Neoprene's Role in 3D Printing of Functional Components

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neoprene 3D Printing Background and Objectives

Neoprene, also known as polychloroprene, has been a versatile synthetic rubber since its invention in 1930. Initially developed as an oil-resistant alternative to natural rubber, neoprene has found applications in various industries due to its unique properties. In recent years, the 3D printing industry has shown increasing interest in neoprene as a potential material for creating functional components.

The evolution of 3D printing technology has led to a growing demand for materials that can produce parts with specific mechanical and chemical properties. Neoprene's combination of flexibility, durability, and resistance to oil, water, and weathering makes it an attractive candidate for 3D printing applications. The potential to create custom-fit, functional components with neoprene opens up new possibilities in industries such as automotive, aerospace, and medical devices.

The primary objective of exploring neoprene's role in 3D printing is to develop methods for effectively processing this material in additive manufacturing systems. This involves overcoming challenges related to material viscosity, curing mechanisms, and layer adhesion. Researchers and engineers are working to optimize printing parameters, such as temperature, pressure, and curing times, to achieve consistent and high-quality neoprene prints.

Another key goal is to expand the range of functional components that can be produced using 3D-printed neoprene. This includes developing techniques for creating multi-material parts that combine neoprene with other materials, enhancing the versatility and functionality of printed components. Additionally, there is a focus on improving the surface finish and dimensional accuracy of neoprene prints to meet the stringent requirements of various industrial applications.

The integration of neoprene into 3D printing processes also aims to address sustainability concerns in manufacturing. By enabling on-demand production of custom parts, 3D printing with neoprene has the potential to reduce waste and inventory costs associated with traditional manufacturing methods. Furthermore, the ability to locally produce neoprene components could lead to more efficient supply chains and reduced transportation emissions.

As research in this field progresses, the ultimate objective is to establish neoprene as a mainstream material in the 3D printing industry. This involves developing standardized printing processes, creating a robust ecosystem of compatible printers and post-processing equipment, and expanding the knowledge base around neoprene's behavior in various 3D printing technologies. The successful integration of neoprene into additive manufacturing workflows could revolutionize the production of flexible, durable, and chemically resistant components across multiple industries.

The evolution of 3D printing technology has led to a growing demand for materials that can produce parts with specific mechanical and chemical properties. Neoprene's combination of flexibility, durability, and resistance to oil, water, and weathering makes it an attractive candidate for 3D printing applications. The potential to create custom-fit, functional components with neoprene opens up new possibilities in industries such as automotive, aerospace, and medical devices.

The primary objective of exploring neoprene's role in 3D printing is to develop methods for effectively processing this material in additive manufacturing systems. This involves overcoming challenges related to material viscosity, curing mechanisms, and layer adhesion. Researchers and engineers are working to optimize printing parameters, such as temperature, pressure, and curing times, to achieve consistent and high-quality neoprene prints.

Another key goal is to expand the range of functional components that can be produced using 3D-printed neoprene. This includes developing techniques for creating multi-material parts that combine neoprene with other materials, enhancing the versatility and functionality of printed components. Additionally, there is a focus on improving the surface finish and dimensional accuracy of neoprene prints to meet the stringent requirements of various industrial applications.

The integration of neoprene into 3D printing processes also aims to address sustainability concerns in manufacturing. By enabling on-demand production of custom parts, 3D printing with neoprene has the potential to reduce waste and inventory costs associated with traditional manufacturing methods. Furthermore, the ability to locally produce neoprene components could lead to more efficient supply chains and reduced transportation emissions.

As research in this field progresses, the ultimate objective is to establish neoprene as a mainstream material in the 3D printing industry. This involves developing standardized printing processes, creating a robust ecosystem of compatible printers and post-processing equipment, and expanding the knowledge base around neoprene's behavior in various 3D printing technologies. The successful integration of neoprene into additive manufacturing workflows could revolutionize the production of flexible, durable, and chemically resistant components across multiple industries.

Market Analysis for Neoprene 3D Printed Components

The market for neoprene 3D printed components is experiencing significant growth, driven by the increasing demand for customized and functional parts across various industries. Neoprene, a synthetic rubber known for its flexibility, durability, and resistance to oil and water, has found a unique niche in the 3D printing sector. This material's properties make it particularly suitable for producing components that require elasticity and chemical resistance.

