How to Integrate Tartaric Acid in Biodegradable Plastics

AUG 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Tartaric Acid in Bioplastics: Background and Objectives

Tartaric acid, a naturally occurring organic compound found predominantly in grapes and other fruits, has emerged as a promising additive in the evolving field of biodegradable plastics. The integration of this dihydroxy dicarboxylic acid into bioplastic formulations represents a convergence of green chemistry principles with sustainable materials science. Historically, conventional plastics derived from petroleum have dominated global markets due to their durability, versatility, and cost-effectiveness. However, the environmental consequences of these non-biodegradable materials have catalyzed research into alternative, eco-friendly solutions.

The evolution of biodegradable plastics has progressed through several distinct phases since the 1990s, beginning with simple starch-based composites and advancing to sophisticated polymer blends with enhanced mechanical properties. Recent technological developments have focused on improving the performance characteristics of bioplastics to match or exceed those of traditional plastics while maintaining biodegradability. Tartaric acid integration represents the next frontier in this technological progression.

Tartaric acid possesses unique stereochemical properties and functional group arrangements that make it particularly valuable for bioplastic applications. Its hydroxyl and carboxyl groups enable it to participate in various chemical reactions, potentially serving as a cross-linking agent, plasticizer, or chain extender in biopolymer systems. The compound's natural origin aligns perfectly with the sustainability objectives of biodegradable plastic development.

The primary technical objectives for tartaric acid integration in biodegradable plastics encompass several dimensions. First, researchers aim to establish optimal incorporation methodologies that preserve the acid's functional properties while ensuring homogeneous distribution throughout the polymer matrix. Second, there is a focus on understanding the influence of tartaric acid on the mechanical properties, thermal stability, and degradation kinetics of the resulting materials. Third, scientists seek to quantify the environmental benefits of tartaric acid-modified bioplastics compared to conventional alternatives.

Current research trends indicate growing interest in utilizing tartaric acid derivatives for enhancing the compatibility between different biopolymers in blended systems. Additionally, the compound's potential to improve moisture resistance—a traditional weakness of many bioplastics—has attracted significant attention. The stereochemistry of tartaric acid also presents opportunities for creating materials with tailored crystallinity and degradation profiles.

Looking forward, the integration of tartaric acid in biodegradable plastics aims to address key industry challenges, including cost-effectiveness, scalability, and performance consistency. The ultimate goal is to develop commercially viable bioplastic formulations that incorporate tartaric acid to enhance biodegradability while maintaining or improving functional properties, thereby accelerating the transition away from petroleum-based plastics toward more sustainable alternatives.

The evolution of biodegradable plastics has progressed through several distinct phases since the 1990s, beginning with simple starch-based composites and advancing to sophisticated polymer blends with enhanced mechanical properties. Recent technological developments have focused on improving the performance characteristics of bioplastics to match or exceed those of traditional plastics while maintaining biodegradability. Tartaric acid integration represents the next frontier in this technological progression.

Tartaric acid possesses unique stereochemical properties and functional group arrangements that make it particularly valuable for bioplastic applications. Its hydroxyl and carboxyl groups enable it to participate in various chemical reactions, potentially serving as a cross-linking agent, plasticizer, or chain extender in biopolymer systems. The compound's natural origin aligns perfectly with the sustainability objectives of biodegradable plastic development.

The primary technical objectives for tartaric acid integration in biodegradable plastics encompass several dimensions. First, researchers aim to establish optimal incorporation methodologies that preserve the acid's functional properties while ensuring homogeneous distribution throughout the polymer matrix. Second, there is a focus on understanding the influence of tartaric acid on the mechanical properties, thermal stability, and degradation kinetics of the resulting materials. Third, scientists seek to quantify the environmental benefits of tartaric acid-modified bioplastics compared to conventional alternatives.

Current research trends indicate growing interest in utilizing tartaric acid derivatives for enhancing the compatibility between different biopolymers in blended systems. Additionally, the compound's potential to improve moisture resistance—a traditional weakness of many bioplastics—has attracted significant attention. The stereochemistry of tartaric acid also presents opportunities for creating materials with tailored crystallinity and degradation profiles.

