Piezoelectric Innovations Using Borosilicate Glass

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Glass Evolution

The evolution of piezoelectric glass, particularly focusing on borosilicate glass, represents a significant advancement in materials science and engineering. This timeline traces the key developments and milestones in the field, showcasing the progression from traditional piezoelectric materials to innovative glass-based solutions.

In the early stages, piezoelectric materials were primarily ceramics and crystals, with quartz being one of the most widely used. The discovery of piezoelectricity in certain types of glass marked a turning point in the field. Borosilicate glass, known for its thermal and chemical resistance, emerged as a promising candidate for piezoelectric applications.

The 1990s saw initial experiments with borosilicate glass in piezoelectric contexts. Researchers began exploring the potential of this material to exhibit piezoelectric properties through various treatments and modifications. These early studies laid the groundwork for future innovations.

A significant breakthrough came in the early 2000s when scientists successfully induced piezoelectric properties in borosilicate glass through thermal poling techniques. This process involved applying high voltages to the glass at elevated temperatures, creating a permanent electric field within the material structure.

The following decade witnessed rapid advancements in the fabrication and characterization of piezoelectric borosilicate glass. Researchers developed more sophisticated poling methods, optimizing parameters such as temperature, voltage, and duration to enhance the piezoelectric response of the glass.

By the mid-2010s, the focus shifted towards understanding the fundamental mechanisms behind piezoelectricity in borosilicate glass. Advanced analytical techniques, including high-resolution microscopy and spectroscopy, provided insights into the structural changes occurring during the poling process.

Recent years have seen a surge in applications for piezoelectric borosilicate glass. Its unique properties, including transparency and biocompatibility, have opened up new possibilities in fields such as biomedical sensing, energy harvesting, and microfluidics. Researchers have also explored composite materials, combining borosilicate glass with other piezoelectric substances to create hybrid materials with enhanced properties.

The latest developments in this field involve the integration of piezoelectric borosilicate glass into micro-electromechanical systems (MEMS) and nanodevices. These advancements are paving the way for miniaturized sensors and actuators with improved performance and reliability.

Looking ahead, the evolution of piezoelectric innovations using borosilicate glass continues to accelerate. Ongoing research focuses on further improving the piezoelectric coefficients, exploring new glass compositions, and developing novel fabrication techniques. The potential for large-scale manufacturing and commercialization of piezoelectric glass devices represents an exciting frontier in this rapidly evolving field.

In the early stages, piezoelectric materials were primarily ceramics and crystals, with quartz being one of the most widely used. The discovery of piezoelectricity in certain types of glass marked a turning point in the field. Borosilicate glass, known for its thermal and chemical resistance, emerged as a promising candidate for piezoelectric applications.

The 1990s saw initial experiments with borosilicate glass in piezoelectric contexts. Researchers began exploring the potential of this material to exhibit piezoelectric properties through various treatments and modifications. These early studies laid the groundwork for future innovations.

A significant breakthrough came in the early 2000s when scientists successfully induced piezoelectric properties in borosilicate glass through thermal poling techniques. This process involved applying high voltages to the glass at elevated temperatures, creating a permanent electric field within the material structure.

The following decade witnessed rapid advancements in the fabrication and characterization of piezoelectric borosilicate glass. Researchers developed more sophisticated poling methods, optimizing parameters such as temperature, voltage, and duration to enhance the piezoelectric response of the glass.

By the mid-2010s, the focus shifted towards understanding the fundamental mechanisms behind piezoelectricity in borosilicate glass. Advanced analytical techniques, including high-resolution microscopy and spectroscopy, provided insights into the structural changes occurring during the poling process.

Recent years have seen a surge in applications for piezoelectric borosilicate glass. Its unique properties, including transparency and biocompatibility, have opened up new possibilities in fields such as biomedical sensing, energy harvesting, and microfluidics. Researchers have also explored composite materials, combining borosilicate glass with other piezoelectric substances to create hybrid materials with enhanced properties.

The latest developments in this field involve the integration of piezoelectric borosilicate glass into micro-electromechanical systems (MEMS) and nanodevices. These advancements are paving the way for miniaturized sensors and actuators with improved performance and reliability.