In the automotive industry, neoprene 3D printed components are gaining traction for applications such as gaskets, seals, and vibration dampeners. The ability to rapidly prototype and produce these parts on-demand has led to reduced lead times and increased efficiency in vehicle manufacturing processes. Similarly, the aerospace sector is exploring neoprene 3D printing for creating lightweight, yet durable components that can withstand extreme conditions.

The medical and healthcare industries represent another significant market for neoprene 3D printed components. Custom-fit orthopedic supports, prosthetics, and medical device components are being produced using this technology, offering personalized solutions for patients. The biocompatibility of certain neoprene formulations has opened up possibilities for creating implantable devices and tissue engineering scaffolds.

Consumer goods and sports equipment manufacturers are also capitalizing on the benefits of neoprene 3D printing. Products such as customized footwear insoles, protective gear, and specialized sporting equipment are being developed, catering to the growing demand for personalized consumer products.

The global market size for neoprene 3D printed components is expected to grow substantially over the next five years. This growth is attributed to the increasing adoption of additive manufacturing technologies across industries and the continuous improvement in 3D printing materials and techniques. North America and Europe currently lead the market, with Asia-Pacific regions showing the fastest growth rate due to rapid industrialization and technological advancements.

Key market drivers include the rising demand for customized products, the need for rapid prototyping in product development cycles, and the push for more sustainable manufacturing processes. Neoprene 3D printing offers advantages in terms of material efficiency and waste reduction compared to traditional manufacturing methods, aligning with global sustainability initiatives.

However, challenges such as the high initial investment in 3D printing equipment and the need for specialized expertise in material handling and printing techniques may hinder market growth to some extent. Additionally, competition from other elastomeric materials in the 3D printing space poses a potential threat to neoprene's market share.

In the automotive industry, neoprene 3D printed components are gaining traction for applications such as gaskets, seals, and vibration dampeners. The ability to rapidly prototype and produce these parts on-demand has led to reduced lead times and increased efficiency in vehicle manufacturing processes. Similarly, the aerospace sector is exploring neoprene 3D printing for creating lightweight, yet durable components that can withstand extreme conditions.

The medical and healthcare industries represent another significant market for neoprene 3D printed components. Custom-fit orthopedic supports, prosthetics, and medical device components are being produced using this technology, offering personalized solutions for patients. The biocompatibility of certain neoprene formulations has opened up possibilities for creating implantable devices and tissue engineering scaffolds.

Consumer goods and sports equipment manufacturers are also capitalizing on the benefits of neoprene 3D printing. Products such as customized footwear insoles, protective gear, and specialized sporting equipment are being developed, catering to the growing demand for personalized consumer products.

The global market size for neoprene 3D printed components is expected to grow substantially over the next five years. This growth is attributed to the increasing adoption of additive manufacturing technologies across industries and the continuous improvement in 3D printing materials and techniques. North America and Europe currently lead the market, with Asia-Pacific regions showing the fastest growth rate due to rapid industrialization and technological advancements.

Key market drivers include the rising demand for customized products, the need for rapid prototyping in product development cycles, and the push for more sustainable manufacturing processes. Neoprene 3D printing offers advantages in terms of material efficiency and waste reduction compared to traditional manufacturing methods, aligning with global sustainability initiatives.

However, challenges such as the high initial investment in 3D printing equipment and the need for specialized expertise in material handling and printing techniques may hinder market growth to some extent. Additionally, competition from other elastomeric materials in the 3D printing space poses a potential threat to neoprene's market share.

Current Challenges in Neoprene 3D Printing

Despite the promising potential of neoprene in 3D printing of functional components, several significant challenges currently hinder its widespread adoption and optimal utilization. One of the primary obstacles is the material's inherent thermal sensitivity. Neoprene, being a synthetic rubber, has a relatively low melting point and can degrade when exposed to high temperatures typically used in 3D printing processes. This thermal instability often results in inconsistent print quality and compromised structural integrity of the final components.

Another major challenge lies in achieving precise control over the material's flow and deposition during the printing process. Neoprene's viscoelastic properties make it difficult to maintain consistent extrusion rates and layer adhesion, leading to issues such as warping, shrinkage, and poor surface finish. These problems are particularly pronounced when attempting to create complex geometries or fine details, limiting the range of applications for neoprene-based 3D printed components.

