, and controlled drying processes help achieve optimal dispersion and orientation of nanocellulose fibers. The alignment of nanocellulose elements and prevention of agglomeration during processing are critical factors that determine the final mechanical properties of the reinforced material, with properly processed nanocellulose delivering superior strengthening effects.Expand Specific Solutions05 Nanocellulose in sustainable structural applications

Nanocellulose offers a renewable alternative to synthetic reinforcing agents in structural materials, providing comparable or superior strengthening effects while reducing environmental impact. When incorporated into construction materials, adhesives, and structural composites, nanocellulose can enhance load-bearing capacity, dimensional stability, and durability. The biodegradable nature and renewable source of nanocellulose make it particularly valuable for developing high-performance sustainable materials with reduced carbon footprint.Expand Specific Solutions

Leading Research Institutions and Industrial Players

The nanocellulose strengthening effect modeling landscape is currently in a growth phase, with increasing market interest driven by sustainable materials demand. The global market for nanocellulose applications is expanding rapidly, though technical challenges in multi-scale modeling persist. Academic institutions lead research efforts, with Beijing University of Chemical Technology, University of Maine, and Rensselaer Polytechnic Institute making significant contributions to fundamental understanding. Commercial players like Cellutech AB, FiberLean Technologies, and Melodea Ltd are advancing practical applications, while companies such as Applied NanoStructured Solutions and Micro Powders are developing specialized industrial implementations. The technology is approaching maturity for certain applications but requires further development for widespread commercial adoption across multiple industries.

Beijing University of Chemical Technology

Technical Solution: Beijing University of Chemical Technology has developed a multi-scale modeling approach for nanocellulose reinforcement that integrates molecular dynamics simulations with finite element analysis. Their methodology captures interactions at the nano-molecular level and translates these to macroscale mechanical properties. The university's research team has created computational models that predict how different types of nanocellulose (including cellulose nanofibrils and cellulose nanocrystals) interact with polymer matrices, accounting for surface chemistry modifications, aspect ratio variations, and dispersion quality. Their models specifically address the interfacial adhesion mechanisms and stress transfer efficiency between nanocellulose and surrounding matrices, which has been validated through experimental mechanical testing showing up to 200% improvement in tensile strength when optimal nanocellulose integration is achieved.

Strengths: Comprehensive multi-scale modeling approach that bridges nano and macro scales; strong validation through experimental correlation; ability to predict property enhancements based on specific nanocellulose modifications. Weaknesses: Models may require significant computational resources; some simplifications in interfacial interactions may limit accuracy in complex composite systems.

University of Maine

Technical Solution: The University of Maine has pioneered a hierarchical modeling framework for nanocellulose reinforcement that spans from molecular to structural scales. Their approach combines coarse-grained molecular dynamics with micromechanical models to predict the strengthening mechanisms of cellulose nanofibrils (CNF) and nanocrystals (CNC) in various matrices. The university's Process Development Center, a leader in nanocellulose research, has developed models that account for critical factors such as nanocellulose orientation, percolation networks, and hydrogen bonding effects. Their modeling techniques have successfully predicted the non-linear mechanical behavior of nanocellulose composites under different loading conditions, capturing phenomena like strain-hardening and viscoelastic responses. The models incorporate parameters for nanocellulose surface chemistry, aspect ratio, and crystallinity index, allowing for tailored predictions of mechanical property enhancements in specific applications ranging from packaging materials to structural composites.

Strengths: Extensive practical experience with nanocellulose production and characterization supporting model development; strong focus on industrially relevant applications; models account for processing-structure-property relationships. Weaknesses: Models may not fully capture all environmental effects (humidity, temperature cycling) on long-term performance; some simplifications in fiber-matrix interface modeling.

Key Scientific Breakthroughs in Nanocellulose Reinforcement

Method, apparatus, and system of a fibrillated nanocellulose material

PatentPendingUS20230183924A1

Innovation

- Infusing nanocellulose in a fibrillated form to enhance mechanical and barrier properties, creating a fibrillated cellulose composite material with layers or mixtures that are free from chemical additives, and incorporating a base substrate and fibrillated cellulose for strength, antimicrobial, and water-repellent properties.