Looking forward, the integration of tartaric acid in biodegradable plastics aims to address key industry challenges, including cost-effectiveness, scalability, and performance consistency. The ultimate goal is to develop commercially viable bioplastic formulations that incorporate tartaric acid to enhance biodegradability while maintaining or improving functional properties, thereby accelerating the transition away from petroleum-based plastics toward more sustainable alternatives.

Market Analysis for Tartaric Acid-Enhanced Biodegradable Plastics

The global market for biodegradable plastics has experienced significant growth in recent years, driven by increasing environmental concerns and regulatory pressures to reduce plastic waste. The biodegradable plastics market was valued at approximately $6.1 billion in 2022 and is projected to reach $12.9 billion by 2028, growing at a CAGR of 13.2% during the forecast period.

The integration of tartaric acid into biodegradable plastics represents an emerging market opportunity within this broader sector. Tartaric acid, a naturally occurring organic acid found in grapes and other fruits, offers several advantages when incorporated into biodegradable plastic formulations, including enhanced biodegradability, improved mechanical properties, and potential antimicrobial effects.

Consumer demand for sustainable packaging solutions continues to rise across various industries, particularly in food and beverage, cosmetics, and consumer goods. Market research indicates that 73% of global consumers are willing to pay more for sustainable packaging, creating a favorable environment for tartaric acid-enhanced biodegradable plastics.

The food packaging segment currently dominates the biodegradable plastics market, accounting for approximately 45% of total market share. This segment presents the most immediate opportunity for tartaric acid-enhanced biodegradable plastics due to tartaric acid's food-grade status and potential preservation properties.

Regional analysis shows Europe leading the market for biodegradable plastics with a 38% market share, followed by North America (29%) and Asia-Pacific (24%). The European market is particularly promising for tartaric acid-enhanced biodegradable plastics due to stringent regulations on single-use plastics and strong consumer environmental awareness.

Key market drivers include increasing government regulations restricting conventional plastics, growing consumer awareness about environmental issues, and corporate sustainability commitments. Major retailers and consumer goods companies have pledged to use 100% recyclable, reusable, or compostable packaging by 2025, creating substantial market pull for innovative biodegradable solutions.

Challenges in the market include price competitiveness, as tartaric acid-enhanced biodegradable plastics currently cost 20-30% more than conventional alternatives. Additionally, performance limitations in certain applications and inconsistent waste management infrastructure across regions may impede market growth.

The competitive landscape features established biodegradable plastic manufacturers seeking differentiation through enhanced formulations, creating partnership opportunities for tartaric acid suppliers. Several pilot projects incorporating organic acids into bioplastic formulations have demonstrated commercial potential, suggesting a receptive market for tartaric acid integration.

The integration of tartaric acid into biodegradable plastics represents an emerging market opportunity within this broader sector. Tartaric acid, a naturally occurring organic acid found in grapes and other fruits, offers several advantages when incorporated into biodegradable plastic formulations, including enhanced biodegradability, improved mechanical properties, and potential antimicrobial effects.

Consumer demand for sustainable packaging solutions continues to rise across various industries, particularly in food and beverage, cosmetics, and consumer goods. Market research indicates that 73% of global consumers are willing to pay more for sustainable packaging, creating a favorable environment for tartaric acid-enhanced biodegradable plastics.

The food packaging segment currently dominates the biodegradable plastics market, accounting for approximately 45% of total market share. This segment presents the most immediate opportunity for tartaric acid-enhanced biodegradable plastics due to tartaric acid's food-grade status and potential preservation properties.

Regional analysis shows Europe leading the market for biodegradable plastics with a 38% market share, followed by North America (29%) and Asia-Pacific (24%). The European market is particularly promising for tartaric acid-enhanced biodegradable plastics due to stringent regulations on single-use plastics and strong consumer environmental awareness.

