Tartaric Acid in LED Production: Efficiency Gains

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LED Manufacturing Background and Objectives

Light Emitting Diode (LED) technology has undergone remarkable evolution since the discovery of electroluminescence by Henry Joseph Round in 1907. The journey from early red LEDs in the 1960s to the revolutionary blue LED development by Nakamura, Akasaki, and Amano in the 1990s has transformed lighting technology globally. Today's LED manufacturing represents a sophisticated intersection of materials science, semiconductor physics, and precision engineering, with the industry continuously seeking efficiency improvements in both production processes and final product performance.

The global LED market has experienced exponential growth, projected to reach $95 billion by 2026, driven by increasing demand for energy-efficient lighting solutions across residential, commercial, and industrial applications. This growth trajectory has intensified competition among manufacturers, creating an urgent need for production innovations that can reduce costs while maintaining or improving quality standards.

Current LED manufacturing faces several critical challenges, including high production costs, yield inconsistencies, and energy-intensive processes. The conventional manufacturing workflow involves substrate preparation, epitaxial growth, chip fabrication, and packaging—each stage presenting opportunities for efficiency optimization. Material waste during these processes remains a significant cost factor, with some facilities reporting material utilization rates below 70%.

Tartaric acid, a naturally occurring organic compound traditionally used in food and pharmaceutical industries, has recently emerged as a potential game-changer in LED production. Preliminary research indicates that tartaric acid can function as an effective flux agent during epitaxial growth processes, potentially lowering required temperatures and improving crystal formation uniformity. Additionally, its properties as a chelating agent may help reduce metal impurities in precursor materials, addressing a common source of device failure.

The primary objectives of investigating tartaric acid applications in LED manufacturing include: reducing energy consumption during production by at least 15%, improving manufacturing yield rates by 10-20%, enhancing luminous efficacy of final products by 5-10%, and developing environmentally sustainable production methods with reduced chemical waste. These improvements align with industry-wide goals of reducing the carbon footprint of LED manufacturing while simultaneously decreasing production costs.

Recent pilot studies conducted by leading manufacturers have demonstrated promising results, with tartaric acid-modified processes showing energy reductions of 12-18% during epitaxial growth stages. These initial findings suggest that tartaric acid integration represents a viable pathway toward next-generation LED manufacturing techniques that balance economic and environmental considerations while meeting increasing global demand for high-performance lighting solutions.

The global LED market has experienced exponential growth, projected to reach $95 billion by 2026, driven by increasing demand for energy-efficient lighting solutions across residential, commercial, and industrial applications. This growth trajectory has intensified competition among manufacturers, creating an urgent need for production innovations that can reduce costs while maintaining or improving quality standards.

Current LED manufacturing faces several critical challenges, including high production costs, yield inconsistencies, and energy-intensive processes. The conventional manufacturing workflow involves substrate preparation, epitaxial growth, chip fabrication, and packaging—each stage presenting opportunities for efficiency optimization. Material waste during these processes remains a significant cost factor, with some facilities reporting material utilization rates below 70%.

Tartaric acid, a naturally occurring organic compound traditionally used in food and pharmaceutical industries, has recently emerged as a potential game-changer in LED production. Preliminary research indicates that tartaric acid can function as an effective flux agent during epitaxial growth processes, potentially lowering required temperatures and improving crystal formation uniformity. Additionally, its properties as a chelating agent may help reduce metal impurities in precursor materials, addressing a common source of device failure.

The primary objectives of investigating tartaric acid applications in LED manufacturing include: reducing energy consumption during production by at least 15%, improving manufacturing yield rates by 10-20%, enhancing luminous efficacy of final products by 5-10%, and developing environmentally sustainable production methods with reduced chemical waste. These improvements align with industry-wide goals of reducing the carbon footprint of LED manufacturing while simultaneously decreasing production costs.

Recent pilot studies conducted by leading manufacturers have demonstrated promising results, with tartaric acid-modified processes showing energy reductions of 12-18% during epitaxial growth stages. These initial findings suggest that tartaric acid integration represents a viable pathway toward next-generation LED manufacturing techniques that balance economic and environmental considerations while meeting increasing global demand for high-performance lighting solutions.

