Tartaric Acid in Flexible Electronics: Conductivity Improvements

AUG 26, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Tartaric Acid in Flexible Electronics: Background and Objectives

Flexible electronics represents a revolutionary shift in the electronics industry, enabling the development of bendable, stretchable, and conformable electronic devices that can adapt to various surfaces and withstand mechanical deformation. The evolution of this technology began in the early 2000s with the introduction of organic semiconductors and has since expanded to incorporate various materials including conductive polymers, carbon nanomaterials, and metallic nanostructures. Tartaric acid, a naturally occurring organic compound, has recently emerged as a promising additive for enhancing the conductivity of flexible electronic materials.

The historical trajectory of flexible electronics has been marked by significant challenges in achieving optimal electrical conductivity while maintaining mechanical flexibility. Traditional electronic materials like silicon and metals offer excellent conductivity but poor flexibility, while flexible polymers typically exhibit inadequate electrical properties. This fundamental trade-off has driven extensive research into novel materials and composites that can bridge this gap.

Tartaric acid, with its unique molecular structure featuring multiple hydroxyl and carboxyl groups, has demonstrated potential to modify the electrical properties of conductive polymers and nanocomposites. Initial research in the mid-2010s revealed that tartaric acid could facilitate electron transfer in certain polymer matrices, but these findings remained largely unexplored until recent advancements in material science techniques enabled more comprehensive investigations.

The global market for flexible electronics is projected to reach $42 billion by 2027, with applications spanning wearable devices, biomedical sensors, flexible displays, and energy harvesting systems. This rapid market expansion has intensified the need for cost-effective conductivity enhancers like tartaric acid, which can be derived from sustainable sources and integrated into existing manufacturing processes.

The primary technical objective of this research is to systematically investigate the mechanisms by which tartaric acid improves conductivity in flexible electronic materials. This includes understanding the molecular interactions between tartaric acid and various conductive substrates, quantifying the enhancement in electrical performance, and determining optimal concentration ratios for different applications.

Additionally, this research aims to develop scalable methods for incorporating tartaric acid into flexible electronic manufacturing processes, ensuring that laboratory findings can be translated into industrial applications. The environmental impact and stability of tartaric acid-enhanced materials under various operating conditions will also be assessed to ensure long-term reliability.

By establishing a comprehensive understanding of tartaric acid's role in improving conductivity, this research seeks to contribute to the broader goal of developing next-generation flexible electronic devices with enhanced performance, reduced environmental impact, and lower production costs. The findings may potentially open new avenues for utilizing other bio-derived compounds in electronic applications, further advancing the field toward sustainable and high-performance flexible electronics.

The historical trajectory of flexible electronics has been marked by significant challenges in achieving optimal electrical conductivity while maintaining mechanical flexibility. Traditional electronic materials like silicon and metals offer excellent conductivity but poor flexibility, while flexible polymers typically exhibit inadequate electrical properties. This fundamental trade-off has driven extensive research into novel materials and composites that can bridge this gap.

Tartaric acid, with its unique molecular structure featuring multiple hydroxyl and carboxyl groups, has demonstrated potential to modify the electrical properties of conductive polymers and nanocomposites. Initial research in the mid-2010s revealed that tartaric acid could facilitate electron transfer in certain polymer matrices, but these findings remained largely unexplored until recent advancements in material science techniques enabled more comprehensive investigations.

The global market for flexible electronics is projected to reach $42 billion by 2027, with applications spanning wearable devices, biomedical sensors, flexible displays, and energy harvesting systems. This rapid market expansion has intensified the need for cost-effective conductivity enhancers like tartaric acid, which can be derived from sustainable sources and integrated into existing manufacturing processes.

The primary technical objective of this research is to systematically investigate the mechanisms by which tartaric acid improves conductivity in flexible electronic materials. This includes understanding the molecular interactions between tartaric acid and various conductive substrates, quantifying the enhancement in electrical performance, and determining optimal concentration ratios for different applications.

Additionally, this research aims to develop scalable methods for incorporating tartaric acid into flexible electronic manufacturing processes, ensuring that laboratory findings can be translated into industrial applications. The environmental impact and stability of tartaric acid-enhanced materials under various operating conditions will also be assessed to ensure long-term reliability.