Key market drivers include increasing government regulations restricting conventional plastics, growing consumer awareness about environmental issues, and corporate sustainability commitments. Major retailers and consumer goods companies have pledged to use 100% recyclable, reusable, or compostable packaging by 2025, creating substantial market pull for innovative biodegradable solutions.

Challenges in the market include price competitiveness, as tartaric acid-enhanced biodegradable plastics currently cost 20-30% more than conventional alternatives. Additionally, performance limitations in certain applications and inconsistent waste management infrastructure across regions may impede market growth.

The competitive landscape features established biodegradable plastic manufacturers seeking differentiation through enhanced formulations, creating partnership opportunities for tartaric acid suppliers. Several pilot projects incorporating organic acids into bioplastic formulations have demonstrated commercial potential, suggesting a receptive market for tartaric acid integration.

Technical Challenges in Tartaric Acid-Bioplastic Integration

The integration of tartaric acid into biodegradable plastics presents several significant technical challenges that must be addressed for successful implementation. One primary obstacle is the hydrophilic nature of tartaric acid, which conflicts with the predominantly hydrophobic character of most biopolymer matrices. This incompatibility leads to phase separation during processing, resulting in non-uniform distribution of tartaric acid within the plastic matrix and compromising the mechanical properties of the final product.

Processing temperature mismatches create another substantial hurdle. Tartaric acid has a relatively low melting point (approximately 170°C) compared to the processing temperatures required for many biodegradable polymers such as PLA (polylactic acid), which typically requires temperatures of 180-220°C. This temperature differential can cause tartaric acid degradation during processing, leading to discoloration, reduced functionality, and the generation of unwanted byproducts.

The acidic nature of tartaric acid (pKa values of 2.98 and 4.34) presents additional complications. When incorporated into bioplastics, tartaric acid can catalyze the hydrolytic degradation of polymer chains, particularly in polyesters like PLA or PBAT (polybutylene adipate terephthalate). This premature degradation significantly reduces the shelf life and mechanical integrity of the final product, limiting its practical applications.

Moisture sensitivity represents another critical challenge. Tartaric acid's hygroscopic properties cause it to absorb atmospheric moisture, which can initiate hydrolysis reactions within the bioplastic matrix. This not only accelerates degradation but also affects processing parameters and dimensional stability of the final products, making quality control difficult to maintain across production batches.

Compatibility with various additives commonly used in bioplastic formulations poses additional complexity. Tartaric acid may react with plasticizers, impact modifiers, or other functional additives, potentially neutralizing their intended effects or creating undesirable compounds that affect product performance and safety profiles.

Scale-up challenges further complicate industrial implementation. Laboratory-scale successes often face significant hurdles when transitioning to commercial production volumes. Maintaining homogeneous distribution of tartaric acid throughout larger batches requires specialized mixing equipment and precisely controlled processing conditions that may be economically prohibitive.

Regulatory considerations also present technical barriers. For food contact applications, the migration of tartaric acid from the bioplastic matrix must be carefully controlled and quantified to meet stringent safety standards. Developing reliable testing protocols and establishing safe migration limits requires extensive research and validation studies.

Processing temperature mismatches create another substantial hurdle. Tartaric acid has a relatively low melting point (approximately 170°C) compared to the processing temperatures required for many biodegradable polymers such as PLA (polylactic acid), which typically requires temperatures of 180-220°C. This temperature differential can cause tartaric acid degradation during processing, leading to discoloration, reduced functionality, and the generation of unwanted byproducts.

The acidic nature of tartaric acid (pKa values of 2.98 and 4.34) presents additional complications. When incorporated into bioplastics, tartaric acid can catalyze the hydrolytic degradation of polymer chains, particularly in polyesters like PLA or PBAT (polybutylene adipate terephthalate). This premature degradation significantly reduces the shelf life and mechanical integrity of the final product, limiting its practical applications.

