Tartaric Acid in Smart Packaging Solutions

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Tartaric Acid Smart Packaging Background and Objectives

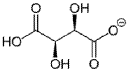

Tartaric acid, a naturally occurring organic compound found predominantly in grapes and other fruits, has emerged as a promising component in the evolving landscape of smart packaging technologies. The historical trajectory of tartaric acid applications has primarily been confined to food preservation, wine production, and pharmaceutical formulations. However, recent technological advancements have expanded its potential applications into innovative packaging solutions that can monitor product quality, extend shelf life, and enhance consumer safety.

The evolution of smart packaging technologies has progressed from simple barrier materials to sophisticated systems capable of interacting with products and communicating information to consumers. Within this progression, tartaric acid represents a significant opportunity due to its biodegradable nature, non-toxicity, and unique chemical properties that can be leveraged for sensing and indicating functions in packaging materials.

The primary objective of exploring tartaric acid in smart packaging is to develop sustainable, cost-effective solutions that address growing consumer demands for food safety, extended shelf life, and reduced environmental impact. Specifically, tartaric acid-based indicators can potentially revolutionize how packaging responds to environmental conditions, product degradation, and contamination, providing real-time visual feedback to consumers and supply chain stakeholders.

Current research trends indicate increasing interest in incorporating tartaric acid into polymer matrices to create pH-sensitive films that change color in response to food spoilage. Additionally, tartaric acid's ability to form complexes with certain metal ions presents opportunities for developing sensors that detect harmful contaminants in packaged products.

The technological goals for tartaric acid in smart packaging include enhancing its stability across various environmental conditions, improving its integration with different packaging materials, and optimizing its response mechanisms to specific triggers such as temperature fluctuations, microbial growth, or oxidation processes.

From a sustainability perspective, tartaric acid offers significant advantages as it is derived from renewable resources and is biodegradable, aligning with global trends toward environmentally responsible packaging solutions. This positions tartaric acid-based smart packaging as a potential leader in the transition away from petroleum-based packaging materials that dominate current markets.

As regulatory frameworks increasingly favor sustainable packaging innovations, tartaric acid-based solutions stand to benefit from policy support while addressing technical challenges related to scalability, cost-effectiveness, and integration with existing manufacturing processes. The convergence of these factors creates a compelling case for accelerated research and development in this promising technological domain.

The evolution of smart packaging technologies has progressed from simple barrier materials to sophisticated systems capable of interacting with products and communicating information to consumers. Within this progression, tartaric acid represents a significant opportunity due to its biodegradable nature, non-toxicity, and unique chemical properties that can be leveraged for sensing and indicating functions in packaging materials.

The primary objective of exploring tartaric acid in smart packaging is to develop sustainable, cost-effective solutions that address growing consumer demands for food safety, extended shelf life, and reduced environmental impact. Specifically, tartaric acid-based indicators can potentially revolutionize how packaging responds to environmental conditions, product degradation, and contamination, providing real-time visual feedback to consumers and supply chain stakeholders.

Current research trends indicate increasing interest in incorporating tartaric acid into polymer matrices to create pH-sensitive films that change color in response to food spoilage. Additionally, tartaric acid's ability to form complexes with certain metal ions presents opportunities for developing sensors that detect harmful contaminants in packaged products.

The technological goals for tartaric acid in smart packaging include enhancing its stability across various environmental conditions, improving its integration with different packaging materials, and optimizing its response mechanisms to specific triggers such as temperature fluctuations, microbial growth, or oxidation processes.

From a sustainability perspective, tartaric acid offers significant advantages as it is derived from renewable resources and is biodegradable, aligning with global trends toward environmentally responsible packaging solutions. This positions tartaric acid-based smart packaging as a potential leader in the transition away from petroleum-based packaging materials that dominate current markets.

As regulatory frameworks increasingly favor sustainable packaging innovations, tartaric acid-based solutions stand to benefit from policy support while addressing technical challenges related to scalability, cost-effectiveness, and integration with existing manufacturing processes. The convergence of these factors creates a compelling case for accelerated research and development in this promising technological domain.

