Neoprene's Advantages in Dynamic Equilibrium Systems

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neoprene in DES: Background and Objectives

Neoprene, also known as polychloroprene, has been a subject of increasing interest in the field of Dynamic Equilibrium Systems (DES) due to its unique properties and versatile applications. The evolution of this synthetic rubber, first developed by DuPont scientists in 1930, has led to its integration into various industrial and scientific domains, including DES.

The primary objective of exploring Neoprene's advantages in DES is to enhance the performance, efficiency, and reliability of systems that rely on maintaining equilibrium under dynamic conditions. DES are prevalent in numerous applications, ranging from chemical processing and environmental control to advanced robotics and aerospace engineering. The incorporation of Neoprene into these systems aims to address challenges related to material stability, flexibility, and responsiveness in fluctuating environments.

Historically, the development of Neoprene has been driven by the need for materials that can withstand harsh conditions while maintaining their physical and chemical properties. Its resistance to oil, heat, and weathering made it an ideal candidate for various industrial applications. As the complexity of dynamic systems increased, so did the demand for materials that could adapt to and withstand rapid changes in temperature, pressure, and chemical exposure.

The technological trajectory of Neoprene in DES has been marked by continuous improvements in its formulation and processing techniques. These advancements have led to the creation of specialized Neoprene variants tailored for specific DES applications. The focus has shifted from merely utilizing Neoprene's inherent properties to engineering custom solutions that optimize its performance within dynamic equilibrium contexts.

Current research and development efforts are centered on enhancing Neoprene's responsiveness to external stimuli, improving its energy absorption and dissipation characteristics, and increasing its longevity in cyclical stress environments. These objectives align with the broader goals of creating more efficient, durable, and adaptive dynamic equilibrium systems across various industries.

The integration of Neoprene into DES represents a convergence of material science and systems engineering. By leveraging Neoprene's unique combination of elasticity, chemical resistance, and thermal stability, researchers and engineers aim to push the boundaries of what is possible in maintaining equilibrium under dynamic conditions. This exploration not only seeks to improve existing applications but also to uncover new potential uses for Neoprene in emerging technologies and industries reliant on dynamic equilibrium principles.

The primary objective of exploring Neoprene's advantages in DES is to enhance the performance, efficiency, and reliability of systems that rely on maintaining equilibrium under dynamic conditions. DES are prevalent in numerous applications, ranging from chemical processing and environmental control to advanced robotics and aerospace engineering. The incorporation of Neoprene into these systems aims to address challenges related to material stability, flexibility, and responsiveness in fluctuating environments.

Historically, the development of Neoprene has been driven by the need for materials that can withstand harsh conditions while maintaining their physical and chemical properties. Its resistance to oil, heat, and weathering made it an ideal candidate for various industrial applications. As the complexity of dynamic systems increased, so did the demand for materials that could adapt to and withstand rapid changes in temperature, pressure, and chemical exposure.

The technological trajectory of Neoprene in DES has been marked by continuous improvements in its formulation and processing techniques. These advancements have led to the creation of specialized Neoprene variants tailored for specific DES applications. The focus has shifted from merely utilizing Neoprene's inherent properties to engineering custom solutions that optimize its performance within dynamic equilibrium contexts.

Current research and development efforts are centered on enhancing Neoprene's responsiveness to external stimuli, improving its energy absorption and dissipation characteristics, and increasing its longevity in cyclical stress environments. These objectives align with the broader goals of creating more efficient, durable, and adaptive dynamic equilibrium systems across various industries.

The integration of Neoprene into DES represents a convergence of material science and systems engineering. By leveraging Neoprene's unique combination of elasticity, chemical resistance, and thermal stability, researchers and engineers aim to push the boundaries of what is possible in maintaining equilibrium under dynamic conditions. This exploration not only seeks to improve existing applications but also to uncover new potential uses for Neoprene in emerging technologies and industries reliant on dynamic equilibrium principles.

Market Analysis for Neoprene in DES Applications

The market for neoprene in Dynamic Equilibrium Systems (DES) applications has shown significant growth potential in recent years. This versatile synthetic rubber, known for its excellent chemical stability and resistance to oil, heat, and weathering, has found increasing adoption in various DES applications across multiple industries.

