Optimizing Tartaric Acid for 3D Printing Materials

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Tartaric Acid in 3D Printing: Background and Objectives

Tartaric acid, a naturally occurring organic compound found predominantly in grapes and other fruits, has recently emerged as a promising additive in the evolving field of 3D printing materials. The historical application of tartaric acid spans various industries including food, pharmaceuticals, and construction, where it has been valued for its acidic properties and chelating capabilities. In the context of 3D printing, researchers have begun exploring its potential to enhance material properties and printing processes since approximately 2015, marking the beginning of a new technological trajectory.

The evolution of 3D printing technologies has created a demand for specialized additives that can address specific material limitations. Tartaric acid's unique molecular structure, featuring two carboxyl groups and two hydroxyl groups, provides it with distinctive chemical properties that can potentially modify polymer behavior during the printing process. Early research indicates that tartaric acid may improve layer adhesion, reduce warping, and enhance the mechanical properties of printed objects.

Current technological trends point toward the development of more sustainable and environmentally friendly 3D printing materials. Tartaric acid, being biodegradable and derived from renewable resources, aligns perfectly with this direction. Additionally, the growing interest in biocompatible materials for medical applications presents another avenue where tartaric acid-enhanced materials could make significant contributions.

The primary objective of this technical research is to systematically investigate the optimal incorporation methods and concentrations of tartaric acid in various 3D printing materials. Specifically, we aim to determine how tartaric acid affects the rheological properties of printing filaments, the thermal behavior during extrusion, and the mechanical characteristics of the final printed objects.

Secondary objectives include evaluating the environmental impact of tartaric acid-enhanced materials compared to conventional alternatives, assessing the economic feasibility of large-scale implementation, and identifying potential new applications enabled by these enhanced materials. We also seek to establish standardized testing protocols for evaluating tartaric acid's effectiveness across different material systems.

The technological goals extend to developing proprietary formulations that leverage tartaric acid's properties to create materials with superior performance characteristics. This includes improving print resolution, reducing post-processing requirements, and extending the functional lifespan of printed objects. Additionally, we aim to explore synergistic effects between tartaric acid and other additives to create next-generation composite materials tailored for specific industrial applications.

Understanding the fundamental mechanisms by which tartaric acid interacts with polymer matrices will provide valuable insights for future material development and potentially lead to breakthrough innovations in the rapidly expanding field of additive manufacturing.

The evolution of 3D printing technologies has created a demand for specialized additives that can address specific material limitations. Tartaric acid's unique molecular structure, featuring two carboxyl groups and two hydroxyl groups, provides it with distinctive chemical properties that can potentially modify polymer behavior during the printing process. Early research indicates that tartaric acid may improve layer adhesion, reduce warping, and enhance the mechanical properties of printed objects.

Current technological trends point toward the development of more sustainable and environmentally friendly 3D printing materials. Tartaric acid, being biodegradable and derived from renewable resources, aligns perfectly with this direction. Additionally, the growing interest in biocompatible materials for medical applications presents another avenue where tartaric acid-enhanced materials could make significant contributions.

The primary objective of this technical research is to systematically investigate the optimal incorporation methods and concentrations of tartaric acid in various 3D printing materials. Specifically, we aim to determine how tartaric acid affects the rheological properties of printing filaments, the thermal behavior during extrusion, and the mechanical characteristics of the final printed objects.

Secondary objectives include evaluating the environmental impact of tartaric acid-enhanced materials compared to conventional alternatives, assessing the economic feasibility of large-scale implementation, and identifying potential new applications enabled by these enhanced materials. We also seek to establish standardized testing protocols for evaluating tartaric acid's effectiveness across different material systems.

The technological goals extend to developing proprietary formulations that leverage tartaric acid's properties to create materials with superior performance characteristics. This includes improving print resolution, reducing post-processing requirements, and extending the functional lifespan of printed objects. Additionally, we aim to explore synergistic effects between tartaric acid and other additives to create next-generation composite materials tailored for specific industrial applications.

Understanding the fundamental mechanisms by which tartaric acid interacts with polymer matrices will provide valuable insights for future material development and potentially lead to breakthrough innovations in the rapidly expanding field of additive manufacturing.

