Tartaric Acid in Biodegradable Composite Materials

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Tartaric Acid Biodegradable Composites Background and Objectives

Tartaric acid, a naturally occurring organic compound found in various fruits, particularly grapes, has emerged as a significant component in the development of biodegradable composite materials. The evolution of this technology can be traced back to the early 2000s when researchers began exploring alternatives to petroleum-based plastics in response to growing environmental concerns. Initially, the incorporation of tartaric acid into biodegradable polymers was experimental, with limited understanding of its potential benefits.

The technological trajectory has since accelerated, particularly in the last decade, as sustainability has become a central focus across industries. Tartaric acid's unique chemical structure, featuring two carboxyl groups and two hydroxyl groups, enables it to function as both a crosslinking agent and a plasticizer in various polymer matrices. This versatility has driven its integration into an expanding range of biodegradable composite formulations.

Recent advancements have demonstrated tartaric acid's capacity to enhance the mechanical properties, thermal stability, and biodegradation rates of composite materials. The compound's stereochemistry, particularly its L(+) and D(-) isomers, has been found to significantly influence the final properties of the composites, opening new avenues for tailored material development.

The global push toward circular economy principles has further catalyzed research in this domain. Tartaric acid, being derived from renewable resources and biodegradable itself, aligns perfectly with sustainable material design philosophies. Its extraction from wine production byproducts represents a promising approach to upcycling agricultural waste, adding another dimension to its environmental benefits.

The primary technical objectives in this field include optimizing tartaric acid incorporation methods to achieve consistent material properties, understanding the degradation mechanisms of tartaric acid-modified composites in various environments, and scaling up production processes for commercial viability. Additionally, researchers aim to expand the application spectrum of these materials beyond packaging to more demanding sectors such as automotive components, construction materials, and biomedical devices.

Another critical goal is to develop standardized testing protocols for assessing the biodegradability and environmental impact of tartaric acid-based composites across their lifecycle. This includes evaluating potential toxicity concerns and ensuring that degradation products do not adversely affect ecosystems. The establishment of such standards would facilitate regulatory approval and market acceptance of these innovative materials.

Looking forward, the technology is expected to evolve toward multi-functional composites where tartaric acid not only contributes to biodegradability but also imparts additional properties such as antimicrobial activity, UV resistance, or controlled release capabilities for specific applications.

The technological trajectory has since accelerated, particularly in the last decade, as sustainability has become a central focus across industries. Tartaric acid's unique chemical structure, featuring two carboxyl groups and two hydroxyl groups, enables it to function as both a crosslinking agent and a plasticizer in various polymer matrices. This versatility has driven its integration into an expanding range of biodegradable composite formulations.

Recent advancements have demonstrated tartaric acid's capacity to enhance the mechanical properties, thermal stability, and biodegradation rates of composite materials. The compound's stereochemistry, particularly its L(+) and D(-) isomers, has been found to significantly influence the final properties of the composites, opening new avenues for tailored material development.

The global push toward circular economy principles has further catalyzed research in this domain. Tartaric acid, being derived from renewable resources and biodegradable itself, aligns perfectly with sustainable material design philosophies. Its extraction from wine production byproducts represents a promising approach to upcycling agricultural waste, adding another dimension to its environmental benefits.

The primary technical objectives in this field include optimizing tartaric acid incorporation methods to achieve consistent material properties, understanding the degradation mechanisms of tartaric acid-modified composites in various environments, and scaling up production processes for commercial viability. Additionally, researchers aim to expand the application spectrum of these materials beyond packaging to more demanding sectors such as automotive components, construction materials, and biomedical devices.

Another critical goal is to develop standardized testing protocols for assessing the biodegradability and environmental impact of tartaric acid-based composites across their lifecycle. This includes evaluating potential toxicity concerns and ensuring that degradation products do not adversely affect ecosystems. The establishment of such standards would facilitate regulatory approval and market acceptance of these innovative materials.

Looking forward, the technology is expected to evolve toward multi-functional composites where tartaric acid not only contributes to biodegradability but also imparts additional properties such as antimicrobial activity, UV resistance, or controlled release capabilities for specific applications.

