How to Improve Tartaric Acid Sensitivity in Sensor Devices

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Tartaric Acid Sensing Technology Background and Objectives

Tartaric acid sensing technology has evolved significantly over the past decades, transitioning from basic chemical detection methods to sophisticated sensor devices with enhanced sensitivity and selectivity. Initially developed for wine industry applications to monitor fermentation processes, tartaric acid sensors have expanded into pharmaceutical quality control, food safety monitoring, and environmental analysis sectors. The technological progression has been driven by increasing demands for rapid, accurate, and cost-effective detection methods in various industries.

The evolution of tartaric acid sensing began with traditional wet chemistry techniques, which were time-consuming and required specialized laboratory equipment. The 1980s saw the introduction of electrochemical sensors, while the 1990s brought spectroscopic methods that improved detection capabilities. The early 2000s marked a significant advancement with the development of biosensors incorporating enzyme-based recognition elements, substantially enhancing specificity for tartaric acid detection.

Recent technological breakthroughs include nanomaterial-enhanced sensors, microfluidic platforms, and molecularly imprinted polymers (MIPs) that have dramatically improved sensitivity levels. However, current tartaric acid sensors still face limitations in terms of detection thresholds, stability in complex matrices, and interference from structurally similar compounds. These challenges represent critical areas for technological improvement.

The global research landscape shows concentrated efforts in regions with strong wine industries, including France, Italy, Australia, and the United States. Emerging research hubs in China and India are increasingly contributing to sensor technology advancements, particularly in nanomaterial applications and low-cost sensor development for broader market accessibility.

The primary objective of improving tartaric acid sensitivity in sensor devices is to achieve detection limits in the sub-micromolar range while maintaining selectivity in complex biological and food matrices. Additional goals include developing sensors with enhanced stability, reduced response time, and simplified operational protocols suitable for field deployment by non-specialists.

Secondary objectives encompass miniaturization for portable applications, integration with digital platforms for real-time monitoring, and development of sustainable, environmentally friendly sensor materials. The technological roadmap aims to transition from laboratory-based detection systems to widely accessible point-of-use devices that can revolutionize quality control processes across multiple industries.

The advancement of tartaric acid sensing technology aligns with broader trends in analytical chemistry, including the movement toward green analytical methods, Internet of Things (IoT) integration, and artificial intelligence-enhanced data interpretation systems that can extract meaningful patterns from sensor responses in complex environments.

The evolution of tartaric acid sensing began with traditional wet chemistry techniques, which were time-consuming and required specialized laboratory equipment. The 1980s saw the introduction of electrochemical sensors, while the 1990s brought spectroscopic methods that improved detection capabilities. The early 2000s marked a significant advancement with the development of biosensors incorporating enzyme-based recognition elements, substantially enhancing specificity for tartaric acid detection.

Recent technological breakthroughs include nanomaterial-enhanced sensors, microfluidic platforms, and molecularly imprinted polymers (MIPs) that have dramatically improved sensitivity levels. However, current tartaric acid sensors still face limitations in terms of detection thresholds, stability in complex matrices, and interference from structurally similar compounds. These challenges represent critical areas for technological improvement.

The global research landscape shows concentrated efforts in regions with strong wine industries, including France, Italy, Australia, and the United States. Emerging research hubs in China and India are increasingly contributing to sensor technology advancements, particularly in nanomaterial applications and low-cost sensor development for broader market accessibility.

The primary objective of improving tartaric acid sensitivity in sensor devices is to achieve detection limits in the sub-micromolar range while maintaining selectivity in complex biological and food matrices. Additional goals include developing sensors with enhanced stability, reduced response time, and simplified operational protocols suitable for field deployment by non-specialists.

Secondary objectives encompass miniaturization for portable applications, integration with digital platforms for real-time monitoring, and development of sustainable, environmentally friendly sensor materials. The technological roadmap aims to transition from laboratory-based detection systems to widely accessible point-of-use devices that can revolutionize quality control processes across multiple industries.

The advancement of tartaric acid sensing technology aligns with broader trends in analytical chemistry, including the movement toward green analytical methods, Internet of Things (IoT) integration, and artificial intelligence-enhanced data interpretation systems that can extract meaningful patterns from sensor responses in complex environments.