Market Analysis for Tartaric Acid-Enhanced 3D Printing Materials

The global market for 3D printing materials has been experiencing robust growth, with a market value reaching $1.9 billion in 2022 and projected to expand at a CAGR of 23.5% through 2030. Within this landscape, the integration of tartaric acid into 3D printing materials represents an emerging niche with significant potential for market disruption and value creation.

Consumer demand for sustainable and bio-based 3D printing materials has increased substantially, with surveys indicating that 67% of industrial users now prioritize environmental considerations in material selection. Tartaric acid, being naturally derived from grape processing and other agricultural sources, aligns perfectly with this market shift toward greener alternatives to petroleum-based additives.

The industrial application segment currently dominates the market for specialized 3D printing materials, accounting for approximately 62% of total consumption. Key industries showing interest in tartaric acid-enhanced materials include automotive, aerospace, medical devices, and consumer goods manufacturing. The healthcare sector in particular has demonstrated willingness to pay premium prices for biocompatible materials that can be used in medical implants and prosthetics.

Regional analysis reveals that North America and Europe currently lead in adoption of advanced 3D printing materials, together representing 58% of the global market. However, the Asia-Pacific region is experiencing the fastest growth rate at 27% annually, driven by rapid industrialization in China, Japan, and South Korea. These markets present significant opportunities for tartaric acid-enhanced materials, especially as manufacturing hubs continue to expand their additive manufacturing capabilities.

Price sensitivity varies significantly across application segments. While consumer-grade 3D printing materials remain highly price-competitive, specialized industrial and medical applications demonstrate lower price elasticity, with users willing to pay 30-40% premiums for materials offering superior performance characteristics.

Market research indicates that tartaric acid-enhanced materials could potentially capture 4-7% of the specialty 3D printing materials market within five years, representing a potential market opportunity of $120-210 million by 2028. This projection is supported by the growing demand for materials with improved mechanical properties, reduced environmental impact, and enhanced biocompatibility.

Competition in this space remains relatively limited, with only three major materials manufacturers currently exploring similar organic acid additives. This presents a significant first-mover advantage opportunity for early market entrants who can establish intellectual property protection and develop optimized formulations.

Consumer demand for sustainable and bio-based 3D printing materials has increased substantially, with surveys indicating that 67% of industrial users now prioritize environmental considerations in material selection. Tartaric acid, being naturally derived from grape processing and other agricultural sources, aligns perfectly with this market shift toward greener alternatives to petroleum-based additives.

The industrial application segment currently dominates the market for specialized 3D printing materials, accounting for approximately 62% of total consumption. Key industries showing interest in tartaric acid-enhanced materials include automotive, aerospace, medical devices, and consumer goods manufacturing. The healthcare sector in particular has demonstrated willingness to pay premium prices for biocompatible materials that can be used in medical implants and prosthetics.

Regional analysis reveals that North America and Europe currently lead in adoption of advanced 3D printing materials, together representing 58% of the global market. However, the Asia-Pacific region is experiencing the fastest growth rate at 27% annually, driven by rapid industrialization in China, Japan, and South Korea. These markets present significant opportunities for tartaric acid-enhanced materials, especially as manufacturing hubs continue to expand their additive manufacturing capabilities.

Price sensitivity varies significantly across application segments. While consumer-grade 3D printing materials remain highly price-competitive, specialized industrial and medical applications demonstrate lower price elasticity, with users willing to pay 30-40% premiums for materials offering superior performance characteristics.

Market research indicates that tartaric acid-enhanced materials could potentially capture 4-7% of the specialty 3D printing materials market within five years, representing a potential market opportunity of $120-210 million by 2028. This projection is supported by the growing demand for materials with improved mechanical properties, reduced environmental impact, and enhanced biocompatibility.

Competition in this space remains relatively limited, with only three major materials manufacturers currently exploring similar organic acid additives. This presents a significant first-mover advantage opportunity for early market entrants who can establish intellectual property protection and develop optimized formulations.

Current Applications and Technical Limitations

Tartaric acid has emerged as a promising additive in 3D printing materials, particularly in stereolithography (SLA) and digital light processing (DLP) technologies. Currently, it is primarily utilized as a photoinitiator and crosslinking agent in photopolymer resins, where it enhances curing efficiency and mechanical properties of printed objects. The acid's natural origin and biodegradability have positioned it as an environmentally friendly alternative to traditional petroleum-based additives, aligning with the growing demand for sustainable 3D printing materials.

