How to Enhance Tartaric Acid Usage in Biodegradable Foams

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Tartaric Acid in Biodegradable Foams: Background and Objectives

Tartaric acid, a naturally occurring organic compound found predominantly in grapes and other fruits, has emerged as a promising component in the development of biodegradable foam materials. The evolution of this technology can be traced back to the early 2000s when researchers began exploring alternatives to petroleum-based foams in response to growing environmental concerns. Initially, the incorporation of tartaric acid in biodegradable formulations was limited due to processing challenges and cost considerations.

The technological trajectory has since witnessed significant advancements, particularly in the last decade, with improved understanding of tartaric acid's chemical properties and its interaction with other biodegradable polymers. The acid's stereochemistry, hydroxyl functionality, and biodegradability have positioned it as an excellent candidate for enhancing the performance characteristics of eco-friendly foam materials.

Current research indicates that tartaric acid can serve multiple functions in biodegradable foam formulations, including acting as a crosslinking agent, pH regulator, and crystallization modifier. These properties contribute to improved mechanical strength, thermal stability, and controlled degradation rates of the resulting foams. The technology has progressed from laboratory-scale experiments to pilot production, with several patents filed globally between 2015 and 2023.

The primary objective of enhancing tartaric acid usage in biodegradable foams is to develop commercially viable alternatives to conventional petroleum-based foam products while maintaining comparable performance characteristics. Specific technical goals include optimizing tartaric acid concentration for maximum mechanical properties, developing processing methodologies that preserve the acid's functional groups during foam formation, and creating formulations with predictable and controllable degradation profiles.

Additionally, researchers aim to establish cost-effective production methods that can scale to industrial levels, potentially reducing the current price premium associated with biodegradable foam products. The technology seeks to address the growing market demand for sustainable packaging solutions while complying with increasingly stringent environmental regulations worldwide.

The technological evolution is expected to continue with further refinements in formulation, processing techniques, and applications. Emerging trends suggest potential integration with other bio-based additives and the development of multi-functional foam systems where tartaric acid contributes to both structural and functional properties. As sustainability becomes increasingly central to product development strategies across industries, enhancing tartaric acid usage in biodegradable foams represents a significant opportunity for technological innovation and market differentiation.

The technological trajectory has since witnessed significant advancements, particularly in the last decade, with improved understanding of tartaric acid's chemical properties and its interaction with other biodegradable polymers. The acid's stereochemistry, hydroxyl functionality, and biodegradability have positioned it as an excellent candidate for enhancing the performance characteristics of eco-friendly foam materials.

Current research indicates that tartaric acid can serve multiple functions in biodegradable foam formulations, including acting as a crosslinking agent, pH regulator, and crystallization modifier. These properties contribute to improved mechanical strength, thermal stability, and controlled degradation rates of the resulting foams. The technology has progressed from laboratory-scale experiments to pilot production, with several patents filed globally between 2015 and 2023.

The primary objective of enhancing tartaric acid usage in biodegradable foams is to develop commercially viable alternatives to conventional petroleum-based foam products while maintaining comparable performance characteristics. Specific technical goals include optimizing tartaric acid concentration for maximum mechanical properties, developing processing methodologies that preserve the acid's functional groups during foam formation, and creating formulations with predictable and controllable degradation profiles.

Additionally, researchers aim to establish cost-effective production methods that can scale to industrial levels, potentially reducing the current price premium associated with biodegradable foam products. The technology seeks to address the growing market demand for sustainable packaging solutions while complying with increasingly stringent environmental regulations worldwide.

The technological evolution is expected to continue with further refinements in formulation, processing techniques, and applications. Emerging trends suggest potential integration with other bio-based additives and the development of multi-functional foam systems where tartaric acid contributes to both structural and functional properties. As sustainability becomes increasingly central to product development strategies across industries, enhancing tartaric acid usage in biodegradable foams represents a significant opportunity for technological innovation and market differentiation.

Market Analysis for Tartaric Acid-Based Biodegradable Materials

The global market for biodegradable materials has experienced significant growth in recent years, driven by increasing environmental concerns and regulatory pressures to reduce plastic waste. Tartaric acid, a naturally occurring organic acid found in many fruits, particularly grapes, has emerged as a promising component in biodegradable foam formulations due to its renewable sourcing and biodegradable properties.

