PMMA Enhancements: Increasing Impact Resistance

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMMA Evolution and Goals

Poly(methyl methacrylate) (PMMA), commonly known as acrylic or plexiglass, has been a cornerstone material in various industries since its development in the 1930s. The evolution of PMMA has been driven by the continuous demand for improved performance, particularly in terms of impact resistance. Initially valued for its optical clarity and weather resistance, PMMA's brittle nature has been a persistent challenge, limiting its application in high-impact environments.

The journey of PMMA enhancements began with the recognition of its potential as a lightweight, shatter-resistant alternative to glass. Early modifications focused on copolymerization with other acrylates to improve flexibility. However, these efforts often compromised the material's optical properties and heat resistance. The 1960s and 1970s saw the introduction of rubber-modified PMMA, marking a significant leap in impact resistance without substantial loss of transparency.

As technology advanced, the goals for PMMA enhancement became more refined. The primary objective shifted towards developing PMMA variants that could maintain the material's desirable properties while significantly increasing impact resistance. This led to the exploration of various strategies, including the incorporation of impact modifiers, nanocomposite formulations, and multilayer structures.

Recent years have witnessed a surge in research aimed at molecular-level modifications of PMMA. Scientists and engineers are now focusing on tailoring the polymer chain architecture to enhance energy absorption capabilities. The advent of computational modeling has accelerated this process, allowing for the prediction of material properties based on molecular structure modifications.

The current technological landscape presents both challenges and opportunities for PMMA enhancement. The goal is to achieve a balance between impact resistance, optical clarity, and processability. Researchers are exploring bio-based additives and sustainable production methods to align with growing environmental concerns. Additionally, there is a push towards developing PMMA composites that can offer multifunctional properties, such as self-healing capabilities or enhanced thermal management.

Looking ahead, the evolution of PMMA is expected to continue with a focus on smart materials. The integration of responsive elements that can adapt to environmental stimuli is a promising frontier. Furthermore, the development of PMMA-based materials with tunable impact resistance properties could revolutionize applications in automotive, construction, and personal protective equipment industries.

In conclusion, the evolution of PMMA and the goals for its enhancement reflect a broader trend in materials science towards creating versatile, high-performance polymers. The ongoing quest for increased impact resistance in PMMA exemplifies the dynamic nature of materials development, driven by technological advancements and changing market demands.

The journey of PMMA enhancements began with the recognition of its potential as a lightweight, shatter-resistant alternative to glass. Early modifications focused on copolymerization with other acrylates to improve flexibility. However, these efforts often compromised the material's optical properties and heat resistance. The 1960s and 1970s saw the introduction of rubber-modified PMMA, marking a significant leap in impact resistance without substantial loss of transparency.

As technology advanced, the goals for PMMA enhancement became more refined. The primary objective shifted towards developing PMMA variants that could maintain the material's desirable properties while significantly increasing impact resistance. This led to the exploration of various strategies, including the incorporation of impact modifiers, nanocomposite formulations, and multilayer structures.

Recent years have witnessed a surge in research aimed at molecular-level modifications of PMMA. Scientists and engineers are now focusing on tailoring the polymer chain architecture to enhance energy absorption capabilities. The advent of computational modeling has accelerated this process, allowing for the prediction of material properties based on molecular structure modifications.

The current technological landscape presents both challenges and opportunities for PMMA enhancement. The goal is to achieve a balance between impact resistance, optical clarity, and processability. Researchers are exploring bio-based additives and sustainable production methods to align with growing environmental concerns. Additionally, there is a push towards developing PMMA composites that can offer multifunctional properties, such as self-healing capabilities or enhanced thermal management.

Looking ahead, the evolution of PMMA is expected to continue with a focus on smart materials. The integration of responsive elements that can adapt to environmental stimuli is a promising frontier. Furthermore, the development of PMMA-based materials with tunable impact resistance properties could revolutionize applications in automotive, construction, and personal protective equipment industries.

In conclusion, the evolution of PMMA and the goals for its enhancement reflect a broader trend in materials science towards creating versatile, high-performance polymers. The ongoing quest for increased impact resistance in PMMA exemplifies the dynamic nature of materials development, driven by technological advancements and changing market demands.