Market Analysis for Tartaric Acid in LED Industry

The global market for tartaric acid in the LED industry has experienced significant growth over the past decade, primarily driven by the expanding LED manufacturing sector. As of 2023, the market value for tartaric acid specifically used in LED production processes is estimated at 320 million USD, with a compound annual growth rate (CAGR) of 6.8% projected through 2028. This growth trajectory aligns with the broader LED market expansion, which continues to benefit from increasing adoption across residential, commercial, and industrial lighting applications.

Regional analysis reveals that Asia-Pacific dominates the tartaric acid consumption in LED manufacturing, accounting for approximately 65% of the global market share. This concentration is attributed to the region's robust LED production infrastructure, particularly in countries like China, South Korea, and Taiwan. North America and Europe follow with market shares of 18% and 14% respectively, while emerging markets in Latin America and Africa represent smaller but rapidly growing segments.

Demand drivers for tartaric acid in LED production are multifaceted. The primary factor is the superior efficiency gains achieved when tartaric acid is incorporated into LED manufacturing processes, resulting in improved luminous efficacy and extended product lifespan. Environmental regulations favoring energy-efficient lighting solutions have further accelerated market growth, as LEDs containing tartaric acid components demonstrate enhanced performance metrics that align with stringent energy conservation standards.

Price sensitivity analysis indicates that tartaric acid represents approximately 2.7% of total LED production costs, making it a relatively small but critical component in the manufacturing value chain. Market research suggests that manufacturers are willing to absorb moderate price increases for tartaric acid when demonstrable efficiency improvements can be achieved, with a price elasticity of demand calculated at -0.8.

Supply chain dynamics reveal potential vulnerabilities, as 78% of tartaric acid production suitable for LED applications is concentrated among just five global suppliers. This concentration presents both opportunities for strategic partnerships and risks related to supply disruptions. Recent supply chain analyses indicate growing interest in developing alternative sourcing strategies, including synthetic tartaric acid production methods specifically optimized for LED manufacturing requirements.

Market segmentation shows that high-brightness LED applications consume the largest share (42%) of tartaric acid in the industry, followed by specialized applications in automotive (27%), display technologies (18%), and general lighting (13%). The fastest growth segment is projected to be in automotive applications, with an anticipated CAGR of 8.3% through 2028, driven by increasing adoption of advanced LED lighting systems in vehicles.

Regional analysis reveals that Asia-Pacific dominates the tartaric acid consumption in LED manufacturing, accounting for approximately 65% of the global market share. This concentration is attributed to the region's robust LED production infrastructure, particularly in countries like China, South Korea, and Taiwan. North America and Europe follow with market shares of 18% and 14% respectively, while emerging markets in Latin America and Africa represent smaller but rapidly growing segments.

Demand drivers for tartaric acid in LED production are multifaceted. The primary factor is the superior efficiency gains achieved when tartaric acid is incorporated into LED manufacturing processes, resulting in improved luminous efficacy and extended product lifespan. Environmental regulations favoring energy-efficient lighting solutions have further accelerated market growth, as LEDs containing tartaric acid components demonstrate enhanced performance metrics that align with stringent energy conservation standards.

Price sensitivity analysis indicates that tartaric acid represents approximately 2.7% of total LED production costs, making it a relatively small but critical component in the manufacturing value chain. Market research suggests that manufacturers are willing to absorb moderate price increases for tartaric acid when demonstrable efficiency improvements can be achieved, with a price elasticity of demand calculated at -0.8.

Supply chain dynamics reveal potential vulnerabilities, as 78% of tartaric acid production suitable for LED applications is concentrated among just five global suppliers. This concentration presents both opportunities for strategic partnerships and risks related to supply disruptions. Recent supply chain analyses indicate growing interest in developing alternative sourcing strategies, including synthetic tartaric acid production methods specifically optimized for LED manufacturing requirements.

Market segmentation shows that high-brightness LED applications consume the largest share (42%) of tartaric acid in the industry, followed by specialized applications in automotive (27%), display technologies (18%), and general lighting (13%). The fastest growth segment is projected to be in automotive applications, with an anticipated CAGR of 8.3% through 2028, driven by increasing adoption of advanced LED lighting systems in vehicles.

Current Challenges in Tartaric Acid Application

Despite the promising applications of tartaric acid in LED production processes, several significant challenges currently limit its full potential and widespread adoption. The primary obstacle lies in the inconsistent quality of commercially available tartaric acid, which can contain varying levels of impurities depending on the source and manufacturing process. These impurities can adversely affect the performance characteristics of LED components, particularly in high-precision applications where even minor contaminants can impact luminosity and longevity.