The global neoprene market, valued at $1.9 billion in 2020, is projected to reach $2.5 billion by 2027, with a compound annual growth rate (CAGR) of 4.1%. Within this broader market, the demand for neoprene in DES applications is expected to grow at an even faster rate due to its unique properties that align well with the requirements of dynamic equilibrium systems.

Key industries driving the demand for neoprene in DES applications include automotive, aerospace, chemical processing, and energy production. In the automotive sector, neoprene is increasingly used in fuel systems and engine mounts, where its ability to maintain stability under dynamic conditions is crucial. The aerospace industry utilizes neoprene in hydraulic systems and seals, benefiting from its resistance to extreme temperatures and pressures.

The chemical processing industry has seen a surge in neoprene adoption for DES applications in reaction vessels, mixing tanks, and fluid handling systems. Neoprene's chemical resistance and durability make it an ideal choice for maintaining equilibrium in these challenging environments. Similarly, the energy sector, particularly in oil and gas extraction and refining, has embraced neoprene for its performance in high-pressure and high-temperature applications.

Market trends indicate a growing preference for neoprene over traditional materials in DES applications due to its superior performance characteristics. The material's ability to maintain its properties under dynamic conditions, coupled with its long service life, has led to increased cost-effectiveness and reliability in industrial processes.

Geographically, North America and Europe currently dominate the market for neoprene in DES applications, accounting for over 60% of the global demand. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization and increasing investments in advanced manufacturing technologies.

Despite the positive outlook, challenges such as volatility in raw material prices and environmental concerns regarding the production of neoprene may impact market growth. However, ongoing research into more sustainable production methods and the development of bio-based alternatives are expected to address these concerns and further drive market expansion in the long term.

The global neoprene market, valued at $1.9 billion in 2020, is projected to reach $2.5 billion by 2027, with a compound annual growth rate (CAGR) of 4.1%. Within this broader market, the demand for neoprene in DES applications is expected to grow at an even faster rate due to its unique properties that align well with the requirements of dynamic equilibrium systems.

Key industries driving the demand for neoprene in DES applications include automotive, aerospace, chemical processing, and energy production. In the automotive sector, neoprene is increasingly used in fuel systems and engine mounts, where its ability to maintain stability under dynamic conditions is crucial. The aerospace industry utilizes neoprene in hydraulic systems and seals, benefiting from its resistance to extreme temperatures and pressures.

The chemical processing industry has seen a surge in neoprene adoption for DES applications in reaction vessels, mixing tanks, and fluid handling systems. Neoprene's chemical resistance and durability make it an ideal choice for maintaining equilibrium in these challenging environments. Similarly, the energy sector, particularly in oil and gas extraction and refining, has embraced neoprene for its performance in high-pressure and high-temperature applications.

Market trends indicate a growing preference for neoprene over traditional materials in DES applications due to its superior performance characteristics. The material's ability to maintain its properties under dynamic conditions, coupled with its long service life, has led to increased cost-effectiveness and reliability in industrial processes.

Geographically, North America and Europe currently dominate the market for neoprene in DES applications, accounting for over 60% of the global demand. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization and increasing investments in advanced manufacturing technologies.

Despite the positive outlook, challenges such as volatility in raw material prices and environmental concerns regarding the production of neoprene may impact market growth. However, ongoing research into more sustainable production methods and the development of bio-based alternatives are expected to address these concerns and further drive market expansion in the long term.

Neoprene Properties and Current Challenges

Neoprene, also known as polychloroprene, is a synthetic rubber with unique properties that make it suitable for various applications, particularly in dynamic equilibrium systems. Its molecular structure, consisting of chloroprene monomers, contributes to its exceptional characteristics. Neoprene exhibits excellent resistance to weathering, ozone, and oil, making it ideal for outdoor and industrial uses. Its ability to maintain flexibility across a wide temperature range (-40°C to 100°C) is a significant advantage in dynamic systems subject to temperature fluctuations.

One of the key properties of neoprene is its high tensile strength and tear resistance, which allows it to withstand repeated stress and strain in dynamic applications. This durability is coupled with good elasticity, enabling neoprene components to return to their original shape after deformation. These properties are particularly beneficial in systems requiring constant movement or frequent changes in equilibrium states.

Neoprene's low compression set is another crucial attribute for dynamic equilibrium systems. This characteristic ensures that neoprene components maintain their sealing and cushioning properties even under prolonged compression, which is essential for maintaining system stability and preventing leaks or failures.