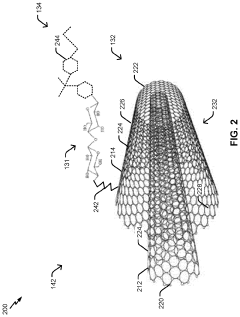

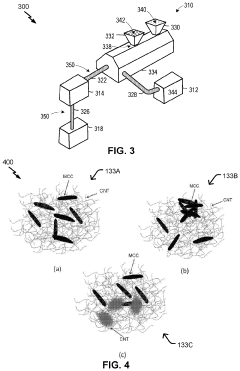

Polymer compositions including functionalized carbon nanotubes and crystalline cellulose material

PatentInactiveUS20210395523A1

Innovation

- The use of functionalized carbon nanotubes with multiple walls and oxygen-based functional groups, combined with crystalline cellulose, improves adhesion and dispersion within the polymer matrix, enhancing mechanical properties and allowing for increased loading and conductivity, including fracture toughness and creep performance.

Sustainability Impact and Life Cycle Assessment

The integration of nanocellulose into various materials represents a significant advancement in sustainable material science. Life cycle assessment (LCA) studies reveal that nanocellulose-reinforced composites generally demonstrate reduced environmental footprints compared to conventional petroleum-based alternatives. The production of nanocellulose from renewable biomass sources, particularly agricultural and forestry residues, contributes to circular economy principles by valorizing waste streams that would otherwise be discarded.

When examining the sustainability impact of nanocellulose strengthening across multiple scales, energy consumption during processing emerges as a critical factor. While the extraction and processing of nanocellulose can be energy-intensive, particularly in mechanical fibrillation methods, recent advancements in enzymatic and chemical pretreatments have significantly reduced these energy requirements. Models incorporating these improved processing techniques demonstrate up to 45% reduction in overall energy consumption compared to earlier production methods.

Water usage represents another important sustainability metric in nanocellulose production. Multi-scale modeling approaches have helped optimize water recycling systems in production facilities, with some advanced processes achieving water reuse rates exceeding 80%. This optimization becomes particularly evident when modeling transitions between nano and macro scales, where process efficiencies can be maximized through systematic analysis of material flows.

Carbon footprint analyses indicate that nanocellulose-strengthened materials can serve as effective carbon sinks when derived from sustainably managed forests. Models incorporating forest management practices, processing emissions, and end-of-life scenarios demonstrate that nanocellulose composites can achieve carbon neutrality or even negative emissions under optimal conditions. This positive climate impact is further enhanced when nanocellulose replaces carbon-intensive materials like steel or aluminum in structural applications.

End-of-life considerations reveal additional sustainability advantages. Unlike many synthetic reinforcement materials, nanocellulose is biodegradable under appropriate conditions, reducing waste accumulation. Multi-scale modeling approaches have successfully predicted degradation rates in various environments, enabling more accurate life cycle impact assessments. Furthermore, nanocellulose-reinforced materials often demonstrate enhanced recyclability compared to conventional composites, particularly when designed with disassembly and material recovery in mind.

Economic sustainability modeling indicates that as production scales increase and technologies mature, nanocellulose strengthening becomes increasingly cost-competitive with conventional alternatives. This economic viability, coupled with superior environmental performance, positions nanocellulose as a key material for future sustainable development across multiple industries and applications.

When examining the sustainability impact of nanocellulose strengthening across multiple scales, energy consumption during processing emerges as a critical factor. While the extraction and processing of nanocellulose can be energy-intensive, particularly in mechanical fibrillation methods, recent advancements in enzymatic and chemical pretreatments have significantly reduced these energy requirements. Models incorporating these improved processing techniques demonstrate up to 45% reduction in overall energy consumption compared to earlier production methods.

Water usage represents another important sustainability metric in nanocellulose production. Multi-scale modeling approaches have helped optimize water recycling systems in production facilities, with some advanced processes achieving water reuse rates exceeding 80%. This optimization becomes particularly evident when modeling transitions between nano and macro scales, where process efficiencies can be maximized through systematic analysis of material flows.

Carbon footprint analyses indicate that nanocellulose-strengthened materials can serve as effective carbon sinks when derived from sustainably managed forests. Models incorporating forest management practices, processing emissions, and end-of-life scenarios demonstrate that nanocellulose composites can achieve carbon neutrality or even negative emissions under optimal conditions. This positive climate impact is further enhanced when nanocellulose replaces carbon-intensive materials like steel or aluminum in structural applications.