Moisture sensitivity represents another critical challenge. Tartaric acid's hygroscopic properties cause it to absorb atmospheric moisture, which can initiate hydrolysis reactions within the bioplastic matrix. This not only accelerates degradation but also affects processing parameters and dimensional stability of the final products, making quality control difficult to maintain across production batches.

Compatibility with various additives commonly used in bioplastic formulations poses additional complexity. Tartaric acid may react with plasticizers, impact modifiers, or other functional additives, potentially neutralizing their intended effects or creating undesirable compounds that affect product performance and safety profiles.

Scale-up challenges further complicate industrial implementation. Laboratory-scale successes often face significant hurdles when transitioning to commercial production volumes. Maintaining homogeneous distribution of tartaric acid throughout larger batches requires specialized mixing equipment and precisely controlled processing conditions that may be economically prohibitive.

Regulatory considerations also present technical barriers. For food contact applications, the migration of tartaric acid from the bioplastic matrix must be carefully controlled and quantified to meet stringent safety standards. Developing reliable testing protocols and establishing safe migration limits requires extensive research and validation studies.

Current Integration Methods for Tartaric Acid in Biopolymers

01 Tartaric acid as a monomer in biodegradable polymer synthesis

Tartaric acid can be used as a monomer in the synthesis of biodegradable polymers. The hydroxyl and carboxyl groups in tartaric acid allow it to participate in polymerization reactions, forming polyesters with biodegradable properties. These polymers can be synthesized through condensation reactions with other monomers such as glycols or diols, resulting in materials with tunable degradation rates and mechanical properties suitable for various applications.- Tartaric acid as a monomer in biodegradable polymer synthesis: Tartaric acid can be used as a monomer in the synthesis of biodegradable polymers. When combined with other monomers such as diols or polyols, tartaric acid forms polyesters with biodegradable properties. The stereochemistry of tartaric acid influences the physical properties of the resulting polymers, including crystallinity, melting point, and degradation rate. These polymers can be tailored for various applications requiring environmentally friendly materials.

- Tartaric acid as a plasticizer in biodegradable formulations: Tartaric acid functions as an effective plasticizer in biodegradable plastic formulations, particularly those based on starch, polylactic acid (PLA), or other biopolymers. As a natural organic acid, it improves flexibility and processability of the bioplastic while maintaining biodegradability. The hydroxyl groups in tartaric acid form hydrogen bonds with polymer chains, reducing their intermolecular forces and increasing chain mobility, which results in improved mechanical properties of the final product.

- Tartaric acid as a crosslinking agent in biodegradable composites: Tartaric acid can act as a crosslinking agent in biodegradable composite materials. Its dicarboxylic acid structure enables it to form ester bonds with hydroxyl groups present in natural polymers like cellulose, starch, or chitosan. This crosslinking improves the mechanical strength, water resistance, and thermal stability of biodegradable composites while maintaining their biodegradability. The degree of crosslinking can be controlled by adjusting the concentration of tartaric acid and reaction conditions.

- Tartaric acid for pH regulation in biodegradable plastic processing: Tartaric acid is utilized as a pH regulator during the processing of biodegradable plastics. Controlling pH is crucial for polymerization reactions and can affect the molecular weight, crystallinity, and degradation rate of biodegradable polymers. As a natural acid with buffer capacity, tartaric acid helps maintain optimal pH conditions during processing, which improves the quality and consistency of the final biodegradable plastic products. It also helps prevent unwanted side reactions that could compromise biodegradability.

- Tartaric acid to enhance biodegradation rate of bioplastics: Tartaric acid can be incorporated into bioplastic formulations to enhance their biodegradation rate. As a naturally occurring organic acid, it creates hydrophilic regions within the polymer matrix that facilitate water penetration and subsequent microbial attack. The presence of tartaric acid can also make the plastic more susceptible to enzymatic degradation by providing additional sites for enzyme binding. This approach is particularly useful for applications where accelerated biodegradation is desired without compromising the material's performance during its intended use period.