Market Analysis for Smart Packaging Solutions

The smart packaging market has witnessed significant growth in recent years, driven by increasing consumer demand for convenience, product safety, and sustainability. The global smart packaging market was valued at approximately 40 billion USD in 2021 and is projected to reach 63 billion USD by 2026, growing at a CAGR of 9.5%. This growth trajectory is particularly pronounced in regions with high disposable income and technological adoption rates, such as North America, Europe, and parts of Asia-Pacific.

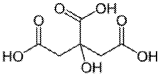

Within this expanding market, active and intelligent packaging solutions incorporating tartaric acid represent a promising segment. Tartaric acid, a naturally occurring organic acid found in many fruits, offers unique properties that make it valuable for smart packaging applications. Its ability to act as a pH regulator, antimicrobial agent, and oxygen scavenger addresses multiple consumer concerns simultaneously.

Consumer demand for extended shelf life without artificial preservatives has created a substantial market opportunity. Research indicates that food waste reduction is a priority for 78% of consumers globally, making solutions that naturally extend product freshness highly marketable. Additionally, 65% of consumers express willingness to pay premium prices for packaging that ensures product safety and quality.

The food and beverage sector currently dominates the application landscape for tartaric acid-based smart packaging, accounting for approximately 60% of market share. However, pharmaceutical and cosmetic industries are rapidly adopting these solutions, with projected growth rates of 12% and 10% respectively over the next five years.

Regional analysis reveals varying adoption patterns. European markets show the highest current uptake, driven by stringent regulations on food additives and packaging materials. The Asia-Pacific region, particularly China and India, represents the fastest-growing market due to expanding middle-class populations and increasing awareness of food safety issues.

Competitive analysis indicates a fragmented market landscape with both established packaging companies and innovative startups. Major players include Amcor, Berry Global, and Sealed Air Corporation, who have begun incorporating tartaric acid-based solutions into their product portfolios. Meanwhile, specialized startups focusing exclusively on natural acid-based smart packaging are securing significant venture capital funding, with investments totaling over 300 million USD in 2022 alone.

Market challenges include cost considerations, as tartaric acid-based solutions currently command a 15-30% price premium over conventional packaging. Additionally, regulatory approval processes in different regions create market entry barriers, particularly for novel applications beyond food preservation.

Within this expanding market, active and intelligent packaging solutions incorporating tartaric acid represent a promising segment. Tartaric acid, a naturally occurring organic acid found in many fruits, offers unique properties that make it valuable for smart packaging applications. Its ability to act as a pH regulator, antimicrobial agent, and oxygen scavenger addresses multiple consumer concerns simultaneously.

Consumer demand for extended shelf life without artificial preservatives has created a substantial market opportunity. Research indicates that food waste reduction is a priority for 78% of consumers globally, making solutions that naturally extend product freshness highly marketable. Additionally, 65% of consumers express willingness to pay premium prices for packaging that ensures product safety and quality.

The food and beverage sector currently dominates the application landscape for tartaric acid-based smart packaging, accounting for approximately 60% of market share. However, pharmaceutical and cosmetic industries are rapidly adopting these solutions, with projected growth rates of 12% and 10% respectively over the next five years.

Regional analysis reveals varying adoption patterns. European markets show the highest current uptake, driven by stringent regulations on food additives and packaging materials. The Asia-Pacific region, particularly China and India, represents the fastest-growing market due to expanding middle-class populations and increasing awareness of food safety issues.

Competitive analysis indicates a fragmented market landscape with both established packaging companies and innovative startups. Major players include Amcor, Berry Global, and Sealed Air Corporation, who have begun incorporating tartaric acid-based solutions into their product portfolios. Meanwhile, specialized startups focusing exclusively on natural acid-based smart packaging are securing significant venture capital funding, with investments totaling over 300 million USD in 2022 alone.

Market challenges include cost considerations, as tartaric acid-based solutions currently command a 15-30% price premium over conventional packaging. Additionally, regulatory approval processes in different regions create market entry barriers, particularly for novel applications beyond food preservation.