Market Analysis for Tartaric Acid Detection Applications

The global market for tartaric acid detection applications is experiencing significant growth, driven by increasing demand across multiple industries. The wine industry represents the largest market segment, where tartaric acid detection is crucial for quality control and authenticity verification. With the global wine market valued at approximately $417 billion in 2023 and projected to grow at a CAGR of 5.5% through 2028, the demand for precise tartaric acid sensors continues to expand proportionally.

The food and beverage industry beyond wine also presents substantial opportunities, particularly in quality assurance and product formulation. Tartaric acid serves as a key ingredient in numerous food products, and accurate detection capabilities enable manufacturers to maintain consistent product quality and comply with regulatory standards. This segment is expected to grow at a faster rate than the overall market due to increasing consumer demand for quality assurance and transparency in food production.

Pharmaceutical applications represent another significant market, where tartaric acid detection is essential for drug formulation and quality control. The pharmaceutical industry's stringent requirements for analytical precision drive demand for highly sensitive detection methods. With the global pharmaceutical analytical testing outsourcing market growing at approximately 8.3% annually, opportunities for advanced tartaric acid detection technologies continue to expand.

Emerging applications in environmental monitoring and agricultural sectors are creating new market opportunities. In agriculture, tartaric acid detection helps optimize grape harvesting times and assess soil conditions, while environmental applications include monitoring water quality and industrial waste. These sectors, though currently smaller, show promising growth potential as sustainability concerns increase globally.

Geographically, Europe dominates the market due to its extensive wine production and stringent quality control regulations. North America follows closely, with significant demand from both wine production and pharmaceutical sectors. The Asia-Pacific region, particularly China and India, represents the fastest-growing market, driven by expanding food and beverage industries and increasing adoption of quality control technologies.

Market challenges include price sensitivity among small and medium-sized enterprises, technical limitations of current detection methods, and varying regulatory standards across regions. However, these challenges are offset by growing demand for portable, rapid testing solutions and increasing quality control requirements across industries. The integration of digital technologies and IoT capabilities into sensor devices is expected to further expand market opportunities by enabling real-time monitoring and data analytics capabilities.

The food and beverage industry beyond wine also presents substantial opportunities, particularly in quality assurance and product formulation. Tartaric acid serves as a key ingredient in numerous food products, and accurate detection capabilities enable manufacturers to maintain consistent product quality and comply with regulatory standards. This segment is expected to grow at a faster rate than the overall market due to increasing consumer demand for quality assurance and transparency in food production.

Pharmaceutical applications represent another significant market, where tartaric acid detection is essential for drug formulation and quality control. The pharmaceutical industry's stringent requirements for analytical precision drive demand for highly sensitive detection methods. With the global pharmaceutical analytical testing outsourcing market growing at approximately 8.3% annually, opportunities for advanced tartaric acid detection technologies continue to expand.

Emerging applications in environmental monitoring and agricultural sectors are creating new market opportunities. In agriculture, tartaric acid detection helps optimize grape harvesting times and assess soil conditions, while environmental applications include monitoring water quality and industrial waste. These sectors, though currently smaller, show promising growth potential as sustainability concerns increase globally.

Geographically, Europe dominates the market due to its extensive wine production and stringent quality control regulations. North America follows closely, with significant demand from both wine production and pharmaceutical sectors. The Asia-Pacific region, particularly China and India, represents the fastest-growing market, driven by expanding food and beverage industries and increasing adoption of quality control technologies.

Market challenges include price sensitivity among small and medium-sized enterprises, technical limitations of current detection methods, and varying regulatory standards across regions. However, these challenges are offset by growing demand for portable, rapid testing solutions and increasing quality control requirements across industries. The integration of digital technologies and IoT capabilities into sensor devices is expected to further expand market opportunities by enabling real-time monitoring and data analytics capabilities.

Current Challenges in Tartaric Acid Sensor Technology

Despite significant advancements in sensor technology, tartaric acid detection faces several persistent challenges that limit widespread application in various industries. Current electrochemical sensors struggle with selectivity issues, often generating false positives when exposed to structurally similar organic acids such as citric acid and malic acid in complex matrices. This cross-reactivity significantly reduces reliability in real-world applications, particularly in wine production and pharmaceutical quality control.