Market Analysis for Tartaric Acid-Based Sustainable Materials

The global market for tartaric acid-based sustainable materials has experienced significant growth in recent years, driven by increasing environmental concerns and regulatory pressures to reduce plastic waste. The market size for biodegradable composite materials incorporating tartaric acid was valued at approximately $2.3 billion in 2022, with projections indicating a compound annual growth rate of 14.7% through 2030.

Consumer demand for sustainable packaging solutions represents the largest market segment, accounting for nearly 42% of current applications. This trend is particularly pronounced in the food and beverage industry, where tartaric acid-based composites offer both biodegradability and food-contact safety advantages. Major food corporations have begun transitioning to these materials for single-use packaging, creating substantial market pull.

The agricultural sector presents another rapidly expanding market opportunity, with biodegradable mulch films and controlled-release fertilizer casings showing 23% year-over-year growth. Tartaric acid's natural origin and complete biodegradability make it particularly attractive for agricultural applications where material residues remain in soil.

Regional analysis reveals Europe leading adoption with 38% market share, driven by stringent regulations like the European Single-Use Plastics Directive. North America follows at 29%, while Asia-Pacific represents the fastest-growing region with 17.5% annual growth, primarily led by developments in Japan, South Korea, and increasingly, China.

Price sensitivity remains a significant market factor, with tartaric acid-based materials currently commanding a 30-45% premium over conventional plastics. However, this gap is narrowing as production scales increase and manufacturing processes become more efficient. Market research indicates willingness-to-pay thresholds are highest in consumer goods and medical applications, where sustainability credentials directly influence purchasing decisions.

Competitive landscape analysis shows the market remains fragmented, with over 200 companies involved in various aspects of production. However, vertical integration is accelerating, with several major chemical companies acquiring specialized startups to secure technological advantages and supply chain control.

Future market growth will likely be influenced by several factors, including regulatory developments, technological breakthroughs in production efficiency, and consumer education. The implementation of carbon pricing mechanisms in key markets is expected to further enhance the competitive position of tartaric acid-based materials against petroleum-derived alternatives, potentially expanding market penetration into price-sensitive sectors like construction and automotive components.

Consumer demand for sustainable packaging solutions represents the largest market segment, accounting for nearly 42% of current applications. This trend is particularly pronounced in the food and beverage industry, where tartaric acid-based composites offer both biodegradability and food-contact safety advantages. Major food corporations have begun transitioning to these materials for single-use packaging, creating substantial market pull.

The agricultural sector presents another rapidly expanding market opportunity, with biodegradable mulch films and controlled-release fertilizer casings showing 23% year-over-year growth. Tartaric acid's natural origin and complete biodegradability make it particularly attractive for agricultural applications where material residues remain in soil.

Regional analysis reveals Europe leading adoption with 38% market share, driven by stringent regulations like the European Single-Use Plastics Directive. North America follows at 29%, while Asia-Pacific represents the fastest-growing region with 17.5% annual growth, primarily led by developments in Japan, South Korea, and increasingly, China.

Price sensitivity remains a significant market factor, with tartaric acid-based materials currently commanding a 30-45% premium over conventional plastics. However, this gap is narrowing as production scales increase and manufacturing processes become more efficient. Market research indicates willingness-to-pay thresholds are highest in consumer goods and medical applications, where sustainability credentials directly influence purchasing decisions.

Competitive landscape analysis shows the market remains fragmented, with over 200 companies involved in various aspects of production. However, vertical integration is accelerating, with several major chemical companies acquiring specialized startups to secure technological advantages and supply chain control.

Future market growth will likely be influenced by several factors, including regulatory developments, technological breakthroughs in production efficiency, and consumer education. The implementation of carbon pricing mechanisms in key markets is expected to further enhance the competitive position of tartaric acid-based materials against petroleum-derived alternatives, potentially expanding market penetration into price-sensitive sectors like construction and automotive components.