Looking ahead, the evolution of piezoelectric innovations using borosilicate glass continues to accelerate. Ongoing research focuses on further improving the piezoelectric coefficients, exploring new glass compositions, and developing novel fabrication techniques. The potential for large-scale manufacturing and commercialization of piezoelectric glass devices represents an exciting frontier in this rapidly evolving field.

Market Demand Analysis

The market demand for piezoelectric innovations using borosilicate glass has been steadily growing, driven by the increasing need for advanced sensing and energy harvesting technologies across various industries. Borosilicate glass, known for its excellent thermal and chemical resistance properties, has emerged as a promising material for piezoelectric applications, offering unique advantages over traditional ceramic-based piezoelectric materials.

In the healthcare sector, there is a rising demand for miniaturized, high-performance sensors for medical devices and diagnostic equipment. Piezoelectric borosilicate glass sensors can provide improved sensitivity and reliability in applications such as ultrasound imaging, blood pressure monitoring, and surgical instruments. The market for these medical devices is expected to expand significantly in the coming years, fueled by the aging population and the growing emphasis on preventive healthcare.

The automotive industry represents another key market for piezoelectric borosilicate glass innovations. As vehicles become increasingly electrified and autonomous, there is a growing need for advanced sensors and energy harvesting systems. Piezoelectric borosilicate glass components can be utilized in tire pressure monitoring systems, engine knock sensors, and vibration energy harvesters, contributing to improved vehicle performance and energy efficiency.

In the consumer electronics sector, the demand for compact, energy-efficient devices continues to drive innovation in piezoelectric technologies. Borosilicate glass-based piezoelectric components offer potential applications in touchscreens, haptic feedback systems, and energy harvesting for wearable devices. The market for these applications is expected to grow rapidly, driven by the increasing adoption of smart devices and the Internet of Things (IoT) ecosystem.

The aerospace and defense industries also present significant market opportunities for piezoelectric borosilicate glass innovations. These materials can be used in structural health monitoring systems, vibration control devices, and energy harvesting for remote sensors. The demand for lightweight, durable, and high-performance materials in these sectors is likely to drive further research and development in this field.

Environmental monitoring and energy harvesting applications represent another growing market segment for piezoelectric borosilicate glass technologies. These materials can be used in sensors for measuring air and water quality, as well as in energy harvesting systems for powering remote monitoring stations. The increasing focus on environmental sustainability and renewable energy sources is expected to fuel demand in this sector.

As the global push for sustainable and efficient technologies continues, the market for piezoelectric innovations using borosilicate glass is poised for substantial growth across multiple industries. The unique properties of borosilicate glass, combined with advancements in piezoelectric technology, offer promising solutions to address the evolving needs of various sectors, from healthcare and automotive to consumer electronics and environmental monitoring.

In the healthcare sector, there is a rising demand for miniaturized, high-performance sensors for medical devices and diagnostic equipment. Piezoelectric borosilicate glass sensors can provide improved sensitivity and reliability in applications such as ultrasound imaging, blood pressure monitoring, and surgical instruments. The market for these medical devices is expected to expand significantly in the coming years, fueled by the aging population and the growing emphasis on preventive healthcare.

The automotive industry represents another key market for piezoelectric borosilicate glass innovations. As vehicles become increasingly electrified and autonomous, there is a growing need for advanced sensors and energy harvesting systems. Piezoelectric borosilicate glass components can be utilized in tire pressure monitoring systems, engine knock sensors, and vibration energy harvesters, contributing to improved vehicle performance and energy efficiency.

In the consumer electronics sector, the demand for compact, energy-efficient devices continues to drive innovation in piezoelectric technologies. Borosilicate glass-based piezoelectric components offer potential applications in touchscreens, haptic feedback systems, and energy harvesting for wearable devices. The market for these applications is expected to grow rapidly, driven by the increasing adoption of smart devices and the Internet of Things (IoT) ecosystem.

The aerospace and defense industries also present significant market opportunities for piezoelectric borosilicate glass innovations. These materials can be used in structural health monitoring systems, vibration control devices, and energy harvesting for remote sensors. The demand for lightweight, durable, and high-performance materials in these sectors is likely to drive further research and development in this field.