The biodegradable foam market was valued at approximately $3.5 billion in 2022 and is projected to grow at a compound annual growth rate of 7.8% through 2028. Within this segment, tartaric acid-based solutions are gaining traction, particularly in packaging applications where end-of-life considerations are becoming increasingly important to consumers and regulators alike.

Consumer packaged goods companies represent the largest potential market for tartaric acid-based biodegradable foams, with food packaging accounting for nearly 40% of current applications. The food service industry follows closely, driven by bans on single-use plastics in many jurisdictions worldwide. Additional growth sectors include protective packaging for electronics and consumer goods, where premium brands are increasingly adopting sustainable packaging solutions as part of their brand positioning.

Regional analysis reveals Europe leading the adoption of tartaric acid-based biodegradable materials, accounting for 38% of global market share. This dominance stems from stringent regulations like the European Single-Use Plastics Directive and strong consumer preference for sustainable products. North America follows at 29% market share, with particularly strong growth in the organic and natural product segments.

Price sensitivity remains a significant market factor, with tartaric acid-based solutions currently commanding a 15-25% premium over conventional petroleum-based foams. However, this gap is narrowing as production scales increase and manufacturing processes become more efficient. Market research indicates that 67% of consumers express willingness to pay a premium for environmentally friendly packaging, though the acceptable premium varies significantly by product category and region.

Supply chain considerations are also shaping market dynamics. The wine industry remains the primary source of tartaric acid, creating potential for circular economy applications where wine production waste becomes a feedstock for biodegradable materials. This integration has created new market opportunities in wine-producing regions like Italy, France, and California, where local sourcing can reduce overall environmental footprint and production costs.

Competitive analysis reveals that while large chemical companies are beginning to enter this space, much of the innovation is currently driven by specialized biomaterials startups and medium-sized enterprises focused exclusively on sustainable materials. This fragmented market structure presents both opportunities for rapid innovation and challenges for achieving economies of scale.

The biodegradable foam market was valued at approximately $3.5 billion in 2022 and is projected to grow at a compound annual growth rate of 7.8% through 2028. Within this segment, tartaric acid-based solutions are gaining traction, particularly in packaging applications where end-of-life considerations are becoming increasingly important to consumers and regulators alike.

Consumer packaged goods companies represent the largest potential market for tartaric acid-based biodegradable foams, with food packaging accounting for nearly 40% of current applications. The food service industry follows closely, driven by bans on single-use plastics in many jurisdictions worldwide. Additional growth sectors include protective packaging for electronics and consumer goods, where premium brands are increasingly adopting sustainable packaging solutions as part of their brand positioning.

Regional analysis reveals Europe leading the adoption of tartaric acid-based biodegradable materials, accounting for 38% of global market share. This dominance stems from stringent regulations like the European Single-Use Plastics Directive and strong consumer preference for sustainable products. North America follows at 29% market share, with particularly strong growth in the organic and natural product segments.

Price sensitivity remains a significant market factor, with tartaric acid-based solutions currently commanding a 15-25% premium over conventional petroleum-based foams. However, this gap is narrowing as production scales increase and manufacturing processes become more efficient. Market research indicates that 67% of consumers express willingness to pay a premium for environmentally friendly packaging, though the acceptable premium varies significantly by product category and region.

Supply chain considerations are also shaping market dynamics. The wine industry remains the primary source of tartaric acid, creating potential for circular economy applications where wine production waste becomes a feedstock for biodegradable materials. This integration has created new market opportunities in wine-producing regions like Italy, France, and California, where local sourcing can reduce overall environmental footprint and production costs.

Competitive analysis reveals that while large chemical companies are beginning to enter this space, much of the innovation is currently driven by specialized biomaterials startups and medium-sized enterprises focused exclusively on sustainable materials. This fragmented market structure presents both opportunities for rapid innovation and challenges for achieving economies of scale.

