Neoprene's Advances in Footwear Cushioning Technology

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neoprene Cushioning Evolution and Objectives

Neoprene, a synthetic rubber developed by DuPont in 1930, has played a significant role in the evolution of footwear cushioning technology. Initially used in wetsuits and industrial applications, neoprene's unique properties of flexibility, durability, and shock absorption soon caught the attention of footwear manufacturers.

The journey of neoprene in footwear cushioning began in the 1960s when athletic shoe companies started experimenting with various materials to enhance comfort and performance. Neoprene's ability to provide both cushioning and support made it an attractive option for shoe insoles and midsoles.

Throughout the 1970s and 1980s, advancements in neoprene formulation and manufacturing processes led to improved shock absorption and energy return properties. This period saw the introduction of neoprene-based cushioning systems in running shoes, which helped reduce impact forces and improve overall comfort for athletes.

The 1990s marked a significant milestone in neoprene cushioning technology with the development of compression-molded neoprene. This innovation allowed for more precise control over the material's density and shape, enabling shoe designers to create targeted cushioning zones within the footwear.

In the early 2000s, the focus shifted towards sustainability and eco-friendly materials. Manufacturers began exploring ways to produce neoprene from renewable sources and improve its recyclability. This led to the development of bio-based neoprene alternatives, which aimed to maintain the material's performance characteristics while reducing its environmental impact.

Recent years have seen a surge in research and development efforts to enhance neoprene's cushioning properties further. The integration of neoprene with other advanced materials, such as foam composites and gel inserts, has resulted in hybrid cushioning systems that offer superior shock absorption and energy return.

The primary objectives of neoprene cushioning technology in footwear have evolved to address several key areas. These include improving impact protection to reduce the risk of injuries, enhancing energy return for better athletic performance, and developing lightweight solutions that do not compromise on durability or support.

Another crucial goal is to create adaptive cushioning systems that can respond to different types of movements and surfaces. This involves developing neoprene formulations that can adjust their properties based on the intensity of impact or the specific needs of various sporting activities.

As we look to the future, the objectives for neoprene cushioning technology in footwear continue to expand. Researchers are exploring ways to incorporate smart materials and sensors into neoprene-based cushioning systems, aiming to create intelligent footwear that can provide real-time feedback and adjust its properties on the fly.

The journey of neoprene in footwear cushioning began in the 1960s when athletic shoe companies started experimenting with various materials to enhance comfort and performance. Neoprene's ability to provide both cushioning and support made it an attractive option for shoe insoles and midsoles.

Throughout the 1970s and 1980s, advancements in neoprene formulation and manufacturing processes led to improved shock absorption and energy return properties. This period saw the introduction of neoprene-based cushioning systems in running shoes, which helped reduce impact forces and improve overall comfort for athletes.

The 1990s marked a significant milestone in neoprene cushioning technology with the development of compression-molded neoprene. This innovation allowed for more precise control over the material's density and shape, enabling shoe designers to create targeted cushioning zones within the footwear.

In the early 2000s, the focus shifted towards sustainability and eco-friendly materials. Manufacturers began exploring ways to produce neoprene from renewable sources and improve its recyclability. This led to the development of bio-based neoprene alternatives, which aimed to maintain the material's performance characteristics while reducing its environmental impact.

Recent years have seen a surge in research and development efforts to enhance neoprene's cushioning properties further. The integration of neoprene with other advanced materials, such as foam composites and gel inserts, has resulted in hybrid cushioning systems that offer superior shock absorption and energy return.

The primary objectives of neoprene cushioning technology in footwear have evolved to address several key areas. These include improving impact protection to reduce the risk of injuries, enhancing energy return for better athletic performance, and developing lightweight solutions that do not compromise on durability or support.

Another crucial goal is to create adaptive cushioning systems that can respond to different types of movements and surfaces. This involves developing neoprene formulations that can adjust their properties based on the intensity of impact or the specific needs of various sporting activities.

As we look to the future, the objectives for neoprene cushioning technology in footwear continue to expand. Researchers are exploring ways to incorporate smart materials and sensors into neoprene-based cushioning systems, aiming to create intelligent footwear that can provide real-time feedback and adjust its properties on the fly.