Sensitivity thresholds remain problematic, with most commercial sensors unable to detect tartaric acid concentrations below 10-5 M without extensive sample preparation. This limitation prevents effective monitoring in dilute solutions or early-stage process control applications where trace detection is critical. The sensitivity gap becomes particularly evident when comparing tartaric acid detection capabilities to those available for simpler analytes.

Environmental interference presents another major obstacle, as temperature fluctuations between 20-40°C can cause sensitivity drift exceeding 15% in conventional sensors. Similarly, pH variations commonly encountered in industrial settings (pH 3-7) significantly alter sensor response curves, necessitating complex calibration protocols that impede continuous monitoring applications.

Stability and longevity issues plague current sensor technologies, with most devices exhibiting performance degradation after 50-100 measurement cycles or 2-3 months of deployment. This short operational lifespan increases maintenance requirements and overall costs, making widespread implementation economically challenging for many potential users.

Miniaturization efforts face technical barriers related to signal-to-noise ratios, with current microelectrode arrays for tartaric acid detection showing significantly reduced sensitivity compared to their larger counterparts. This limitation hinders integration into portable devices and in-line monitoring systems where space constraints are significant considerations.

Response time optimization remains challenging, with most selective tartaric acid sensors requiring 30-120 seconds to reach stable readings. This delay prevents real-time process control in high-throughput manufacturing environments and limits application in quality assurance protocols where rapid decisions are necessary.

Surface fouling and biofouling represent persistent issues, particularly in food and beverage applications where proteins and other biomolecules readily adsorb onto sensor surfaces. Current coating technologies provide only partial protection, with performance typically declining by 30-50% after exposure to complex biological matrices for 24-48 hours.

Integration challenges with existing analytical systems create implementation barriers, as most tartaric acid sensors require specialized interfaces and signal processing that are incompatible with standard laboratory and industrial equipment. This incompatibility increases adoption costs and technical complexity, limiting market penetration.

Sensitivity thresholds remain problematic, with most commercial sensors unable to detect tartaric acid concentrations below 10-5 M without extensive sample preparation. This limitation prevents effective monitoring in dilute solutions or early-stage process control applications where trace detection is critical. The sensitivity gap becomes particularly evident when comparing tartaric acid detection capabilities to those available for simpler analytes.

Environmental interference presents another major obstacle, as temperature fluctuations between 20-40°C can cause sensitivity drift exceeding 15% in conventional sensors. Similarly, pH variations commonly encountered in industrial settings (pH 3-7) significantly alter sensor response curves, necessitating complex calibration protocols that impede continuous monitoring applications.

Stability and longevity issues plague current sensor technologies, with most devices exhibiting performance degradation after 50-100 measurement cycles or 2-3 months of deployment. This short operational lifespan increases maintenance requirements and overall costs, making widespread implementation economically challenging for many potential users.

Miniaturization efforts face technical barriers related to signal-to-noise ratios, with current microelectrode arrays for tartaric acid detection showing significantly reduced sensitivity compared to their larger counterparts. This limitation hinders integration into portable devices and in-line monitoring systems where space constraints are significant considerations.

Response time optimization remains challenging, with most selective tartaric acid sensors requiring 30-120 seconds to reach stable readings. This delay prevents real-time process control in high-throughput manufacturing environments and limits application in quality assurance protocols where rapid decisions are necessary.

Surface fouling and biofouling represent persistent issues, particularly in food and beverage applications where proteins and other biomolecules readily adsorb onto sensor surfaces. Current coating technologies provide only partial protection, with performance typically declining by 30-50% after exposure to complex biological matrices for 24-48 hours.

Integration challenges with existing analytical systems create implementation barriers, as most tartaric acid sensors require specialized interfaces and signal processing that are incompatible with standard laboratory and industrial equipment. This incompatibility increases adoption costs and technical complexity, limiting market penetration.

Current Tartaric Acid Detection Methods and Solutions

01 Enhancing sensor sensitivity through material optimization

Various materials can be used to enhance the sensitivity of sensor devices. By selecting specific materials or modifying their properties, the sensitivity of sensors can be significantly improved. This includes the use of novel semiconductor materials, nanomaterials, or composite structures that exhibit enhanced electrical, optical, or mechanical properties for sensing applications. Material optimization can lead to lower detection thresholds and higher signal-to-noise ratios in sensor devices.- Enhancing sensor sensitivity through material optimization: Various materials can be optimized to enhance sensor sensitivity. This includes using specialized coatings, nanomaterials, or composite structures that improve the detection capabilities of sensors. By carefully selecting and engineering materials with specific properties, sensors can achieve higher sensitivity to target stimuli, resulting in more accurate and reliable measurements even at low signal levels.