The compatibility of neoprene with existing 3D printing hardware and software also presents a significant hurdle. Most commercial 3D printers and slicing software are optimized for thermoplastics, not elastomers like neoprene. This mismatch often results in suboptimal print settings, leading to reduced print quality and increased failure rates. Developing specialized printing systems and software algorithms tailored to neoprene's unique properties is crucial for overcoming this challenge.

Furthermore, ensuring consistent material properties across different batches of neoprene filament or resin poses a considerable challenge. Variations in chemical composition, moisture content, and aging can significantly affect the printing process and the mechanical properties of the final product. This inconsistency makes it difficult to achieve reproducible results and maintain quality standards in industrial applications.

The post-processing of neoprene 3D printed components also presents challenges. Unlike many thermoplastics, neoprene parts often require specialized curing or treatment processes to achieve optimal mechanical properties. Developing efficient and cost-effective post-processing techniques that do not compromise the material's unique properties is essential for expanding its applications in functional component manufacturing.

Lastly, the environmental impact and recyclability of neoprene in 3D printing contexts remain significant concerns. As sustainability becomes increasingly important in manufacturing, finding ways to recycle or reuse neoprene 3D printing waste and end-of-life components is crucial. Current recycling methods for neoprene are limited and often energy-intensive, presenting both an environmental and economic challenge for widespread adoption in additive manufacturing.

Another major challenge lies in achieving precise control over the material's flow and deposition during the printing process. Neoprene's viscoelastic properties make it difficult to maintain consistent extrusion rates and layer adhesion, leading to issues such as warping, shrinkage, and poor surface finish. These problems are particularly pronounced when attempting to create complex geometries or fine details, limiting the range of applications for neoprene-based 3D printed components.

The compatibility of neoprene with existing 3D printing hardware and software also presents a significant hurdle. Most commercial 3D printers and slicing software are optimized for thermoplastics, not elastomers like neoprene. This mismatch often results in suboptimal print settings, leading to reduced print quality and increased failure rates. Developing specialized printing systems and software algorithms tailored to neoprene's unique properties is crucial for overcoming this challenge.

Furthermore, ensuring consistent material properties across different batches of neoprene filament or resin poses a considerable challenge. Variations in chemical composition, moisture content, and aging can significantly affect the printing process and the mechanical properties of the final product. This inconsistency makes it difficult to achieve reproducible results and maintain quality standards in industrial applications.

The post-processing of neoprene 3D printed components also presents challenges. Unlike many thermoplastics, neoprene parts often require specialized curing or treatment processes to achieve optimal mechanical properties. Developing efficient and cost-effective post-processing techniques that do not compromise the material's unique properties is essential for expanding its applications in functional component manufacturing.

Lastly, the environmental impact and recyclability of neoprene in 3D printing contexts remain significant concerns. As sustainability becomes increasingly important in manufacturing, finding ways to recycle or reuse neoprene 3D printing waste and end-of-life components is crucial. Current recycling methods for neoprene are limited and often energy-intensive, presenting both an environmental and economic challenge for widespread adoption in additive manufacturing.

Existing Neoprene 3D Printing Solutions

01 Composition and synthesis of neoprene

Neoprene is a synthetic rubber produced by polymerization of chloroprene. It is known for its resistance to oil, heat, and weathering. The manufacturing process involves careful control of reaction conditions and may include various additives to enhance specific properties.- Composition and synthesis of neoprene: Neoprene is a synthetic rubber produced by polymerization of chloroprene. Various methods and compositions are used to synthesize neoprene with specific properties, including the use of different catalysts, additives, and polymerization techniques to control the molecular structure and characteristics of the final product.

- Applications of neoprene in protective gear: Neoprene is widely used in the production of protective gear due to its excellent insulation, flexibility, and durability properties. It is commonly used in wetsuits, diving suits, and other water-resistant clothing. The material can be engineered to provide varying levels of thermal insulation and protection against environmental factors.

- Neoprene foam production and properties: Neoprene foam is a versatile material with applications in various industries. The production process involves the introduction of gas bubbles into the neoprene compound, creating a cellular structure. The resulting foam can be engineered to have specific properties such as density, compression resistance, and thermal insulation.

- Neoprene in adhesive and sealant applications: Neoprene-based adhesives and sealants are widely used due to their excellent bonding properties, chemical resistance, and durability. These formulations can be tailored for specific applications, such as construction, automotive, and marine industries, by adjusting the composition and incorporating various additives to enhance performance characteristics.