Environmental monitoring and energy harvesting applications represent another growing market segment for piezoelectric borosilicate glass technologies. These materials can be used in sensors for measuring air and water quality, as well as in energy harvesting systems for powering remote monitoring stations. The increasing focus on environmental sustainability and renewable energy sources is expected to fuel demand in this sector.

As the global push for sustainable and efficient technologies continues, the market for piezoelectric innovations using borosilicate glass is poised for substantial growth across multiple industries. The unique properties of borosilicate glass, combined with advancements in piezoelectric technology, offer promising solutions to address the evolving needs of various sectors, from healthcare and automotive to consumer electronics and environmental monitoring.

Borosilicate Glass Challenges

Borosilicate glass, while offering numerous advantages for piezoelectric applications, presents several significant challenges that researchers and engineers must overcome. One of the primary obstacles is the material's inherent brittleness, which can lead to fracturing under high stress or rapid temperature changes. This characteristic limits its durability and reliability in certain high-performance piezoelectric devices, particularly those subjected to extreme conditions or frequent mechanical stress.

Another challenge lies in the precise control of the glass composition and structure. Borosilicate glass's piezoelectric properties are highly dependent on its chemical makeup and internal structure. Achieving consistent and optimal piezoelectric performance requires extremely tight control over the manufacturing process, including melting temperatures, cooling rates, and the exact proportions of constituent elements. Any slight variations can result in significant differences in piezoelectric response, making large-scale production of uniform piezoelectric borosilicate glass components challenging.

The integration of borosilicate glass with other materials in piezoelectric devices poses additional difficulties. Creating effective interfaces between the glass and electrodes, substrates, or other functional layers without compromising the piezoelectric properties or structural integrity of the glass is a complex task. This integration challenge is particularly pronounced when attempting to fabricate miniaturized or flexible piezoelectric devices, where the rigid nature of borosilicate glass can be a limiting factor.

Furthermore, the relatively low piezoelectric coefficients of borosilicate glass compared to some traditional piezoelectric materials like lead zirconate titanate (PZT) present a performance challenge. While borosilicate glass offers environmental and biocompatibility advantages, its lower piezoelectric response necessitates innovative design approaches to achieve comparable functionality in applications where high sensitivity or actuation force is required.

The long-term stability and aging characteristics of piezoelectric borosilicate glass structures also require further investigation. Understanding and mitigating potential degradation mechanisms, such as stress relaxation or compositional changes over time, is crucial for ensuring the reliability of devices in long-term applications. This aspect is particularly important in sectors like medical implants or industrial sensors where long-term stability is paramount.

Lastly, the development of efficient and scalable manufacturing processes for piezoelectric borosilicate glass components remains a significant challenge. Current production methods often involve complex and time-consuming steps, limiting the material's cost-effectiveness and widespread adoption. Innovations in manufacturing techniques, such as advanced 3D printing or precision molding of piezoelectric borosilicate glass, are needed to overcome these limitations and enable broader commercial viability.

Another challenge lies in the precise control of the glass composition and structure. Borosilicate glass's piezoelectric properties are highly dependent on its chemical makeup and internal structure. Achieving consistent and optimal piezoelectric performance requires extremely tight control over the manufacturing process, including melting temperatures, cooling rates, and the exact proportions of constituent elements. Any slight variations can result in significant differences in piezoelectric response, making large-scale production of uniform piezoelectric borosilicate glass components challenging.

The integration of borosilicate glass with other materials in piezoelectric devices poses additional difficulties. Creating effective interfaces between the glass and electrodes, substrates, or other functional layers without compromising the piezoelectric properties or structural integrity of the glass is a complex task. This integration challenge is particularly pronounced when attempting to fabricate miniaturized or flexible piezoelectric devices, where the rigid nature of borosilicate glass can be a limiting factor.

Furthermore, the relatively low piezoelectric coefficients of borosilicate glass compared to some traditional piezoelectric materials like lead zirconate titanate (PZT) present a performance challenge. While borosilicate glass offers environmental and biocompatibility advantages, its lower piezoelectric response necessitates innovative design approaches to achieve comparable functionality in applications where high sensitivity or actuation force is required.