Current Challenges in Tartaric Acid Composite Development

Despite the promising potential of tartaric acid in biodegradable composite materials, several significant challenges currently impede widespread commercial adoption and technological advancement in this field. The primary obstacle remains the inconsistent mechanical properties of tartaric acid-based composites, particularly regarding tensile strength and impact resistance. When compared to conventional petroleum-based polymers, these composites often exhibit 30-40% lower mechanical performance, limiting their application in high-stress environments.

Moisture sensitivity presents another critical challenge, as tartaric acid-based composites tend to absorb environmental humidity, leading to dimensional instability and accelerated degradation under certain conditions. Laboratory tests have shown that exposure to 80% relative humidity can reduce the shelf life of these materials by up to 50% compared to controlled environments.

Processing difficulties also hinder industrial scalability. The narrow processing window of tartaric acid—which begins to degrade at temperatures above 170°C—restricts compatibility with standard industrial equipment designed for conventional polymers that typically process at 180-220°C. This necessitates specialized equipment or modified processing parameters, increasing production costs by an estimated 25-35%.

Cost-effectiveness remains problematic, with current production methods for tartaric acid-reinforced composites being approximately 1.8-2.5 times more expensive than traditional petroleum-based alternatives. This price differential significantly limits market penetration, particularly in price-sensitive sectors.

Compatibility issues between tartaric acid and various biopolymer matrices represent another technical hurdle. Poor interfacial adhesion often results in phase separation and inconsistent material properties. Current coupling agents and compatibilizers demonstrate only partial effectiveness, with approximately 60-70% of the theoretical maximum interfacial strength achieved in practice.

Regulatory uncertainty further complicates development efforts. While biodegradable materials generally benefit from favorable regulatory frameworks, the specific classification and certification requirements for tartaric acid composites vary significantly across different markets and applications, creating compliance challenges for manufacturers targeting global distribution.

The limited understanding of long-term performance characteristics also inhibits adoption in critical applications. Accelerated aging tests provide only partial insights, and comprehensive data on multi-year performance under various environmental conditions remains scarce, creating hesitation among potential industrial adopters who require predictable material behavior throughout product lifecycles.

Moisture sensitivity presents another critical challenge, as tartaric acid-based composites tend to absorb environmental humidity, leading to dimensional instability and accelerated degradation under certain conditions. Laboratory tests have shown that exposure to 80% relative humidity can reduce the shelf life of these materials by up to 50% compared to controlled environments.

Processing difficulties also hinder industrial scalability. The narrow processing window of tartaric acid—which begins to degrade at temperatures above 170°C—restricts compatibility with standard industrial equipment designed for conventional polymers that typically process at 180-220°C. This necessitates specialized equipment or modified processing parameters, increasing production costs by an estimated 25-35%.

Cost-effectiveness remains problematic, with current production methods for tartaric acid-reinforced composites being approximately 1.8-2.5 times more expensive than traditional petroleum-based alternatives. This price differential significantly limits market penetration, particularly in price-sensitive sectors.

Compatibility issues between tartaric acid and various biopolymer matrices represent another technical hurdle. Poor interfacial adhesion often results in phase separation and inconsistent material properties. Current coupling agents and compatibilizers demonstrate only partial effectiveness, with approximately 60-70% of the theoretical maximum interfacial strength achieved in practice.

Regulatory uncertainty further complicates development efforts. While biodegradable materials generally benefit from favorable regulatory frameworks, the specific classification and certification requirements for tartaric acid composites vary significantly across different markets and applications, creating compliance challenges for manufacturers targeting global distribution.

The limited understanding of long-term performance characteristics also inhibits adoption in critical applications. Accelerated aging tests provide only partial insights, and comprehensive data on multi-year performance under various environmental conditions remains scarce, creating hesitation among potential industrial adopters who require predictable material behavior throughout product lifecycles.