- Modifications and blends of neoprene: To enhance its properties and expand its applications, neoprene is often modified or blended with other materials. This can include the incorporation of reinforcing agents, plasticizers, or other polymers to create composite materials with improved mechanical, thermal, or chemical resistance properties. These modifications allow for the development of specialized neoprene-based materials for specific industrial applications.

02 Applications of neoprene in protective gear

Neoprene is widely used in the production of protective gear such as wetsuits, diving suits, and other water-resistant clothing. Its flexibility, insulation properties, and durability make it ideal for these applications. Neoprene-based protective gear often incorporates additional layers or treatments for enhanced performance.Expand Specific Solutions03 Neoprene foams and cellular structures

Neoprene can be processed into foam or cellular structures, which offer improved insulation and cushioning properties. These foams are used in various applications, including padding, gaskets, and seals. The production of neoprene foams often involves the use of blowing agents and specific curing processes.Expand Specific Solutions04 Neoprene blends and composites

Neoprene can be blended with other materials or used in composite structures to enhance its properties or create specialized materials. These blends and composites may offer improved strength, chemical resistance, or other desirable characteristics for specific applications.Expand Specific Solutions05 Neoprene in adhesives and sealants

Neoprene-based adhesives and sealants are valued for their strong bonding properties, flexibility, and resistance to environmental factors. These products are used in various industries, including construction, automotive, and marine applications. Formulations may include additional components to enhance specific properties or curing characteristics.Expand Specific Solutions

Key Players in Neoprene 3D Printing Industry

The market for neoprene in 3D printing of functional components is in an early growth stage, with increasing adoption across industries. While the market size is still relatively small, it's expanding rapidly due to neoprene's unique properties and versatility. The technology's maturity is progressing, with companies like 3M Innovative Properties, Solvay Specialty Polymers, and Avient Corp. leading research and development efforts. These firms are advancing neoprene formulations and processing techniques specifically for 3D printing applications. Academic institutions such as MIT and Northwestern University are also contributing to technological advancements, indicating a collaborative ecosystem driving innovation in this field.

3M Innovative Properties Co.

Technical Solution: 3M has developed a neoprene-based 3D printing filament that combines the flexibility and durability of neoprene with the precision of 3D printing. This material is designed for creating functional components with enhanced elastomeric properties. The company's approach involves modifying neoprene to improve its printability while maintaining its characteristic resilience. 3M's neoprene filament incorporates additives that enhance layer adhesion and reduce warping during the printing process[1]. The material is compatible with standard FDM (Fused Deposition Modeling) printers, making it accessible for a wide range of users. 3M has also developed specialized post-processing techniques to further improve the mechanical properties of printed neoprene parts, including heat treatment and chemical curing methods[3].

Strengths: Excellent flexibility and durability, improved printability of neoprene, compatibility with standard FDM printers. Weaknesses: May require specialized post-processing for optimal performance, potentially higher cost compared to traditional neoprene manufacturing.

Solvay Specialty Polymers USA LLC

Technical Solution: Solvay has introduced a high-performance neoprene powder specifically engineered for selective laser sintering (SLS) 3D printing. This innovative material combines the chemical resistance and flexibility of neoprene with the precision and complexity achievable through additive manufacturing. Solvay's neoprene powder features optimized particle size distribution and flow characteristics to ensure consistent layer formation during the SLS process[2]. The company has also developed proprietary additives that enhance the powder's laser absorption properties, resulting in improved print resolution and surface finish. Solvay's technology allows for the creation of complex geometries and internal structures that are difficult or impossible to achieve with traditional neoprene manufacturing methods[4]. The printed components exhibit excellent elasticity, tear resistance, and oil resistance, making them suitable for a wide range of industrial applications.

Strengths: High-performance material suitable for SLS printing, enables complex geometries, excellent chemical and mechanical properties. Weaknesses: Requires specialized SLS equipment, potentially higher material cost compared to traditional neoprene.