Technical Challenges in Tartaric Acid Foam Applications

The integration of tartaric acid into biodegradable foam formulations presents several significant technical challenges that must be addressed to enhance its usage effectively. One primary obstacle is the inherent hydrophilicity of tartaric acid, which creates compatibility issues with hydrophobic polymer matrices commonly used in foam production. This incompatibility leads to phase separation during processing, resulting in inconsistent distribution of tartaric acid throughout the foam structure and compromising mechanical properties.

Another critical challenge involves the thermal stability limitations of tartaric acid during foam processing. Most industrial foam manufacturing processes require elevated temperatures (typically 160-200°C), while tartaric acid begins to degrade at approximately 170°C. This narrow processing window restricts the selection of compatible polymers and necessitates careful temperature control during production to prevent acid degradation and subsequent loss of functionality.

The catalytic effect of tartaric acid on polymer degradation presents a double-edged sword in biodegradable foam applications. While beneficial for end-of-life biodegradation, premature degradation during processing or storage significantly reduces shelf life and mechanical integrity. Controlling this catalytic activity through appropriate stabilizers or encapsulation techniques remains technically challenging.

Moisture sensitivity represents another substantial hurdle in tartaric acid foam applications. When exposed to humid environments, tartaric acid can absorb atmospheric moisture, leading to plasticization effects that compromise foam dimensional stability and mechanical properties. This hygroscopic nature necessitates specialized processing conditions and potentially moisture-resistant coatings or additives.

The reactivity of tartaric acid's carboxylic and hydroxyl functional groups with certain polymer components can lead to undesired side reactions during foam formation. These reactions may consume blowing agents, alter crosslinking density, or create unwanted byproducts that affect foam quality and performance characteristics. Controlling these reactions requires precise formulation engineering and potentially protective chemical modifications.

Scale-up challenges further complicate industrial implementation. Laboratory-scale successes with tartaric acid in biodegradable foams often encounter difficulties when transferred to production environments due to differences in mixing efficiency, heat transfer, and reaction kinetics. These scale-dependent variables can significantly alter foam morphology, cell structure uniformity, and overall performance properties.

Finally, cost considerations present practical barriers to widespread adoption. Current methods for incorporating tartaric acid into biodegradable foams often require specialized processing equipment, additional manufacturing steps, or expensive compatibilizers, all of which increase production costs and reduce market competitiveness against conventional petroleum-based alternatives.

Another critical challenge involves the thermal stability limitations of tartaric acid during foam processing. Most industrial foam manufacturing processes require elevated temperatures (typically 160-200°C), while tartaric acid begins to degrade at approximately 170°C. This narrow processing window restricts the selection of compatible polymers and necessitates careful temperature control during production to prevent acid degradation and subsequent loss of functionality.

The catalytic effect of tartaric acid on polymer degradation presents a double-edged sword in biodegradable foam applications. While beneficial for end-of-life biodegradation, premature degradation during processing or storage significantly reduces shelf life and mechanical integrity. Controlling this catalytic activity through appropriate stabilizers or encapsulation techniques remains technically challenging.

Moisture sensitivity represents another substantial hurdle in tartaric acid foam applications. When exposed to humid environments, tartaric acid can absorb atmospheric moisture, leading to plasticization effects that compromise foam dimensional stability and mechanical properties. This hygroscopic nature necessitates specialized processing conditions and potentially moisture-resistant coatings or additives.

The reactivity of tartaric acid's carboxylic and hydroxyl functional groups with certain polymer components can lead to undesired side reactions during foam formation. These reactions may consume blowing agents, alter crosslinking density, or create unwanted byproducts that affect foam quality and performance characteristics. Controlling these reactions requires precise formulation engineering and potentially protective chemical modifications.

Scale-up challenges further complicate industrial implementation. Laboratory-scale successes with tartaric acid in biodegradable foams often encounter difficulties when transferred to production environments due to differences in mixing efficiency, heat transfer, and reaction kinetics. These scale-dependent variables can significantly alter foam morphology, cell structure uniformity, and overall performance properties.

Finally, cost considerations present practical barriers to widespread adoption. Current methods for incorporating tartaric acid into biodegradable foams often require specialized processing equipment, additional manufacturing steps, or expensive compatibilizers, all of which increase production costs and reduce market competitiveness against conventional petroleum-based alternatives.

