Phenolphthalein’s Role in Real-Time Bioreactor pH Control

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Phenolphthalein pH Indicator Background

Phenolphthalein, a widely recognized pH indicator, has played a crucial role in various scientific and industrial applications since its discovery in the late 19th century. This organic compound, with the chemical formula C20H14O4, exhibits a remarkable color-changing property in response to pH variations, making it an invaluable tool in analytical chemistry and process control.

The history of phenolphthalein dates back to 1871 when it was first synthesized by Adolf von Baeyer. Its pH-sensitive characteristics were soon recognized, leading to its widespread adoption as a pH indicator in laboratories and industrial settings. The compound's ability to transition from colorless in acidic solutions to a vibrant pink-purple hue in alkaline environments has made it particularly useful in titrations and pH monitoring.

In the context of bioreactor pH control, phenolphthalein's role has evolved significantly over the years. Initially used primarily in manual pH testing, it has since been incorporated into more sophisticated real-time monitoring systems. The compound's sharp color transition at pH levels between 8.2 and 10.0 makes it especially suitable for applications requiring precise pH control in alkaline environments, which is often critical in bioprocessing.

The mechanism behind phenolphthalein's color change is rooted in its molecular structure. In acidic and neutral solutions, the molecule exists in a closed-ring form, which is colorless. As the pH increases, the ring opens, resulting in a resonance-stabilized structure that absorbs light in the visible spectrum, producing the characteristic pink color. This structural change is reversible, allowing for continuous pH monitoring in dynamic systems such as bioreactors.

The sensitivity and reliability of phenolphthalein as a pH indicator have led to its integration into various pH control systems in bioreactors. These systems often combine the visual indication provided by phenolphthalein with electronic sensors and automated control mechanisms, enabling precise and real-time pH adjustments. This integration has significantly improved the efficiency and consistency of bioprocesses, particularly in industries such as pharmaceuticals, food production, and wastewater treatment.

Despite the advent of more advanced pH measurement technologies, phenolphthalein continues to be valued for its simplicity, cost-effectiveness, and visual clarity. Its use in bioreactor pH control exemplifies the enduring relevance of classical chemical indicators in modern biotechnology. As research in bioprocessing advances, phenolphthalein's role is likely to evolve further, potentially leading to new applications and improved methodologies in real-time pH monitoring and control.

The history of phenolphthalein dates back to 1871 when it was first synthesized by Adolf von Baeyer. Its pH-sensitive characteristics were soon recognized, leading to its widespread adoption as a pH indicator in laboratories and industrial settings. The compound's ability to transition from colorless in acidic solutions to a vibrant pink-purple hue in alkaline environments has made it particularly useful in titrations and pH monitoring.

In the context of bioreactor pH control, phenolphthalein's role has evolved significantly over the years. Initially used primarily in manual pH testing, it has since been incorporated into more sophisticated real-time monitoring systems. The compound's sharp color transition at pH levels between 8.2 and 10.0 makes it especially suitable for applications requiring precise pH control in alkaline environments, which is often critical in bioprocessing.

The mechanism behind phenolphthalein's color change is rooted in its molecular structure. In acidic and neutral solutions, the molecule exists in a closed-ring form, which is colorless. As the pH increases, the ring opens, resulting in a resonance-stabilized structure that absorbs light in the visible spectrum, producing the characteristic pink color. This structural change is reversible, allowing for continuous pH monitoring in dynamic systems such as bioreactors.

The sensitivity and reliability of phenolphthalein as a pH indicator have led to its integration into various pH control systems in bioreactors. These systems often combine the visual indication provided by phenolphthalein with electronic sensors and automated control mechanisms, enabling precise and real-time pH adjustments. This integration has significantly improved the efficiency and consistency of bioprocesses, particularly in industries such as pharmaceuticals, food production, and wastewater treatment.

Despite the advent of more advanced pH measurement technologies, phenolphthalein continues to be valued for its simplicity, cost-effectiveness, and visual clarity. Its use in bioreactor pH control exemplifies the enduring relevance of classical chemical indicators in modern biotechnology. As research in bioprocessing advances, phenolphthalein's role is likely to evolve further, potentially leading to new applications and improved methodologies in real-time pH monitoring and control.