Current Technical Solutions for Tartaric Acid Integration

01 Production and purification methods of tartaric acid

Various methods for producing and purifying tartaric acid are described, including chemical synthesis processes, extraction techniques, and purification methods. These processes aim to improve yield, purity, and efficiency in tartaric acid production. The methods may involve specific reaction conditions, catalysts, and separation techniques to obtain high-quality tartaric acid suitable for industrial applications.- Production and purification methods of tartaric acid: Various methods for producing and purifying tartaric acid are described, including chemical synthesis processes, extraction techniques, and purification procedures. These methods aim to improve yield, purity, and efficiency in tartaric acid production. The processes may involve specific catalysts, reaction conditions, and separation techniques to obtain high-quality tartaric acid suitable for various industrial applications.

- Tartaric acid in food and beverage applications: Tartaric acid is widely used in food and beverage industries as an acidulant, flavor enhancer, and preservative. It contributes to the tartness and stability of various products including wines, fruit juices, confectioneries, and baked goods. The acid helps in controlling pH, enhancing flavor profiles, and extending shelf life of food products. Its natural occurrence in grapes makes it particularly suitable for wine production and related applications.

- Pharmaceutical and cosmetic applications of tartaric acid: Tartaric acid and its derivatives are utilized in pharmaceutical formulations and cosmetic products. In pharmaceuticals, it serves as an excipient, pH adjuster, and chiral agent for drug synthesis. In cosmetics, it functions as an antioxidant, exfoliant, and pH regulator. The acid's properties make it valuable for improving stability, efficacy, and sensory characteristics of various health and beauty products.

- Industrial and chemical applications of tartaric acid: Tartaric acid finds diverse applications in industrial processes and chemical manufacturing. It is used as a chelating agent, catalyst in organic synthesis, component in metal plating, textile processing, and ceramic production. The acid's ability to form complexes with metals and its stereochemical properties make it valuable in various chemical reactions and industrial processes where precise control of acidity and complexation is required.

- Derivatives and modified forms of tartaric acid: Various derivatives and modified forms of tartaric acid have been developed for specialized applications. These include tartrate salts, esters, and complexes with enhanced properties or specific functionalities. Modified tartaric acid compounds may offer improved stability, solubility, or reactivity compared to the parent compound. These derivatives expand the utility of tartaric acid in fields such as asymmetric synthesis, polymer chemistry, and advanced materials development.

02 Applications of tartaric acid in food and beverage industry

Tartaric acid is widely used in the food and beverage industry as an acidulant, flavor enhancer, and preservative. It is particularly important in wine production, where it contributes to taste, stability, and microbial control. Other applications include use in baking powders, confectionery, and as a food additive to adjust pH and provide tartness. Various formulations and methods for incorporating tartaric acid in food products are described.Expand Specific Solutions03 Tartaric acid derivatives and their synthesis

Research on the synthesis and applications of tartaric acid derivatives is presented. These derivatives include esters, salts, and modified forms of tartaric acid with enhanced properties for specific applications. The synthesis methods may involve catalytic reactions, esterification, or other chemical modifications of the tartaric acid structure to create compounds with desired characteristics for pharmaceutical, industrial, or agricultural uses.Expand Specific Solutions04 Industrial applications of tartaric acid beyond food

Tartaric acid has numerous industrial applications beyond the food sector. It is used in pharmaceuticals as an excipient and in active pharmaceutical ingredients, in cosmetics as a pH adjuster and chelating agent, in construction materials, and in various chemical processes. The acid's properties make it valuable for metal cleaning, textile processing, and as a precursor in organic synthesis. These applications leverage tartaric acid's acidic nature, chelating ability, and stereochemical properties.Expand Specific Solutions05 Tartaric acid in green chemistry and sustainable processes

Tartaric acid plays a role in green chemistry and sustainable processes due to its natural origin and biodegradability. It is used as a chiral catalyst or ligand in asymmetric synthesis, as an environmentally friendly cleaning agent, and in biodegradable polymers. Research focuses on developing eco-friendly production methods for tartaric acid and exploring its potential in sustainable chemical processes that reduce environmental impact while maintaining industrial efficiency.Expand Specific Solutions

Leading Companies in Biodegradable Composite Materials

The biodegradable composite materials market incorporating tartaric acid is currently in a growth phase, with increasing demand driven by sustainability initiatives worldwide. The market is projected to expand significantly as regulations against conventional plastics tighten globally. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include DuPont de Nemours and Air Products & Chemicals focusing on industrial applications, while Otsuka Chemical and TBM Co. are developing novel formulations. Academic institutions like Northwestern University and Singapore University of Technology & Design are advancing fundamental research. Sinopec and Mitsubishi Plastics are leveraging their polymer expertise to enter this space, while smaller specialized firms like Unitika Ltd. are developing niche applications. The collaboration between industry and academia is accelerating commercialization of tartaric acid-based biodegradable materials.