Market Demand Analysis

The market demand for enhanced PMMA with increased impact resistance has been steadily growing across various industries. This demand is primarily driven by the need for more durable and versatile materials in applications where traditional PMMA's brittleness limits its use. The automotive sector, in particular, has shown significant interest in impact-resistant PMMA as a lightweight alternative to glass for windows, headlights, and interior components. This shift is largely motivated by the industry's push towards fuel efficiency and electric vehicles, where weight reduction is crucial.

In the construction industry, there's an increasing demand for impact-resistant PMMA in skylights, windows, and architectural panels. This trend is fueled by stricter building safety regulations and the desire for more resilient structures in areas prone to extreme weather conditions. The material's transparency, combined with enhanced impact resistance, makes it an attractive option for designers and architects seeking both aesthetics and functionality.

The electronics and consumer goods sectors have also contributed to the rising demand for impact-resistant PMMA. With the proliferation of portable devices and wearable technology, manufacturers are seeking materials that can withstand daily wear and tear while maintaining optical clarity. This has led to an increased adoption of enhanced PMMA in smartphone screens, smartwatch faces, and other personal electronic devices.

Market analysis indicates that the global demand for impact-resistant PMMA is expected to grow at a compound annual growth rate (CAGR) of over 5% in the next five years. This growth is not only driven by established markets in North America and Europe but also by emerging economies in Asia-Pacific, where rapid industrialization and urbanization are creating new opportunities for advanced materials.

The medical device industry represents another significant market for impact-resistant PMMA. The material's biocompatibility, combined with improved durability, makes it ideal for a range of medical applications, including diagnostic equipment, surgical instruments, and implants. As healthcare systems worldwide continue to advance, the demand for high-performance materials in medical settings is expected to rise.

Environmental concerns and sustainability initiatives are also influencing market demand. Manufacturers are increasingly looking for materials that not only offer enhanced performance but also align with circular economy principles. This has led to research into recyclable and bio-based impact-resistant PMMA formulations, potentially opening new market segments and applications in the near future.

In the construction industry, there's an increasing demand for impact-resistant PMMA in skylights, windows, and architectural panels. This trend is fueled by stricter building safety regulations and the desire for more resilient structures in areas prone to extreme weather conditions. The material's transparency, combined with enhanced impact resistance, makes it an attractive option for designers and architects seeking both aesthetics and functionality.

The electronics and consumer goods sectors have also contributed to the rising demand for impact-resistant PMMA. With the proliferation of portable devices and wearable technology, manufacturers are seeking materials that can withstand daily wear and tear while maintaining optical clarity. This has led to an increased adoption of enhanced PMMA in smartphone screens, smartwatch faces, and other personal electronic devices.

Market analysis indicates that the global demand for impact-resistant PMMA is expected to grow at a compound annual growth rate (CAGR) of over 5% in the next five years. This growth is not only driven by established markets in North America and Europe but also by emerging economies in Asia-Pacific, where rapid industrialization and urbanization are creating new opportunities for advanced materials.

The medical device industry represents another significant market for impact-resistant PMMA. The material's biocompatibility, combined with improved durability, makes it ideal for a range of medical applications, including diagnostic equipment, surgical instruments, and implants. As healthcare systems worldwide continue to advance, the demand for high-performance materials in medical settings is expected to rise.

Environmental concerns and sustainability initiatives are also influencing market demand. Manufacturers are increasingly looking for materials that not only offer enhanced performance but also align with circular economy principles. This has led to research into recyclable and bio-based impact-resistant PMMA formulations, potentially opening new market segments and applications in the near future.

Current Challenges

PMMA, or polymethyl methacrylate, is widely used in various industries due to its optical clarity, UV resistance, and weatherability. However, its inherent brittleness and low impact resistance have long been significant challenges limiting its application in areas requiring higher mechanical strength and durability.

One of the primary technical hurdles in enhancing PMMA's impact resistance is maintaining its desirable properties while improving its toughness. Attempts to increase impact resistance often result in a trade-off with other crucial characteristics such as transparency, thermal stability, or processability. This balance between improved impact resistance and preservation of other properties remains a key challenge for researchers and manufacturers.