Bioreactor pH Control Market Analysis

The bioreactor pH control market has experienced significant growth in recent years, driven by the expanding biotechnology and pharmaceutical industries. This market segment is crucial for maintaining optimal conditions in bioreactors, ensuring the efficiency and quality of various bioprocesses. The global bioreactor market, which includes pH control systems, was valued at approximately $1.5 billion in 2020 and is projected to reach $3.9 billion by 2028, with a compound annual growth rate (CAGR) of 13.7% during this period.

The demand for precise pH control in bioreactors is primarily fueled by the increasing production of biopharmaceuticals, including vaccines, monoclonal antibodies, and cell therapies. The COVID-19 pandemic has further accelerated this trend, with a surge in vaccine production and research activities. Additionally, the growing adoption of single-use bioreactors in the pharmaceutical industry has created new opportunities for innovative pH control solutions.

In the context of phenolphthalein's role in real-time bioreactor pH control, the market shows a particular interest in advanced sensor technologies and automated control systems. While traditional pH measurement methods remain prevalent, there is a shift towards more sophisticated, real-time monitoring solutions that can provide continuous, accurate pH readings without compromising the sterility of the bioreactor environment.

The bioreactor pH control market is segmented based on technology type, end-user industry, and geography. Key technology segments include electrode-based sensors, optical sensors, and colorimetric indicators like phenolphthalein. The pharmaceutical and biotechnology sectors dominate the end-user segment, followed by food and beverage, and environmental applications.

Geographically, North America leads the market due to its strong presence in the biopharmaceutical industry and high R&D investments. Europe follows closely, with Asia-Pacific emerging as the fastest-growing region, driven by increasing biotechnology research and manufacturing activities in countries like China and India.

Key market players in the bioreactor pH control segment include Sartorius AG, Eppendorf AG, Thermo Fisher Scientific, and Mettler-Toledo International Inc. These companies are focusing on developing integrated bioreactor systems with advanced pH control capabilities, including those that could potentially incorporate phenolphthalein-based technologies for enhanced visual monitoring.

The market trends indicate a growing demand for more precise, reliable, and user-friendly pH control systems. There is a particular emphasis on developing non-invasive pH measurement techniques that can maintain the integrity of the bioprocess while providing real-time data. This trend aligns well with the potential applications of phenolphthalein in bioreactor pH control, especially in systems where visual indicators can complement electronic sensors for improved monitoring and control.

The demand for precise pH control in bioreactors is primarily fueled by the increasing production of biopharmaceuticals, including vaccines, monoclonal antibodies, and cell therapies. The COVID-19 pandemic has further accelerated this trend, with a surge in vaccine production and research activities. Additionally, the growing adoption of single-use bioreactors in the pharmaceutical industry has created new opportunities for innovative pH control solutions.

In the context of phenolphthalein's role in real-time bioreactor pH control, the market shows a particular interest in advanced sensor technologies and automated control systems. While traditional pH measurement methods remain prevalent, there is a shift towards more sophisticated, real-time monitoring solutions that can provide continuous, accurate pH readings without compromising the sterility of the bioreactor environment.

The bioreactor pH control market is segmented based on technology type, end-user industry, and geography. Key technology segments include electrode-based sensors, optical sensors, and colorimetric indicators like phenolphthalein. The pharmaceutical and biotechnology sectors dominate the end-user segment, followed by food and beverage, and environmental applications.

Geographically, North America leads the market due to its strong presence in the biopharmaceutical industry and high R&D investments. Europe follows closely, with Asia-Pacific emerging as the fastest-growing region, driven by increasing biotechnology research and manufacturing activities in countries like China and India.

Key market players in the bioreactor pH control segment include Sartorius AG, Eppendorf AG, Thermo Fisher Scientific, and Mettler-Toledo International Inc. These companies are focusing on developing integrated bioreactor systems with advanced pH control capabilities, including those that could potentially incorporate phenolphthalein-based technologies for enhanced visual monitoring.