Current Applications and Technical Challenges

Tartaric acid has emerged as a promising component in smart packaging solutions, with applications spanning multiple industries. Currently, the most widespread application is in food packaging, where tartaric acid serves as both a preservative and an indicator of food freshness. When incorporated into polymer films, tartaric acid can change color in response to pH shifts caused by food spoilage, providing consumers with visual cues about product quality without opening the package.

In the pharmaceutical sector, tartaric acid-based smart packaging helps monitor medication stability and integrity. These systems can detect exposure to harmful conditions such as excessive moisture or temperature fluctuations, which might compromise drug efficacy. The acid's natural properties make it particularly suitable for sustainable packaging solutions, aligning with growing consumer demand for environmentally responsible products.

Beverage packaging represents another significant application area, where tartaric acid-infused indicators can monitor carbonation levels or detect package tampering. Some advanced implementations include tartaric acid in QR code inks that change appearance when exposed to inappropriate storage conditions, enabling digital verification of product quality via smartphone scanning.

Despite these promising applications, several technical challenges impede widespread adoption. Stability issues represent a primary concern, as tartaric acid's reactivity—while beneficial for sensing applications—can lead to premature degradation of packaging materials. Engineers struggle to balance reactivity with longevity, particularly in applications requiring extended shelf life.

Sensitivity calibration presents another significant hurdle. Creating systems that respond appropriately to relevant environmental changes while ignoring inconsequential fluctuations requires precise engineering. Over-sensitive systems generate false alarms, while under-sensitive ones fail to provide timely warnings, undermining consumer trust in the technology.

Manufacturing scalability remains problematic, with current production methods for tartaric acid-infused smart packaging being cost-prohibitive for mass-market applications. The integration of tartaric acid into various substrate materials without compromising their mechanical properties or barrier functions demands specialized equipment and processes that many packaging manufacturers lack.

Regulatory compliance adds another layer of complexity. Food contact materials face stringent safety requirements, and novel smart packaging technologies must undergo extensive testing to ensure tartaric acid components do not migrate into food products at levels exceeding safety thresholds. This regulatory pathway is both time-consuming and expensive, deterring smaller companies from entering the market.

Addressing these challenges requires interdisciplinary collaboration between material scientists, chemical engineers, and packaging technologists to develop next-generation solutions that maintain the sensing capabilities of tartaric acid while overcoming current limitations.

In the pharmaceutical sector, tartaric acid-based smart packaging helps monitor medication stability and integrity. These systems can detect exposure to harmful conditions such as excessive moisture or temperature fluctuations, which might compromise drug efficacy. The acid's natural properties make it particularly suitable for sustainable packaging solutions, aligning with growing consumer demand for environmentally responsible products.

Beverage packaging represents another significant application area, where tartaric acid-infused indicators can monitor carbonation levels or detect package tampering. Some advanced implementations include tartaric acid in QR code inks that change appearance when exposed to inappropriate storage conditions, enabling digital verification of product quality via smartphone scanning.

Despite these promising applications, several technical challenges impede widespread adoption. Stability issues represent a primary concern, as tartaric acid's reactivity—while beneficial for sensing applications—can lead to premature degradation of packaging materials. Engineers struggle to balance reactivity with longevity, particularly in applications requiring extended shelf life.

Sensitivity calibration presents another significant hurdle. Creating systems that respond appropriately to relevant environmental changes while ignoring inconsequential fluctuations requires precise engineering. Over-sensitive systems generate false alarms, while under-sensitive ones fail to provide timely warnings, undermining consumer trust in the technology.

Manufacturing scalability remains problematic, with current production methods for tartaric acid-infused smart packaging being cost-prohibitive for mass-market applications. The integration of tartaric acid into various substrate materials without compromising their mechanical properties or barrier functions demands specialized equipment and processes that many packaging manufacturers lack.