Footwear Market Demand Analysis

The global footwear market has experienced significant growth in recent years, driven by increasing consumer demand for comfortable, stylish, and performance-enhancing shoes. Within this market, the demand for advanced cushioning technologies, particularly those utilizing neoprene, has shown a notable upward trend. Consumers are increasingly seeking footwear that provides superior comfort, shock absorption, and support for various activities, from everyday wear to high-intensity sports.

The athletic footwear segment, which heavily relies on cushioning technologies, has been a key driver of market growth. As more people engage in fitness activities and adopt active lifestyles, the demand for shoes with enhanced cushioning properties has surged. This trend is particularly evident in running shoes, where neoprene-based cushioning systems have gained popularity due to their ability to provide excellent energy return and impact protection.

In the casual footwear sector, there's a growing preference for shoes that combine style with comfort. Consumers are willing to pay premium prices for shoes that incorporate advanced cushioning technologies, including those based on neoprene. This shift in consumer behavior has prompted many footwear brands to invest in research and development of innovative cushioning solutions.

The aging population in many developed countries has also contributed to the increased demand for footwear with superior cushioning. Older consumers often require shoes that offer better support and shock absorption to alleviate joint pain and improve overall comfort. This demographic trend has opened up new opportunities for neoprene-based cushioning technologies in the orthopedic and comfort footwear segments.

Environmental concerns and sustainability have become important factors influencing consumer choices in the footwear market. Neoprene, being a synthetic rubber, has faced some scrutiny regarding its environmental impact. However, advancements in eco-friendly neoprene alternatives and recycling processes have helped address these concerns, potentially expanding the market for neoprene-based cushioning technologies among environmentally conscious consumers.

The COVID-19 pandemic has accelerated certain market trends, particularly the demand for comfortable footwear suitable for home and casual wear. As remote work became more prevalent, consumers sought shoes that offer all-day comfort, creating new opportunities for cushioning technologies in the home and leisure footwear categories.

Looking ahead, the footwear market is expected to continue its growth trajectory, with cushioning technologies playing a crucial role in product differentiation and consumer appeal. The integration of smart technologies with cushioning systems, such as adaptive cushioning that responds to individual gait patterns, represents an emerging trend that could further drive market demand for advanced neoprene-based solutions in the footwear industry.

The athletic footwear segment, which heavily relies on cushioning technologies, has been a key driver of market growth. As more people engage in fitness activities and adopt active lifestyles, the demand for shoes with enhanced cushioning properties has surged. This trend is particularly evident in running shoes, where neoprene-based cushioning systems have gained popularity due to their ability to provide excellent energy return and impact protection.

In the casual footwear sector, there's a growing preference for shoes that combine style with comfort. Consumers are willing to pay premium prices for shoes that incorporate advanced cushioning technologies, including those based on neoprene. This shift in consumer behavior has prompted many footwear brands to invest in research and development of innovative cushioning solutions.

The aging population in many developed countries has also contributed to the increased demand for footwear with superior cushioning. Older consumers often require shoes that offer better support and shock absorption to alleviate joint pain and improve overall comfort. This demographic trend has opened up new opportunities for neoprene-based cushioning technologies in the orthopedic and comfort footwear segments.

Environmental concerns and sustainability have become important factors influencing consumer choices in the footwear market. Neoprene, being a synthetic rubber, has faced some scrutiny regarding its environmental impact. However, advancements in eco-friendly neoprene alternatives and recycling processes have helped address these concerns, potentially expanding the market for neoprene-based cushioning technologies among environmentally conscious consumers.

The COVID-19 pandemic has accelerated certain market trends, particularly the demand for comfortable footwear suitable for home and casual wear. As remote work became more prevalent, consumers sought shoes that offer all-day comfort, creating new opportunities for cushioning technologies in the home and leisure footwear categories.

Looking ahead, the footwear market is expected to continue its growth trajectory, with cushioning technologies playing a crucial role in product differentiation and consumer appeal. The integration of smart technologies with cushioning systems, such as adaptive cushioning that responds to individual gait patterns, represents an emerging trend that could further drive market demand for advanced neoprene-based solutions in the footwear industry.