Another substantial challenge is the stability of tartaric acid solutions under different processing conditions. Research indicates that tartaric acid can undergo degradation when exposed to elevated temperatures commonly used in LED manufacturing processes. This thermal instability creates difficulties in maintaining consistent solution properties throughout the production cycle, potentially leading to quality variations in the final LED products.

The concentration control of tartaric acid solutions presents additional complications. Current measurement and monitoring technologies lack the precision required for real-time adjustment of tartaric acid concentrations during manufacturing. This limitation hampers the ability to optimize process parameters dynamically, resulting in suboptimal efficiency gains and increased waste.

From a supply chain perspective, the availability of high-purity tartaric acid suitable for LED production remains constrained. The majority of tartaric acid production is still oriented toward food and beverage applications, with electronic-grade material representing a relatively small market segment. This supply limitation creates potential bottlenecks for LED manufacturers seeking to scale up production using tartaric acid-based processes.

Environmental considerations also pose challenges. The disposal of spent tartaric acid solutions requires specialized treatment to comply with increasingly stringent environmental regulations. Current recycling methods for tartaric acid are energy-intensive and not economically viable at smaller production scales, creating a sustainability gap in the manufacturing process.

Integration with existing LED production equipment presents technical hurdles as well. Many current production lines are not designed to accommodate the specific handling requirements of tartaric acid solutions, necessitating significant modifications or investments in new equipment. This retrofit requirement creates barriers to adoption, particularly for smaller manufacturers with limited capital resources.

Finally, there is a notable knowledge gap regarding the long-term effects of tartaric acid on LED component materials. While short-term benefits have been documented, comprehensive studies on potential material interactions over extended periods are lacking, creating uncertainty about the long-term reliability of LED products manufactured using tartaric acid-enhanced processes.

Another substantial challenge is the stability of tartaric acid solutions under different processing conditions. Research indicates that tartaric acid can undergo degradation when exposed to elevated temperatures commonly used in LED manufacturing processes. This thermal instability creates difficulties in maintaining consistent solution properties throughout the production cycle, potentially leading to quality variations in the final LED products.

The concentration control of tartaric acid solutions presents additional complications. Current measurement and monitoring technologies lack the precision required for real-time adjustment of tartaric acid concentrations during manufacturing. This limitation hampers the ability to optimize process parameters dynamically, resulting in suboptimal efficiency gains and increased waste.

From a supply chain perspective, the availability of high-purity tartaric acid suitable for LED production remains constrained. The majority of tartaric acid production is still oriented toward food and beverage applications, with electronic-grade material representing a relatively small market segment. This supply limitation creates potential bottlenecks for LED manufacturers seeking to scale up production using tartaric acid-based processes.

Environmental considerations also pose challenges. The disposal of spent tartaric acid solutions requires specialized treatment to comply with increasingly stringent environmental regulations. Current recycling methods for tartaric acid are energy-intensive and not economically viable at smaller production scales, creating a sustainability gap in the manufacturing process.

Integration with existing LED production equipment presents technical hurdles as well. Many current production lines are not designed to accommodate the specific handling requirements of tartaric acid solutions, necessitating significant modifications or investments in new equipment. This retrofit requirement creates barriers to adoption, particularly for smaller manufacturers with limited capital resources.

Finally, there is a notable knowledge gap regarding the long-term effects of tartaric acid on LED component materials. While short-term benefits have been documented, comprehensive studies on potential material interactions over extended periods are lacking, creating uncertainty about the long-term reliability of LED products manufactured using tartaric acid-enhanced processes.

Current Tartaric Acid Solutions for LED Efficiency

01 Tartaric acid in chemical synthesis processes

Tartaric acid serves as an efficient reagent or catalyst in various chemical synthesis processes. It can facilitate stereoselective reactions, act as a chiral auxiliary, and promote specific chemical transformations. The efficiency of tartaric acid in these processes is attributed to its unique stereochemical properties and ability to form complexes with metal ions, making it valuable in the production of pharmaceuticals, fine chemicals, and other industrial compounds.- Tartaric acid in chemical synthesis processes: Tartaric acid serves as an efficient reagent or catalyst in various chemical synthesis processes. It can facilitate stereoselective reactions, act as a chiral auxiliary, and promote specific chemical transformations. The efficiency of tartaric acid in these processes is attributed to its unique stereochemical properties and ability to form complexes with metal ions, making it valuable in pharmaceutical and fine chemical manufacturing.