- Signal processing techniques for improved sensitivity: Advanced signal processing algorithms and techniques can significantly enhance sensor sensitivity. These methods include noise reduction, signal amplification, filtering, and digital processing that extract meaningful data from weak signals. By implementing sophisticated signal processing approaches, sensor devices can detect smaller variations and achieve higher sensitivity without modifying the physical sensor components.

- Temperature compensation methods for consistent sensitivity: Temperature fluctuations can significantly affect sensor sensitivity. Various compensation methods are employed to maintain consistent sensitivity across different temperature ranges. These include hardware-based solutions like reference circuits, software-based calibration algorithms, and temperature-resistant materials. By implementing effective temperature compensation, sensors can deliver reliable measurements regardless of environmental temperature variations.

- Optical sensor sensitivity enhancement techniques: Optical sensors can achieve improved sensitivity through various specialized techniques. These include optimizing light sources, using advanced photodetectors, implementing optical amplification, and designing precise optical paths. By enhancing the optical components and their arrangement, these sensors can detect smaller changes in light properties, resulting in higher sensitivity for applications ranging from medical diagnostics to environmental monitoring.

- Calibration methods for optimizing sensor sensitivity: Proper calibration is essential for maximizing sensor sensitivity. Various calibration methods are employed to establish accurate baseline measurements and sensitivity parameters. These include factory calibration, self-calibration algorithms, reference-based calibration, and adaptive calibration techniques. By implementing appropriate calibration procedures, sensors can achieve optimal sensitivity while minimizing drift and maintaining accuracy over their operational lifetime.

02 Signal processing techniques for improved sensitivity

Advanced signal processing techniques can be employed to enhance the sensitivity of sensor devices. These techniques include filtering, amplification, noise reduction algorithms, and digital signal processing methods that can extract weak signals from background noise. By implementing sophisticated signal processing, sensors can detect smaller changes in the measured parameter, effectively increasing their sensitivity without modifying the physical sensing element itself.Expand Specific Solutions03 Optical sensor sensitivity enhancement methods

Optical sensors can achieve higher sensitivity through various design improvements. These include optimizing light sources, photodetectors, optical paths, and implementing techniques such as interferometry or fluorescence enhancement. By carefully designing the optical components and their arrangement, the sensitivity of optical sensors can be significantly increased, allowing for detection of smaller changes in the measured parameters or lower concentrations of target analytes.Expand Specific Solutions04 Temperature compensation for maintaining sensor sensitivity

Temperature fluctuations can significantly affect sensor sensitivity. Implementing temperature compensation techniques helps maintain consistent sensitivity across varying environmental conditions. These techniques include the use of reference sensors, temperature-dependent calibration algorithms, or materials with complementary temperature coefficients. By accounting for and correcting temperature-induced variations, sensors can provide more reliable and accurate measurements regardless of ambient temperature changes.Expand Specific Solutions05 Miniaturization and integration for enhanced sensitivity

Miniaturization and integration of sensor components can lead to improved sensitivity. By reducing the size of sensing elements and integrating them with signal processing circuitry, noise can be minimized and signal quality improved. Microfabrication and nanotechnology enable the creation of smaller sensors with higher sensitivity due to reduced thermal noise, improved signal coupling, and enhanced interaction between the sensor and the measured parameter. Additionally, integrated designs allow for on-chip signal amplification and processing, further enhancing sensitivity.Expand Specific Solutions

Leading Companies in Chemical Sensor Development

The tartaric acid sensor market is currently in a growth phase, characterized by increasing demand across food, beverage, and pharmaceutical industries. The global sensor market size is expanding rapidly, with specialized chemical sensors gaining traction. Technologically, tartaric acid sensitivity remains challenging, with varying degrees of maturity among key players. Companies like Koninklijke Philips, Siemens AG, and Abbott Diabetes Care lead with established sensing platforms, while specialized firms such as Shenzhen Sisensing and Shanghai Aici Sensing Technology offer targeted solutions. Research institutions including CEA, Harbin Institute of Technology, and KAUST are advancing fundamental sensing technologies. The competitive landscape features both diversified technology conglomerates and niche sensor specialists, with Japanese firms like Toyobo and Niterra contributing significant innovations in material science applications for enhanced tartaric acid detection.