Neoprene Tech Status and Challenges

Neoprene, a synthetic rubber developed by DuPont in the 1930s, has made significant strides in footwear cushioning technology. Currently, the material is widely used in various athletic and casual footwear applications due to its excellent shock absorption, durability, and flexibility properties. However, the technology faces several challenges that limit its widespread adoption and effectiveness in high-performance footwear.

One of the primary technical challenges is achieving an optimal balance between cushioning and energy return. While neoprene provides excellent shock absorption, it tends to have lower energy return compared to newer foam technologies like EVA or polyurethane. This limitation affects its performance in athletic footwear where both cushioning and responsiveness are crucial.

Another significant challenge is weight reduction. Despite its many positive attributes, neoprene is relatively heavy compared to modern foam materials. This weight issue becomes particularly problematic in performance athletic shoes where every gram matters. Manufacturers are actively seeking ways to reduce the density of neoprene without compromising its cushioning properties.

Durability under extreme conditions remains an area of concern. While neoprene performs well in most environments, it can degrade faster than some competing materials when exposed to high heat, UV radiation, or certain chemicals. This limits its application in specialized footwear designed for extreme sports or harsh working conditions.

The manufacturing process of neoprene cushioning systems also presents challenges. The material requires specific molding techniques and can be more complex to integrate into advanced shoe designs compared to injection-molded foams. This complexity can lead to higher production costs and potential quality control issues.

From a geographical perspective, the development and production of advanced neoprene cushioning technologies are primarily concentrated in Asia, particularly in countries like China, Japan, and South Korea. However, research initiatives are also ongoing in North America and Europe, focusing on enhancing neoprene's properties and exploring hybrid materials.

Environmental concerns pose another significant challenge. As sustainability becomes increasingly important in the footwear industry, the non-biodegradable nature of neoprene is a drawback. Researchers are exploring eco-friendly alternatives and recycling methods, but progress in this area has been limited.

Despite these challenges, ongoing research and development efforts are focused on addressing these limitations. Innovations in neoprene compounding, structural design, and manufacturing processes are gradually improving its performance in footwear applications. The industry is also exploring ways to combine neoprene with other materials to create hybrid cushioning systems that leverage the strengths of multiple technologies.

One of the primary technical challenges is achieving an optimal balance between cushioning and energy return. While neoprene provides excellent shock absorption, it tends to have lower energy return compared to newer foam technologies like EVA or polyurethane. This limitation affects its performance in athletic footwear where both cushioning and responsiveness are crucial.

Another significant challenge is weight reduction. Despite its many positive attributes, neoprene is relatively heavy compared to modern foam materials. This weight issue becomes particularly problematic in performance athletic shoes where every gram matters. Manufacturers are actively seeking ways to reduce the density of neoprene without compromising its cushioning properties.

Durability under extreme conditions remains an area of concern. While neoprene performs well in most environments, it can degrade faster than some competing materials when exposed to high heat, UV radiation, or certain chemicals. This limits its application in specialized footwear designed for extreme sports or harsh working conditions.

The manufacturing process of neoprene cushioning systems also presents challenges. The material requires specific molding techniques and can be more complex to integrate into advanced shoe designs compared to injection-molded foams. This complexity can lead to higher production costs and potential quality control issues.

From a geographical perspective, the development and production of advanced neoprene cushioning technologies are primarily concentrated in Asia, particularly in countries like China, Japan, and South Korea. However, research initiatives are also ongoing in North America and Europe, focusing on enhancing neoprene's properties and exploring hybrid materials.

Environmental concerns pose another significant challenge. As sustainability becomes increasingly important in the footwear industry, the non-biodegradable nature of neoprene is a drawback. Researchers are exploring eco-friendly alternatives and recycling methods, but progress in this area has been limited.

Despite these challenges, ongoing research and development efforts are focused on addressing these limitations. Innovations in neoprene compounding, structural design, and manufacturing processes are gradually improving its performance in footwear applications. The industry is also exploring ways to combine neoprene with other materials to create hybrid cushioning systems that leverage the strengths of multiple technologies.