Current Methodologies for Tartaric Acid Incorporation

01 Tartaric acid in food and beverage applications

Tartaric acid is widely used as an acidulant and flavor enhancer in food and beverage products. It provides a tart taste and helps in preserving food quality. The acid can be incorporated into various formulations to improve taste profiles, adjust pH levels, and extend shelf life. Its natural occurrence in fruits, particularly grapes, makes it a preferred choice for wine production and fruit-based products.- Tartaric acid in food and beverage applications: Tartaric acid is widely used as an acidulant and flavor enhancer in various food and beverage products. It provides a tart taste and helps in preserving food quality. The acid can be incorporated into beverages, confectionery, bakery products, and wine production to improve taste profiles and extend shelf life. Its natural occurrence in grapes makes it particularly suitable for wine-related applications, where it contributes to the overall acidity and stability of the final product.

- Tartaric acid in pharmaceutical formulations: Tartaric acid serves as an important excipient in pharmaceutical formulations, enhancing drug solubility, stability, and bioavailability. It functions as a pH adjuster, buffering agent, and complexing agent in various drug delivery systems. The acid can improve the dissolution rate of poorly soluble drugs and contribute to controlled release formulations. Its safety profile makes it suitable for oral, topical, and injectable pharmaceutical preparations, where it helps optimize therapeutic efficacy.

- Industrial synthesis and production methods of tartaric acid: Various methods have been developed to enhance the production and synthesis of tartaric acid for industrial applications. These include improved fermentation processes, chemical synthesis routes, and extraction techniques from natural sources. Advanced catalytic processes have been implemented to increase yield and purity while reducing environmental impact. Innovations in crystallization, purification, and recovery methods have also contributed to more efficient and cost-effective production of tartaric acid at commercial scale.

- Tartaric acid in cosmetic and personal care products: Tartaric acid is utilized in cosmetic and personal care formulations as an exfoliating agent, pH adjuster, and chelating agent. It helps in skin renewal processes by gently removing dead skin cells and promoting cell turnover. The acid can be incorporated into facial cleansers, masks, and anti-aging products to improve skin texture and appearance. Its mild acidic properties make it suitable for sensitive skin applications, where it helps maintain the skin's natural pH balance while providing gentle exfoliation.

- Tartaric acid in agricultural and environmental applications: Tartaric acid has found enhanced usage in agricultural and environmental applications, including soil amendment, plant growth regulation, and metal chelation. It can improve nutrient availability in soils and enhance plant uptake of essential minerals. The acid also serves as a biodegradable chelating agent for environmental remediation processes, helping in the removal of heavy metals from contaminated soils and water. Its natural origin and biodegradability make it an environmentally friendly alternative to synthetic chemicals in various agricultural and remediation applications.

02 Tartaric acid in pharmaceutical formulations

Tartaric acid serves multiple functions in pharmaceutical preparations, including as a pH adjuster, stabilizer, and complexing agent. It enhances the solubility and bioavailability of certain active pharmaceutical ingredients. The acid can be used in various dosage forms such as tablets, capsules, and solutions to improve drug delivery and efficacy. Its safety profile makes it suitable for a wide range of medicinal applications.Expand Specific Solutions03 Industrial and chemical processing applications

Tartaric acid plays a significant role in various industrial processes as a chelating agent, catalyst, and intermediate in chemical synthesis. It can be used in metal plating, textile processing, and as a precursor for producing other valuable chemicals. The acid's stereochemistry makes it particularly useful in asymmetric synthesis and as a chiral resolving agent in the separation of racemic mixtures.Expand Specific Solutions04 Tartaric acid in cleaning and personal care products

Tartaric acid is utilized in cleaning formulations and personal care products due to its acidic properties and biodegradability. It functions as a descaling agent, pH adjuster, and exfoliant. In personal care products, it can help in skin renewal processes and maintaining the acid mantle of the skin. Its natural origin makes it appealing for eco-friendly cleaning solutions and cosmetic applications.Expand Specific Solutions05 Sustainable production and purification methods