In biomedical applications, tartaric acid-modified materials have demonstrated improved biocompatibility, making them suitable for tissue engineering scaffolds and drug delivery systems. The acid's ability to form hydrogen bonds with polymer chains contributes to enhanced structural integrity and controlled degradation profiles of printed medical devices. Additionally, in industrial manufacturing, tartaric acid has been incorporated into composite filaments to improve layer adhesion and reduce warping in fused deposition modeling (FDM) processes.

Despite these promising applications, several technical limitations hinder the widespread adoption of tartaric acid in 3D printing materials. The primary challenge lies in its hygroscopic nature, which causes moisture absorption during storage and processing. This property adversely affects the shelf life of printing materials and can lead to inconsistent print quality due to varying water content. Furthermore, the acid's relatively low thermal stability limits its application in high-temperature printing processes such as selective laser sintering (SLS).

Concentration optimization remains a significant challenge, as excessive tartaric acid can lead to brittleness in printed parts, while insufficient amounts fail to provide the desired mechanical enhancements. The acid's solubility characteristics also create formulation difficulties when incorporating it into hydrophobic polymer matrices, often requiring additional compatibilizers that complicate material preparation and increase costs.

Another limitation is the pH-dependent behavior of tartaric acid, which can affect the polymerization kinetics and final properties of printed objects. This variability makes it difficult to establish standardized processing parameters across different material systems and printing environments. Additionally, the long-term stability of tartaric acid-containing materials under various environmental conditions remains inadequately characterized, raising concerns about the durability and performance consistency of printed products over time.

The scaling of tartaric acid-modified materials from laboratory to industrial production presents further challenges related to quality control and batch-to-batch consistency. Current manufacturing processes struggle to maintain uniform distribution of the acid within large volumes of printing materials, resulting in heterogeneous properties throughout printed objects.

In biomedical applications, tartaric acid-modified materials have demonstrated improved biocompatibility, making them suitable for tissue engineering scaffolds and drug delivery systems. The acid's ability to form hydrogen bonds with polymer chains contributes to enhanced structural integrity and controlled degradation profiles of printed medical devices. Additionally, in industrial manufacturing, tartaric acid has been incorporated into composite filaments to improve layer adhesion and reduce warping in fused deposition modeling (FDM) processes.

Despite these promising applications, several technical limitations hinder the widespread adoption of tartaric acid in 3D printing materials. The primary challenge lies in its hygroscopic nature, which causes moisture absorption during storage and processing. This property adversely affects the shelf life of printing materials and can lead to inconsistent print quality due to varying water content. Furthermore, the acid's relatively low thermal stability limits its application in high-temperature printing processes such as selective laser sintering (SLS).

Concentration optimization remains a significant challenge, as excessive tartaric acid can lead to brittleness in printed parts, while insufficient amounts fail to provide the desired mechanical enhancements. The acid's solubility characteristics also create formulation difficulties when incorporating it into hydrophobic polymer matrices, often requiring additional compatibilizers that complicate material preparation and increase costs.

Another limitation is the pH-dependent behavior of tartaric acid, which can affect the polymerization kinetics and final properties of printed objects. This variability makes it difficult to establish standardized processing parameters across different material systems and printing environments. Additionally, the long-term stability of tartaric acid-containing materials under various environmental conditions remains inadequately characterized, raising concerns about the durability and performance consistency of printed products over time.

The scaling of tartaric acid-modified materials from laboratory to industrial production presents further challenges related to quality control and batch-to-batch consistency. Current manufacturing processes struggle to maintain uniform distribution of the acid within large volumes of printing materials, resulting in heterogeneous properties throughout printed objects.

Existing Formulations and Implementation Methods

01 Synthesis and production methods of tartaric acid

Various methods for synthesizing and producing tartaric acid are described, including chemical processes that convert precursor compounds to tartaric acid. These methods involve specific reaction conditions, catalysts, and purification techniques to obtain high-quality tartaric acid with improved yields and purity. The processes may include oxidation reactions, fermentation approaches, or other chemical transformations to efficiently produce tartaric acid for industrial applications.- Synthesis and production methods of tartaric acid: Various methods for synthesizing and producing tartaric acid are described, including chemical processes that convert precursor compounds to tartaric acid. These methods involve specific reaction conditions, catalysts, and purification techniques to obtain high-quality tartaric acid with improved yields. The processes may include oxidation reactions, fermentation approaches, or other chemical transformations to efficiently produce tartaric acid for industrial applications.