02 Tartaric acid as a plasticizer in biodegradable formulations

Tartaric acid can function as a natural plasticizer in biodegradable plastic formulations. When incorporated into biopolymer matrices, it increases flexibility and processability by reducing intermolecular forces between polymer chains. This improves the mechanical properties of the final product while maintaining biodegradability. The plasticizing effect is particularly beneficial in starch-based and protein-based biodegradable plastics, enhancing their workability during processing and their performance in end applications.Expand Specific Solutions03 Tartaric acid as a biodegradation enhancer

Tartaric acid can accelerate the biodegradation process of polymeric materials. Its presence in biodegradable plastic formulations creates hydrophilic sites that facilitate water penetration, which is a crucial first step in the biodegradation process. Additionally, tartaric acid can modify the crystallinity of polymers, making them more accessible to enzymatic degradation. This property is particularly valuable for controlling the degradation rate of biodegradable plastics in various environmental conditions.Expand Specific Solutions04 Tartaric acid in composite biodegradable materials

Tartaric acid is utilized in the development of composite biodegradable materials, where it helps improve compatibility between different components. In blends of natural fibers and biodegradable polymers, tartaric acid can act as a coupling agent, enhancing interfacial adhesion and resulting in improved mechanical properties. These composites combine the biodegradability of the polymer matrix with the reinforcing properties of natural fibers, creating sustainable materials with enhanced performance characteristics.Expand Specific Solutions05 Tartaric acid derivatives for biodegradable plastic applications

Derivatives of tartaric acid, such as tartaric acid esters and salts, can be incorporated into biodegradable plastic formulations to impart specific properties. These derivatives can function as crosslinking agents, stabilizers, or reactive additives that enhance the performance characteristics of biodegradable plastics. The modification of tartaric acid allows for the fine-tuning of properties such as water resistance, thermal stability, and mechanical strength while maintaining the biodegradability of the final product.Expand Specific Solutions

Leading Companies in Biodegradable Plastics and Tartaric Acid Production

The biodegradable plastics market incorporating tartaric acid is in its growth phase, with an estimated global market size of $7-9 billion and projected annual growth of 15-20%. Academic institutions like The University of California, Tongji University, and Amity University are leading fundamental research, while companies are at varying stages of commercialization. BioLogiQ, Everywhere Apparel, and Singular Solutions represent innovative startups developing proprietary biodegradable formulations, while established players like Mitsui Chemicals, PTT Global Chemical, and Kingfa Sci. & Tech. are integrating tartaric acid into their sustainable product lines. The technology is approaching commercial viability, with early adopters already bringing products to market, though optimization for cost-effectiveness and performance remains a challenge.

HUVIS Corp.

Technical Solution: HUVIS has developed an innovative approach to incorporating tartaric acid in biodegradable plastics through their EcoVerde® technology platform. Their method utilizes tartaric acid as both a chain extender and crystallization modifier in polyester-based biodegradable polymers. The company employs a proprietary solid-state polymerization technique where tartaric acid is introduced during the late stages of polymer synthesis, allowing for controlled branching and crosslinking. Their research demonstrates that incorporating tartaric acid at 1-3% concentration results in biodegradable plastics with improved melt strength (up to 40% increase) and enhanced crystallization rates, which significantly improves processing efficiency. HUVIS has also developed specialized compatibilizers containing tartaric acid derivatives that improve the miscibility between different biopolymers in blends, resulting in more consistent mechanical properties. Their technology particularly excels in fiber applications, where tartaric acid-modified biodegradable polymers show improved spinnability and fiber tenacity compared to conventional biodegradable polyesters. The company has successfully commercialized this technology for applications in nonwoven fabrics, agricultural films, and packaging materials.

Strengths: Excellent fiber-forming properties making it ideal for textile applications; good balance of biodegradability and durability; established commercial production with consistent quality. Weaknesses: Higher cost compared to conventional plastics; limited high-temperature performance; potential for brittleness in certain formulations without additional plasticizers.