Current Neoprene Cushioning Solutions

01 Composition of neoprene cushioning materials

Neoprene cushioning materials are typically composed of polychloroprene foam or rubber. These materials can be formulated with various additives to enhance their properties, such as improved durability, flexibility, and shock absorption. The composition may include other polymers, fillers, and chemical agents to achieve desired characteristics for specific applications.- Composition of neoprene cushioning materials: Neoprene cushioning materials are typically composed of polychloroprene rubber and other additives. These materials can be formulated to have specific properties such as density, hardness, and resilience. The composition may include foaming agents, fillers, and other chemicals to enhance performance and durability.

- Manufacturing processes for neoprene cushioning: Various manufacturing processes are employed to produce neoprene cushioning, including molding, extrusion, and lamination techniques. These processes can involve the use of heat and pressure to shape the material and create specific textures or patterns. Some methods focus on creating closed-cell foam structures for improved cushioning properties.

- Applications of neoprene cushioning in products: Neoprene cushioning finds applications in a wide range of products, including sports equipment, protective gear, automotive components, and medical devices. It is used in items such as wetsuits, orthopedic supports, shoe insoles, and vibration dampeners due to its shock-absorbing and insulating properties.

- Enhancements to neoprene cushioning properties: Researchers and manufacturers have developed various methods to enhance the properties of neoprene cushioning. These improvements may include increasing durability, enhancing moisture-wicking capabilities, improving heat resistance, and optimizing compression set characteristics. Some techniques involve blending neoprene with other materials or applying surface treatments.

- Testing and quality control of neoprene cushioning: To ensure the performance and reliability of neoprene cushioning, various testing and quality control methods are employed. These may include compression testing, durability assessments, chemical analysis, and environmental stress testing. Standardized procedures and equipment are used to evaluate properties such as resilience, tear strength, and aging characteristics.

02 Manufacturing processes for neoprene cushioning

The production of neoprene cushioning involves various manufacturing processes, including foaming, molding, and curing. These processes can be optimized to control the density, cell structure, and overall performance of the cushioning material. Advanced techniques may be employed to create specialized neoprene cushioning products with specific properties tailored to different applications.Expand Specific Solutions03 Applications of neoprene cushioning in various industries

Neoprene cushioning finds applications in diverse industries, including sports equipment, automotive, marine, and construction. It is used in products such as wetsuits, orthopedic supports, vibration dampeners, and insulation materials. The versatility of neoprene cushioning allows it to be adapted for specific requirements in different sectors, providing comfort, protection, and performance benefits.Expand Specific Solutions04 Enhancements and modifications to neoprene cushioning

Researchers and manufacturers continue to develop enhancements and modifications to neoprene cushioning materials. These improvements may include incorporating additional layers, reinforcing structures, or surface treatments to enhance durability, comfort, or specific performance characteristics. Advanced formulations and processing techniques are explored to create neoprene cushioning with superior properties for specialized applications.Expand Specific Solutions05 Testing and quality control of neoprene cushioning

Ensuring the quality and performance of neoprene cushioning involves various testing and quality control measures. These may include tests for compression set, tensile strength, elongation, and durability. Specialized equipment and methodologies are employed to evaluate the cushioning properties, thermal insulation, and other relevant characteristics of neoprene materials to meet industry standards and specific application requirements.Expand Specific Solutions

Key Players in Neoprene Footwear

The competitive landscape for neoprene's advances in footwear cushioning technology is characterized by a mature market with established players and ongoing innovation. The industry is in a growth phase, driven by increasing demand for comfortable and performance-enhancing footwear. Major companies like Nike, Reebok, and Adidas are at the forefront of this technology, investing heavily in research and development. The market size is substantial, with global athletic footwear sales reaching billions annually. Technological maturity varies, with some companies like Nike and Reebok leading in patent filings and product innovations, while others focus on specific niche applications or materials improvements. Smaller players like Base Protection and Implus Footcare are also contributing to advancements, indicating a diverse and competitive field.

Reebok International Ltd.