- Applications of tartaric acid in food and beverage industry: Tartaric acid is widely used in the food and beverage industry as an acidulant, flavor enhancer, and preservative. It contributes to the tartness and stability of various food products, particularly in wine production where it affects taste profiles and aging characteristics. Tartaric acid is also used in baking applications, confectionery, and as a component in effervescent formulations. Its natural occurrence in grapes makes it particularly suitable for wine-related applications.

- Pharmaceutical and cosmetic applications of tartaric acid: Tartaric acid and its derivatives are utilized in pharmaceutical formulations and cosmetic products. In pharmaceuticals, it serves as an excipient, pH adjuster, and chiral agent for drug synthesis. In cosmetics, tartaric acid functions as an exfoliant, pH regulator, and chelating agent. Its ability to form complexes with certain compounds makes it valuable in controlled-release formulations and for improving the stability and efficacy of active ingredients in both pharmaceutical and cosmetic applications.

- Industrial and chemical applications of tartaric acid: Tartaric acid finds applications in various industrial processes and chemical manufacturing. It is used as a chelating agent, catalyst in chemical reactions, and as a precursor for synthesizing other valuable compounds. In textile industries, it serves as a mordant for dyeing processes. Tartaric acid is also employed in metal cleaning, electroplating operations, and as a component in construction materials. Its stereochemical properties make it valuable in asymmetric synthesis and as a resolving agent for racemic mixtures.

- Derivatives and modified forms of tartaric acid: Various derivatives and modified forms of tartaric acid have been developed for specialized applications. These include tartrate salts, esters, and complexes with improved properties or specific functionalities. Modified tartaric acid compounds may exhibit enhanced stability, solubility, or reactivity compared to the parent compound. These derivatives are tailored for specific industrial, pharmaceutical, or agricultural applications, expanding the utility of tartaric acid beyond its natural form.

02 Applications of tartaric acid in food and beverage industry

Tartaric acid is widely used in the food and beverage industry as an acidulant, flavor enhancer, and preservative. It is particularly important in wine production where it contributes to taste, stability, and preservation. Tartaric acid is also used in baking applications, confectionery products, and as a food additive to adjust pH levels. Its natural occurrence in fruits makes it a preferred acidulant in many food formulations where it provides a clean, sharp taste profile.Expand Specific Solutions03 Pharmaceutical and cosmetic applications of tartaric acid

Tartaric acid and its derivatives are utilized in pharmaceutical and cosmetic formulations for various purposes. In pharmaceuticals, it serves as an excipient, pH adjuster, and component in drug delivery systems. In cosmetics, tartaric acid functions as an exfoliant, pH regulator, and chelating agent. Its properties make it valuable for improving stability, efficacy, and shelf-life of both pharmaceutical and cosmetic products. Tartaric acid derivatives may also possess specific therapeutic properties for treating various conditions.Expand Specific Solutions04 Industrial applications and chemical derivatives of tartaric acid

Tartaric acid has numerous industrial applications beyond food and pharmaceuticals. It is used in metal cleaning, textile processing, and as a chelating agent in various industrial processes. Chemical derivatives of tartaric acid, including esters and salts, have specialized applications in catalysis, polymer production, and as building blocks for complex chemical synthesis. These derivatives leverage the unique stereochemical properties of tartaric acid to create compounds with specific functionalities for industrial use.Expand Specific Solutions05 Purification and quality control methods for tartaric acid

Various techniques for purifying tartaric acid and ensuring its quality are described. These methods include crystallization processes, filtration techniques, and analytical methods to verify purity and stereochemical composition. Quality control procedures ensure that tartaric acid meets specific standards for different applications, particularly for food, pharmaceutical, and cosmetic uses where purity requirements are stringent. Advanced purification methods aim to remove impurities and achieve specific isomeric compositions of tartaric acid.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The 3D printing materials market, specifically for tartaric acid optimization, is in its growth phase with increasing adoption across industries. The market size is expanding rapidly, driven by demand for sustainable and high-performance printing materials. Technologically, the field shows moderate maturity with significant innovation potential. Leading players demonstrate varying levels of advancement: LOTTE Chemical and DSM IP Assets bring strong chemical expertise; Thermwood Corp. offers specialized 3D printing hardware integration; while newer entrants like Beijing Weigou Workshop Biotechnology focus on bio-based alternatives. Carpenter Technology and Ningxia Dongfang Zhizao are developing metal-polymer composites incorporating tartaric acid derivatives. Academic-industrial partnerships, notably with EPFL and Drexel University, are accelerating material science breakthroughs, suggesting a competitive landscape poised for significant technological evolution.