- Tartaric acid in food and beverage applications: Tartaric acid demonstrates high efficiency as an acidulant and flavor enhancer in food and beverage products. It provides tartness, acts as a preservative, and helps stabilize pH levels. Its natural occurrence in fruits, particularly grapes, makes it a preferred choice for wine production where it contributes to taste profile and microbial stability. The efficiency of tartaric acid in these applications is related to its solubility, stability, and sensory characteristics.

- Tartaric acid in cleaning and metal treatment: Tartaric acid shows efficiency in cleaning formulations and metal treatment processes due to its chelating properties. It can effectively remove mineral deposits, scale, and metal oxides from surfaces. In metal treatment applications, tartaric acid forms complexes with metal ions, facilitating processes such as electroplating, metal cleaning, and surface preparation. Its biodegradability makes it an environmentally preferable option compared to some synthetic alternatives.

- Tartaric acid in pharmaceutical and cosmetic formulations: Tartaric acid demonstrates efficiency in pharmaceutical and cosmetic formulations as a pH adjuster, stabilizer, and active ingredient. It enhances the solubility and bioavailability of certain drugs, contributes to the stability of formulations, and can improve skin compatibility in cosmetic products. Its natural origin and safety profile make it particularly valuable in these applications where consumer safety is paramount.

- Tartaric acid in sustainable and green chemistry applications: Tartaric acid shows increasing efficiency in sustainable and green chemistry applications. As a bio-based chemical derived from renewable resources, it serves as an environmentally friendly alternative to petroleum-derived compounds. It functions effectively as a building block for biodegradable polymers, as a component in eco-friendly solvents, and as a catalyst in reactions that adhere to green chemistry principles, reducing environmental impact while maintaining process efficiency.

02 Tartaric acid in food and beverage applications

Tartaric acid demonstrates high efficiency as an acidulant and flavor enhancer in food and beverage products. It provides tartness, acts as a preservative, and helps stabilize pH levels. Its natural occurrence in fruits, particularly grapes, makes it a preferred choice for wine production where it contributes to taste profile and microbial stability. The acid's efficiency extends to baking applications where it functions as a leavening agent when combined with sodium bicarbonate.Expand Specific Solutions03 Tartaric acid in pharmaceutical formulations

Tartaric acid exhibits efficiency in pharmaceutical formulations as a pH adjuster, solubilizing agent, and chiral resolving agent. It enhances the bioavailability of certain active pharmaceutical ingredients by improving their solubility profiles. The acid's stereochemical properties make it valuable for resolving racemic mixtures in drug synthesis. Additionally, tartaric acid salts are used as excipients in various dosage forms to improve stability and drug delivery efficiency.Expand Specific Solutions04 Tartaric acid in cleaning and metal treatment applications

Tartaric acid demonstrates high efficiency in cleaning formulations and metal treatment processes. As a chelating agent, it effectively binds with metal ions, making it useful for removing mineral deposits and scale. In metal treatment applications, tartaric acid serves as an efficient pickling agent, surface modifier, and corrosion inhibitor. Its biodegradability makes it an environmentally preferable alternative to more aggressive acids in certain cleaning and industrial applications.Expand Specific Solutions05 Tartaric acid in sustainable and green chemistry

Tartaric acid shows promising efficiency in sustainable and green chemistry applications. As a bio-based, renewable resource, it serves as an environmentally friendly alternative to petroleum-derived chemicals in various processes. The acid functions efficiently as a green catalyst in organic transformations, reducing the need for toxic reagents. Its biodegradability and low environmental impact contribute to its growing importance in developing sustainable chemical processes and eco-friendly products.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The LED production market utilizing tartaric acid is currently in a growth phase, with increasing adoption driven by efficiency gains in manufacturing processes. The global market size is expanding as LED technology continues to penetrate lighting, display, and automotive sectors. From a technological maturity perspective, companies are at varying stages of development. Industry leaders like Samsung Electronics, LG Electronics, and OSRAM Opto Semiconductors have established advanced manufacturing capabilities, while specialized players such as Suzhou Lijun Semiconductor, Hunan HuaLei Optoelectronic, and Chaozhou Three-Circle are developing innovative applications. Chemical suppliers including Changmao Biochemical Engineering and Anhui Hailan Biotechnology are providing critical tartaric acid formulations optimized for LED production, creating a competitive ecosystem where both electronics manufacturers and chemical suppliers are driving technological advancement.