Another significant obstacle is the molecular structure of PMMA itself. The polymer's rigid backbone and lack of flexibility contribute to its brittleness. Modifying this structure to enhance impact resistance without compromising the material's fundamental properties requires sophisticated chemical engineering and polymer science approaches.

The development of cost-effective methods for improving PMMA's impact resistance also presents a challenge. While various techniques have shown promise in laboratory settings, scaling these solutions for industrial production while maintaining economic viability has proven difficult. This economic barrier often hinders the widespread adoption of enhanced PMMA materials in commercial applications.

Environmental concerns and regulatory pressures add another layer of complexity to the challenge. As sustainability becomes increasingly important, any modifications or additives used to enhance PMMA's impact resistance must also meet stringent environmental and safety standards. This requirement further narrows the field of potential solutions and adds to the complexity of the development process.

The variability in performance requirements across different applications also poses a challenge. PMMA is used in diverse fields, from automotive parts to medical devices, each with its specific set of requirements for impact resistance. Developing a universal solution that can be easily adapted to meet these varied needs while maintaining PMMA's core properties is a significant technical hurdle.

Lastly, the integration of enhanced PMMA into existing manufacturing processes presents its own set of challenges. New formulations or modifications may require adjustments to molding, extrusion, or other processing techniques. This need for process adaptation can be a barrier to adoption, particularly for manufacturers with established production lines.

One of the primary technical hurdles in enhancing PMMA's impact resistance is maintaining its desirable properties while improving its toughness. Attempts to increase impact resistance often result in a trade-off with other crucial characteristics such as transparency, thermal stability, or processability. This balance between improved impact resistance and preservation of other properties remains a key challenge for researchers and manufacturers.

Another significant obstacle is the molecular structure of PMMA itself. The polymer's rigid backbone and lack of flexibility contribute to its brittleness. Modifying this structure to enhance impact resistance without compromising the material's fundamental properties requires sophisticated chemical engineering and polymer science approaches.

The development of cost-effective methods for improving PMMA's impact resistance also presents a challenge. While various techniques have shown promise in laboratory settings, scaling these solutions for industrial production while maintaining economic viability has proven difficult. This economic barrier often hinders the widespread adoption of enhanced PMMA materials in commercial applications.

Environmental concerns and regulatory pressures add another layer of complexity to the challenge. As sustainability becomes increasingly important, any modifications or additives used to enhance PMMA's impact resistance must also meet stringent environmental and safety standards. This requirement further narrows the field of potential solutions and adds to the complexity of the development process.

The variability in performance requirements across different applications also poses a challenge. PMMA is used in diverse fields, from automotive parts to medical devices, each with its specific set of requirements for impact resistance. Developing a universal solution that can be easily adapted to meet these varied needs while maintaining PMMA's core properties is a significant technical hurdle.

Lastly, the integration of enhanced PMMA into existing manufacturing processes presents its own set of challenges. New formulations or modifications may require adjustments to molding, extrusion, or other processing techniques. This need for process adaptation can be a barrier to adoption, particularly for manufacturers with established production lines.

Existing Enhancement Methods

01 Incorporation of impact modifiers

Adding impact modifiers to PMMA can significantly improve its impact resistance. These modifiers are typically elastomeric materials that can absorb and dissipate energy from impacts. Common impact modifiers include core-shell particles, acrylic-based copolymers, and rubber-like substances. The incorporation of these modifiers can enhance the toughness of PMMA without significantly compromising its optical properties.- Incorporation of impact modifiers: Adding impact modifiers to PMMA can significantly improve its impact resistance. These modifiers are typically elastomeric particles or core-shell structures that absorb and dissipate energy upon impact. Common impact modifiers include acrylic-based copolymers, silicone-based additives, and rubber particles.

- Blending with other polymers: Blending PMMA with other polymers can enhance its impact resistance. Compatible polymers such as ABS, PVC, or polyurethane can be mixed with PMMA to create a composite material with improved toughness and impact strength. The ratio and processing conditions of the blend are crucial for optimizing properties.