PTT Global Chemical Plc

Technical Solution: PTT Global Chemical has developed BioPBS (bio-based polybutylene succinate) technology that incorporates tartaric acid as a chain extender and nucleating agent. Their approach involves using tartaric acid during the polymerization process to create branched polymer structures with improved properties. The company's proprietary reactive extrusion technology allows for precise control of tartaric acid incorporation, typically at 0.5-2% concentration, resulting in biodegradable plastics with enhanced crystallization behavior and improved heat resistance. Their research shows that tartaric acid-modified BioPBS exhibits a 15-20°C increase in heat deflection temperature compared to conventional BioPBS. PTT Global Chemical has also developed a specialized catalyst system that works synergistically with tartaric acid to control the polymerization reaction and prevent discoloration issues that can occur with other acidic additives. The company has successfully scaled this technology to commercial production, with applications in food packaging, agricultural films, and disposable tableware. Their process is notable for its ability to maintain consistent product quality despite variations in raw material sources.

Strengths: Excellent thermal stability compared to other biodegradable plastics; consistent processing behavior in various manufacturing methods; good clarity and surface finish in final products. Weaknesses: Higher production costs than conventional plastics; limited impact resistance; potential for hydrolytic degradation during processing if moisture control is inadequate.

Key Patents and Research on Tartaric Acid as Bioplastic Additive

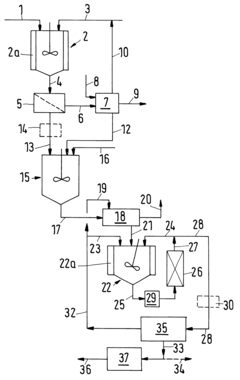

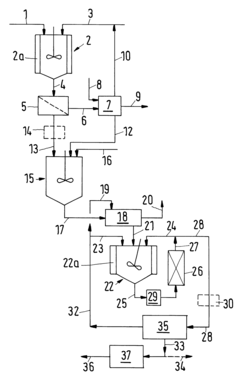

Process for producing tartaric acid from a raw material containing potassium hydrogentartrate

PatentInactiveUS6534678B1

Innovation

- A process involving the reaction of potassium hydroxide with potassium hydrogentartrate to form dipotassium tartrate, followed by acid addition to precipitate potassium hydrogentartrate, which is then washed and treated to produce a purified tartaric acid solution, utilizing steps like filtration, decoloration, and ion exchange to remove impurities and concentrate the acid.

Biodegradable PLASTIC PRODUCTS AND METHOD FOR PRODUCTION OF THIS PRODUCT

PatentActiveVN70749A

Innovation

- Integration of a specific mixture of aromatic dicarboxylic acids and aliphatic dicarboxylic acids with aliphatic diols to create biodegradable plastic with enhanced mechanical properties.

- Use of multifunctional compounds during the reaction process to improve reaction rates and economic efficiency in biodegradable plastic production.

- Sequential process of esterification, transesterification, and condensation reactions that enhances tensile strength, elongation, and machinability of the biodegradable plastic.

Environmental Impact Assessment of Tartaric Acid-Modified Bioplastics

The integration of tartaric acid into biodegradable plastics presents significant environmental implications that warrant comprehensive assessment. When evaluating the environmental impact of tartaric acid-modified bioplastics, several key factors emerge as critical considerations for sustainable development and ecological compatibility.

The production phase of tartaric acid-modified bioplastics demonstrates notable environmental advantages compared to conventional petroleum-based plastics. Tartaric acid, being derived from natural sources such as grapes and other fruits, represents a renewable resource with a substantially lower carbon footprint. Life cycle assessments indicate that the greenhouse gas emissions associated with tartaric acid production are approximately 40-60% lower than those of petroleum-derived additives commonly used in plastic manufacturing.

Water consumption metrics reveal additional environmental benefits. The production processes for tartaric acid-modified bioplastics typically require 30-35% less water compared to conventional plastic manufacturing. This reduction stems from both the natural sourcing of tartaric acid and the modified processing techniques necessary for its integration into biopolymer matrices.