The market trends indicate a growing demand for more precise, reliable, and user-friendly pH control systems. There is a particular emphasis on developing non-invasive pH measurement techniques that can maintain the integrity of the bioprocess while providing real-time data. This trend aligns well with the potential applications of phenolphthalein in bioreactor pH control, especially in systems where visual indicators can complement electronic sensors for improved monitoring and control.

Current Challenges in Real-Time pH Monitoring

Real-time pH monitoring in bioreactors presents several significant challenges that hinder the development of efficient and accurate control systems. One of the primary issues is the inherent complexity of biological systems, which can lead to rapid and unpredictable pH fluctuations. These fluctuations are often caused by metabolic activities of microorganisms, substrate consumption, and byproduct formation, making it difficult to maintain a stable pH environment.

The sensitivity and response time of pH sensors pose another major challenge. Traditional pH probes may not be sufficiently responsive to detect rapid pH changes, leading to delayed control actions. This lag can result in suboptimal growth conditions for microorganisms and potentially compromise the entire bioprocess. Additionally, the harsh conditions within bioreactors, including high temperatures, pressure variations, and the presence of corrosive substances, can affect the longevity and accuracy of pH sensors.

Fouling and contamination of pH probes represent a persistent problem in bioreactor systems. Biomass accumulation, protein adsorption, and mineral scaling on sensor surfaces can interfere with accurate pH measurements. This not only reduces the reliability of pH readings but also necessitates frequent sensor cleaning or replacement, leading to increased downtime and operational costs.

The integration of pH monitoring systems with other process parameters presents another hurdle. Effective pH control often requires simultaneous consideration of multiple variables such as temperature, dissolved oxygen, and nutrient concentrations. Developing a comprehensive control strategy that accounts for these interdependencies while maintaining real-time responsiveness is a complex task.

Calibration and standardization of pH monitoring systems across different scales and types of bioreactors remain challenging. The behavior of pH indicators and sensors can vary significantly between laboratory-scale experiments and industrial-scale production, making it difficult to translate pH control strategies effectively.

The use of traditional pH indicators like phenolphthalein in real-time monitoring systems introduces its own set of challenges. While phenolphthalein offers a visual indication of pH changes, its application in automated, continuous monitoring systems is limited. The indicator's color change may not be easily detectable by optical sensors in turbid fermentation broths, and its potential interaction with biological components in the reactor could affect both the accuracy of pH measurements and the bioprocess itself.

Addressing these challenges requires innovative approaches that combine advanced sensor technologies, robust control algorithms, and a deep understanding of bioprocess dynamics. The development of non-invasive pH monitoring techniques, such as spectroscopic methods or advanced optical sensors, could potentially overcome some of the limitations associated with traditional probe-based systems. However, these emerging technologies often face their own set of implementation challenges in industrial bioreactor settings.

The sensitivity and response time of pH sensors pose another major challenge. Traditional pH probes may not be sufficiently responsive to detect rapid pH changes, leading to delayed control actions. This lag can result in suboptimal growth conditions for microorganisms and potentially compromise the entire bioprocess. Additionally, the harsh conditions within bioreactors, including high temperatures, pressure variations, and the presence of corrosive substances, can affect the longevity and accuracy of pH sensors.

Fouling and contamination of pH probes represent a persistent problem in bioreactor systems. Biomass accumulation, protein adsorption, and mineral scaling on sensor surfaces can interfere with accurate pH measurements. This not only reduces the reliability of pH readings but also necessitates frequent sensor cleaning or replacement, leading to increased downtime and operational costs.

The integration of pH monitoring systems with other process parameters presents another hurdle. Effective pH control often requires simultaneous consideration of multiple variables such as temperature, dissolved oxygen, and nutrient concentrations. Developing a comprehensive control strategy that accounts for these interdependencies while maintaining real-time responsiveness is a complex task.

Calibration and standardization of pH monitoring systems across different scales and types of bioreactors remain challenging. The behavior of pH indicators and sensors can vary significantly between laboratory-scale experiments and industrial-scale production, making it difficult to translate pH control strategies effectively.