- Surface modification techniques: Various surface modification techniques can be applied to PMMA to improve its impact resistance. These include plasma treatment, chemical etching, or applying protective coatings. Such modifications can alter the surface properties of PMMA, enhancing its ability to withstand impacts and prevent crack propagation.

- Nanocomposite reinforcement: Incorporating nanoparticles or nanofibers into PMMA can significantly enhance its impact resistance. Materials such as carbon nanotubes, graphene, or silica nanoparticles can be dispersed within the PMMA matrix, creating a nanocomposite with improved mechanical properties, including impact strength.

- Optimization of molecular weight and crosslinking: Controlling the molecular weight distribution and degree of crosslinking in PMMA can improve its impact resistance. Higher molecular weight PMMA typically exhibits better impact strength. Additionally, introducing controlled crosslinking can enhance the material's ability to absorb and dissipate impact energy without compromising other desirable properties.

02 Blending with other polymers

Blending PMMA with other polymers can improve its impact resistance. Compatible polymers such as ABS (Acrylonitrile Butadiene Styrene), polycarbonate, or certain polyolefins can be mixed with PMMA to create a composite material with enhanced impact strength. The ratio and type of polymers used in the blend can be optimized to achieve the desired balance of properties.Expand Specific Solutions03 Surface modification techniques

Various surface modification techniques can be applied to PMMA to improve its impact resistance. These may include plasma treatment, chemical etching, or the application of protective coatings. Such modifications can alter the surface properties of PMMA, creating a more impact-resistant outer layer while maintaining the bulk properties of the material.Expand Specific Solutions04 Nanocomposite reinforcement

Incorporating nanoparticles or nanofibers into PMMA can significantly enhance its impact resistance. Materials such as carbon nanotubes, graphene, or nanosilica can be dispersed within the PMMA matrix to create nanocomposites. These nanofillers can improve the mechanical properties, including impact strength, by acting as reinforcing agents and energy dissipators.Expand Specific Solutions05 Molecular weight and crosslinking optimization

Optimizing the molecular weight distribution and introducing controlled crosslinking in PMMA can improve its impact resistance. Higher molecular weight PMMA generally exhibits better impact strength. Additionally, introducing a degree of crosslinking between polymer chains can enhance the material's ability to absorb impact energy without fracturing.Expand Specific Solutions

Key Industry Players

The PMMA impact resistance enhancement market is in a growth phase, driven by increasing demand for high-performance materials in various industries. The global market size for modified PMMA is expanding, with a projected CAGR of 6-8% over the next five years. Technologically, the field is moderately mature, with ongoing innovations focused on improving impact resistance without compromising other properties. Key players like LG Chem, Röhm GmbH, and Wanhua Chemical Group are investing heavily in R&D to develop advanced PMMA formulations. Emerging companies such as Shanghai KUMHO-SUNNY Plastics and Kingfa Sci. & Tech. are also making significant strides, particularly in Asia. The competitive landscape is characterized by a mix of established chemical giants and specialized materials firms, with increasing collaborations between industry and academic institutions like Zhejiang University to drive innovation.

Röhm GmbH

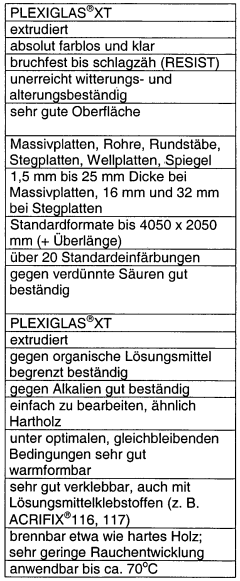

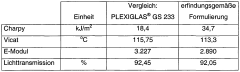

Technical Solution: Röhm GmbH has developed PLEXIGLAS® Hi-Gloss NTA-5, a high-impact modified acrylic resin that significantly enhances the impact resistance of PMMA. This innovative material incorporates specially designed core-shell particles that absorb and dissipate impact energy[1]. The company has also introduced PLEXIGLAS® Resist AG 100, which offers up to 10 times the impact strength of standard PMMA[2]. Röhm's approach involves optimizing the molecular structure of PMMA and incorporating impact modifiers to create a balance between transparency, weather resistance, and impact strength[3].