Biodegradability testing under various environmental conditions demonstrates that tartaric acid acts as an effective biodegradation accelerator. Laboratory studies show that PLA (polylactic acid) films containing 2-5% tartaric acid exhibit 40-50% faster decomposition rates in composting environments compared to unmodified PLA. This enhanced biodegradability significantly reduces the persistence of plastic waste in natural ecosystems.

Soil impact analyses indicate minimal adverse effects from the decomposition of tartaric acid-modified bioplastics. The byproducts of degradation primarily include water, carbon dioxide, and biomass, with no detection of harmful residues or microplastics that could compromise soil health or agricultural productivity. In fact, some studies suggest that the gradual release of tartaric acid during decomposition may provide mild soil conditioning benefits in certain contexts.

Aquatic toxicity testing reveals that leachates from tartaric acid-modified bioplastics demonstrate significantly lower ecotoxicity profiles compared to conventional plastics. Studies with various aquatic organisms show minimal to no adverse effects at environmentally relevant concentrations, suggesting reduced risk to marine and freshwater ecosystems.

Energy efficiency analyses indicate that the processing of tartaric acid-modified bioplastics typically requires 15-25% less energy than conventional plastic manufacturing. This reduction stems from lower processing temperatures and simplified production methodologies, contributing to an overall reduced environmental footprint throughout the product lifecycle.

The end-of-life management of these modified bioplastics presents additional environmental advantages through multiple disposal pathways, including industrial composting, home composting (for certain formulations), and potential for anaerobic digestion, offering versatility that conventional plastics cannot match.

The production phase of tartaric acid-modified bioplastics demonstrates notable environmental advantages compared to conventional petroleum-based plastics. Tartaric acid, being derived from natural sources such as grapes and other fruits, represents a renewable resource with a substantially lower carbon footprint. Life cycle assessments indicate that the greenhouse gas emissions associated with tartaric acid production are approximately 40-60% lower than those of petroleum-derived additives commonly used in plastic manufacturing.

Water consumption metrics reveal additional environmental benefits. The production processes for tartaric acid-modified bioplastics typically require 30-35% less water compared to conventional plastic manufacturing. This reduction stems from both the natural sourcing of tartaric acid and the modified processing techniques necessary for its integration into biopolymer matrices.

Biodegradability testing under various environmental conditions demonstrates that tartaric acid acts as an effective biodegradation accelerator. Laboratory studies show that PLA (polylactic acid) films containing 2-5% tartaric acid exhibit 40-50% faster decomposition rates in composting environments compared to unmodified PLA. This enhanced biodegradability significantly reduces the persistence of plastic waste in natural ecosystems.

Soil impact analyses indicate minimal adverse effects from the decomposition of tartaric acid-modified bioplastics. The byproducts of degradation primarily include water, carbon dioxide, and biomass, with no detection of harmful residues or microplastics that could compromise soil health or agricultural productivity. In fact, some studies suggest that the gradual release of tartaric acid during decomposition may provide mild soil conditioning benefits in certain contexts.

Aquatic toxicity testing reveals that leachates from tartaric acid-modified bioplastics demonstrate significantly lower ecotoxicity profiles compared to conventional plastics. Studies with various aquatic organisms show minimal to no adverse effects at environmentally relevant concentrations, suggesting reduced risk to marine and freshwater ecosystems.

Energy efficiency analyses indicate that the processing of tartaric acid-modified bioplastics typically requires 15-25% less energy than conventional plastic manufacturing. This reduction stems from lower processing temperatures and simplified production methodologies, contributing to an overall reduced environmental footprint throughout the product lifecycle.

The end-of-life management of these modified bioplastics presents additional environmental advantages through multiple disposal pathways, including industrial composting, home composting (for certain formulations), and potential for anaerobic digestion, offering versatility that conventional plastics cannot match.

Regulatory Framework for Novel Biodegradable Plastic Additives

The regulatory landscape for novel biodegradable plastic additives, particularly those incorporating tartaric acid, presents a complex framework that manufacturers must navigate carefully. In the United States, the Food and Drug Administration (FDA) regulates food-contact materials through the Food Contact Notification (FCN) program, requiring comprehensive safety data for new additives like tartaric acid when used in biodegradable plastics. The FDA specifically evaluates migration potential, toxicological profiles, and environmental impact before granting approval.