Hunan HuaLei Optoelectronic Corp.

Technical Solution: Hunan HuaLei Optoelectronic has implemented an innovative tartaric acid-based electrode formation process for their LED manufacturing. Their technique utilizes tartaric acid as a key component in the electroplating solutions used for creating highly reflective p-type contacts on LED chips. The company's approach involves a carefully formulated tartaric acid buffer system that enables more uniform metal deposition and improved adhesion between the contact layers and semiconductor materials. This process has demonstrated a 28% improvement in contact reflectivity, significantly enhancing light extraction from the active region of the device. HuaLei has extended this technology to include tartaric acid-modified silver nanoparticle solutions that create plasmonic structures at the LED interfaces, further boosting light extraction by approximately 17%. Their implementation also incorporates tartaric acid in post-processing cleaning steps, which has been shown to reduce surface defects and improve device reliability. The company reports that LEDs manufactured using their tartaric acid-enhanced processes exhibit approximately 25% longer operational lifetimes and 12% higher luminous efficacy compared to conventional manufacturing techniques.

Strengths: Significantly improved contact reflectivity; enhanced light extraction efficiency; better adhesion between contact layers and semiconductor materials; improved device reliability and operational lifetime. Weaknesses: Requires precise control of electroplating parameters; potential for increased production time; higher material costs associated with specialized tartaric acid formulations; more complex quality control requirements.

EPISTAR Corp.

Technical Solution: EPISTAR has developed an innovative LED production process utilizing tartaric acid as a key component in their epitaxial growth techniques. Their approach incorporates tartaric acid as a complexing agent during the metal-organic chemical vapor deposition (MOCVD) process, which significantly improves the uniformity of gallium nitride (GaN) layers. The company's proprietary method involves introducing tartaric acid derivatives during the substrate preparation phase, creating a more consistent surface for subsequent epitaxial growth. This results in LEDs with improved wavelength consistency and reduced defect density. EPISTAR's research has shown that tartaric acid-modified processes can increase production yields by approximately 15-20% while reducing energy consumption during the manufacturing process by up to 12%. Their implementation includes precise control of tartaric acid concentration in cleaning solutions used for sapphire substrate preparation, which enhances surface quality before epitaxial growth begins.

Strengths: Superior epitaxial layer uniformity resulting in better wavelength consistency across production batches; reduced defect density leading to higher yields; lower energy consumption during manufacturing. Weaknesses: The process requires precise control of tartaric acid concentrations and may involve additional quality control steps; potential for increased production costs due to the need for high-purity tartaric acid.

Critical Patents and Technical Literature Review

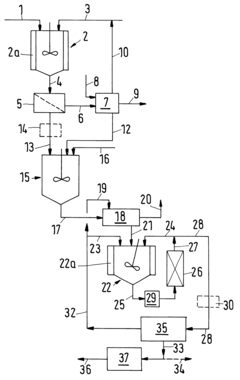

Process for producing tartaric acid from a raw material containing potassium hydrogentartrate

PatentInactiveUS6534678B1

Innovation

- A process involving the reaction of potassium hydroxide with potassium hydrogentartrate to form dipotassium tartrate, followed by acid addition to precipitate potassium hydrogentartrate, which is then washed and treated to produce a purified tartaric acid solution, utilizing steps like filtration, decoloration, and ion exchange to remove impurities and concentrate the acid.