The use of traditional pH indicators like phenolphthalein in real-time monitoring systems introduces its own set of challenges. While phenolphthalein offers a visual indication of pH changes, its application in automated, continuous monitoring systems is limited. The indicator's color change may not be easily detectable by optical sensors in turbid fermentation broths, and its potential interaction with biological components in the reactor could affect both the accuracy of pH measurements and the bioprocess itself.

Addressing these challenges requires innovative approaches that combine advanced sensor technologies, robust control algorithms, and a deep understanding of bioprocess dynamics. The development of non-invasive pH monitoring techniques, such as spectroscopic methods or advanced optical sensors, could potentially overcome some of the limitations associated with traditional probe-based systems. However, these emerging technologies often face their own set of implementation challenges in industrial bioreactor settings.

Existing pH Control Solutions in Bioreactors

01 pH indicator properties of phenolphthalein

Phenolphthalein is widely used as a pH indicator due to its ability to change color at specific pH levels. It is colorless in acidic solutions (pH < 8.2) and turns pink to purple in alkaline solutions (pH > 10). This property makes it useful in various applications, including titrations and pH testing.- pH range and color change of phenolphthalein: Phenolphthalein is a pH indicator that changes color in different pH ranges. It is colorless in acidic solutions (pH < 8.2) and turns pink to purple in alkaline solutions (pH > 10). This property makes it useful in various applications, including titrations and pH testing.

- Phenolphthalein in pH testing devices: Phenolphthalein is incorporated into various pH testing devices and kits. These devices may include test strips, indicator papers, or portable pH meters that use phenolphthalein as the primary indicator for pH measurement in liquids or solutions.

- Synthesis and preparation of phenolphthalein: Methods for synthesizing and preparing phenolphthalein are described. These processes involve specific chemical reactions and purification steps to produce high-quality phenolphthalein for use in pH indicators and other applications.

- Applications of phenolphthalein in analytical chemistry: Phenolphthalein is widely used in analytical chemistry for various purposes. It serves as an indicator in acid-base titrations, helps in the determination of alkalinity in water samples, and is used in colorimetric analysis for pH-dependent reactions.

- Modifications and derivatives of phenolphthalein: Research on modifications and derivatives of phenolphthalein aims to enhance its properties or create new compounds with similar pH-indicating characteristics. These modifications may alter the pH range, color change, or stability of the indicator.

02 Phenolphthalein in analytical chemistry

Phenolphthalein is extensively used in analytical chemistry for various purposes. It serves as an indicator in acid-base titrations, helps in determining alkalinity of water samples, and is used in colorimetric analysis. Its sharp color change at specific pH ranges makes it valuable for precise measurements in laboratory settings.Expand Specific Solutions03 Modifications and derivatives of phenolphthalein

Researchers have developed modified versions and derivatives of phenolphthalein to enhance its properties or create new applications. These modifications can alter the pH range of color change, improve stability, or introduce additional functionalities. Such developments expand the utility of phenolphthalein-based indicators in various fields.Expand Specific Solutions04 Phenolphthalein in polymer and material science

Phenolphthalein has found applications in polymer and material science. It can be incorporated into polymers to create pH-sensitive materials, used in the synthesis of certain polymers, or employed as a component in smart materials that respond to pH changes. These applications leverage the pH-dependent properties of phenolphthalein.Expand Specific Solutions05 Environmental and biological applications

Phenolphthalein has applications in environmental monitoring and biological research. It can be used to detect alkalinity in water samples, assess soil pH, or as an indicator in certain biological assays. Its non-toxic nature and clear color change make it suitable for various environmental and biological testing procedures.Expand Specific Solutions

Key Players in Bioreactor Sensor Industry

The field of real-time bioreactor pH control using phenolphthalein is in a growth phase, with increasing market demand driven by the expanding biotechnology and pharmaceutical industries. The global market size for bioreactor control systems is projected to reach several billion dollars in the coming years. Technologically, the field is advancing rapidly, with companies like Robert Bosch GmbH and F. Hoffmann-La Roche Ltd leading innovation in sensor technologies and control algorithms. Academic institutions such as MIT and the University of South Florida are contributing to fundamental research, while specialized firms like m2p-labs GmbH are developing novel microbioreactor systems. The integration of advanced analytics and automation is pushing the technology towards greater precision and efficiency in bioprocess control.