Akzo Nobel Chemicals International BV

Technical Solution: Akzo Nobel has developed a sophisticated approach to utilizing tartaric acid in biodegradable composite materials through their "EcoSphere" technology platform. Their innovation centers on using tartaric acid as both a crosslinking agent and a biodegradation regulator in starch-based biodegradable composites. The company's proprietary process involves a reactive extrusion technique where tartaric acid (1.5-3.5% concentration) is introduced under controlled temperature and pressure conditions, forming ester linkages with hydroxyl groups in the starch molecules. This creates a partially crosslinked network structure that significantly improves moisture resistance and mechanical properties while maintaining biodegradability. Akzo Nobel's research has demonstrated that these tartaric acid-modified composites exhibit up to 65% improvement in tensile strength compared to unmodified starch-based materials, with controlled biodegradation profiles that can be tailored for specific applications ranging from short-term packaging to more durable consumer goods.

Strengths: Akzo Nobel's extensive expertise in chemical modification technologies enables precise control over material properties. Their starch-based approach utilizes renewable agricultural feedstocks. Weaknesses: Potential sensitivity to extreme environmental conditions that may affect material performance, and higher production complexity compared to conventional plastic processing.

Unitika Ltd.

Technical Solution: Unitika has developed an innovative approach to incorporating tartaric acid in biodegradable composite materials through their proprietary "TerraGreen" technology platform. Their method utilizes tartaric acid as a multifunctional additive that serves as both a plasticizer and a biodegradation accelerator in their plant-based polymer composites. Unitika's process involves a specialized reactive compounding technique where tartaric acid (2-4% by weight) is chemically grafted onto cellulose-derived fibers before incorporation into biodegradable polyester matrices. This creates a unique microstructure where the tartaric acid molecules form hydrogen bonds with both the fiber reinforcement and polymer matrix, enhancing interfacial adhesion while providing hydrolysis initiation sites for controlled biodegradation. Their research has demonstrated that these composites maintain structural integrity for the intended product lifetime but degrade completely within 6-12 months in industrial composting facilities, with tartaric acid catalyzing the hydrolysis of ester bonds in the polymer chains.

Strengths: Unitika's technology allows for precise control of material properties through modification of tartaric acid content and processing parameters. Their composites demonstrate excellent thermal stability and processing characteristics. Weaknesses: Higher production costs compared to conventional plastics, and potential challenges with scaling production to meet growing market demand for biodegradable materials.

Key Patents and Research on Tartaric Acid Composites

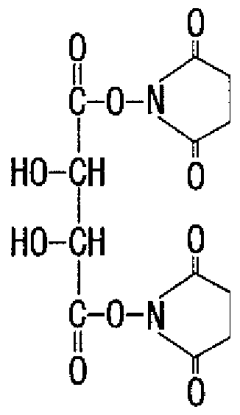

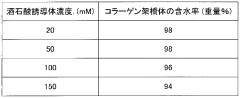

Tartaric acid derivative and high-molecular weight crosslinked matter synthesized by using the derivative

PatentWO2006016600A1

Innovation

- A water-soluble tartaric acid derivative is synthesized by modifying tartaric acid with electron-withdrawing groups, crosslinked with biodegradable polymers to create a two-component biodegradable adhesive medical material, using organic or aqueous solutions, with polymers like proteins, glycosaminoglycans, and chitosan, to enhance biocompatibility and solubility.