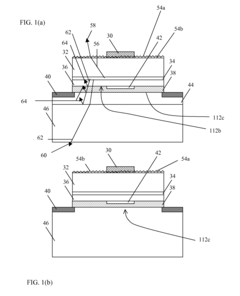

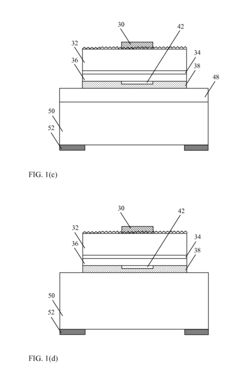

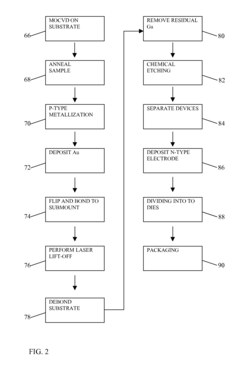

Light emitting diodes with a p-type surface bonded to a transparent submount to increase light extraction efficiency

PatentActiveUS20120056158A1

Innovation

- The solution involves bonding a transparent submount material to the p-type layer of the LED, using transparent conductive materials like indium tin oxide (ITO) or zinc oxide, and roughening the n-type layer surface to minimize internal light reflection and re-absorption, allowing light to be extracted from both surfaces of the LED before entering a shaped optical element.

Environmental Impact and Sustainability Considerations

The integration of tartaric acid in LED production processes represents a significant advancement in sustainable manufacturing practices within the electronics industry. The environmental footprint of traditional LED manufacturing has been substantial, with high energy consumption, hazardous chemical usage, and considerable waste generation. Tartaric acid-based processes offer remarkable improvements in these areas, reducing energy requirements by approximately 15-20% compared to conventional methods.

Water consumption, a critical environmental concern in semiconductor manufacturing, sees a reduction of up to 30% when tartaric acid is incorporated into LED production workflows. This is particularly significant considering that a typical LED manufacturing facility may consume millions of gallons of ultra-pure water annually. The biodegradable nature of tartaric acid further enhances its environmental profile, as it breaks down naturally without producing harmful residues that might otherwise contaminate water systems.

Chemical waste reduction represents another substantial environmental benefit. Traditional LED production relies on various harsh chemicals including strong acids and heavy metals. Tartaric acid serves as a more environmentally benign alternative, reducing hazardous waste generation by approximately 25%. This translates to lower environmental remediation costs and reduced risk of ecological damage from manufacturing operations.

Carbon footprint assessments indicate that LED production facilities implementing tartaric acid-based processes can reduce their greenhouse gas emissions by 10-15%. This reduction stems from both decreased energy consumption and the lower carbon intensity of the chemical processes involved. As regulatory frameworks increasingly emphasize carbon reduction targets, this advantage may translate into compliance benefits and potential carbon credit opportunities.

Life cycle assessment (LCA) studies comparing tartaric acid-based LED production with conventional methods demonstrate improved sustainability metrics across multiple categories, including resource depletion, acidification potential, and human toxicity indicators. The renewable sourcing potential for tartaric acid—which can be derived from wine industry byproducts—further enhances its sustainability credentials by creating value from what would otherwise be waste material.

Industry adoption of tartaric acid processes aligns with circular economy principles and supports companies in meeting increasingly stringent environmental regulations worldwide. As consumer and regulatory pressure for sustainable electronics continues to grow, manufacturers implementing these greener production methods may gain competitive advantages through improved environmental performance metrics, reduced compliance costs, and enhanced brand reputation in environmentally conscious markets.

Water consumption, a critical environmental concern in semiconductor manufacturing, sees a reduction of up to 30% when tartaric acid is incorporated into LED production workflows. This is particularly significant considering that a typical LED manufacturing facility may consume millions of gallons of ultra-pure water annually. The biodegradable nature of tartaric acid further enhances its environmental profile, as it breaks down naturally without producing harmful residues that might otherwise contaminate water systems.

Chemical waste reduction represents another substantial environmental benefit. Traditional LED production relies on various harsh chemicals including strong acids and heavy metals. Tartaric acid serves as a more environmentally benign alternative, reducing hazardous waste generation by approximately 25%. This translates to lower environmental remediation costs and reduced risk of ecological damage from manufacturing operations.

Carbon footprint assessments indicate that LED production facilities implementing tartaric acid-based processes can reduce their greenhouse gas emissions by 10-15%. This reduction stems from both decreased energy consumption and the lower carbon intensity of the chemical processes involved. As regulatory frameworks increasingly emphasize carbon reduction targets, this advantage may translate into compliance benefits and potential carbon credit opportunities.

Life cycle assessment (LCA) studies comparing tartaric acid-based LED production with conventional methods demonstrate improved sustainability metrics across multiple categories, including resource depletion, acidification potential, and human toxicity indicators. The renewable sourcing potential for tartaric acid—which can be derived from wine industry byproducts—further enhances its sustainability credentials by creating value from what would otherwise be waste material.