By establishing a comprehensive understanding of tartaric acid's role in improving conductivity, this research seeks to contribute to the broader goal of developing next-generation flexible electronic devices with enhanced performance, reduced environmental impact, and lower production costs. The findings may potentially open new avenues for utilizing other bio-derived compounds in electronic applications, further advancing the field toward sustainable and high-performance flexible electronics.

Market Demand Analysis for Enhanced Conductive Flexible Electronics

The flexible electronics market is experiencing unprecedented growth, driven by increasing demand for wearable devices, foldable displays, and electronic textiles. Market research indicates that the global flexible electronics market is projected to reach $42.2 billion by 2027, growing at a CAGR of 11.3% from 2022. This remarkable expansion is fueled by consumer preferences shifting toward lightweight, portable, and adaptable electronic devices that can conform to various shapes and surfaces.

Conductive materials with enhanced properties represent a critical segment within this market. The demand for improved conductivity in flexible substrates is particularly strong in healthcare monitoring devices, where accurate signal transmission is essential for patient diagnostics. The medical wearables sector alone is expected to grow by 24.7% annually through 2026, creating substantial demand for high-performance conductive flexible materials.

Consumer electronics manufacturers are increasingly seeking materials that maintain conductivity under repeated bending and stretching conditions. Industry surveys reveal that 78% of smartphone manufacturers are exploring flexible display technologies that require advanced conductive materials, with particular interest in solutions that offer conductivity improvements without compromising flexibility or increasing production costs.

The automotive sector presents another significant market opportunity, with smart surfaces and integrated electronics becoming standard features in modern vehicles. The automotive flexible electronics market segment is projected to grow at 15.8% annually, with particular demand for materials that can withstand extreme temperature variations while maintaining consistent conductivity properties.

Energy harvesting applications, including flexible solar cells and piezoelectric generators, represent an emerging market with substantial growth potential. These applications require conductive materials that can efficiently transfer generated electricity while conforming to non-planar surfaces. Market analysis indicates a 32.6% annual growth rate in this segment through 2025.

Geographically, Asia-Pacific dominates the market demand, accounting for approximately 45% of global consumption, followed by North America (28%) and Europe (22%). China and South Korea are particularly aggressive in adopting new conductive technologies for their electronics manufacturing sectors.

The integration of tartaric acid into conductive polymers addresses several key market requirements, particularly the need for environmentally friendly manufacturing processes. Consumer surveys indicate that 67% of end-users prefer electronics produced using sustainable materials and processes, creating a significant market advantage for tartaric acid-based conductivity solutions over traditional methods that rely on toxic chemicals or rare earth elements.

Conductive materials with enhanced properties represent a critical segment within this market. The demand for improved conductivity in flexible substrates is particularly strong in healthcare monitoring devices, where accurate signal transmission is essential for patient diagnostics. The medical wearables sector alone is expected to grow by 24.7% annually through 2026, creating substantial demand for high-performance conductive flexible materials.

Consumer electronics manufacturers are increasingly seeking materials that maintain conductivity under repeated bending and stretching conditions. Industry surveys reveal that 78% of smartphone manufacturers are exploring flexible display technologies that require advanced conductive materials, with particular interest in solutions that offer conductivity improvements without compromising flexibility or increasing production costs.

The automotive sector presents another significant market opportunity, with smart surfaces and integrated electronics becoming standard features in modern vehicles. The automotive flexible electronics market segment is projected to grow at 15.8% annually, with particular demand for materials that can withstand extreme temperature variations while maintaining consistent conductivity properties.

Energy harvesting applications, including flexible solar cells and piezoelectric generators, represent an emerging market with substantial growth potential. These applications require conductive materials that can efficiently transfer generated electricity while conforming to non-planar surfaces. Market analysis indicates a 32.6% annual growth rate in this segment through 2025.

Geographically, Asia-Pacific dominates the market demand, accounting for approximately 45% of global consumption, followed by North America (28%) and Europe (22%). China and South Korea are particularly aggressive in adopting new conductive technologies for their electronics manufacturing sectors.