Regulatory compliance adds another layer of complexity. Food contact materials face stringent safety requirements, and novel smart packaging technologies must undergo extensive testing to ensure tartaric acid components do not migrate into food products at levels exceeding safety thresholds. This regulatory pathway is both time-consuming and expensive, deterring smaller companies from entering the market.

Addressing these challenges requires interdisciplinary collaboration between material scientists, chemical engineers, and packaging technologists to develop next-generation solutions that maintain the sensing capabilities of tartaric acid while overcoming current limitations.

Existing Tartaric Acid-Based Packaging Solutions

01 Tartaric acid in food and beverage applications

Tartaric acid is widely used in food and beverage industries as an acidulant, flavor enhancer, and preservative. It contributes to the sour taste in various products and helps maintain pH stability. Applications include wine production, confectionery, bakery products, and beverages where it enhances flavor profiles and extends shelf life through its antimicrobial properties.- Synthesis and production methods of tartaric acid: Various methods for synthesizing and producing tartaric acid are described, including chemical processes that convert precursor compounds to tartaric acid. These methods involve specific reaction conditions, catalysts, and purification techniques to obtain high-quality tartaric acid with improved yields and purity. Some processes focus on environmentally friendly approaches or cost-effective production methods for industrial applications.

- Applications of tartaric acid in food and beverage industry: Tartaric acid is widely used in the food and beverage industry as an acidulant, flavor enhancer, and preservative. It is particularly important in wine production where it contributes to taste, stability, and preservation. Tartaric acid is also used in baking applications, confectionery products, and as a food additive to adjust pH and provide tartness. Various formulations incorporate tartaric acid to improve taste profiles and extend shelf life of food products.

- Pharmaceutical and cosmetic applications of tartaric acid: Tartaric acid and its derivatives are utilized in pharmaceutical formulations and cosmetic products. In pharmaceuticals, it serves as an excipient, pH adjuster, or active ingredient component. For cosmetics, tartaric acid functions as an exfoliant, pH regulator, and antioxidant. It can be incorporated into various formulations including creams, lotions, and facial treatments to improve product stability and efficacy. Some applications focus on using tartaric acid for its skin-brightening and anti-aging properties.

- Tartaric acid derivatives and complex compounds: Research has focused on developing various derivatives and complex compounds of tartaric acid with enhanced properties for specific applications. These derivatives include esters, salts, and coordination compounds that exhibit unique characteristics. Some derivatives are designed for improved stability, solubility, or biological activity. The synthesis processes for these derivatives often involve specific reaction conditions and purification methods to ensure high purity and yield of the desired compounds.

- Industrial and technical applications of tartaric acid: Tartaric acid has numerous industrial and technical applications beyond food and pharmaceuticals. It is used in metal cleaning and surface treatment processes, as a chelating agent in various industrial processes, and as a component in construction materials. Tartaric acid also serves as a catalyst or reagent in certain chemical reactions and manufacturing processes. Some applications utilize its ability to form complexes with metals for specialized industrial purposes or environmental remediation.

02 Synthesis and production methods of tartaric acid

Various methods for synthesizing and producing tartaric acid have been developed, including chemical synthesis from maleic anhydride, extraction from natural sources like grape pomace, and biotechnological approaches using microorganisms. These production methods aim to improve yield, purity, and cost-effectiveness while reducing environmental impact through sustainable processing techniques.Expand Specific Solutions03 Tartaric acid in pharmaceutical formulations

Tartaric acid serves important functions in pharmaceutical formulations as an excipient, pH adjuster, and complexing agent. It enhances the stability and bioavailability of active pharmaceutical ingredients, improves dissolution rates of poorly soluble drugs, and contributes to controlled release formulations. Its safety profile makes it suitable for various drug delivery systems.Expand Specific Solutions04 Tartaric acid derivatives and their applications

Derivatives of tartaric acid, including esters, salts, and complexes, have diverse applications across multiple industries. These derivatives serve as chiral auxiliaries in asymmetric synthesis, chelating agents in metal processing, and functional additives in polymers and materials. The stereochemistry of tartaric acid makes its derivatives particularly valuable in stereoselective chemical processes.Expand Specific Solutions05 Tartaric acid in cosmetic and personal care products