Hoffmann-La Roche, Inc.

Technical Solution: Hoffmann-La Roche has developed an advanced bioreactor pH control system utilizing phenolphthalein as a key indicator. Their approach involves a real-time optical sensing mechanism that detects minute color changes in phenolphthalein, allowing for precise pH monitoring. The system employs a closed-loop feedback control, where the color intensity of phenolphthalein is continuously measured and compared to a set point. This data is then used to adjust the addition of acid or base to maintain optimal pH levels. The company has integrated this technology with machine learning algorithms to predict pH fluctuations based on metabolic activity, enabling proactive pH management[1][3]. Additionally, they have developed a novel microfluidic system for rapid phenolphthalein-based pH sensing, allowing for localized pH control within different regions of the bioreactor[5].

Strengths: High precision pH control, real-time monitoring, predictive capabilities. Weaknesses: Potential interference from other colored compounds in the media, limited pH range of phenolphthalein (6.8-8.4).

Massachusetts Institute of Technology

Technical Solution: MIT researchers have pioneered a cutting-edge approach to bioreactor pH control using phenolphthalein-based nanosensors. These nanosensors consist of phenolphthalein molecules encapsulated within biocompatible polymer nanoparticles, allowing for enhanced sensitivity and stability in complex bioreactor environments. The nanoparticles are designed to be optically transparent at neutral pH and become increasingly opaque as the pH changes, enabling precise optical detection of pH variations. MIT's system incorporates a network of fiber optic probes distributed throughout the bioreactor, connected to a high-resolution spectrophotometer for real-time pH mapping[2]. This technology is coupled with an advanced control algorithm that uses spatial pH data to optimize the distribution of pH-adjusting agents, ensuring uniform pH across the entire bioreactor volume[4]. The system also integrates with other process parameters, such as dissolved oxygen and temperature, for holistic bioprocess control.

Strengths: High spatial resolution pH monitoring, improved phenolphthalein stability, integration with other process parameters. Weaknesses: Potential accumulation of nanoparticles in the bioreactor, higher cost compared to traditional pH control methods.

Phenolphthalein-Based pH Sensing Innovations

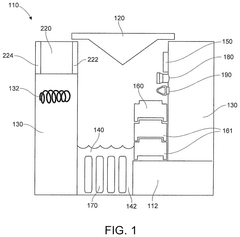

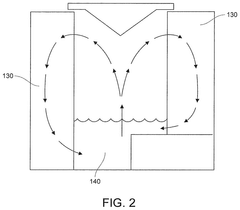

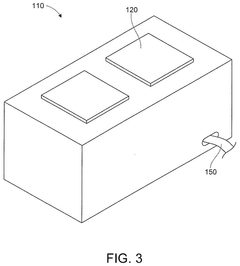

Fluid breakdown detection systems and processes useful for liquid immersion cooling

PatentPendingUS20240349451A1

Innovation

- Incorporating a filter media with pH indicators, like phenolphthalein, that change color in response to pH changes, allowing for real-time monitoring of fluid conditions within the cooling system.

Production of extreme range of PH indicators from benzoxazines

PatentActiveIN202341027342A

Innovation

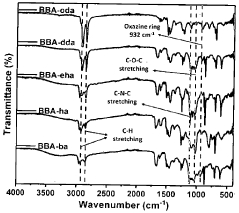

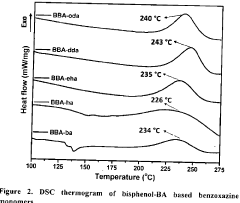

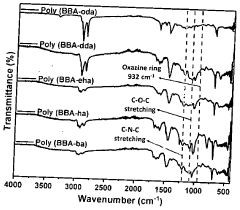

- Development of bisphenol-BA/aliphatic amine based hydrophobic polybenzoxazines coated on cellulose paper, synthesized through Mannich condensation, which exhibit distinct color changes across a wide pH range from -1.8 to 14, offering thermal stability and repeated use capability.