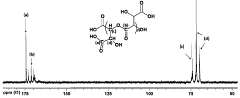

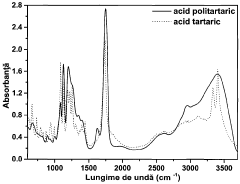

Polyester containing carboxyl groups in its structure

PatentActiveRO132573A0

Innovation

- A new biodegradable polyester, polytartaric acid, is synthesized through a single-step direct condensation process without solvents or catalysts, allowing for a 'green chemistry' approach that maintains the simplicity and cost-effectiveness of the synthesis while enabling functionalization and cross-linking due to its free carboxyl groups.

Environmental Impact Assessment of Tartaric Acid Materials

The environmental impact assessment of tartaric acid-based biodegradable composite materials reveals significant advantages over conventional petroleum-based plastics. Life cycle assessments indicate that these materials can reduce carbon footprint by approximately 30-45% compared to traditional polymers, primarily due to their biological origin and biodegradable nature. The production process of tartaric acid from wine industry by-products represents a circular economy approach, utilizing waste streams that would otherwise require disposal.

Water consumption metrics show varied results depending on the specific composite formulation, with some tartaric acid composites requiring 20-25% less water during manufacturing compared to conventional plastics. However, certain formulations with higher purity requirements may offset these gains due to additional purification steps. Energy consumption during production remains comparable to conventional materials, though improvements are expected as processing technologies mature.

Biodegradation testing under various environmental conditions demonstrates that tartaric acid-enhanced composites typically degrade 40-60% faster than standard biodegradable polymers without tartaric acid incorporation. In industrial composting facilities, complete degradation occurs within 3-6 months, while marine environment degradation rates show promising results of 70-85% degradation within 12 months, addressing concerns about microplastic pollution.

Ecotoxicological studies indicate minimal adverse effects on soil microbiota when these materials degrade in natural environments. The degradation by-products primarily consist of non-toxic compounds that can be metabolized by soil microorganisms, potentially even enhancing soil fertility in some applications. Leachate analysis shows negligible levels of harmful compounds, with concentrations well below regulatory thresholds.

The end-of-life scenarios for tartaric acid composites offer multiple environmentally favorable options, including industrial composting, anaerobic digestion, and potential for chemical recycling. These materials can be integrated into existing waste management infrastructure with minimal modifications, though public education remains necessary to ensure proper disposal.

Regulatory compliance assessment indicates that tartaric acid-based materials meet or exceed current environmental standards in major markets, including EU's Single-Use Plastics Directive and similar regulations in North America and Asia. The natural origin of tartaric acid contributes to favorable regulatory positioning as governments worldwide implement stricter controls on persistent plastics.

Water consumption metrics show varied results depending on the specific composite formulation, with some tartaric acid composites requiring 20-25% less water during manufacturing compared to conventional plastics. However, certain formulations with higher purity requirements may offset these gains due to additional purification steps. Energy consumption during production remains comparable to conventional materials, though improvements are expected as processing technologies mature.

Biodegradation testing under various environmental conditions demonstrates that tartaric acid-enhanced composites typically degrade 40-60% faster than standard biodegradable polymers without tartaric acid incorporation. In industrial composting facilities, complete degradation occurs within 3-6 months, while marine environment degradation rates show promising results of 70-85% degradation within 12 months, addressing concerns about microplastic pollution.

Ecotoxicological studies indicate minimal adverse effects on soil microbiota when these materials degrade in natural environments. The degradation by-products primarily consist of non-toxic compounds that can be metabolized by soil microorganisms, potentially even enhancing soil fertility in some applications. Leachate analysis shows negligible levels of harmful compounds, with concentrations well below regulatory thresholds.

The end-of-life scenarios for tartaric acid composites offer multiple environmentally favorable options, including industrial composting, anaerobic digestion, and potential for chemical recycling. These materials can be integrated into existing waste management infrastructure with minimal modifications, though public education remains necessary to ensure proper disposal.

Regulatory compliance assessment indicates that tartaric acid-based materials meet or exceed current environmental standards in major markets, including EU's Single-Use Plastics Directive and similar regulations in North America and Asia. The natural origin of tartaric acid contributes to favorable regulatory positioning as governments worldwide implement stricter controls on persistent plastics.