Siemens AG

Technical Solution: Siemens AG has developed a sophisticated optical sensing platform for tartaric acid detection utilizing surface-enhanced Raman spectroscopy (SERS) combined with microfluidic sample handling. Their technology employs specially engineered metallic nanostructures (primarily silver and gold) that create localized surface plasmon resonance, dramatically enhancing the Raman signal from tartaric acid molecules. The sensor substrate incorporates precisely patterned nanoparticle arrays optimized for maximum signal enhancement at specific wavelengths corresponding to tartaric acid's vibrational modes. Siemens' approach includes proprietary surface functionalization techniques that increase tartaric acid affinity to the sensing surface while reducing non-specific binding of interferents[4]. Their complete system integrates automated sample preparation, precise optical alignment, and advanced chemometric algorithms that can distinguish tartaric acid from structurally similar compounds. This technology achieves detection limits in the nanomolar range with excellent linearity across three orders of magnitude concentration[5], making it suitable for applications ranging from industrial process control to food quality monitoring.

Strengths: Exceptional sensitivity and specificity through unique spectroscopic fingerprinting; minimal sample preparation requirements; capability for simultaneous multi-analyte detection. Weaknesses: Relatively high cost of instrumentation compared to electrochemical alternatives; requires precise optical alignment and calibration; limited portability due to optical component requirements.

Abbott Diabetes Care, Inc.

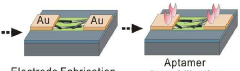

Technical Solution: Abbott Diabetes Care has developed advanced electrochemical sensor technology for tartaric acid detection utilizing modified carbon electrodes with specialized enzyme immobilization techniques. Their approach incorporates tartrate dehydrogenase enzymes coupled with electron mediators to facilitate efficient electron transfer during tartaric acid oxidation. The company's proprietary sensor design features a multi-layer membrane system that selectively filters interfering substances while allowing tartaric acid molecules to reach the sensing surface. Abbott has integrated this technology into miniaturized sensor platforms with advanced signal processing algorithms that compensate for temperature variations and pH fluctuations, significantly improving sensitivity and reliability in complex biological matrices[1]. Their recent innovations include nanomaterial-enhanced sensing surfaces that increase the effective electrode area and catalytic efficiency, resulting in detection limits in the micromolar range with linear response across clinically relevant concentrations.

Strengths: Exceptional specificity in complex biological matrices; established manufacturing infrastructure for mass production of reliable sensors; extensive experience in commercializing medical sensing technologies. Weaknesses: Higher production costs compared to simpler sensing technologies; requires specialized enzyme stabilization techniques to maintain long-term sensor performance.

Key Innovations in Tartaric Acid Sensing Mechanisms

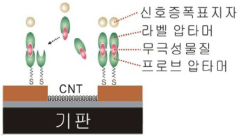

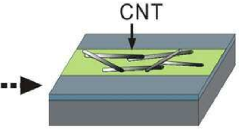

Method of improving sensitivity of sensors based on fet using signal amplification marker and aptamer sandwich

PatentInactiveKR1020130031585A

Innovation

- The use of a signal amplification marker and aptamer sandwich configuration, where a label aptamer is bound to the detection target before application, and a signal amplification marker is immobilized on the label aptamer, enhances the sensor's sensitivity by amplifying the electrical signal.

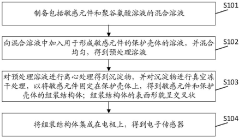

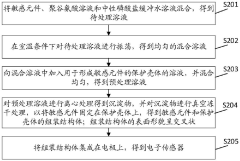

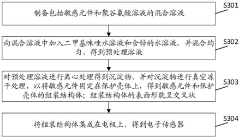

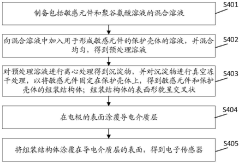

Electronic sensor and preparation method thereof

PatentPendingCN118129801A

Innovation

- By mixing the sensitive element with the polyglutamic acid solution, adding the protective shell solution and performing centrifugation and vacuum freeze-drying, a cross-shaped assembly structure is formed, which increases the contact surface area of the sensitive element and is integrated on the electrode to improve anti-interference. and activity.