The long-term stability and aging characteristics of piezoelectric borosilicate glass structures also require further investigation. Understanding and mitigating potential degradation mechanisms, such as stress relaxation or compositional changes over time, is crucial for ensuring the reliability of devices in long-term applications. This aspect is particularly important in sectors like medical implants or industrial sensors where long-term stability is paramount.

Lastly, the development of efficient and scalable manufacturing processes for piezoelectric borosilicate glass components remains a significant challenge. Current production methods often involve complex and time-consuming steps, limiting the material's cost-effectiveness and widespread adoption. Innovations in manufacturing techniques, such as advanced 3D printing or precision molding of piezoelectric borosilicate glass, are needed to overcome these limitations and enable broader commercial viability.

Current Piezoelectric Solutions

01 Composition and structure of piezoelectric borosilicate glass

Borosilicate glass can be engineered to exhibit piezoelectric properties by carefully controlling its composition and structure. This typically involves incorporating specific elements or compounds that enhance the glass's ability to generate an electric charge in response to mechanical stress. The precise formulation and manufacturing process are crucial in achieving the desired piezoelectric effect in borosilicate glass.- Composition and structure of piezoelectric borosilicate glass: Borosilicate glass can be modified to exhibit piezoelectric properties through careful control of its composition and structure. This typically involves incorporating specific elements or compounds that enhance the glass's ability to generate an electric charge in response to mechanical stress. The precise formulation and manufacturing process are crucial in achieving the desired piezoelectric effect in borosilicate glass.

- Applications of piezoelectric borosilicate glass: Piezoelectric borosilicate glass finds applications in various fields due to its unique properties. It can be used in sensors, actuators, and transducers for measuring pressure, acceleration, and vibration. The material's durability and chemical resistance make it suitable for harsh environment applications. Additionally, it has potential uses in energy harvesting devices and microelectromechanical systems (MEMS).

- Manufacturing processes for piezoelectric borosilicate glass: The production of piezoelectric borosilicate glass involves specialized manufacturing processes. These may include controlled cooling rates, specific heat treatments, or the application of electric fields during the glass formation. Advanced techniques such as ion exchange or surface modification may be employed to enhance the piezoelectric properties. The manufacturing process is critical in determining the final piezoelectric characteristics of the glass.

- Characterization and measurement of piezoelectric properties: Various methods are used to characterize and measure the piezoelectric properties of borosilicate glass. These include techniques such as impedance analysis, laser vibrometry, and piezoresponse force microscopy. The piezoelectric coefficients, electromechanical coupling factors, and frequency response are important parameters that are typically measured to assess the performance of piezoelectric borosilicate glass.

- Comparison with other piezoelectric materials: Piezoelectric borosilicate glass is often compared to other piezoelectric materials such as ceramics and polymers. While it may not have the highest piezoelectric coefficients, borosilicate glass offers advantages in terms of transparency, chemical stability, and ease of shaping. The unique combination of properties makes it suitable for specific applications where traditional piezoelectric materials may not be ideal.

02 Applications of piezoelectric borosilicate glass

Piezoelectric borosilicate glass finds applications in various fields due to its unique properties. It can be used in sensors, actuators, and transducers for measuring pressure, acceleration, and vibration. The material's durability and chemical resistance make it suitable for harsh environments. Additionally, it has potential uses in energy harvesting devices and microelectromechanical systems (MEMS).Expand Specific Solutions03 Fabrication methods for piezoelectric borosilicate glass

Various fabrication methods can be employed to produce piezoelectric borosilicate glass. These may include specialized melting and cooling processes, ion exchange techniques, or the incorporation of nanoparticles or crystalline phases. The choice of method depends on the desired properties and intended application of the piezoelectric glass.Expand Specific Solutions04 Characterization and measurement of piezoelectric properties

Characterizing the piezoelectric properties of borosilicate glass involves various measurement techniques. These may include impedance analysis, piezoresponse force microscopy, and direct measurement of charge generation under applied stress. Understanding and quantifying these properties are essential for optimizing the material's performance in specific applications.Expand Specific Solutions05 Comparison with other piezoelectric materials

Piezoelectric borosilicate glass offers unique advantages compared to traditional piezoelectric materials like ceramics or polymers. These may include better chemical stability, higher temperature resistance, or improved optical properties. However, it may also have limitations in terms of piezoelectric coefficient or coupling factor. Understanding these trade-offs is crucial for selecting the most appropriate material for a given application.Expand Specific Solutions