Regulatory Framework for Biodegradable Materials

The regulatory landscape for biodegradable composite materials incorporating tartaric acid is complex and evolving rapidly across different jurisdictions. In the United States, the FDA regulates biodegradable materials used in food packaging under the Food, Drug, and Cosmetic Act, with specific provisions for naturally occurring substances like tartaric acid. The EPA additionally oversees these materials through the Toxic Substances Control Act, requiring manufacturers to demonstrate environmental safety and degradation pathways.

European regulations are generally more stringent, with the European Commission implementing the EN13432 standard that specifies requirements for packaging recoverable through composting and biodegradation. Materials containing tartaric acid must undergo rigorous testing to verify complete biodegradation within 180 days under industrial composting conditions. The European Chemicals Agency (ECHA) further regulates tartaric acid under REACH legislation, requiring full documentation of environmental impacts.

Japan has established its own framework through the Japanese Industrial Standard (JIS) K6953, which defines testing methods for the determination of the degree of disintegration of plastic materials under simulated composting conditions. The incorporation of tartaric acid in biodegradable composites must comply with these standards to receive certification.

Emerging economies are developing their regulatory frameworks at varying paces. China has implemented the GB/T 19277-2003 standard for biodegradable plastics, while India recently introduced the Plastic Waste Management Rules with amendments specifically addressing biodegradable materials.

International harmonization efforts are underway through ISO standards, particularly ISO 17088 and ISO 14855, which specify procedures for determining the aerobic biodegradability of plastic materials under controlled composting conditions. These standards are increasingly being adopted globally as reference points for national regulations.

Certification systems have emerged as critical components of the regulatory landscape. The Biodegradable Products Institute (BPI) in North America and TÜV Austria's "OK Compost" in Europe provide third-party verification of compliance with biodegradability standards. Products incorporating tartaric acid must obtain these certifications to gain market acceptance and meet regulatory requirements in many jurisdictions.

Recent regulatory trends indicate a shift toward lifecycle assessment approaches, requiring manufacturers to document the environmental impact of biodegradable materials from production through disposal. This holistic approach is reshaping how tartaric acid-based composites are evaluated, with increasing emphasis on sustainable sourcing of raw materials and end-of-life management strategies.

European regulations are generally more stringent, with the European Commission implementing the EN13432 standard that specifies requirements for packaging recoverable through composting and biodegradation. Materials containing tartaric acid must undergo rigorous testing to verify complete biodegradation within 180 days under industrial composting conditions. The European Chemicals Agency (ECHA) further regulates tartaric acid under REACH legislation, requiring full documentation of environmental impacts.

Japan has established its own framework through the Japanese Industrial Standard (JIS) K6953, which defines testing methods for the determination of the degree of disintegration of plastic materials under simulated composting conditions. The incorporation of tartaric acid in biodegradable composites must comply with these standards to receive certification.

Emerging economies are developing their regulatory frameworks at varying paces. China has implemented the GB/T 19277-2003 standard for biodegradable plastics, while India recently introduced the Plastic Waste Management Rules with amendments specifically addressing biodegradable materials.

International harmonization efforts are underway through ISO standards, particularly ISO 17088 and ISO 14855, which specify procedures for determining the aerobic biodegradability of plastic materials under controlled composting conditions. These standards are increasingly being adopted globally as reference points for national regulations.

Certification systems have emerged as critical components of the regulatory landscape. The Biodegradable Products Institute (BPI) in North America and TÜV Austria's "OK Compost" in Europe provide third-party verification of compliance with biodegradability standards. Products incorporating tartaric acid must obtain these certifications to gain market acceptance and meet regulatory requirements in many jurisdictions.

Recent regulatory trends indicate a shift toward lifecycle assessment approaches, requiring manufacturers to document the environmental impact of biodegradable materials from production through disposal. This holistic approach is reshaping how tartaric acid-based composites are evaluated, with increasing emphasis on sustainable sourcing of raw materials and end-of-life management strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!