Enhanced methods for producing and purifying tartaric acid from natural sources or through synthetic routes have been developed to improve yield and quality. These methods include optimized extraction techniques from wine by-products, fermentation processes, and chemical synthesis pathways. Innovations in crystallization, filtration, and purification steps have led to higher purity tartaric acid with reduced environmental impact, making its production more sustainable and economically viable.Expand Specific Solutions

Leading Companies in Biodegradable Foam Industry

The biodegradable foam market is currently in a growth phase, with increasing demand driven by environmental regulations and consumer preferences for sustainable packaging solutions. The global market is projected to expand significantly as companies seek alternatives to petroleum-based foams. Technologically, tartaric acid enhancement in biodegradable foams represents an emerging innovation with moderate maturity. Leading players include BASF Corp. and Lubrizol Corp., who possess advanced polymer expertise, while Tianjin GreenBio Materials and BIOTEC Biologische Naturverpackungen are developing specialized bio-based solutions. Kaneka Corp. and Anhui Hailan Biotechnology bring valuable expertise in biodegradable polymers and tartaric acid production respectively. Research institutions like Qingdao Institute of Bioenergy and academic partners such as Tongji University are accelerating technological advancement through collaborative innovation in this promising sustainable materials sector.

The Lubrizol Corp.

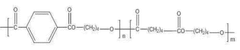

Technical Solution: Lubrizol has developed an advanced technology platform for incorporating tartaric acid into biodegradable thermoplastic polyurethane (TPU) foams. Their approach utilizes tartaric acid as both a chain extender and a biodegradation accelerator in their Estane® Eco line of biodegradable polymers. The company's research has shown that tartaric acid's hydroxyl groups participate in urethane linkage formation, creating biodegradable segments within the polymer backbone. Lubrizol's process involves a proprietary reactive extrusion technique where tartaric acid is introduced under controlled conditions to optimize dispersion and reaction with the polyurethane precursors. This results in foams with enhanced biodegradability while maintaining the excellent mechanical properties and durability that TPU materials are known for. Their technology enables the production of biodegradable foams with tunable degradation rates based on tartaric acid concentration and distribution within the polymer matrix.

Strengths: Lubrizol's extensive experience in polyurethane chemistry allows them to create biodegradable foams with superior mechanical properties and durability. Their global technical service network provides excellent customer support for implementation. Weaknesses: Their solutions may require specialized processing equipment, potentially limiting adoption by smaller foam manufacturers without advanced technical capabilities.

BASF Corp.

Technical Solution: BASF has developed proprietary technology that incorporates tartaric acid as a key component in their biodegradable foam formulations. Their approach involves using tartaric acid as both a crosslinking agent and pH regulator in polyurethane-based biodegradable foams. The company's research has shown that tartaric acid's stereochemistry and multiple functional groups enable improved foam cell structure and enhanced biodegradability. BASF's process involves esterification of tartaric acid with polyols to create bio-based polyester polyols that serve as building blocks for biodegradable foam systems. Their technology also utilizes tartaric acid derivatives to catalyze the foam formation reaction while simultaneously improving the foam's resistance to hydrolysis during its useful life, yet enabling controlled degradation after disposal.

Strengths: BASF's extensive polymer chemistry expertise allows for precise control of foam properties and degradation rates. Their global manufacturing capabilities ensure consistent quality and supply chain reliability. Weaknesses: Their solutions may be more expensive than conventional foam technologies, potentially limiting market penetration in cost-sensitive applications.

Key Patents and Research on Tartaric Acid Foam Formulations

Biodegradable foam composition

PatentWO2022240084A1

Innovation

- A biodegradable foam composition incorporating polyalkylene adipate terephthalate (PAAT) resin, peroxide crosslinking agents, and crosslinkable polymers or rubbers, along with a blowing agent, to enhance processability, moldability, and biodegradability, while adjusting hardness and physical properties.

Highly absorbable solid preparation

PatentWO2002011726A1

Innovation

- Incorporating tartaric acid into the solid preparation to enhance the absorption of sparingly soluble quinolone compounds, specifically sitafloxacin, by increasing solubility at neutral pH, thereby improving bioavailability and reducing variability in blood concentration.