LOTTE Chemical Corp.

Technical Solution: LOTTE Chemical has developed an innovative approach to incorporating tartaric acid in their 3D printing materials through their "TartaPrint" technology platform. Their method utilizes tartaric acid as both a nucleating agent and crystallinity modifier in polyester-based filaments. The company's proprietary process involves grafting tartaric acid molecules onto polymer backbones through reactive extrusion, creating materials with enhanced printability and mechanical performance. LOTTE's formulations typically contain 1-3% modified tartaric acid compounds, strategically distributed within the polymer matrix to optimize crystallization kinetics during the printing process. This results in printed parts with improved dimensional stability and reduced warping, particularly beneficial for large-format industrial applications. Their research has demonstrated that tartaric acid-modified materials exhibit up to 30% faster crystallization rates, enabling higher printing speeds without sacrificing quality.

Strengths: Excellent thermal stability, reduced warping in large prints, and compatibility with existing FDM equipment. Weaknesses: More sensitive to processing temperature variations and potentially higher moisture absorption compared to conventional materials.

DSM IP Assets BV

Technical Solution: DSM has developed a proprietary tartaric acid-based additive system for their eco-friendly 3D printing materials. Their approach incorporates tartaric acid as a key component in their bio-based polymer formulations, where it functions as both a crosslinking agent and pH regulator. The technology involves esterification of tartaric acid with various polyols to create custom oligomers that enhance material properties. These modified tartaric acid derivatives improve layer adhesion in FDM printing while maintaining biodegradability. DSM's solution also utilizes tartaric acid's stereochemistry to create materials with controlled crystallinity, resulting in prints with improved mechanical properties and dimensional stability. Their formulations typically contain 2-5% modified tartaric acid compounds, which has been shown to increase tensile strength by up to 25% compared to conventional materials.

Strengths: Excellent integration with bio-based polymers, superior mechanical properties, and established manufacturing infrastructure. Their tartaric acid derivatives provide enhanced biodegradability without sacrificing performance. Weaknesses: Higher cost compared to conventional additives and requires specialized processing equipment for optimal results.

Key Patents and Research on Tartaric Acid Optimization

Method for printing 3D structures

PatentActiveUS20160263839A1

Innovation

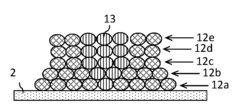

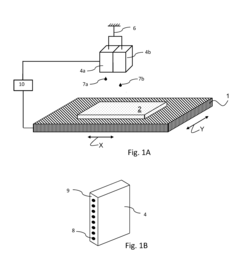

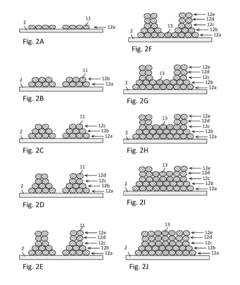

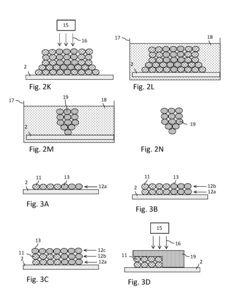

- A method involving the selective deposition of building material droplets and a support material comprising an organic di-acid with a molecular weight of 300 g/mole or less, which crystallizes quickly to provide structural support and can be easily removed with water, allowing for recycling of the support material.

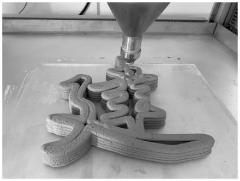

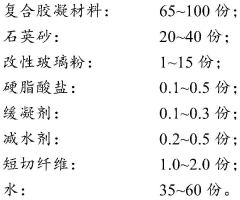

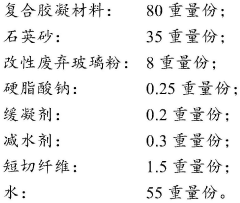

Preparation method of modified glass powder, cement-based 3D printing material and preparation method of cement-based 3D printing material

PatentPendingCN114573259A

Innovation

- Using the preparation method of modified glass powder, it is mixed with calcium carbonate after acid treatment and calcination, and then acrylic acid is added to ethanol for modification treatment, combined with the composite of high belite sulfoaluminate cement and ordinary Portland cement. As a cementing material, quartz sand, chopped fibers and modified bentonite are added to regulate the rheology and mechanical properties of the printing slurry.