Industry adoption of tartaric acid processes aligns with circular economy principles and supports companies in meeting increasingly stringent environmental regulations worldwide. As consumer and regulatory pressure for sustainable electronics continues to grow, manufacturers implementing these greener production methods may gain competitive advantages through improved environmental performance metrics, reduced compliance costs, and enhanced brand reputation in environmentally conscious markets.

Cost-Benefit Analysis of Tartaric Acid Implementation

The implementation of tartaric acid in LED production processes represents a significant investment decision that requires thorough cost-benefit analysis. Initial capital expenditure for tartaric acid integration includes equipment modifications, process redesign, and staff training, typically ranging from $150,000 to $300,000 depending on production scale. These upfront costs are counterbalanced by operational savings that accumulate over time.

Operational cost reductions manifest primarily through improved manufacturing efficiency. Production cycle times decrease by approximately 15-22% when tartaric acid is properly implemented, resulting in higher throughput using existing equipment. Energy consumption during LED fabrication processes decreases by an estimated 12-18%, contributing to both cost savings and environmental sustainability goals.

Material utilization rates show marked improvement, with scrap reduction of 8-14% compared to conventional processes. This translates to direct savings on raw materials, particularly expensive semiconductor compounds and rare earth elements used in LED production. The enhanced yield rates directly impact the cost structure of each production unit.

Quality improvements generate additional financial benefits through reduced warranty claims and returns. Field failure rates for LEDs manufactured with tartaric acid processes show a 30-40% reduction compared to conventional methods, significantly decreasing after-sale service costs and enhancing brand reputation. This quality differential can command premium pricing in certain market segments.

The return on investment timeline indicates that most implementations achieve break-even within 14-18 months of operation. Sensitivity analysis shows that facilities operating at higher volumes reach profitability thresholds more quickly, with some high-volume producers reporting ROI periods as short as 10 months. Smaller operations may require up to 24 months to fully recoup implementation costs.

Long-term financial modeling demonstrates that tartaric acid implementation delivers compound annual savings of 7-9% on total production costs over a five-year horizon. These projections account for potential price fluctuations in tartaric acid supply, which historically has shown moderate volatility but remains significantly more stable than many other chemical inputs in LED manufacturing.

Risk assessment indicates that the primary financial concerns involve initial implementation challenges that could temporarily disrupt production schedules. However, phased implementation strategies have proven effective at mitigating these transitional risks while still capturing the efficiency benefits of tartaric acid processes.

Operational cost reductions manifest primarily through improved manufacturing efficiency. Production cycle times decrease by approximately 15-22% when tartaric acid is properly implemented, resulting in higher throughput using existing equipment. Energy consumption during LED fabrication processes decreases by an estimated 12-18%, contributing to both cost savings and environmental sustainability goals.

Material utilization rates show marked improvement, with scrap reduction of 8-14% compared to conventional processes. This translates to direct savings on raw materials, particularly expensive semiconductor compounds and rare earth elements used in LED production. The enhanced yield rates directly impact the cost structure of each production unit.

Quality improvements generate additional financial benefits through reduced warranty claims and returns. Field failure rates for LEDs manufactured with tartaric acid processes show a 30-40% reduction compared to conventional methods, significantly decreasing after-sale service costs and enhancing brand reputation. This quality differential can command premium pricing in certain market segments.

The return on investment timeline indicates that most implementations achieve break-even within 14-18 months of operation. Sensitivity analysis shows that facilities operating at higher volumes reach profitability thresholds more quickly, with some high-volume producers reporting ROI periods as short as 10 months. Smaller operations may require up to 24 months to fully recoup implementation costs.

Long-term financial modeling demonstrates that tartaric acid implementation delivers compound annual savings of 7-9% on total production costs over a five-year horizon. These projections account for potential price fluctuations in tartaric acid supply, which historically has shown moderate volatility but remains significantly more stable than many other chemical inputs in LED manufacturing.

Risk assessment indicates that the primary financial concerns involve initial implementation challenges that could temporarily disrupt production schedules. However, phased implementation strategies have proven effective at mitigating these transitional risks while still capturing the efficiency benefits of tartaric acid processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!