Environmental Impact Assessment of Tartaric Acid-Based Foams

The environmental impact of tartaric acid-based biodegradable foams represents a critical consideration in their development and application. These foams offer significant advantages over conventional petroleum-based alternatives, primarily due to their biodegradability and renewable sourcing. Tartaric acid, derived from wine production byproducts, provides a sustainable foundation for these materials.

Life cycle assessment (LCA) studies indicate that tartaric acid-based foams generate approximately 40-60% lower carbon emissions compared to traditional polyurethane foams. This reduction stems from both the renewable nature of the raw materials and the less energy-intensive manufacturing processes. The carbon sequestration potential during biomass growth further enhances their environmental profile.

Water usage represents another important environmental factor. Production of tartaric acid from wine industry waste streams requires significantly less water than virgin petrochemical production - approximately 70% reduction according to recent industry analyses. However, purification processes for tartaric acid can still be water-intensive, presenting opportunities for optimization.

Biodegradability testing under various environmental conditions demonstrates that tartaric acid-based foams can decompose within 3-6 months in industrial composting facilities, compared to hundreds of years for conventional foams. This characteristic substantially reduces end-of-life environmental impacts, including microplastic pollution and landfill burden.

Ecotoxicological studies show minimal adverse effects on aquatic and soil organisms during the degradation process. The breakdown products primarily consist of naturally occurring organic compounds that integrate into existing biogeochemical cycles without disruption to ecosystem functions.

Land use considerations reveal mixed impacts. While utilizing agricultural byproducts reduces waste, increased demand could potentially drive dedicated cultivation, raising concerns about land conversion and food security. Current models suggest that existing wine industry waste streams could support approximately 15-20% of the global foam market without additional land requirements.

Chemical safety assessments indicate that tartaric acid-based foams eliminate many hazardous substances common in conventional foams, including flame retardants and isocyanates associated with respiratory and environmental health concerns. This reduction in hazardous materials improves workplace safety and reduces pollution potential throughout the product lifecycle.

Resource efficiency metrics demonstrate that tartaric acid-based foams represent a circular economy opportunity, transforming what would otherwise be waste material into value-added products. This approach aligns with sustainable development goals and supports waste reduction initiatives across multiple industries.

Life cycle assessment (LCA) studies indicate that tartaric acid-based foams generate approximately 40-60% lower carbon emissions compared to traditional polyurethane foams. This reduction stems from both the renewable nature of the raw materials and the less energy-intensive manufacturing processes. The carbon sequestration potential during biomass growth further enhances their environmental profile.

Water usage represents another important environmental factor. Production of tartaric acid from wine industry waste streams requires significantly less water than virgin petrochemical production - approximately 70% reduction according to recent industry analyses. However, purification processes for tartaric acid can still be water-intensive, presenting opportunities for optimization.

Biodegradability testing under various environmental conditions demonstrates that tartaric acid-based foams can decompose within 3-6 months in industrial composting facilities, compared to hundreds of years for conventional foams. This characteristic substantially reduces end-of-life environmental impacts, including microplastic pollution and landfill burden.

Ecotoxicological studies show minimal adverse effects on aquatic and soil organisms during the degradation process. The breakdown products primarily consist of naturally occurring organic compounds that integrate into existing biogeochemical cycles without disruption to ecosystem functions.

Land use considerations reveal mixed impacts. While utilizing agricultural byproducts reduces waste, increased demand could potentially drive dedicated cultivation, raising concerns about land conversion and food security. Current models suggest that existing wine industry waste streams could support approximately 15-20% of the global foam market without additional land requirements.

Chemical safety assessments indicate that tartaric acid-based foams eliminate many hazardous substances common in conventional foams, including flame retardants and isocyanates associated with respiratory and environmental health concerns. This reduction in hazardous materials improves workplace safety and reduces pollution potential throughout the product lifecycle.

Resource efficiency metrics demonstrate that tartaric acid-based foams represent a circular economy opportunity, transforming what would otherwise be waste material into value-added products. This approach aligns with sustainable development goals and supports waste reduction initiatives across multiple industries.