Core Innovations in Neoprene 3D Printing

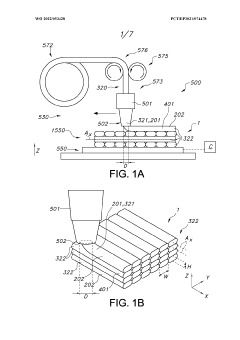

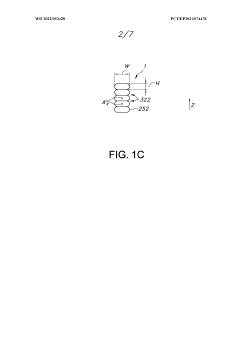

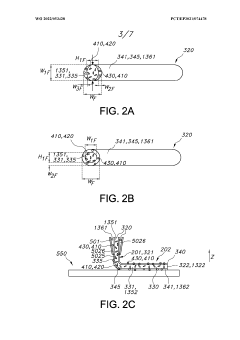

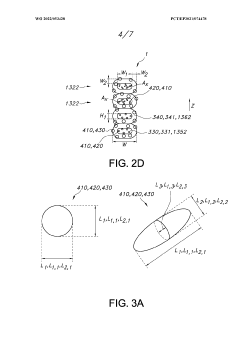

Retroreflective surface using 3D printing

PatentWO2022053428A1

Innovation

- A method using fused deposition modeling (FDM) to create a 3D item with a core-shell structure, where the shell material is transparent and transmissive for visible wavelengths, allowing at least part of the shell particles to protrude, achieving retroreflective properties by layer-wise depositing 3D printable material comprising core and shell materials with specific particle sizes and refractive indices.

Material Properties and Performance Analysis

Neoprene, a synthetic rubber known for its versatility, exhibits unique properties that make it a promising material for 3D printing of functional components. Its excellent elasticity and resilience allow for the creation of flexible yet durable parts. Neoprene's resistance to oil, grease, and many chemicals enhances its suitability for components exposed to harsh environments. The material's thermal stability across a wide temperature range (-40°C to 120°C) ensures consistent performance in various applications.

In 3D printing processes, neoprene demonstrates good layer adhesion, crucial for producing structurally sound components. Its low shrinkage rate during cooling contributes to dimensional accuracy and reduces the risk of warping. Neoprene's ability to maintain its properties over time, including resistance to weathering and ozone degradation, makes it ideal for long-lasting functional parts.

The material's shock-absorbing capabilities are particularly valuable in applications requiring vibration dampening or impact resistance. This property, combined with its flexibility, allows for the creation of complex geometries that can deform under stress and return to their original shape. Such characteristics are beneficial in producing components like gaskets, seals, and protective covers.

Neoprene's performance in 3D printing is further enhanced by its compatibility with various additives and fillers. These can be incorporated to modify specific properties such as electrical conductivity, flame retardancy, or UV resistance, expanding the range of potential applications. The material's ability to bond well with other substances also facilitates the production of multi-material components.

However, challenges exist in optimizing neoprene for 3D printing processes. The material's relatively high viscosity when melted can affect print resolution and surface finish. Careful control of printing parameters, including temperature, speed, and layer height, is essential to achieve optimal results. Additionally, post-processing techniques may be required to enhance the surface quality and mechanical properties of printed components.

Comparative analysis with other elastomeric materials used in 3D printing, such as TPU (Thermoplastic Polyurethane), reveals neoprene's advantages in chemical resistance and thermal stability. However, TPU often offers superior elasticity and tear resistance. The choice between these materials depends on the specific requirements of the intended application, highlighting the importance of thorough material selection in functional component design.

In 3D printing processes, neoprene demonstrates good layer adhesion, crucial for producing structurally sound components. Its low shrinkage rate during cooling contributes to dimensional accuracy and reduces the risk of warping. Neoprene's ability to maintain its properties over time, including resistance to weathering and ozone degradation, makes it ideal for long-lasting functional parts.

The material's shock-absorbing capabilities are particularly valuable in applications requiring vibration dampening or impact resistance. This property, combined with its flexibility, allows for the creation of complex geometries that can deform under stress and return to their original shape. Such characteristics are beneficial in producing components like gaskets, seals, and protective covers.

Neoprene's performance in 3D printing is further enhanced by its compatibility with various additives and fillers. These can be incorporated to modify specific properties such as electrical conductivity, flame retardancy, or UV resistance, expanding the range of potential applications. The material's ability to bond well with other substances also facilitates the production of multi-material components.

However, challenges exist in optimizing neoprene for 3D printing processes. The material's relatively high viscosity when melted can affect print resolution and surface finish. Careful control of printing parameters, including temperature, speed, and layer height, is essential to achieve optimal results. Additionally, post-processing techniques may be required to enhance the surface quality and mechanical properties of printed components.