Key Industry Players

The piezoelectric innovations using borosilicate glass market is in an early growth stage, with increasing research and development activities. The market size is expanding as applications in sensors, actuators, and energy harvesting devices grow. While the technology is still evolving, several key players are advancing its maturity. Companies like SCHOTT AG, Corning, and AGC are leveraging their expertise in specialty glass to develop piezoelectric borosilicate materials. Emerging players such as Ionix Advanced Technologies and Sunshine Lake Pharma are focusing on novel applications. Established electronics firms like Canon, TDK, and Murata are exploring integration into their product lines. Overall, the competitive landscape is diverse, with both glass and electronics companies vying for leadership in this promising field.

SCHOTT AG

Technical Solution: SCHOTT AG has developed innovative piezoelectric borosilicate glass compositions with enhanced piezoelectric properties. Their approach involves doping borosilicate glass with specific elements to create a non-crystalline structure that exhibits piezoelectric behavior. This allows for the production of thin, flexible piezoelectric elements with improved sensitivity and durability compared to traditional ceramic materials[1][3]. SCHOTT's piezoelectric glass can be precisely shaped and integrated into complex geometries, enabling new applications in sensors, actuators, and energy harvesting devices[2].

Strengths: High flexibility, durability, and integration potential. Weaknesses: May have lower piezoelectric coefficients compared to some ceramics.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed advanced piezoelectric borosilicate glass composites that combine the benefits of both materials. Their approach involves embedding piezoelectric ceramic particles within a borosilicate glass matrix, creating a material with enhanced mechanical properties and tailored piezoelectric response[4]. This composite structure allows for fine-tuning of the piezoelectric properties while maintaining the chemical stability and thermal resistance of borosilicate glass. Murata's technology enables the production of miniaturized piezoelectric components with improved performance in harsh environments[5].

Strengths: Customizable properties, miniaturization potential, and environmental resistance. Weaknesses: Manufacturing complexity and potential cost increase.

Borosilicate Glass Innovations

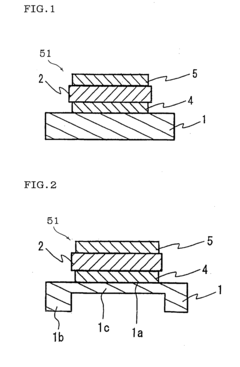

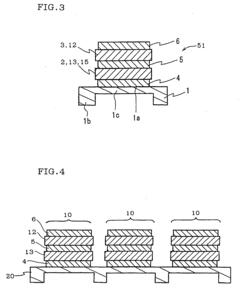

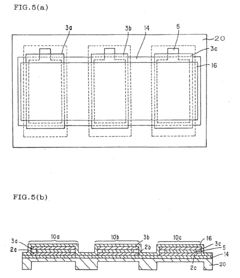

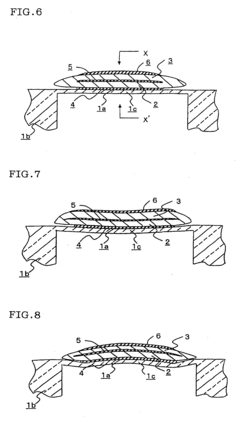

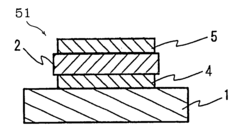

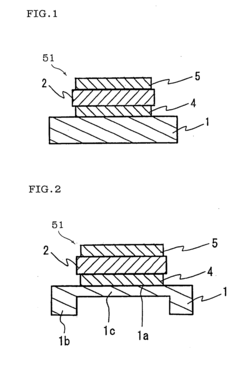

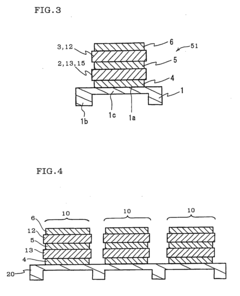

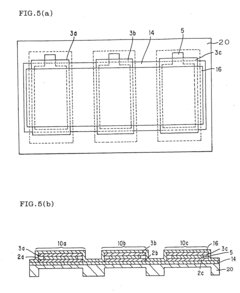

Piezoelectric/electrostrictive ceramic composition and piezoelectric/electrostrictive film type device

PatentInactiveEP1575100A2

Innovation

- A piezoelectric/electrostrictive porcelain composition containing lead titanate zirconate and a controlled amount of glass component with silicic acid, allowing for denser and more crystalline ceramics to be formed at lower firing temperatures, with a glass layer in the grain boundary to prevent moisture penetration and crack formation.