Despite its numerous advantages, neoprene faces several challenges in modern applications. One significant issue is its limited chemical resistance compared to some newer synthetic rubbers. While neoprene performs well against many common chemicals, it can degrade when exposed to certain solvents, strong acids, or bases. This limitation can restrict its use in some chemical processing or highly corrosive environments.

Another challenge is neoprene's relatively high density compared to other elastomers, which can be a drawback in applications where weight is a critical factor. This property can limit its use in aerospace or automotive industries where lightweight materials are preferred. Additionally, neoprene's thermal conductivity is lower than some alternative materials, which may pose challenges in applications requiring efficient heat dissipation.

The manufacturing process of neoprene also presents environmental concerns. The production of chloroprene, neoprene's primary component, involves the use of potentially harmful chemicals and can result in the emission of volatile organic compounds (VOCs). As environmental regulations become stricter, finding more sustainable production methods for neoprene is becoming increasingly important.

Lastly, while neoprene performs well in moderate temperature ranges, it may not be suitable for extreme temperature applications. At very low temperatures, it can become brittle, and at very high temperatures, it may degrade more quickly than some specialized high-temperature elastomers. This limitation can be problematic in certain industrial or aerospace applications where extreme temperature resistance is required.

One of the key properties of neoprene is its high tensile strength and tear resistance, which allows it to withstand repeated stress and strain in dynamic applications. This durability is coupled with good elasticity, enabling neoprene components to return to their original shape after deformation. These properties are particularly beneficial in systems requiring constant movement or frequent changes in equilibrium states.

Neoprene's low compression set is another crucial attribute for dynamic equilibrium systems. This characteristic ensures that neoprene components maintain their sealing and cushioning properties even under prolonged compression, which is essential for maintaining system stability and preventing leaks or failures.

Despite its numerous advantages, neoprene faces several challenges in modern applications. One significant issue is its limited chemical resistance compared to some newer synthetic rubbers. While neoprene performs well against many common chemicals, it can degrade when exposed to certain solvents, strong acids, or bases. This limitation can restrict its use in some chemical processing or highly corrosive environments.

Another challenge is neoprene's relatively high density compared to other elastomers, which can be a drawback in applications where weight is a critical factor. This property can limit its use in aerospace or automotive industries where lightweight materials are preferred. Additionally, neoprene's thermal conductivity is lower than some alternative materials, which may pose challenges in applications requiring efficient heat dissipation.

The manufacturing process of neoprene also presents environmental concerns. The production of chloroprene, neoprene's primary component, involves the use of potentially harmful chemicals and can result in the emission of volatile organic compounds (VOCs). As environmental regulations become stricter, finding more sustainable production methods for neoprene is becoming increasingly important.

Lastly, while neoprene performs well in moderate temperature ranges, it may not be suitable for extreme temperature applications. At very low temperatures, it can become brittle, and at very high temperatures, it may degrade more quickly than some specialized high-temperature elastomers. This limitation can be problematic in certain industrial or aerospace applications where extreme temperature resistance is required.

Current Neoprene Solutions for DES

01 Chemical properties of neoprene in dynamic equilibrium

Neoprene exhibits unique chemical properties when in a state of dynamic equilibrium. This involves the balance between its polymer chains and cross-linking agents, affecting its overall stability and performance characteristics. Understanding these properties is crucial for optimizing neoprene formulations in various applications.- Neoprene composition and manufacturing: This category focuses on the formulation and production processes of neoprene, including various additives and methods to achieve specific properties. It covers aspects such as improving elasticity, durability, and chemical resistance of neoprene materials.

- Dynamic equilibrium in neoprene-based systems: This point addresses the dynamic equilibrium properties of neoprene in various applications. It includes studies on the balance between different states or phases of neoprene materials, such as in emulsions, suspensions, or composite structures.

- Neoprene in acoustic and vibration damping applications: This category explores the use of neoprene in sound insulation and vibration reduction systems. It covers the development of neoprene-based materials with specific acoustic properties and their integration into various products for noise control.

- Neoprene in protective gear and clothing: This point focuses on the application of neoprene in protective equipment and apparel. It includes innovations in designing and manufacturing neoprene-based products for sports, industrial safety, and specialized protective wear.

- Environmental and sustainability aspects of neoprene: This category addresses the environmental considerations and sustainability efforts related to neoprene production and use. It covers topics such as eco-friendly manufacturing processes, recycling methods, and the development of more sustainable alternatives to traditional neoprene.