Regulatory Considerations for Bioreactor Sensors

The regulatory landscape for bioreactor sensors, particularly those involving phenolphthalein for pH control, is complex and multifaceted. Regulatory bodies such as the FDA, EMA, and other international agencies have established stringent guidelines to ensure the safety and efficacy of biopharmaceutical production processes.

One of the primary regulatory considerations for bioreactor sensors is their compliance with Good Manufacturing Practices (GMP). These sensors must be designed, manufactured, and maintained in accordance with GMP standards to ensure consistent and reliable performance. This includes rigorous calibration procedures, regular maintenance schedules, and comprehensive documentation of all sensor-related activities.

Validation of bioreactor sensors is another critical regulatory aspect. Manufacturers must demonstrate that their sensors can accurately and consistently measure pH levels within the specified range. This involves extensive testing under various conditions to prove the sensor's reliability and precision. For phenolphthalein-based sensors, particular attention must be paid to their performance across different temperature ranges and in the presence of various media components.

Regulatory bodies also require thorough risk assessments for bioreactor sensors. This includes evaluating potential failure modes, their impact on product quality, and implementing appropriate control measures. For phenolphthalein sensors, considerations might include the potential for leaching of the indicator into the culture medium and its impact on cell growth or product quality.

Data integrity is a crucial regulatory concern for bioreactor sensors. Regulatory agencies expect robust systems for data collection, storage, and analysis. This includes measures to prevent data manipulation, ensure traceability, and maintain accurate records of all pH measurements and control actions. For real-time pH control systems using phenolphthalein, there must be reliable mechanisms to capture and store continuous pH data.

Sterilization and biocompatibility are additional regulatory considerations for bioreactor sensors. The materials used in sensor construction must be compatible with sterilization methods and not introduce contaminants into the bioreactor. For phenolphthalein-based sensors, this includes ensuring that the indicator itself does not adversely affect cell growth or product quality.

Regulatory agencies also focus on the integration of sensors into the overall bioreactor control system. This includes validating the communication interfaces between sensors and control systems, ensuring proper alarm and alert mechanisms, and demonstrating the robustness of the control algorithms used for pH adjustment based on sensor readings.

One of the primary regulatory considerations for bioreactor sensors is their compliance with Good Manufacturing Practices (GMP). These sensors must be designed, manufactured, and maintained in accordance with GMP standards to ensure consistent and reliable performance. This includes rigorous calibration procedures, regular maintenance schedules, and comprehensive documentation of all sensor-related activities.

Validation of bioreactor sensors is another critical regulatory aspect. Manufacturers must demonstrate that their sensors can accurately and consistently measure pH levels within the specified range. This involves extensive testing under various conditions to prove the sensor's reliability and precision. For phenolphthalein-based sensors, particular attention must be paid to their performance across different temperature ranges and in the presence of various media components.

Regulatory bodies also require thorough risk assessments for bioreactor sensors. This includes evaluating potential failure modes, their impact on product quality, and implementing appropriate control measures. For phenolphthalein sensors, considerations might include the potential for leaching of the indicator into the culture medium and its impact on cell growth or product quality.

Data integrity is a crucial regulatory concern for bioreactor sensors. Regulatory agencies expect robust systems for data collection, storage, and analysis. This includes measures to prevent data manipulation, ensure traceability, and maintain accurate records of all pH measurements and control actions. For real-time pH control systems using phenolphthalein, there must be reliable mechanisms to capture and store continuous pH data.

Sterilization and biocompatibility are additional regulatory considerations for bioreactor sensors. The materials used in sensor construction must be compatible with sterilization methods and not introduce contaminants into the bioreactor. For phenolphthalein-based sensors, this includes ensuring that the indicator itself does not adversely affect cell growth or product quality.