Piezoelectric/electrostrictive porcelain composition, piezoelectric/electrostrictive ceramic and piezoelectric/electrostrictive film type device

PatentInactiveUS20050194868A1

Innovation

- A piezoelectric/electrostrictive porcelain composition containing lead titanate zirconate with a controlled amount of glass component, specifically 0.5 to 5% by mass with 8% or less silicic acid, is used to create a dense and crystalline ceramic or film type device that can withstand high temperature and humidity, allowing for lower firing temperatures and the use of Ag or Ag-Pd electrodes.

Environmental Impact Assessment

The environmental impact assessment of piezoelectric innovations using borosilicate glass reveals both potential benefits and concerns. Borosilicate glass, known for its durability and resistance to thermal shock, offers advantages over traditional piezoelectric materials in terms of sustainability and recyclability. Its production process generally requires less energy and generates fewer harmful emissions compared to conventional piezoelectric ceramics.

The use of borosilicate glass in piezoelectric devices can lead to reduced electronic waste, as these components tend to have longer lifespans and are less prone to degradation. This longevity contributes to a decrease in the overall environmental footprint of electronic products incorporating such innovations. Additionally, the recyclability of borosilicate glass allows for more efficient resource management and waste reduction in the long term.

However, the manufacturing process of borosilicate glass still involves energy-intensive melting and forming stages, which contribute to carbon emissions. The extraction of raw materials, particularly boron compounds, may have localized environmental impacts on mining areas. It is crucial to implement sustainable mining practices and optimize production processes to mitigate these effects.

The potential for improved energy harvesting efficiency in piezoelectric devices using borosilicate glass could lead to positive environmental outcomes. Enhanced energy recovery from ambient vibrations and mechanical stress could reduce reliance on traditional power sources, potentially lowering overall energy consumption and associated carbon emissions in various applications.

Concerns arise regarding the end-of-life management of borosilicate glass-based piezoelectric devices. While the glass itself is recyclable, the composite nature of these devices, often including metallic electrodes and other materials, may complicate recycling processes. Developing effective separation and recycling techniques for these composite materials is essential to maximize the environmental benefits of this innovation.

The potential for reduced toxicity compared to lead-based piezoelectric materials is a significant environmental advantage. Borosilicate glass-based piezoelectric devices could help in phasing out hazardous substances from electronic components, aligning with global initiatives for greener electronics and reducing the risk of environmental contamination.

In conclusion, while piezoelectric innovations using borosilicate glass show promise in terms of sustainability and reduced environmental impact, a comprehensive life cycle assessment is necessary to fully quantify their environmental benefits and address potential challenges in production and end-of-life management.

The use of borosilicate glass in piezoelectric devices can lead to reduced electronic waste, as these components tend to have longer lifespans and are less prone to degradation. This longevity contributes to a decrease in the overall environmental footprint of electronic products incorporating such innovations. Additionally, the recyclability of borosilicate glass allows for more efficient resource management and waste reduction in the long term.

However, the manufacturing process of borosilicate glass still involves energy-intensive melting and forming stages, which contribute to carbon emissions. The extraction of raw materials, particularly boron compounds, may have localized environmental impacts on mining areas. It is crucial to implement sustainable mining practices and optimize production processes to mitigate these effects.

The potential for improved energy harvesting efficiency in piezoelectric devices using borosilicate glass could lead to positive environmental outcomes. Enhanced energy recovery from ambient vibrations and mechanical stress could reduce reliance on traditional power sources, potentially lowering overall energy consumption and associated carbon emissions in various applications.

Concerns arise regarding the end-of-life management of borosilicate glass-based piezoelectric devices. While the glass itself is recyclable, the composite nature of these devices, often including metallic electrodes and other materials, may complicate recycling processes. Developing effective separation and recycling techniques for these composite materials is essential to maximize the environmental benefits of this innovation.