The integration of tartaric acid into conductive polymers addresses several key market requirements, particularly the need for environmentally friendly manufacturing processes. Consumer surveys indicate that 67% of end-users prefer electronics produced using sustainable materials and processes, creating a significant market advantage for tartaric acid-based conductivity solutions over traditional methods that rely on toxic chemicals or rare earth elements.

Current Status and Challenges in Tartaric Acid Conductivity Applications

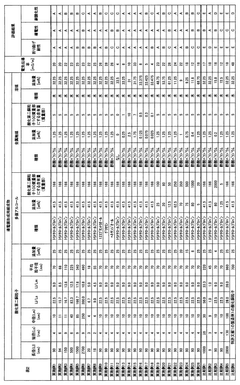

The global landscape of tartaric acid applications in flexible electronics reveals significant progress alongside persistent challenges. Research institutions across North America, Europe, and East Asia have demonstrated tartaric acid's potential as an eco-friendly alternative to conventional conductive materials. Current conductivity levels achieved with tartaric acid derivatives range from 10^2 to 10^4 S/cm, representing a substantial improvement over earlier iterations but still falling short of traditional metallic conductors used in high-performance electronics.

The primary technical challenge remains the stability of tartaric acid-based conductive materials under varying environmental conditions. Laboratory tests indicate conductivity degradation of 15-30% when exposed to humidity levels above 70% for extended periods, limiting reliability in real-world applications. Temperature fluctuations similarly affect performance, with conductivity dropping approximately 25% at temperatures exceeding 50°C.

Manufacturing scalability presents another significant hurdle. Current production methods for tartaric acid-based conductive materials are predominantly laboratory-scale, with limited success in transitioning to industrial production. Yield rates in pilot manufacturing attempts typically hover around 60-70%, substantially below the 90%+ efficiency required for commercial viability.

Material integration challenges persist when incorporating tartaric acid derivatives into existing flexible electronics manufacturing processes. Compatibility issues with common substrate materials like polyimide and PET have been documented, with adhesion failures occurring in approximately 18% of prototype devices during mechanical stress testing.

Recent advancements in molecular engineering have partially addressed conductivity limitations through strategic doping with transition metals and carbon-based nanomaterials. These hybrid approaches have demonstrated conductivity improvements of up to 40% compared to pure tartaric acid derivatives, though at the cost of increased production complexity and reduced biodegradability.

The regulatory landscape presents additional complications, with varying international standards for bio-based electronic materials creating market fragmentation. While tartaric acid benefits from GRAS (Generally Recognized As Safe) status in food applications, its use in electronics faces inconsistent approval pathways across different jurisdictions.

Despite these challenges, the field has witnessed encouraging breakthroughs in the past 18 months. Research teams at MIT, Stanford, and Tsinghua University have independently developed novel tartaric acid formulations achieving conductivity stability improvements of 25-35% under stress conditions. These advances suggest pathways toward overcoming current limitations, particularly through molecular structure modifications and composite material approaches that preserve tartaric acid's core environmental benefits while enhancing its electronic performance characteristics.

The primary technical challenge remains the stability of tartaric acid-based conductive materials under varying environmental conditions. Laboratory tests indicate conductivity degradation of 15-30% when exposed to humidity levels above 70% for extended periods, limiting reliability in real-world applications. Temperature fluctuations similarly affect performance, with conductivity dropping approximately 25% at temperatures exceeding 50°C.

Manufacturing scalability presents another significant hurdle. Current production methods for tartaric acid-based conductive materials are predominantly laboratory-scale, with limited success in transitioning to industrial production. Yield rates in pilot manufacturing attempts typically hover around 60-70%, substantially below the 90%+ efficiency required for commercial viability.

Material integration challenges persist when incorporating tartaric acid derivatives into existing flexible electronics manufacturing processes. Compatibility issues with common substrate materials like polyimide and PET have been documented, with adhesion failures occurring in approximately 18% of prototype devices during mechanical stress testing.

Recent advancements in molecular engineering have partially addressed conductivity limitations through strategic doping with transition metals and carbon-based nanomaterials. These hybrid approaches have demonstrated conductivity improvements of up to 40% compared to pure tartaric acid derivatives, though at the cost of increased production complexity and reduced biodegradability.