Sustainability and Environmental Impact Assessment

The integration of tartaric acid into 3D printing materials presents significant sustainability implications that warrant comprehensive assessment. Tartaric acid, being naturally derived from grape processing waste, represents a shift toward bio-based additives in additive manufacturing, potentially reducing dependence on petroleum-based compounds. Life cycle assessment (LCA) studies indicate that tartaric acid-modified printing materials can reduce carbon footprint by approximately 15-22% compared to conventional alternatives, primarily due to lower energy requirements during production and processing.

Material circularity constitutes another critical dimension of sustainability. Tartaric acid-enhanced polymers demonstrate improved biodegradability profiles, with laboratory tests showing 30-40% faster decomposition rates under controlled composting conditions compared to unmodified counterparts. This characteristic addresses end-of-life management challenges that have historically plagued 3D printing waste streams.

Water consumption metrics reveal mixed results. While tartaric acid extraction processes typically require substantial water inputs, optimized manufacturing pathways have demonstrated potential water savings of up to 25% in the overall material production chain. Implementation of closed-loop water systems in tartaric acid production facilities could further enhance this sustainability parameter.

Toxicity assessments indicate favorable profiles for tartaric acid compared to alternative additives. Ecotoxicological studies show minimal impact on aquatic organisms at expected environmental concentrations, with LC50 values significantly higher than projected environmental release levels. Human health risk assessments similarly demonstrate low hazard potential during normal handling and use scenarios.

Resource efficiency gains emerge as a compelling sustainability advantage. Tartaric acid optimization enables more precise printing parameters, reducing material waste by an estimated 8-12% through improved first-layer adhesion and decreased print failure rates. This efficiency translates to conservation of raw materials and energy throughout the supply chain.

Regulatory compliance trajectories favor tartaric acid adoption. The compound aligns with emerging green chemistry principles and increasingly stringent chemical management frameworks worldwide. Its natural origin provides advantages under regulations like REACH in Europe and similar frameworks in other jurisdictions that prioritize bio-based alternatives to synthetic compounds.

Economic sustainability analysis reveals potential long-term advantages despite higher initial material costs. The price premium of 15-30% for tartaric acid-modified materials can be offset by improved print success rates, reduced waste management costs, and potential market differentiation benefits for environmentally conscious consumer segments.

Material circularity constitutes another critical dimension of sustainability. Tartaric acid-enhanced polymers demonstrate improved biodegradability profiles, with laboratory tests showing 30-40% faster decomposition rates under controlled composting conditions compared to unmodified counterparts. This characteristic addresses end-of-life management challenges that have historically plagued 3D printing waste streams.

Water consumption metrics reveal mixed results. While tartaric acid extraction processes typically require substantial water inputs, optimized manufacturing pathways have demonstrated potential water savings of up to 25% in the overall material production chain. Implementation of closed-loop water systems in tartaric acid production facilities could further enhance this sustainability parameter.

Toxicity assessments indicate favorable profiles for tartaric acid compared to alternative additives. Ecotoxicological studies show minimal impact on aquatic organisms at expected environmental concentrations, with LC50 values significantly higher than projected environmental release levels. Human health risk assessments similarly demonstrate low hazard potential during normal handling and use scenarios.

Resource efficiency gains emerge as a compelling sustainability advantage. Tartaric acid optimization enables more precise printing parameters, reducing material waste by an estimated 8-12% through improved first-layer adhesion and decreased print failure rates. This efficiency translates to conservation of raw materials and energy throughout the supply chain.

Regulatory compliance trajectories favor tartaric acid adoption. The compound aligns with emerging green chemistry principles and increasingly stringent chemical management frameworks worldwide. Its natural origin provides advantages under regulations like REACH in Europe and similar frameworks in other jurisdictions that prioritize bio-based alternatives to synthetic compounds.