Technical Solution: Reebok has innovated in Neoprene-based cushioning with their Floatride Energy Foam technology. This advanced cushioning system utilizes a Neoprene-infused thermoplastic elastomer (TPE) to create a foam that's 50% lighter than traditional EVA foams[4]. The Floatride Energy Foam provides superior energy return, enhancing the wearer's performance. Reebok has also developed a Neoprene-based collar design for their shoes, offering improved comfort and fit around the ankle[5]. Additionally, their ZigTech sole technology incorporates Neoprene elements to create a unique energy-returning zigzag shape, designed to reduce heel strike impact and return energy to the forefoot[6].

Strengths: Exceptional energy return; significantly lighter than traditional foams; innovative design for impact reduction. Weaknesses: May be more expensive to produce; could be less durable in certain conditions.

NIKE, Inc.

Technical Solution: NIKE has developed advanced Neoprene-based cushioning technologies for footwear, including their patented Lunarlon foam. This technology combines soft and firm foam for a unique responsive cushioning system. The Neoprene-infused Lunarlon is 30% lighter than traditional Phylon, providing enhanced comfort and impact protection[1]. NIKE has also integrated Neoprene into their Flyknit technology, creating a more adaptive and supportive fit around the foot[2]. Their Air Zoom units, which often incorporate Neoprene elements, deliver responsive cushioning that springs back fast, helping to reduce injury risk and enhance performance[3].

Strengths: Lightweight, responsive cushioning; excellent impact protection; versatile application across various shoe types. Weaknesses: Potentially higher production costs; may require specialized manufacturing processes.

Innovative Neoprene Cushioning Patents

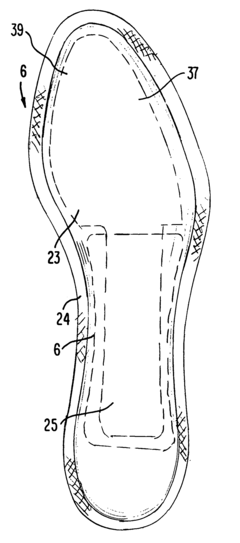

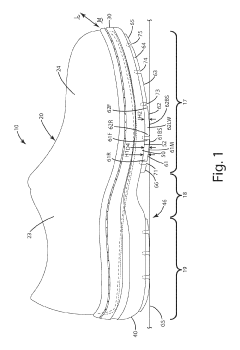

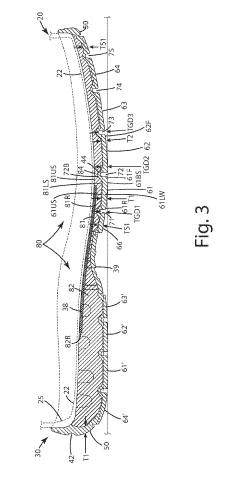

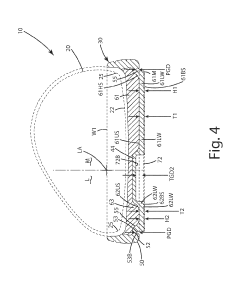

Footwear with enhanced cushioning

PatentInactiveUS7444766B2

Innovation

- An insole with a low density polyurethane core and an integral border of harder material is stitched to the upper, allowing the insole to be securely attached without directly stitching the low density polyurethane, while additional polyurethane layers of varying densities enhance cushioning, and a fiberboard shank stabilizer supports the insole during the shoe forming process.

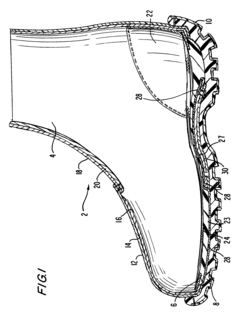

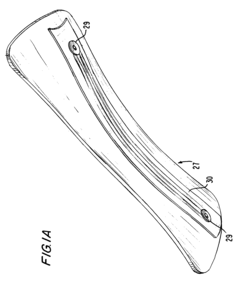

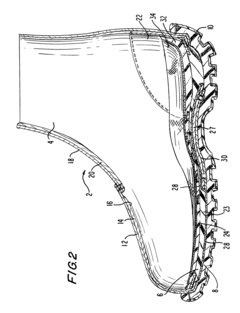

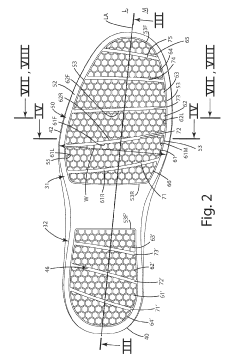

Cushioning system for footwear

PatentActiveUS10413015B2

Innovation

- The design features independent compression pods in the outsole, separated by peripheral and transverse grooves, allowing for individual compression and rebound, as well as lateral and medial flexibility, with a resilient shell and cushion units for enhanced shock absorption and comfort.