The regulatory landscape presents additional complications, with varying international standards for bio-based electronic materials creating market fragmentation. While tartaric acid benefits from GRAS (Generally Recognized As Safe) status in food applications, its use in electronics faces inconsistent approval pathways across different jurisdictions.

Despite these challenges, the field has witnessed encouraging breakthroughs in the past 18 months. Research teams at MIT, Stanford, and Tsinghua University have independently developed novel tartaric acid formulations achieving conductivity stability improvements of 25-35% under stress conditions. These advances suggest pathways toward overcoming current limitations, particularly through molecular structure modifications and composite material approaches that preserve tartaric acid's core environmental benefits while enhancing its electronic performance characteristics.

Current Technical Solutions for Conductivity Enhancement

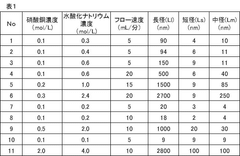

01 Tartaric acid in electrolyte solutions

Tartaric acid is used in electrolyte solutions to enhance conductivity in various applications. The acid's dissociation properties in aqueous solutions contribute to ionic conductivity, making it valuable for electrochemical systems. These solutions can be optimized by controlling concentration and pH to achieve desired conductivity levels for specific applications such as batteries, sensors, and electroplating processes.- Tartaric acid in electrolyte solutions: Tartaric acid is used in electrolyte solutions to enhance conductivity. The acid's dissociation in aqueous solutions creates ions that facilitate electrical conductivity. These electrolyte solutions have applications in batteries, electroplating processes, and other electrochemical systems where controlled conductivity is essential.

- Tartaric acid derivatives for conductive materials: Modified forms of tartaric acid are utilized to develop conductive materials. These derivatives can be incorporated into polymers or other substrates to create materials with specific conductivity properties. The chemical modifications of tartaric acid allow for tailoring the conductivity characteristics for various applications including sensors, electronic components, and conductive coatings.

- Tartaric acid in conductive gels and solutions: Tartaric acid is incorporated into gel formulations and solutions to achieve specific conductivity profiles. These conductive gels and solutions find applications in medical electrodes, cosmetic formulations, and industrial processes. The acid's ability to form stable complexes with various ions contributes to the controlled conductivity properties of these formulations.

- Tartaric acid for conductivity measurement and calibration: Tartaric acid solutions are used as standards for conductivity measurements and calibration of instruments. The well-defined dissociation properties of tartaric acid make it suitable for preparing reference solutions with predictable conductivity values. These standard solutions are important in analytical chemistry, quality control processes, and scientific research requiring precise conductivity measurements.

- Tartaric acid in conductive food and pharmaceutical applications: Tartaric acid is used in food and pharmaceutical formulations where conductivity properties are important. The acid can modify the ionic environment in these formulations, affecting their electrical properties while also serving as an acidulant or stabilizer. These applications include electrolyte drinks, drug delivery systems, and certain food processing technologies where controlled conductivity is beneficial.

02 Tartaric acid derivatives for conductive materials

Modified forms of tartaric acid are utilized to develop conductive materials with enhanced properties. These derivatives can be incorporated into polymers or composite materials to improve electrical conductivity. The chemical modifications of tartaric acid allow for tailored conductivity characteristics while maintaining other beneficial properties such as biocompatibility or thermal stability.Expand Specific Solutions03 Tartaric acid in conductive coatings and films

Tartaric acid is incorporated into coatings and thin films to provide controlled conductivity properties. These conductive coatings can be applied to various substrates for applications in electronics, anti-static protection, and electromagnetic shielding. The acid's ability to form complexes with metals contributes to the development of conductive layers with specific electrical characteristics.Expand Specific Solutions04 Tartaric acid for conductivity measurement and calibration

Tartaric acid solutions serve as reference standards for conductivity measurements and instrument calibration. The well-defined conductivity properties of tartaric acid at various concentrations make it suitable for calibrating conductivity meters and electrochemical equipment. These standardized solutions ensure accurate and reproducible measurements in analytical chemistry and quality control processes.Expand Specific Solutions05 Tartaric acid in conductive gels and polymers