Comparative analysis with other elastomeric materials used in 3D printing, such as TPU (Thermoplastic Polyurethane), reveals neoprene's advantages in chemical resistance and thermal stability. However, TPU often offers superior elasticity and tear resistance. The choice between these materials depends on the specific requirements of the intended application, highlighting the importance of thorough material selection in functional component design.

Environmental Impact and Sustainability Considerations

The integration of neoprene in 3D printing of functional components raises important environmental and sustainability considerations. Neoprene, a synthetic rubber, has both advantages and drawbacks in terms of its ecological impact. On the positive side, the use of neoprene in 3D printing can lead to more efficient material utilization compared to traditional manufacturing methods, potentially reducing waste and resource consumption.

However, the production of neoprene involves the use of petrochemicals, which contributes to carbon emissions and environmental pollution. The manufacturing process also requires significant energy inputs, further increasing its carbon footprint. As 3D printing with neoprene becomes more widespread, it is crucial to address these environmental concerns and explore more sustainable alternatives.

One approach to mitigating the environmental impact is the development of bio-based neoprene alternatives. Researchers are investigating the use of renewable resources, such as plant-based oils, to create neoprene-like materials with similar properties but reduced ecological footprints. These bio-based alternatives could potentially offer a more sustainable option for 3D printing applications.

Recycling and circular economy principles also play a vital role in improving the sustainability of neoprene-based 3D printing. Efforts are being made to develop effective recycling processes for neoprene products, allowing for the reuse of materials and reduction of waste. Implementing closed-loop systems in manufacturing and encouraging the return of used neoprene products can significantly enhance the overall sustainability of the industry.

The durability and longevity of neoprene components produced through 3D printing can contribute to sustainability by reducing the need for frequent replacements. This aspect is particularly relevant in industries where functional components are subjected to harsh conditions, such as marine or outdoor applications. By extending the lifespan of products, the overall environmental impact can be reduced.

Energy efficiency in the 3D printing process itself is another critical factor to consider. Optimizing printing parameters, such as temperature and speed, can help minimize energy consumption during production. Additionally, the development of more energy-efficient 3D printers specifically designed for neoprene and similar materials can further reduce the environmental footprint of the manufacturing process.

As the adoption of neoprene in 3D printing continues to grow, it is essential for manufacturers and researchers to prioritize sustainability considerations. This includes exploring eco-friendly material alternatives, improving recycling capabilities, and optimizing production processes to minimize environmental impact. By addressing these challenges, the industry can work towards more sustainable practices in the 3D printing of functional components using neoprene and related materials.

However, the production of neoprene involves the use of petrochemicals, which contributes to carbon emissions and environmental pollution. The manufacturing process also requires significant energy inputs, further increasing its carbon footprint. As 3D printing with neoprene becomes more widespread, it is crucial to address these environmental concerns and explore more sustainable alternatives.

One approach to mitigating the environmental impact is the development of bio-based neoprene alternatives. Researchers are investigating the use of renewable resources, such as plant-based oils, to create neoprene-like materials with similar properties but reduced ecological footprints. These bio-based alternatives could potentially offer a more sustainable option for 3D printing applications.

Recycling and circular economy principles also play a vital role in improving the sustainability of neoprene-based 3D printing. Efforts are being made to develop effective recycling processes for neoprene products, allowing for the reuse of materials and reduction of waste. Implementing closed-loop systems in manufacturing and encouraging the return of used neoprene products can significantly enhance the overall sustainability of the industry.

The durability and longevity of neoprene components produced through 3D printing can contribute to sustainability by reducing the need for frequent replacements. This aspect is particularly relevant in industries where functional components are subjected to harsh conditions, such as marine or outdoor applications. By extending the lifespan of products, the overall environmental impact can be reduced.

Energy efficiency in the 3D printing process itself is another critical factor to consider. Optimizing printing parameters, such as temperature and speed, can help minimize energy consumption during production. Additionally, the development of more energy-efficient 3D printers specifically designed for neoprene and similar materials can further reduce the environmental footprint of the manufacturing process.

As the adoption of neoprene in 3D printing continues to grow, it is essential for manufacturers and researchers to prioritize sustainability considerations. This includes exploring eco-friendly material alternatives, improving recycling capabilities, and optimizing production processes to minimize environmental impact. By addressing these challenges, the industry can work towards more sustainable practices in the 3D printing of functional components using neoprene and related materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!