Sustainability in Neoprene Production

Sustainability in neoprene production has become a critical focus in the footwear industry, particularly as environmental concerns continue to shape consumer preferences and regulatory landscapes. The traditional production of neoprene, a synthetic rubber widely used in footwear cushioning, has been associated with significant environmental impacts, including high energy consumption and the release of harmful chemicals.

In recent years, manufacturers have made substantial strides in developing more sustainable neoprene production methods. One key innovation has been the introduction of limestone-based neoprene, which reduces reliance on petroleum-derived raw materials. This shift not only decreases the carbon footprint of production but also enhances the material's overall performance in terms of durability and flexibility.

Water-based adhesives have replaced solvent-based options in many production processes, significantly reducing volatile organic compound (VOC) emissions. This change has improved air quality in manufacturing facilities and minimized the environmental impact of neoprene production. Additionally, closed-loop water systems have been implemented to reduce water consumption and prevent the release of pollutants into local water sources.

Energy efficiency has been another area of focus, with manufacturers investing in advanced equipment and optimizing production processes. The use of renewable energy sources, such as solar and wind power, in neoprene production facilities has further reduced the industry's carbon emissions. Some companies have even achieved carbon-neutral production through a combination of efficiency measures and carbon offset programs.

Recycling and upcycling initiatives have gained traction, with some manufacturers developing technologies to reclaim and repurpose neoprene from end-of-life products. These efforts not only reduce waste but also create a circular economy model for neoprene production. Bio-based alternatives to traditional neoprene are also emerging, utilizing plant-derived materials to create more environmentally friendly cushioning solutions.

The push for sustainability in neoprene production has led to the development of new certifications and standards. These benchmarks help consumers and businesses identify products that meet specific environmental criteria, driving further innovation and transparency in the industry. As sustainability continues to be a key differentiator in the market, ongoing research and development efforts are focused on further improving the eco-friendliness of neoprene production while maintaining or enhancing its performance characteristics in footwear cushioning applications.

In recent years, manufacturers have made substantial strides in developing more sustainable neoprene production methods. One key innovation has been the introduction of limestone-based neoprene, which reduces reliance on petroleum-derived raw materials. This shift not only decreases the carbon footprint of production but also enhances the material's overall performance in terms of durability and flexibility.

Water-based adhesives have replaced solvent-based options in many production processes, significantly reducing volatile organic compound (VOC) emissions. This change has improved air quality in manufacturing facilities and minimized the environmental impact of neoprene production. Additionally, closed-loop water systems have been implemented to reduce water consumption and prevent the release of pollutants into local water sources.

Energy efficiency has been another area of focus, with manufacturers investing in advanced equipment and optimizing production processes. The use of renewable energy sources, such as solar and wind power, in neoprene production facilities has further reduced the industry's carbon emissions. Some companies have even achieved carbon-neutral production through a combination of efficiency measures and carbon offset programs.

Recycling and upcycling initiatives have gained traction, with some manufacturers developing technologies to reclaim and repurpose neoprene from end-of-life products. These efforts not only reduce waste but also create a circular economy model for neoprene production. Bio-based alternatives to traditional neoprene are also emerging, utilizing plant-derived materials to create more environmentally friendly cushioning solutions.

The push for sustainability in neoprene production has led to the development of new certifications and standards. These benchmarks help consumers and businesses identify products that meet specific environmental criteria, driving further innovation and transparency in the industry. As sustainability continues to be a key differentiator in the market, ongoing research and development efforts are focused on further improving the eco-friendliness of neoprene production while maintaining or enhancing its performance characteristics in footwear cushioning applications.