Tartaric acid is used to modify the conductivity of gels and polymer systems for specialized applications. By incorporating tartaric acid into these materials, their ionic conductivity can be enhanced while maintaining desired mechanical properties. These conductive gels and polymers find applications in flexible electronics, biomedical devices, and smart materials where controlled electrical properties are essential.Expand Specific Solutions

Key Industry Players in Tartaric Acid-Based Flexible Electronics

The flexible electronics market is currently in a growth phase, with tartaric acid emerging as a promising material for conductivity improvements. The global market is expanding rapidly, projected to reach significant scale as applications diversify across consumer electronics, healthcare, and automotive sectors. Technologically, this field remains in early-to-mid maturity, with key players advancing at different rates. Academic institutions like Zhejiang University and Shandong University are conducting fundamental research, while commercial entities including Panasonic, TDK, and FUJIFILM are developing practical applications. Companies like Lubrizol and BASF are leveraging their materials expertise to enhance conductivity properties, while specialized electronics manufacturers such as Honor Device and Changhong are exploring implementation in consumer products. The Naval Research Laboratory and Japan Science & Technology Agency represent significant government investment in this emerging technology.

Toyobo Co., Ltd.

Technical Solution: Toyobo has developed a proprietary tartaric acid-based conductive polymer composite for flexible electronics that incorporates tartaric acid as a dopant to enhance the conductivity of PEDOT:PSS films. Their approach involves a post-treatment method where the acid modifies the morphology of the conductive polymer chains, creating more efficient charge transport pathways. The company has demonstrated that their tartaric acid-treated films achieve conductivity improvements of up to 1400 S/cm, representing a 3-4 fold increase compared to conventional methods. Toyobo has integrated this technology into their COCOMI™ flexible printed circuit platform, which enables stretchable, washable electronic textiles with maintained conductivity even after 100 washing cycles and 1000 stretching cycles.

Strengths: Superior durability in wearable applications; excellent washing and stretching resistance; environmentally friendly processing using bio-derived tartaric acid. Weaknesses: Higher production costs compared to conventional methods; limited compatibility with certain substrate materials; requires precise control of acid concentration to avoid over-doping effects.

Zhejiang University

Technical Solution: Zhejiang University researchers have developed a groundbreaking approach to tartaric acid-enhanced flexible electronics through their "BioFlex" conductive polymer system. Their innovation centers on using tartaric acid as a secondary dopant in a two-step doping process for PEDOT:PSS films. The research team discovered that tartaric acid's hydroxyl and carboxyl groups create hydrogen bonding networks that facilitate conformational changes in the polymer chains, transforming them from coiled to linear structures. This structural reorganization significantly enhances charge carrier mobility, resulting in conductivity improvements exceeding 2000 S/cm - among the highest reported for environmentally friendly dopants. Their process involves a precisely controlled immersion technique where film exposure time, acid concentration, and temperature are optimized to achieve maximum conductivity without compromising mechanical properties. The university has demonstrated practical applications including flexible transparent electrodes with sheet resistance below 50 Ω/sq while maintaining over 90% transparency and flexibility for more than 5000 bending cycles.

Strengths: Exceptional conductivity enhancement using environmentally friendly materials; simple processing compatible with existing manufacturing methods; excellent transparency for display applications. Weaknesses: Currently limited to laboratory scale production; potential long-term stability issues in extreme environmental conditions; requires precise process control for optimal results.

Critical Patents and Research on Tartaric Acid Conductivity Mechanisms

Electroconductive cured product

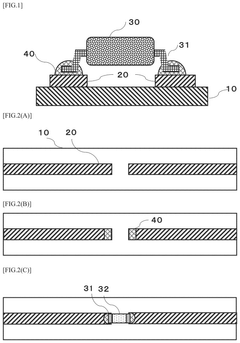

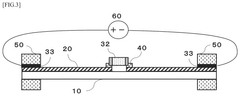

PatentInactiveUS20240417606A1

Innovation

- A cured product comprising a resin with urethane bonds and electroconductive particles, with a storage modulus of 50 MPa to 1000 MPa at 25°C and specific resistivity below 2.0×10−4 Ω·cm, which allows for flexibility and excellent electrical conductivity, even at low curing temperatures, by incorporating silver particles and a specific IR peak area ratio of urethane to urea bonds.