Regulatory Framework for Bio-Based Packaging Materials

The regulatory landscape for bio-based packaging materials has evolved significantly in response to growing environmental concerns and sustainability goals. In the context of enhancing tartaric acid usage in biodegradable foams, understanding the regulatory framework is essential for successful product development and market entry. Currently, several major regulatory bodies govern the use of bio-based materials in packaging applications, including the European Food Safety Authority (EFSA), the U.S. Food and Drug Administration (FDA), and similar organizations in Asia-Pacific regions.

The European Union has established comprehensive regulations through the Packaging and Packaging Waste Directive (94/62/EC) and its amendments, which set targets for recovery and recycling of packaging waste. More specifically, Regulation (EC) No 1935/2004 addresses materials intended to come into contact with food, requiring that they do not transfer constituents to food in quantities that could endanger human health. For biodegradable foams incorporating tartaric acid, compliance with these regulations is mandatory for market access.

In the United States, the FDA regulates food contact substances under the Federal Food, Drug, and Cosmetic Act. Manufacturers must submit Food Contact Notifications (FCNs) for new applications of substances like tartaric acid in packaging materials. Additionally, the EPA's Toxic Substances Control Act (TSCA) may apply to novel biodegradable foam formulations, requiring premanufacture notifications for new chemical substances.

Globally, the ISO standards, particularly ISO 17088 and ISO 14855, provide specifications for compostable and biodegradable plastics. These standards establish testing protocols and criteria for biodegradability and compostability, which are crucial for validating claims about tartaric acid-enhanced biodegradable foams. Compliance with these standards often facilitates certification by organizations such as the Biodegradable Products Institute (BPI) or European Bioplastics.

Recent regulatory trends indicate a shift toward more stringent requirements for environmental claims and end-of-life management of packaging materials. The EU's Single-Use Plastics Directive and similar initiatives worldwide are accelerating the transition away from conventional plastics toward biodegradable alternatives, potentially creating favorable regulatory conditions for tartaric acid-based biodegradable foams.

For manufacturers developing these innovative materials, navigating the complex regulatory landscape requires a comprehensive strategy that includes early engagement with regulatory authorities, thorough toxicological assessments, and robust documentation of environmental benefits. Staying informed about evolving regulations and participating in industry standardization efforts can provide competitive advantages in this rapidly changing field.

The European Union has established comprehensive regulations through the Packaging and Packaging Waste Directive (94/62/EC) and its amendments, which set targets for recovery and recycling of packaging waste. More specifically, Regulation (EC) No 1935/2004 addresses materials intended to come into contact with food, requiring that they do not transfer constituents to food in quantities that could endanger human health. For biodegradable foams incorporating tartaric acid, compliance with these regulations is mandatory for market access.

In the United States, the FDA regulates food contact substances under the Federal Food, Drug, and Cosmetic Act. Manufacturers must submit Food Contact Notifications (FCNs) for new applications of substances like tartaric acid in packaging materials. Additionally, the EPA's Toxic Substances Control Act (TSCA) may apply to novel biodegradable foam formulations, requiring premanufacture notifications for new chemical substances.

Globally, the ISO standards, particularly ISO 17088 and ISO 14855, provide specifications for compostable and biodegradable plastics. These standards establish testing protocols and criteria for biodegradability and compostability, which are crucial for validating claims about tartaric acid-enhanced biodegradable foams. Compliance with these standards often facilitates certification by organizations such as the Biodegradable Products Institute (BPI) or European Bioplastics.

Recent regulatory trends indicate a shift toward more stringent requirements for environmental claims and end-of-life management of packaging materials. The EU's Single-Use Plastics Directive and similar initiatives worldwide are accelerating the transition away from conventional plastics toward biodegradable alternatives, potentially creating favorable regulatory conditions for tartaric acid-based biodegradable foams.

For manufacturers developing these innovative materials, navigating the complex regulatory landscape requires a comprehensive strategy that includes early engagement with regulatory authorities, thorough toxicological assessments, and robust documentation of environmental benefits. Staying informed about evolving regulations and participating in industry standardization efforts can provide competitive advantages in this rapidly changing field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!