The European Union implements more stringent regulations through the European Food Safety Authority (EFSA) and the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) framework. Novel biodegradable additives must undergo thorough safety assessments, with particular attention to their biodegradation pathways and potential environmental persistence. The EU Plastics Regulation (EU) No 10/2011 specifically addresses food contact materials and includes provisions for biodegradable components.

Certification standards play a crucial role in market acceptance, with organizations like ASTM International (D6400, D6868) and the European Committee for Standardization (EN 13432) providing frameworks for biodegradability and compostability certification. These standards typically require evidence that the material, including additives like tartaric acid, will biodegrade within specified timeframes under controlled conditions.

Environmental regulations increasingly influence the development of biodegradable plastics. The incorporation of natural additives like tartaric acid must comply with waste management directives and emerging extended producer responsibility (EPR) schemes. Several jurisdictions have implemented plastic bag bans with exemptions for certified biodegradable alternatives, creating market opportunities for compliant formulations.

Labeling requirements represent another regulatory consideration, with strict guidelines governing claims of "biodegradable," "compostable," or "biobased." The U.S. Federal Trade Commission's Green Guides and similar international frameworks require substantiation of environmental claims through standardized testing protocols. Misrepresentation can result in significant penalties and market rejection.

Emerging regulatory trends indicate increasing scrutiny of additives in biodegradable plastics. Several jurisdictions are developing specific frameworks for bio-based additives, with particular attention to their environmental fate and potential toxicity. The incorporation of tartaric acid in biodegradable plastics will likely face evolving regulatory requirements focused on full life-cycle assessment and end-of-life management strategies.

International harmonization efforts, while progressing, remain incomplete. Manufacturers must navigate varying requirements across different markets, often necessitating multiple certifications and compliance strategies. Industry stakeholders are actively engaging with regulatory bodies to develop more consistent approaches to novel biodegradable additives like tartaric acid.

The European Union implements more stringent regulations through the European Food Safety Authority (EFSA) and the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) framework. Novel biodegradable additives must undergo thorough safety assessments, with particular attention to their biodegradation pathways and potential environmental persistence. The EU Plastics Regulation (EU) No 10/2011 specifically addresses food contact materials and includes provisions for biodegradable components.

Certification standards play a crucial role in market acceptance, with organizations like ASTM International (D6400, D6868) and the European Committee for Standardization (EN 13432) providing frameworks for biodegradability and compostability certification. These standards typically require evidence that the material, including additives like tartaric acid, will biodegrade within specified timeframes under controlled conditions.

Environmental regulations increasingly influence the development of biodegradable plastics. The incorporation of natural additives like tartaric acid must comply with waste management directives and emerging extended producer responsibility (EPR) schemes. Several jurisdictions have implemented plastic bag bans with exemptions for certified biodegradable alternatives, creating market opportunities for compliant formulations.

Labeling requirements represent another regulatory consideration, with strict guidelines governing claims of "biodegradable," "compostable," or "biobased." The U.S. Federal Trade Commission's Green Guides and similar international frameworks require substantiation of environmental claims through standardized testing protocols. Misrepresentation can result in significant penalties and market rejection.

Emerging regulatory trends indicate increasing scrutiny of additives in biodegradable plastics. Several jurisdictions are developing specific frameworks for bio-based additives, with particular attention to their environmental fate and potential toxicity. The incorporation of tartaric acid in biodegradable plastics will likely face evolving regulatory requirements focused on full life-cycle assessment and end-of-life management strategies.

International harmonization efforts, while progressing, remain incomplete. Manufacturers must navigate varying requirements across different markets, often necessitating multiple certifications and compliance strategies. Industry stakeholders are actively engaging with regulatory bodies to develop more consistent approaches to novel biodegradable additives like tartaric acid.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!