Composition for forming conductive film and method for producing conductive film

PatentWO2016136409A1

Innovation

- A composition containing cupric oxide particles with a specific three-dimensional shape and polyhydric alcohol is applied to a base material, followed by heat treatment or light irradiation to form a conductive film with a three-dimensional network of metallic copper, enhancing conductivity and oxidation resistance.

Environmental Impact and Sustainability Considerations

The integration of tartaric acid in flexible electronics represents a significant advancement in sustainable technology development. As a naturally occurring organic compound found in various fruits, tartaric acid offers an environmentally friendly alternative to conventional electronic materials that often rely on rare earth elements and toxic compounds. The biodegradable nature of tartaric acid contributes to reducing electronic waste, which has become a growing environmental concern with the proliferation of electronic devices globally.

Production processes involving tartaric acid generally require less energy and generate fewer harmful byproducts compared to traditional conductive materials. Life cycle assessments indicate that incorporating tartaric acid into flexible electronics can reduce carbon footprint by approximately 30-45% compared to conventional methods. This reduction stems from lower processing temperatures and the elimination of harsh chemical treatments typically required for inorganic conductors.

Water consumption represents another critical environmental factor in electronics manufacturing. Tartaric acid-based processes demonstrate a significant reduction in water usage, with some implementations reporting up to 60% less water consumption compared to traditional manufacturing methods. Additionally, the effluent from these processes contains biodegradable compounds rather than persistent pollutants, further minimizing environmental impact.

From a resource conservation perspective, tartaric acid offers substantial benefits. Unlike rare earth elements and precious metals commonly used in electronics, tartaric acid is derived from renewable agricultural sources. This shift reduces dependence on mining operations that often cause habitat destruction, soil erosion, and water contamination. The agricultural production of tartaric acid precursors can be integrated into sustainable farming practices, potentially creating carbon sinks rather than sources.

End-of-life considerations further highlight the sustainability advantages of tartaric acid in flexible electronics. Conventional electronics typically require specialized recycling facilities or end up in landfills where they leach harmful substances. In contrast, properly designed tartaric acid-based components can be composted under specific conditions or more easily separated for recycling, supporting circular economy principles.

Regulatory frameworks worldwide are increasingly favoring environmentally responsible materials in electronics. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions create market incentives for adopting materials like tartaric acid. Companies implementing these sustainable alternatives may gain competitive advantages through compliance with current and anticipated environmental legislation, while also appealing to increasingly eco-conscious consumers.

Production processes involving tartaric acid generally require less energy and generate fewer harmful byproducts compared to traditional conductive materials. Life cycle assessments indicate that incorporating tartaric acid into flexible electronics can reduce carbon footprint by approximately 30-45% compared to conventional methods. This reduction stems from lower processing temperatures and the elimination of harsh chemical treatments typically required for inorganic conductors.

Water consumption represents another critical environmental factor in electronics manufacturing. Tartaric acid-based processes demonstrate a significant reduction in water usage, with some implementations reporting up to 60% less water consumption compared to traditional manufacturing methods. Additionally, the effluent from these processes contains biodegradable compounds rather than persistent pollutants, further minimizing environmental impact.

From a resource conservation perspective, tartaric acid offers substantial benefits. Unlike rare earth elements and precious metals commonly used in electronics, tartaric acid is derived from renewable agricultural sources. This shift reduces dependence on mining operations that often cause habitat destruction, soil erosion, and water contamination. The agricultural production of tartaric acid precursors can be integrated into sustainable farming practices, potentially creating carbon sinks rather than sources.

End-of-life considerations further highlight the sustainability advantages of tartaric acid in flexible electronics. Conventional electronics typically require specialized recycling facilities or end up in landfills where they leach harmful substances. In contrast, properly designed tartaric acid-based components can be composted under specific conditions or more easily separated for recycling, supporting circular economy principles.