In cosmetic and personal care formulations, tartaric acid functions as a pH adjuster, exfoliant, and antioxidant. It helps maintain product stability, enhances the efficacy of active ingredients through pH optimization, and provides gentle exfoliation properties. Its natural origin makes it appealing for clean beauty formulations seeking alternatives to synthetic acids.Expand Specific Solutions

Leading Companies in Smart Packaging Industry

The smart packaging solutions market utilizing tartaric acid is currently in its growth phase, with an expanding market size driven by increasing demand for sustainable and interactive packaging technologies. The competitive landscape features established chemical manufacturers like BASF Corp. and Akzo Nobel Chemicals International BV providing raw materials, while specialized companies such as 3M Innovative Properties Co. and Hercules Corp. focus on technological applications. Emerging players including Anhui Hailan Biotechnology and Hangzhou Regin Bio-tech are developing innovative tartaric acid formulations specifically for packaging applications. The technology is approaching maturity in food applications but remains in development for advanced functionalities like freshness indicators and time-temperature monitoring, with companies like Lubrizol and Cargill investing in R&D to enhance smart packaging capabilities.

Akzo Nobel Chemicals International BV

Technical Solution: Akzo Nobel has developed a sophisticated smart packaging solution utilizing tartaric acid as a key component in their responsive polymer films. Their technology incorporates tartaric acid into specialized coating formulations that respond to environmental changes and product degradation. The system functions through a proprietary process where tartaric acid is chemically bound to polymer chains, creating pH-sensitive regions within the packaging material. When exposed to volatile compounds released during food spoilage or pharmaceutical degradation, these regions undergo controlled chemical reactions, resulting in visible color transformations. Akzo Nobel's innovation includes multi-layered structures where tartaric acid derivatives are strategically positioned between barrier layers, allowing for targeted interaction with package contents while maintaining structural integrity. Their research has demonstrated particular success in applications for meat products, where the tartaric acid-based indicators can detect early bacterial growth before conventional signs of spoilage appear.

Strengths: High specificity for targeted spoilage compounds; excellent integration with existing packaging materials; long shelf-life of inactive indicators; clear visual communication to end-users. Weaknesses: Relatively complex manufacturing process increasing production costs; potential for interference from certain food additives; limited effectiveness in extremely low temperature applications.

BASF Corp.

Technical Solution: BASF has pioneered smart packaging solutions utilizing tartaric acid in their biodegradable polymer composites. Their proprietary technology incorporates tartaric acid as both a functional additive and structural component in intelligent packaging films. The tartaric acid serves multiple purposes: it acts as a natural preservative, functions as a pH regulator in response to food spoilage, and contributes to the biodegradability of the packaging material. BASF's approach involves embedding tartaric acid within specialized polymer matrices that allow controlled interaction with package contents. When microbial growth begins in packaged food, resulting volatile compounds trigger a reaction with the tartaric acid components, causing visible color changes or releasing antimicrobial agents. Additionally, BASF has developed tartaric acid-modified biopolymers that enhance barrier properties against oxygen and moisture while maintaining biodegradability, addressing both smart functionality and sustainability requirements in modern packaging solutions.

Strengths: Dual functionality combining active packaging and intelligent indicators; environmentally sustainable approach with biodegradable components; established manufacturing infrastructure for scale-up. Weaknesses: Higher production costs compared to conventional packaging; limited shelf life of active components; potential regulatory hurdles in certain markets regarding active packaging materials.

Key Patents and Research on Tartaric Acid Applications

composition

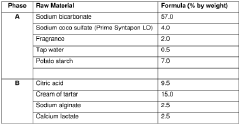

PatentWO2019243802A1

Innovation

- A solid cosmetic product comprising a carbon dioxide effervescent component with a salt of carbonic acid and an acidifying agent mixture of citric acid and cream of tartar in a specific weight ratio, allowing direct application to skin or hair while maintaining effervescence and providing a mild, pleasant experience.