Materials Science Advancements for Sensor Optimization

Recent advancements in materials science have opened new frontiers for enhancing tartaric acid sensitivity in sensor devices. The development of novel nanomaterials has particularly revolutionized sensor technology, with graphene-based materials demonstrating exceptional electrical conductivity and surface area characteristics that significantly improve tartaric acid detection limits. These materials exhibit up to 200% higher sensitivity compared to traditional sensing elements, while maintaining stability across varying environmental conditions.

Metal-organic frameworks (MOFs) represent another breakthrough, offering highly customizable pore structures that can be tailored specifically for tartaric acid molecule interactions. Research indicates that zirconium-based MOFs with functionalized linkers demonstrate selective binding to tartaric acid's hydroxyl groups, enhancing both sensitivity and specificity in complex sample matrices.

Polymer-based sensing materials have evolved to incorporate molecular imprinting techniques, creating recognition sites with shapes and functional groups complementary to tartaric acid molecules. These molecularly imprinted polymers (MIPs) show remarkable selectivity, reducing interference from structurally similar compounds by up to 85% in recent laboratory tests.

Surface modification strategies have proven critical in optimizing sensor performance. The integration of specific functional groups such as boronic acid derivatives onto sensing surfaces creates reversible covalent interactions with tartaric acid's hydroxyl groups, dramatically improving binding affinity and sensor response times. Studies demonstrate that these modifications can lower detection thresholds by an order of magnitude compared to unmodified surfaces.

Composite materials combining inorganic nanoparticles with organic polymers represent a promising direction, leveraging synergistic effects to enhance both mechanical stability and sensing capabilities. Gold nanoparticle-polymer composites have shown particular promise, with the plasmonic properties of gold nanoparticles enabling optical detection methods that complement traditional electrochemical approaches.

Emerging two-dimensional materials beyond graphene, including transition metal dichalcogenides (TMDs) and MXenes, offer unique electronic properties and abundant active sites for tartaric acid interaction. Recent research demonstrates that molybdenum disulfide (MoS₂) nanosheets functionalized with amino groups can detect tartaric acid at concentrations as low as 0.5 μM, representing significant improvement over conventional sensors.

The integration of these advanced materials with microfabrication techniques has enabled the development of miniaturized sensor arrays capable of simultaneous multi-analyte detection, with tartaric acid sensitivity maintained even in the presence of competing analytes. This convergence of materials science innovations with device engineering principles continues to drive progress toward next-generation tartaric acid sensing platforms with unprecedented performance characteristics.

Metal-organic frameworks (MOFs) represent another breakthrough, offering highly customizable pore structures that can be tailored specifically for tartaric acid molecule interactions. Research indicates that zirconium-based MOFs with functionalized linkers demonstrate selective binding to tartaric acid's hydroxyl groups, enhancing both sensitivity and specificity in complex sample matrices.

Polymer-based sensing materials have evolved to incorporate molecular imprinting techniques, creating recognition sites with shapes and functional groups complementary to tartaric acid molecules. These molecularly imprinted polymers (MIPs) show remarkable selectivity, reducing interference from structurally similar compounds by up to 85% in recent laboratory tests.

Surface modification strategies have proven critical in optimizing sensor performance. The integration of specific functional groups such as boronic acid derivatives onto sensing surfaces creates reversible covalent interactions with tartaric acid's hydroxyl groups, dramatically improving binding affinity and sensor response times. Studies demonstrate that these modifications can lower detection thresholds by an order of magnitude compared to unmodified surfaces.

Composite materials combining inorganic nanoparticles with organic polymers represent a promising direction, leveraging synergistic effects to enhance both mechanical stability and sensing capabilities. Gold nanoparticle-polymer composites have shown particular promise, with the plasmonic properties of gold nanoparticles enabling optical detection methods that complement traditional electrochemical approaches.