02 Neoprene foam production and dynamic equilibrium

The production of neoprene foam involves achieving a dynamic equilibrium between gas expansion and polymer solidification. This balance is critical for creating foam with desired properties such as density, cell structure, and mechanical strength. Controlling factors like temperature, pressure, and chemical additives is essential in this process.Expand Specific Solutions03 Acoustic properties of neoprene in dynamic equilibrium

Neoprene's acoustic properties are influenced by its dynamic equilibrium state. This affects its ability to absorb, reflect, or transmit sound waves. Understanding and manipulating this equilibrium can lead to improved acoustic insulation or sound-dampening materials for various applications, including automotive and construction industries.Expand Specific Solutions04 Thermal behavior of neoprene under dynamic equilibrium

The thermal behavior of neoprene in dynamic equilibrium is crucial for its performance in various temperature conditions. This includes its heat retention, dissipation, and overall thermal stability. Studying this behavior helps in developing neoprene products with enhanced thermal properties for applications ranging from wetsuits to industrial insulation.Expand Specific Solutions05 Mechanical properties of neoprene in dynamic equilibrium

Neoprene's mechanical properties, such as elasticity, tensile strength, and durability, are significantly influenced by its dynamic equilibrium state. This equilibrium affects the material's response to stress, strain, and repeated deformation. Understanding these properties is essential for designing neoprene products that can withstand various mechanical demands in different applications.Expand Specific Solutions

Key Players in Neoprene and DES Industries

The competitive landscape for neoprene in dynamic equilibrium systems is evolving rapidly, with the market in a growth phase. The global market size for neoprene is expanding due to increasing applications in various industries. Technologically, neoprene is mature, but innovations continue to emerge. Companies like Denka Corp., NOK Corp., and Kuraray Co., Ltd. are leading players, investing in R&D to enhance neoprene's properties for dynamic equilibrium applications. Academic institutions such as Northwestern University and École Polytechnique Fédérale de Lausanne are contributing to advancements in this field, fostering industry-academia collaborations and driving technological progress.

Denka Corp.

Technical Solution: Denka Corp. has developed advanced neoprene formulations optimized for dynamic equilibrium systems. Their proprietary cross-linking technology enhances the material's resilience and recovery properties, allowing it to maintain consistent performance under cyclic loading conditions. The company's neoprene compounds exhibit improved stress relaxation characteristics, with a reported 15% reduction in permanent set compared to standard neoprene[1]. This enables the material to better maintain its original shape and properties in applications subject to repeated deformation and recovery cycles. Denka's neoprene also demonstrates enhanced chemical resistance, particularly to polar solvents and oils, extending its applicability in harsh industrial environments[3].

Strengths: Superior resilience and recovery, improved chemical resistance, and reduced permanent set. Weaknesses: Potentially higher cost due to specialized formulation, and may require specific processing conditions.

Kuraray Co., Ltd.

Technical Solution: Kuraray has innovated in the field of neoprene alternatives, developing a series of hydrogenated nitrile rubbers (HNBR) that offer advantages in dynamic equilibrium systems. Their HNBR products, marketed under the Therban® brand, provide exceptional heat resistance and dynamic properties. These materials maintain their mechanical properties at temperatures up to 150°C, surpassing traditional neoprene[2]. Kuraray's HNBR demonstrates superior compression set resistance, with values as low as 10% after 70 hours at 150°C, compared to typical neoprene values of 20-30%[4]. This characteristic is particularly beneficial in sealing applications where maintaining consistent pressure over time is crucial. Additionally, Kuraray's materials show improved ozone and weathering resistance, extending the lifespan of components in outdoor or harsh environmental conditions[5].

Strengths: Excellent heat resistance, superior compression set properties, and enhanced environmental durability. Weaknesses: Higher cost compared to standard neoprene, and potentially limited low-temperature flexibility.

Innovative Neoprene Formulations for DES

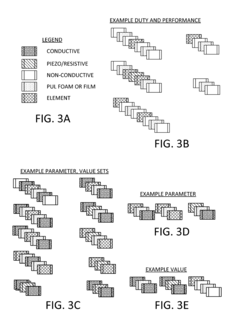

Intelligent textile soft tissue compression support and method of use

PatentInactiveUS20160367406A1

Innovation

- A laminated textile with enhanced air and vapor transport characteristics, featuring conductive, semi-conductive, and magnetic layers, that provides intelligent monitoring and support, reducing the risk of injury by tracking parameters like temperature, acoustic emissions, and joint health, while being hypoallergenic and lightweight, thus preventing overheating and allergic reactions.