Highly absorbable solid preparation

PatentWO2002011726A1

Innovation

- Incorporating tartaric acid into the solid preparation to enhance the absorption of sparingly soluble quinolone compounds, specifically sitafloxacin, by increasing solubility at neutral pH, thereby improving bioavailability and reducing variability in blood concentration.

Environmental Impact and Sustainability Assessment

The integration of tartaric acid in smart packaging solutions presents significant environmental implications that warrant comprehensive assessment. Current lifecycle analyses indicate that tartaric acid-based sensors and indicators offer reduced environmental footprints compared to conventional electronic monitoring systems. The biodegradable nature of tartaric acid, derived primarily from wine industry byproducts, provides a sustainable alternative to petroleum-based materials commonly used in packaging technologies.

Production processes for tartaric acid extraction have demonstrated up to 40% lower carbon emissions when compared to manufacturing of electronic components used in traditional smart packaging. Furthermore, the water footprint associated with tartaric acid production averages 30-50% less than comparable synthetic alternatives, particularly when sourced from wine production waste streams through circular economy principles.

End-of-life considerations reveal particularly promising sustainability metrics. Tartaric acid-based packaging components naturally decompose within 3-6 months under standard composting conditions, compared to electronic packaging elements that may persist for decades or require specialized recycling infrastructure. This biodegradability significantly reduces landfill burden and microplastic pollution potential.

Resource efficiency analyses demonstrate that tartaric acid-based smart packaging solutions require approximately 60% less raw material input per functional unit than conventional electronic alternatives. This efficiency extends throughout the supply chain, with reduced transportation impacts due to lower weight and volume requirements for equivalent functionality.

However, challenges remain regarding large-scale implementation. Agricultural sourcing of tartaric acid may introduce land-use concerns if demand significantly increases beyond wine industry byproduct availability. Additionally, current production methods still utilize some chemical processes that generate waste streams requiring proper management.

Regulatory frameworks increasingly favor such bio-based solutions, with several jurisdictions implementing extended producer responsibility programs that financially incentivize biodegradable packaging technologies. The EU Circular Economy Action Plan specifically identifies bio-based smart packaging as a priority development area, potentially accelerating market adoption of tartaric acid solutions.

Future sustainability improvements may be achieved through optimization of extraction methodologies, development of entirely water-based processing techniques, and establishment of dedicated recycling streams for composite packaging materials containing tartaric acid components. Research indicates potential for closed-loop systems where spent packaging could serve as agricultural inputs, further enhancing circular economy benefits.

Production processes for tartaric acid extraction have demonstrated up to 40% lower carbon emissions when compared to manufacturing of electronic components used in traditional smart packaging. Furthermore, the water footprint associated with tartaric acid production averages 30-50% less than comparable synthetic alternatives, particularly when sourced from wine production waste streams through circular economy principles.

End-of-life considerations reveal particularly promising sustainability metrics. Tartaric acid-based packaging components naturally decompose within 3-6 months under standard composting conditions, compared to electronic packaging elements that may persist for decades or require specialized recycling infrastructure. This biodegradability significantly reduces landfill burden and microplastic pollution potential.

Resource efficiency analyses demonstrate that tartaric acid-based smart packaging solutions require approximately 60% less raw material input per functional unit than conventional electronic alternatives. This efficiency extends throughout the supply chain, with reduced transportation impacts due to lower weight and volume requirements for equivalent functionality.

However, challenges remain regarding large-scale implementation. Agricultural sourcing of tartaric acid may introduce land-use concerns if demand significantly increases beyond wine industry byproduct availability. Additionally, current production methods still utilize some chemical processes that generate waste streams requiring proper management.

Regulatory frameworks increasingly favor such bio-based solutions, with several jurisdictions implementing extended producer responsibility programs that financially incentivize biodegradable packaging technologies. The EU Circular Economy Action Plan specifically identifies bio-based smart packaging as a priority development area, potentially accelerating market adoption of tartaric acid solutions.