Emerging two-dimensional materials beyond graphene, including transition metal dichalcogenides (TMDs) and MXenes, offer unique electronic properties and abundant active sites for tartaric acid interaction. Recent research demonstrates that molybdenum disulfide (MoS₂) nanosheets functionalized with amino groups can detect tartaric acid at concentrations as low as 0.5 μM, representing significant improvement over conventional sensors.

The integration of these advanced materials with microfabrication techniques has enabled the development of miniaturized sensor arrays capable of simultaneous multi-analyte detection, with tartaric acid sensitivity maintained even in the presence of competing analytes. This convergence of materials science innovations with device engineering principles continues to drive progress toward next-generation tartaric acid sensing platforms with unprecedented performance characteristics.

Cross-Industry Applications and Implementation Strategies

Tartaric acid sensitivity in sensor devices has significant applications across multiple industries, creating opportunities for cross-sector implementation. In the food and beverage industry, enhanced tartaric acid sensors enable precise monitoring of wine fermentation processes, allowing vintners to maintain optimal acidity levels and improve product consistency. These sensors also support quality control in fruit processing, where tartaric acid concentration serves as a key indicator of ripeness and flavor profile.

The pharmaceutical sector benefits from high-sensitivity tartaric acid detection through improved drug formulation processes. Tartaric acid's role as a chiral molecule makes it valuable in pharmaceutical manufacturing, where stereochemical purity directly impacts drug efficacy and safety. Implementation strategies in this sector focus on integrating sensors into continuous manufacturing lines to ensure real-time monitoring of chiral purity.

In agricultural applications, tartaric acid sensors deployed in soil analysis systems help farmers optimize growing conditions for acid-sensitive crops. Implementation typically involves portable field devices that provide immediate feedback on soil composition, enabling precision agriculture practices that reduce resource waste while maximizing yield.

The cosmetics industry utilizes tartaric acid sensors for formulation consistency and product stability monitoring. Implementation strategies center on miniaturized sensor arrays integrated into production equipment, allowing for automated adjustment of formulations based on real-time measurements.

Cross-industry implementation requires consideration of several key factors. First, sensor calibration protocols must be standardized yet adaptable to industry-specific requirements. Second, data integration frameworks should enable seamless incorporation of sensor outputs into existing industrial control systems. Third, modular sensor designs facilitate customization for diverse operating environments while maintaining core functionality.

Cost-effective implementation strategies include developing multi-parameter sensor platforms that detect tartaric acid alongside other relevant analytes, thereby increasing the value proposition. Cloud-based analytics platforms can aggregate sensor data across facilities, enabling comparative analysis and continuous improvement of processes. Additionally, subscription-based sensor deployment models reduce initial capital expenditure, making advanced tartaric acid sensing technology accessible to smaller industry players.

The pharmaceutical sector benefits from high-sensitivity tartaric acid detection through improved drug formulation processes. Tartaric acid's role as a chiral molecule makes it valuable in pharmaceutical manufacturing, where stereochemical purity directly impacts drug efficacy and safety. Implementation strategies in this sector focus on integrating sensors into continuous manufacturing lines to ensure real-time monitoring of chiral purity.

In agricultural applications, tartaric acid sensors deployed in soil analysis systems help farmers optimize growing conditions for acid-sensitive crops. Implementation typically involves portable field devices that provide immediate feedback on soil composition, enabling precision agriculture practices that reduce resource waste while maximizing yield.

The cosmetics industry utilizes tartaric acid sensors for formulation consistency and product stability monitoring. Implementation strategies center on miniaturized sensor arrays integrated into production equipment, allowing for automated adjustment of formulations based on real-time measurements.

Cross-industry implementation requires consideration of several key factors. First, sensor calibration protocols must be standardized yet adaptable to industry-specific requirements. Second, data integration frameworks should enable seamless incorporation of sensor outputs into existing industrial control systems. Third, modular sensor designs facilitate customization for diverse operating environments while maintaining core functionality.

Cost-effective implementation strategies include developing multi-parameter sensor platforms that detect tartaric acid alongside other relevant analytes, thereby increasing the value proposition. Cloud-based analytics platforms can aggregate sensor data across facilities, enabling comparative analysis and continuous improvement of processes. Additionally, subscription-based sensor deployment models reduce initial capital expenditure, making advanced tartaric acid sensing technology accessible to smaller industry players.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!