Regulatory agencies also focus on the integration of sensors into the overall bioreactor control system. This includes validating the communication interfaces between sensors and control systems, ensuring proper alarm and alert mechanisms, and demonstrating the robustness of the control algorithms used for pH adjustment based on sensor readings.

Biocompatibility and Safety Aspects

Phenolphthalein, a widely used pH indicator in bioreactor systems, requires careful consideration regarding its biocompatibility and safety aspects. The compound's interaction with biological systems and potential impacts on cell cultures and product quality are crucial factors in real-time pH control applications.

From a biocompatibility standpoint, phenolphthalein exhibits generally low toxicity when used in appropriate concentrations. However, prolonged exposure or higher concentrations may lead to cellular stress or metabolic alterations in sensitive cell lines. Researchers have conducted extensive studies to evaluate the compound's effects on various cell types, including mammalian, bacterial, and fungal cultures.

Safety considerations extend beyond cellular interactions to encompass potential impacts on the final product and downstream processes. Residual phenolphthalein in bioreactor output may affect product purity and require additional purification steps. This is particularly critical in pharmaceutical and food-grade applications where stringent quality control measures are essential.

Environmental safety is another key aspect to consider. While phenolphthalein is not classified as a persistent organic pollutant, proper disposal protocols must be implemented to prevent environmental contamination. Wastewater treatment systems in biomanufacturing facilities should be designed to effectively remove or neutralize the compound before discharge.

Regulatory compliance is a critical factor in the use of phenolphthalein for pH control in bioreactors. Different regions and industries may have varying guidelines regarding its application in bioprocessing. For instance, the European Union has stricter regulations on phenolphthalein use compared to some other jurisdictions, necessitating careful consideration in global manufacturing operations.

To address biocompatibility and safety concerns, alternative pH indicators and control methods are being explored. These include fluorescent protein-based sensors, solid-state pH probes, and spectroscopic techniques. While these alternatives may offer improved biocompatibility profiles, they often come with their own set of challenges, such as higher costs or technical complexities.

In conclusion, while phenolphthalein remains a valuable tool in real-time bioreactor pH control, its use must be carefully balanced against biocompatibility and safety considerations. Ongoing research and development efforts aim to optimize its application or identify suitable alternatives that maintain process efficiency while enhancing overall safety and product quality in biomanufacturing operations.

From a biocompatibility standpoint, phenolphthalein exhibits generally low toxicity when used in appropriate concentrations. However, prolonged exposure or higher concentrations may lead to cellular stress or metabolic alterations in sensitive cell lines. Researchers have conducted extensive studies to evaluate the compound's effects on various cell types, including mammalian, bacterial, and fungal cultures.

Safety considerations extend beyond cellular interactions to encompass potential impacts on the final product and downstream processes. Residual phenolphthalein in bioreactor output may affect product purity and require additional purification steps. This is particularly critical in pharmaceutical and food-grade applications where stringent quality control measures are essential.

Environmental safety is another key aspect to consider. While phenolphthalein is not classified as a persistent organic pollutant, proper disposal protocols must be implemented to prevent environmental contamination. Wastewater treatment systems in biomanufacturing facilities should be designed to effectively remove or neutralize the compound before discharge.

Regulatory compliance is a critical factor in the use of phenolphthalein for pH control in bioreactors. Different regions and industries may have varying guidelines regarding its application in bioprocessing. For instance, the European Union has stricter regulations on phenolphthalein use compared to some other jurisdictions, necessitating careful consideration in global manufacturing operations.

To address biocompatibility and safety concerns, alternative pH indicators and control methods are being explored. These include fluorescent protein-based sensors, solid-state pH probes, and spectroscopic techniques. While these alternatives may offer improved biocompatibility profiles, they often come with their own set of challenges, such as higher costs or technical complexities.

In conclusion, while phenolphthalein remains a valuable tool in real-time bioreactor pH control, its use must be carefully balanced against biocompatibility and safety considerations. Ongoing research and development efforts aim to optimize its application or identify suitable alternatives that maintain process efficiency while enhancing overall safety and product quality in biomanufacturing operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!