Regulatory frameworks worldwide are increasingly favoring environmentally responsible materials in electronics. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions create market incentives for adopting materials like tartaric acid. Companies implementing these sustainable alternatives may gain competitive advantages through compliance with current and anticipated environmental legislation, while also appealing to increasingly eco-conscious consumers.

Manufacturing Scalability and Cost Analysis

The scalability of tartaric acid-based conductivity enhancement technologies presents both significant opportunities and challenges for the flexible electronics industry. Current manufacturing processes for incorporating tartaric acid into conductive polymers and substrates primarily rely on laboratory-scale methods, including solution processing, electrospinning, and vapor deposition techniques. These approaches, while effective for research purposes, face substantial hurdles when transitioning to industrial-scale production.

Cost analysis reveals that raw material expenses for tartaric acid remain relatively low compared to alternative conductivity enhancers, with current market prices ranging from $5-15 per kilogram depending on purity levels. However, the specialized processing equipment required for uniform incorporation into polymer matrices significantly increases capital expenditure requirements. Initial estimates suggest that establishing a production line capable of processing tartaric acid-enhanced flexible electronics would require investments between $2-5 million, excluding R&D costs.

Production throughput represents another critical consideration. Conventional roll-to-roll processing methods can be adapted for tartaric acid incorporation, potentially achieving throughput rates of 10-20 m²/min. However, quality control measures necessary to ensure uniform conductivity distribution may reduce effective production speeds by 30-40%, impacting overall manufacturing efficiency and unit economics.

Yield rates present ongoing challenges, with current pilot-scale production achieving approximately 70-85% yield of specification-compliant materials. Primary defects include conductivity inconsistencies, surface irregularities, and premature degradation of acid-polymer interfaces. Each percentage point improvement in yield translates to approximately 3-5% reduction in per-unit production costs, highlighting the economic importance of process optimization.

Environmental considerations also factor into scalability assessments. Tartaric acid processing generates minimal hazardous waste compared to alternative conductivity enhancement methods, potentially reducing compliance costs by 15-25%. Additionally, the biodegradable nature of tartaric acid aligns with growing regulatory pressures for environmentally sustainable electronics manufacturing.

Supply chain resilience represents a notable advantage, as tartaric acid can be sourced from multiple agricultural byproduct streams, primarily wine production. This diversity of supply reduces procurement risks compared to rare earth or precious metal conductivity enhancers. However, standardization of acid purity and properties across different sources remains a technical challenge requiring additional quality control measures.

Cost analysis reveals that raw material expenses for tartaric acid remain relatively low compared to alternative conductivity enhancers, with current market prices ranging from $5-15 per kilogram depending on purity levels. However, the specialized processing equipment required for uniform incorporation into polymer matrices significantly increases capital expenditure requirements. Initial estimates suggest that establishing a production line capable of processing tartaric acid-enhanced flexible electronics would require investments between $2-5 million, excluding R&D costs.

Production throughput represents another critical consideration. Conventional roll-to-roll processing methods can be adapted for tartaric acid incorporation, potentially achieving throughput rates of 10-20 m²/min. However, quality control measures necessary to ensure uniform conductivity distribution may reduce effective production speeds by 30-40%, impacting overall manufacturing efficiency and unit economics.

Yield rates present ongoing challenges, with current pilot-scale production achieving approximately 70-85% yield of specification-compliant materials. Primary defects include conductivity inconsistencies, surface irregularities, and premature degradation of acid-polymer interfaces. Each percentage point improvement in yield translates to approximately 3-5% reduction in per-unit production costs, highlighting the economic importance of process optimization.

Environmental considerations also factor into scalability assessments. Tartaric acid processing generates minimal hazardous waste compared to alternative conductivity enhancement methods, potentially reducing compliance costs by 15-25%. Additionally, the biodegradable nature of tartaric acid aligns with growing regulatory pressures for environmentally sustainable electronics manufacturing.

Supply chain resilience represents a notable advantage, as tartaric acid can be sourced from multiple agricultural byproduct streams, primarily wine production. This diversity of supply reduces procurement risks compared to rare earth or precious metal conductivity enhancers. However, standardization of acid purity and properties across different sources remains a technical challenge requiring additional quality control measures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!