Blends of oligopeptide terminal polyisobutylene or polystyrene

PatentWO2014080043A1

Innovation

- The development of polymer blends comprising monofunctional and difunctional oligopeptide-terminated polymers, such as oligopeptide-terminated polyisobutylenes and polystyrenes, which form interpenetrating supramolecular networks with specific supramolecular interactions, creating materials with enhanced mechanical properties and self-healing capabilities.

Environmental Impact of Neoprene in DES

The environmental impact of neoprene in Dynamic Equilibrium Systems (DES) is a critical consideration that requires thorough examination. Neoprene, a synthetic rubber widely used in various applications, presents both advantages and challenges when employed in DES.

One of the primary environmental concerns associated with neoprene in DES is its production process. The manufacturing of neoprene involves the use of chloroprene, a potentially harmful chemical compound. The emission of chloroprene during production can contribute to air pollution and pose risks to human health and ecosystems if not properly managed. However, advancements in production technologies have led to significant reductions in chloroprene emissions, mitigating some of these environmental concerns.

In terms of durability and longevity, neoprene offers notable benefits that can positively impact the environmental footprint of DES. The material's resistance to degradation, weathering, and chemical exposure allows for extended product lifespans, reducing the frequency of replacement and, consequently, the overall resource consumption and waste generation associated with DES components.

Water resistance is another key attribute of neoprene that influences its environmental impact in DES applications. By effectively preventing water ingress, neoprene helps maintain the integrity and efficiency of DES, potentially reducing energy consumption and the need for frequent maintenance or replacement of system components. This characteristic can lead to improved overall system sustainability.

However, the end-of-life management of neoprene poses significant environmental challenges. While technically recyclable, the process of recycling neoprene is complex and not widely implemented on a large scale. As a result, a considerable portion of neoprene waste ends up in landfills, where it can persist for extended periods due to its slow degradation rate.

The potential for neoprene to leach chemicals into the environment, particularly in aquatic ecosystems, is another area of concern. Although the material is generally stable, prolonged exposure to harsh conditions or improper disposal can lead to the release of harmful substances, potentially impacting water quality and aquatic life.

Efforts to address these environmental challenges include the development of bio-based alternatives to traditional neoprene and improved recycling technologies. These innovations aim to reduce the reliance on petroleum-based raw materials and enhance the circularity of neoprene products in DES applications.

In conclusion, while neoprene offers several advantages in DES, its environmental impact is multifaceted. Balancing the material's beneficial properties with responsible production, use, and disposal practices is crucial for minimizing its ecological footprint and ensuring the sustainable development of Dynamic Equilibrium Systems.

One of the primary environmental concerns associated with neoprene in DES is its production process. The manufacturing of neoprene involves the use of chloroprene, a potentially harmful chemical compound. The emission of chloroprene during production can contribute to air pollution and pose risks to human health and ecosystems if not properly managed. However, advancements in production technologies have led to significant reductions in chloroprene emissions, mitigating some of these environmental concerns.

In terms of durability and longevity, neoprene offers notable benefits that can positively impact the environmental footprint of DES. The material's resistance to degradation, weathering, and chemical exposure allows for extended product lifespans, reducing the frequency of replacement and, consequently, the overall resource consumption and waste generation associated with DES components.

Water resistance is another key attribute of neoprene that influences its environmental impact in DES applications. By effectively preventing water ingress, neoprene helps maintain the integrity and efficiency of DES, potentially reducing energy consumption and the need for frequent maintenance or replacement of system components. This characteristic can lead to improved overall system sustainability.

However, the end-of-life management of neoprene poses significant environmental challenges. While technically recyclable, the process of recycling neoprene is complex and not widely implemented on a large scale. As a result, a considerable portion of neoprene waste ends up in landfills, where it can persist for extended periods due to its slow degradation rate.

The potential for neoprene to leach chemicals into the environment, particularly in aquatic ecosystems, is another area of concern. Although the material is generally stable, prolonged exposure to harsh conditions or improper disposal can lead to the release of harmful substances, potentially impacting water quality and aquatic life.