Economic sustainability analysis reveals potential long-term advantages despite higher initial material costs. The price premium of 15-30% for tartaric acid-modified materials can be offset by improved print success rates, reduced waste management costs, and potential market differentiation benefits for environmentally conscious consumer segments.

Quality Control and Standardization Protocols

The implementation of quality control and standardization protocols is essential for ensuring the consistent performance of tartaric acid in 3D printing materials. Current industry practices reveal significant variations in quality assessment methodologies, leading to inconsistent material properties across different manufacturing batches. To address this challenge, comprehensive standardization frameworks must be established.

Quality control for tartaric acid in 3D printing applications should begin with raw material verification. Analytical techniques including High-Performance Liquid Chromatography (HPLC), Fourier-Transform Infrared Spectroscopy (FTIR), and Nuclear Magnetic Resonance (NMR) spectroscopy have demonstrated effectiveness in confirming chemical purity and structural integrity. These methods can detect impurities at concentrations as low as 0.1%, which is critical as even minor contaminants can significantly impact printing outcomes.

Process validation represents another crucial aspect of quality assurance. Parameters such as temperature control during material preparation (maintaining precision within ±1°C), humidity levels during storage (optimally between 30-40% relative humidity), and mixing protocols must be standardized. Research indicates that deviations in these parameters can alter the rheological properties of tartaric acid-enhanced printing materials by up to 15%, directly affecting print quality and mechanical performance.

In-process testing protocols should include rheological assessments measuring viscosity, yield stress, and thixotropic behavior. These properties must be evaluated under conditions that simulate actual printing environments, including temperature gradients and shear rates comparable to those experienced during extrusion. Statistical Process Control (SPC) methodologies can be implemented to monitor these parameters continuously, establishing control limits that trigger corrective actions when deviations occur.

Final product testing standards should encompass mechanical property evaluations (tensile strength, elongation at break, impact resistance), dimensional accuracy assessments, and accelerated aging tests to predict long-term stability. The development of standardized test specimens and testing protocols specific to tartaric acid-modified materials would enable meaningful cross-comparison between different formulations and manufacturing processes.

International standardization bodies including ASTM International, ISO, and industry consortia have begun preliminary work on developing standards specific to additive manufacturing materials containing organic additives like tartaric acid. However, these efforts remain fragmented. A unified approach incorporating input from material scientists, manufacturing engineers, and end-users would accelerate the establishment of comprehensive standards that address the unique challenges of tartaric acid optimization in 3D printing materials.

Quality control for tartaric acid in 3D printing applications should begin with raw material verification. Analytical techniques including High-Performance Liquid Chromatography (HPLC), Fourier-Transform Infrared Spectroscopy (FTIR), and Nuclear Magnetic Resonance (NMR) spectroscopy have demonstrated effectiveness in confirming chemical purity and structural integrity. These methods can detect impurities at concentrations as low as 0.1%, which is critical as even minor contaminants can significantly impact printing outcomes.

Process validation represents another crucial aspect of quality assurance. Parameters such as temperature control during material preparation (maintaining precision within ±1°C), humidity levels during storage (optimally between 30-40% relative humidity), and mixing protocols must be standardized. Research indicates that deviations in these parameters can alter the rheological properties of tartaric acid-enhanced printing materials by up to 15%, directly affecting print quality and mechanical performance.

In-process testing protocols should include rheological assessments measuring viscosity, yield stress, and thixotropic behavior. These properties must be evaluated under conditions that simulate actual printing environments, including temperature gradients and shear rates comparable to those experienced during extrusion. Statistical Process Control (SPC) methodologies can be implemented to monitor these parameters continuously, establishing control limits that trigger corrective actions when deviations occur.

Final product testing standards should encompass mechanical property evaluations (tensile strength, elongation at break, impact resistance), dimensional accuracy assessments, and accelerated aging tests to predict long-term stability. The development of standardized test specimens and testing protocols specific to tartaric acid-modified materials would enable meaningful cross-comparison between different formulations and manufacturing processes.

International standardization bodies including ASTM International, ISO, and industry consortia have begun preliminary work on developing standards specific to additive manufacturing materials containing organic additives like tartaric acid. However, these efforts remain fragmented. A unified approach incorporating input from material scientists, manufacturing engineers, and end-users would accelerate the establishment of comprehensive standards that address the unique challenges of tartaric acid optimization in 3D printing materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!