Biomechanical Impact Assessment

Neoprene's advancements in footwear cushioning technology have necessitated a comprehensive biomechanical impact assessment to evaluate their effectiveness and potential benefits for users. This assessment involves a multifaceted approach, combining laboratory testing, field trials, and computational modeling to analyze the interaction between the human foot and the neoprene-based cushioning system.

Laboratory testing utilizes specialized equipment such as force plates, pressure mapping systems, and high-speed cameras to measure key biomechanical parameters. These include ground reaction forces, pressure distribution, and foot motion during various activities like walking, running, and jumping. The data collected provides quantitative insights into how neoprene cushioning affects impact forces and load distribution across the foot.

Field trials complement laboratory tests by assessing the performance of neoprene-cushioned footwear in real-world conditions. Participants engage in a range of activities while wearing instrumented shoes, allowing researchers to gather data on factors such as comfort, fatigue, and injury prevention over extended periods of use. This approach helps validate laboratory findings and uncover potential long-term effects of the cushioning technology.

Computational modeling plays a crucial role in understanding the complex interactions between the foot, neoprene cushioning, and the ground. Finite element analysis (FEA) and musculoskeletal modeling techniques are employed to simulate various loading scenarios and predict stress distribution within the foot and lower limb. These models enable researchers to optimize cushioning designs and explore the effects of different neoprene formulations without the need for extensive physical prototyping.

The biomechanical impact assessment also considers the variability in foot morphology and gait patterns among different user groups. This includes analyzing how neoprene cushioning performs for individuals with specific foot conditions or biomechanical abnormalities, as well as across different age groups and activity levels.

Comparative studies form an essential part of the assessment, evaluating neoprene cushioning against traditional materials such as EVA foam and polyurethane. These comparisons focus on key performance metrics like energy return, shock absorption, and durability, providing a comprehensive understanding of neoprene's advantages and potential limitations in footwear applications.

The results of the biomechanical impact assessment are crucial for informing the development and refinement of neoprene-based cushioning technologies. They guide designers in optimizing cushioning properties for specific applications, whether for athletic performance, everyday comfort, or therapeutic footwear. Furthermore, these findings contribute to the broader scientific understanding of foot biomechanics and the role of cushioning in injury prevention and performance enhancement.

Laboratory testing utilizes specialized equipment such as force plates, pressure mapping systems, and high-speed cameras to measure key biomechanical parameters. These include ground reaction forces, pressure distribution, and foot motion during various activities like walking, running, and jumping. The data collected provides quantitative insights into how neoprene cushioning affects impact forces and load distribution across the foot.

Field trials complement laboratory tests by assessing the performance of neoprene-cushioned footwear in real-world conditions. Participants engage in a range of activities while wearing instrumented shoes, allowing researchers to gather data on factors such as comfort, fatigue, and injury prevention over extended periods of use. This approach helps validate laboratory findings and uncover potential long-term effects of the cushioning technology.

Computational modeling plays a crucial role in understanding the complex interactions between the foot, neoprene cushioning, and the ground. Finite element analysis (FEA) and musculoskeletal modeling techniques are employed to simulate various loading scenarios and predict stress distribution within the foot and lower limb. These models enable researchers to optimize cushioning designs and explore the effects of different neoprene formulations without the need for extensive physical prototyping.

The biomechanical impact assessment also considers the variability in foot morphology and gait patterns among different user groups. This includes analyzing how neoprene cushioning performs for individuals with specific foot conditions or biomechanical abnormalities, as well as across different age groups and activity levels.

Comparative studies form an essential part of the assessment, evaluating neoprene cushioning against traditional materials such as EVA foam and polyurethane. These comparisons focus on key performance metrics like energy return, shock absorption, and durability, providing a comprehensive understanding of neoprene's advantages and potential limitations in footwear applications.

The results of the biomechanical impact assessment are crucial for informing the development and refinement of neoprene-based cushioning technologies. They guide designers in optimizing cushioning properties for specific applications, whether for athletic performance, everyday comfort, or therapeutic footwear. Furthermore, these findings contribute to the broader scientific understanding of foot biomechanics and the role of cushioning in injury prevention and performance enhancement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!