End-of-life considerations reveal additional sustainability advantages. Unlike many synthetic reinforcement materials, nanocellulose is biodegradable under appropriate conditions, reducing waste accumulation. Multi-scale modeling approaches have successfully predicted degradation rates in various environments, enabling more accurate life cycle impact assessments. Furthermore, nanocellulose-reinforced materials often demonstrate enhanced recyclability compared to conventional composites, particularly when designed with disassembly and material recovery in mind.

Economic sustainability modeling indicates that as production scales increase and technologies mature, nanocellulose strengthening becomes increasingly cost-competitive with conventional alternatives. This economic viability, coupled with superior environmental performance, positions nanocellulose as a key material for future sustainable development across multiple industries and applications.

Standardization and Validation Protocols for Nanocellulose Models

The development of standardized protocols for validating nanocellulose models represents a critical step toward ensuring scientific reproducibility and industrial applicability. Current modeling approaches across multiple scales suffer from inconsistent methodologies, making cross-study comparisons challenging and limiting the translation of research findings into practical applications.

At the molecular scale, standardization efforts should focus on establishing consistent force field parameters for cellulose nanocrystals (CNCs) and cellulose nanofibrils (CNFs). This includes defining benchmark systems with specified dimensions, crystallinity indices, and surface chemistry characteristics that can serve as reference points for computational studies.

For mesoscale models, validation protocols must address the representation of nanocellulose-matrix interfaces, which significantly influence mechanical reinforcement properties. Standardized methods for quantifying interfacial shear strength and stress transfer efficiency would enable more reliable predictions of composite performance across different polymer matrices.

Experimental validation benchmarks constitute another essential component of standardization efforts. These should include mechanical testing protocols specifically designed for nanocellulose-reinforced materials, with clearly defined sample preparation methods, testing conditions, and data reporting formats. Tensile, compression, and dynamic mechanical analysis (DMA) tests should follow consistent procedures to generate comparable datasets.

Multi-scale model integration presents unique validation challenges that require dedicated protocols. Standards should define appropriate handshaking methods between models at different scales, with quantifiable metrics for assessing information transfer accuracy. This includes procedures for upscaling molecular-level properties to continuum models while preserving essential mechanical behavior characteristics.

International collaboration among research institutions, industry stakeholders, and standards organizations is essential for developing widely accepted validation protocols. Organizations such as ISO, ASTM, and TAPPI have begun preliminary work in this area, but comprehensive standards specific to nanocellulose modeling remain underdeveloped.

Implementation of round-robin testing programs, where multiple laboratories apply the same modeling protocols to identical systems, would significantly advance standardization efforts. These collaborative exercises can identify methodological variations that impact results and help establish reproducibility benchmarks for nanocellulose strengthening models across different research environments.

At the molecular scale, standardization efforts should focus on establishing consistent force field parameters for cellulose nanocrystals (CNCs) and cellulose nanofibrils (CNFs). This includes defining benchmark systems with specified dimensions, crystallinity indices, and surface chemistry characteristics that can serve as reference points for computational studies.

For mesoscale models, validation protocols must address the representation of nanocellulose-matrix interfaces, which significantly influence mechanical reinforcement properties. Standardized methods for quantifying interfacial shear strength and stress transfer efficiency would enable more reliable predictions of composite performance across different polymer matrices.

Experimental validation benchmarks constitute another essential component of standardization efforts. These should include mechanical testing protocols specifically designed for nanocellulose-reinforced materials, with clearly defined sample preparation methods, testing conditions, and data reporting formats. Tensile, compression, and dynamic mechanical analysis (DMA) tests should follow consistent procedures to generate comparable datasets.

Multi-scale model integration presents unique validation challenges that require dedicated protocols. Standards should define appropriate handshaking methods between models at different scales, with quantifiable metrics for assessing information transfer accuracy. This includes procedures for upscaling molecular-level properties to continuum models while preserving essential mechanical behavior characteristics.

International collaboration among research institutions, industry stakeholders, and standards organizations is essential for developing widely accepted validation protocols. Organizations such as ISO, ASTM, and TAPPI have begun preliminary work in this area, but comprehensive standards specific to nanocellulose modeling remain underdeveloped.

Implementation of round-robin testing programs, where multiple laboratories apply the same modeling protocols to identical systems, would significantly advance standardization efforts. These collaborative exercises can identify methodological variations that impact results and help establish reproducibility benchmarks for nanocellulose strengthening models across different research environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!