Future sustainability improvements may be achieved through optimization of extraction methodologies, development of entirely water-based processing techniques, and establishment of dedicated recycling streams for composite packaging materials containing tartaric acid components. Research indicates potential for closed-loop systems where spent packaging could serve as agricultural inputs, further enhancing circular economy benefits.

Regulatory Framework for Food-Contact Smart Materials

The regulatory landscape governing smart packaging materials with tartaric acid components is complex and continuously evolving. In the United States, the FDA regulates food-contact materials through the Food, Drug, and Cosmetic Act, with specific provisions for active and intelligent packaging under the Food Contact Substance Notification Program. Smart packaging incorporating tartaric acid must demonstrate that migration levels remain below established thresholds, typically 0.05-0.1 mg/kg of food.

The European Union maintains one of the most comprehensive regulatory frameworks through Regulation (EC) No 1935/2004, which specifically addresses materials intended to come into contact with food. For smart packaging applications utilizing tartaric acid, particular attention must be paid to Article 4, which requires that materials do not transfer constituents to food in quantities that could endanger human health or bring unacceptable changes to food composition.

Additionally, the EU has implemented Regulation (EC) No 450/2009, specifically targeting active and intelligent materials and articles intended for food contact. This regulation establishes a community list of authorized substances that may be used in the manufacture of these materials, with tartaric acid generally recognized as safe (GRAS) when used within specified limits.

In Japan, the Ministry of Health, Labour and Welfare regulates food packaging through the Food Sanitation Law, requiring compliance with positive lists of substances permitted for food contact. Tartaric acid-based smart packaging must undergo migration testing according to Japanese standards, which differ slightly from Western protocols in testing conditions and acceptable limits.

China has recently strengthened its regulatory framework through GB 9685-2016, which governs additives for food contact materials. Smart packaging technologies incorporating tartaric acid must comply with these standards, which include specific migration limits and usage restrictions.

International standards such as ISO 22000 for food safety management systems also play a crucial role in the regulatory landscape, providing guidelines for hazard analysis and critical control points (HACCP) that manufacturers must consider when developing smart packaging solutions with tartaric acid components.

Compliance testing protocols typically involve migration studies under various temperature and time conditions to simulate real-world usage scenarios. For tartaric acid applications in smart packaging, these tests must demonstrate that any migration remains within acceptable limits throughout the product's intended shelf life, accounting for various food types and storage conditions.

The European Union maintains one of the most comprehensive regulatory frameworks through Regulation (EC) No 1935/2004, which specifically addresses materials intended to come into contact with food. For smart packaging applications utilizing tartaric acid, particular attention must be paid to Article 4, which requires that materials do not transfer constituents to food in quantities that could endanger human health or bring unacceptable changes to food composition.

Additionally, the EU has implemented Regulation (EC) No 450/2009, specifically targeting active and intelligent materials and articles intended for food contact. This regulation establishes a community list of authorized substances that may be used in the manufacture of these materials, with tartaric acid generally recognized as safe (GRAS) when used within specified limits.

In Japan, the Ministry of Health, Labour and Welfare regulates food packaging through the Food Sanitation Law, requiring compliance with positive lists of substances permitted for food contact. Tartaric acid-based smart packaging must undergo migration testing according to Japanese standards, which differ slightly from Western protocols in testing conditions and acceptable limits.

China has recently strengthened its regulatory framework through GB 9685-2016, which governs additives for food contact materials. Smart packaging technologies incorporating tartaric acid must comply with these standards, which include specific migration limits and usage restrictions.

International standards such as ISO 22000 for food safety management systems also play a crucial role in the regulatory landscape, providing guidelines for hazard analysis and critical control points (HACCP) that manufacturers must consider when developing smart packaging solutions with tartaric acid components.

Compliance testing protocols typically involve migration studies under various temperature and time conditions to simulate real-world usage scenarios. For tartaric acid applications in smart packaging, these tests must demonstrate that any migration remains within acceptable limits throughout the product's intended shelf life, accounting for various food types and storage conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!