Efforts to address these environmental challenges include the development of bio-based alternatives to traditional neoprene and improved recycling technologies. These innovations aim to reduce the reliance on petroleum-based raw materials and enhance the circularity of neoprene products in DES applications.

In conclusion, while neoprene offers several advantages in DES, its environmental impact is multifaceted. Balancing the material's beneficial properties with responsible production, use, and disposal practices is crucial for minimizing its ecological footprint and ensuring the sustainable development of Dynamic Equilibrium Systems.

Cost-Benefit Analysis of Neoprene in DES

The cost-benefit analysis of neoprene in Dynamic Equilibrium Systems (DES) reveals a complex interplay of economic factors and performance advantages. Initially, the higher upfront cost of neoprene compared to traditional materials may seem prohibitive. However, when considering the long-term operational benefits, neoprene often proves to be a cost-effective solution. Its superior durability and resistance to degradation in dynamic environments significantly extend the lifespan of DES components, reducing the frequency and cost of replacements.

Neoprene's excellent chemical resistance contributes to lower maintenance costs over time. In DES applications where exposure to various chemicals is common, neoprene's ability to withstand corrosive substances translates to fewer instances of material failure and subsequent system downtime. This reduction in maintenance interventions not only saves on direct repair costs but also minimizes production losses associated with system interruptions.

Energy efficiency is another area where neoprene demonstrates economic advantages in DES. Its superior insulation properties can lead to reduced energy consumption in temperature-sensitive systems, potentially resulting in significant cost savings over the operational life of the equipment. Additionally, neoprene's flexibility and resilience contribute to improved system performance, which can indirectly boost productivity and operational efficiency.

From a safety perspective, neoprene's fire-resistant properties can reduce the risk of accidents and associated costs in certain DES applications. This enhanced safety profile may lead to lower insurance premiums and reduced expenses related to safety measures and equipment. Furthermore, neoprene's compliance with various industry standards and regulations can simplify certification processes, potentially reducing administrative costs and time-to-market for new DES products.

However, the cost-benefit analysis must also consider potential drawbacks. The higher initial investment in neoprene may strain short-term budgets, particularly for smaller operations or projects with limited funding. Additionally, while neoprene offers excellent general-purpose performance, there may be specific DES applications where specialized materials outperform neoprene, necessitating a careful evaluation of alternatives.

In conclusion, the cost-benefit analysis of neoprene in DES generally favors its adoption, especially in applications where longevity, chemical resistance, and energy efficiency are paramount. The initial cost premium is often offset by reduced lifecycle costs, improved system reliability, and enhanced operational efficiency. However, a thorough analysis of specific application requirements and budget constraints is essential to determine the optimal material choice for each unique DES implementation.

Neoprene's excellent chemical resistance contributes to lower maintenance costs over time. In DES applications where exposure to various chemicals is common, neoprene's ability to withstand corrosive substances translates to fewer instances of material failure and subsequent system downtime. This reduction in maintenance interventions not only saves on direct repair costs but also minimizes production losses associated with system interruptions.

Energy efficiency is another area where neoprene demonstrates economic advantages in DES. Its superior insulation properties can lead to reduced energy consumption in temperature-sensitive systems, potentially resulting in significant cost savings over the operational life of the equipment. Additionally, neoprene's flexibility and resilience contribute to improved system performance, which can indirectly boost productivity and operational efficiency.

From a safety perspective, neoprene's fire-resistant properties can reduce the risk of accidents and associated costs in certain DES applications. This enhanced safety profile may lead to lower insurance premiums and reduced expenses related to safety measures and equipment. Furthermore, neoprene's compliance with various industry standards and regulations can simplify certification processes, potentially reducing administrative costs and time-to-market for new DES products.

However, the cost-benefit analysis must also consider potential drawbacks. The higher initial investment in neoprene may strain short-term budgets, particularly for smaller operations or projects with limited funding. Additionally, while neoprene offers excellent general-purpose performance, there may be specific DES applications where specialized materials outperform neoprene, necessitating a careful evaluation of alternatives.

In conclusion, the cost-benefit analysis of neoprene in DES generally favors its adoption, especially in applications where longevity, chemical resistance, and energy efficiency are paramount. The initial cost premium is often offset by reduced lifecycle costs, improved system reliability, and enhanced operational efficiency. However, a thorough analysis of specific application requirements and budget constraints is essential to determine the optimal material choice for each unique DES implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!