The potential for reduced toxicity compared to lead-based piezoelectric materials is a significant environmental advantage. Borosilicate glass-based piezoelectric devices could help in phasing out hazardous substances from electronic components, aligning with global initiatives for greener electronics and reducing the risk of environmental contamination.

In conclusion, while piezoelectric innovations using borosilicate glass show promise in terms of sustainability and reduced environmental impact, a comprehensive life cycle assessment is necessary to fully quantify their environmental benefits and address potential challenges in production and end-of-life management.

Intellectual Property Landscape

The intellectual property landscape surrounding piezoelectric innovations using borosilicate glass is characterized by a diverse array of patents and ongoing research efforts. Major players in this field include both established glass manufacturers and specialized piezoelectric technology companies, who have been actively filing patents to protect their innovations.

Several key patent clusters have emerged in recent years. One significant area focuses on the development of novel borosilicate glass compositions optimized for piezoelectric properties. These patents typically claim specific chemical formulations and manufacturing processes that enhance the glass's piezoelectric response. Another prominent cluster revolves around the integration of borosilicate glass-based piezoelectric elements into various devices and systems, such as sensors, actuators, and energy harvesting units.

The geographical distribution of patent filings reveals interesting trends. While traditional glass manufacturing powerhouses like Germany and Japan maintain a strong presence, there has been a notable increase in patent activity from China and South Korea. This shift reflects the growing emphasis on piezoelectric technologies in these emerging economies.

In terms of application areas, the patent landscape shows a broad spectrum of potential uses for borosilicate glass-based piezoelectric materials. Medical devices, particularly ultrasound transducers and implantable sensors, represent a significant portion of the patent filings. Additionally, there is substantial interest in utilizing these materials for energy harvesting applications, with patents covering innovative designs for vibration-based power generation systems.

Recent patent trends indicate an increasing focus on nanoscale structures and surface modifications of borosilicate glass to enhance its piezoelectric properties. Several patents describe methods for creating nanocomposites or introducing specific dopants to amplify the piezoelectric effect. This direction suggests that future innovations may lie in the realm of advanced materials engineering at the nanoscale.

The competitive landscape revealed through patent analysis shows a mix of established players and emerging startups. While large corporations hold foundational patents on basic technologies, smaller companies are actively pursuing niche applications and novel manufacturing techniques. This dynamic ecosystem is likely to drive further innovation and commercialization of borosilicate glass-based piezoelectric technologies in the coming years.

Several key patent clusters have emerged in recent years. One significant area focuses on the development of novel borosilicate glass compositions optimized for piezoelectric properties. These patents typically claim specific chemical formulations and manufacturing processes that enhance the glass's piezoelectric response. Another prominent cluster revolves around the integration of borosilicate glass-based piezoelectric elements into various devices and systems, such as sensors, actuators, and energy harvesting units.

The geographical distribution of patent filings reveals interesting trends. While traditional glass manufacturing powerhouses like Germany and Japan maintain a strong presence, there has been a notable increase in patent activity from China and South Korea. This shift reflects the growing emphasis on piezoelectric technologies in these emerging economies.

In terms of application areas, the patent landscape shows a broad spectrum of potential uses for borosilicate glass-based piezoelectric materials. Medical devices, particularly ultrasound transducers and implantable sensors, represent a significant portion of the patent filings. Additionally, there is substantial interest in utilizing these materials for energy harvesting applications, with patents covering innovative designs for vibration-based power generation systems.

Recent patent trends indicate an increasing focus on nanoscale structures and surface modifications of borosilicate glass to enhance its piezoelectric properties. Several patents describe methods for creating nanocomposites or introducing specific dopants to amplify the piezoelectric effect. This direction suggests that future innovations may lie in the realm of advanced materials engineering at the nanoscale.

The competitive landscape revealed through patent analysis shows a mix of established players and emerging startups. While large corporations hold foundational patents on basic technologies, smaller companies are actively pursuing niche applications and novel manufacturing techniques. This dynamic ecosystem is likely to drive further innovation and commercialization of borosilicate glass-based piezoelectric technologies in the coming years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!