Strengths: Expertise in PMMA modifications, wide range of high-impact PMMA grades, maintains optical clarity. Weaknesses: Potential trade-off between impact resistance and other properties, higher cost compared to standard PMMA.

LG Chem Ltd.

Technical Solution: LG Chem has developed a high-impact PMMA grade called LUPOY® HR, which utilizes a proprietary blend of acrylic copolymers and elastomeric impact modifiers. This material offers up to 8 times the impact strength of conventional PMMA while maintaining excellent transparency[4]. The company employs a multi-layer extrusion technology to create PMMA sheets with a high-impact core and weather-resistant surface layers, providing enhanced durability for outdoor applications[5]. LG Chem's research also focuses on nano-reinforced PMMA composites, incorporating nanoparticles to improve both impact resistance and scratch resistance[6].

Strengths: Advanced multi-layer technology, balanced performance in impact resistance and transparency, diverse product range. Weaknesses: Potential limitations in extreme temperature applications, higher production costs.

Core Impact Resistance Innovations

Method for producing an impact-resistant polymethylmethacrylate, and corresponding polymethylmethacrylate (PMMA)

PatentWO2003064485A1

Innovation

- Dissolving impact modifiers in methyl methacrylate (MMA) or polymerized MMA, followed by polymerization in a chamber process, allowing for the production of impact-resistant PMMA without interpenetrating networks or complex isolation steps, using a formulation with stabilizers and additives, and utilizing core-shell impact modifiers.

A polymethylmethacrylate resin with an impact modifier capsulated therein and a process of preparing for the same

PatentInactiveEP1090070B1

Innovation

- A three-layer structured PMMA resin with a glass polymer core, a rubber copolymer intermediate layer, and a chain transfer agent-containing outer glass polymer layer, produced through a three-stage emulsion polymerization process, ensuring improved impact resistance and transparency without degrading the thickness of the shell layer.

Environmental Considerations

Environmental considerations play a crucial role in the development and application of enhanced PMMA with increased impact resistance. As the demand for more durable and sustainable materials grows, it is essential to evaluate the environmental impact of these improvements throughout the entire lifecycle of PMMA products.

The production process of enhanced PMMA often involves the incorporation of additives or modifications to the polymer structure. These changes may affect the energy consumption and emissions associated with manufacturing. It is important to assess whether the increased impact resistance leads to a net positive environmental impact by extending product lifespan and reducing waste generation.

Recycling and end-of-life management of enhanced PMMA products present both challenges and opportunities. The additives used to improve impact resistance may complicate traditional recycling processes, potentially requiring the development of new recycling technologies. However, the increased durability of these materials may lead to longer product lifespans, reducing the overall waste generated and the frequency of replacement.

The potential for biodegradability and compostability of enhanced PMMA should also be explored. While traditional PMMA is not biodegradable, research into bio-based additives or modifications that improve impact resistance while maintaining or enhancing biodegradability could offer significant environmental benefits.

Life Cycle Assessment (LCA) studies are essential to quantify the environmental impacts of enhanced PMMA compared to traditional PMMA and alternative materials. These assessments should consider factors such as raw material extraction, energy consumption during production, transportation, use phase, and end-of-life scenarios. The results can guide decision-making processes for manufacturers and consumers alike.

The potential for enhanced PMMA to contribute to energy efficiency in various applications should not be overlooked. For instance, in automotive and aerospace industries, the use of lighter, more impact-resistant PMMA could lead to improved fuel efficiency and reduced emissions during the use phase of vehicles and aircraft.

Regulatory compliance and environmental standards play a significant role in the development and adoption of enhanced PMMA. Manufacturers must ensure that their products meet or exceed environmental regulations in different markets, which may include restrictions on certain additives or requirements for recyclability and waste management.

As the focus on circular economy principles intensifies, the design of enhanced PMMA products should incorporate considerations for disassembly, repair, and reuse. This approach can significantly extend the useful life of products and reduce the overall environmental footprint of PMMA applications.

The production process of enhanced PMMA often involves the incorporation of additives or modifications to the polymer structure. These changes may affect the energy consumption and emissions associated with manufacturing. It is important to assess whether the increased impact resistance leads to a net positive environmental impact by extending product lifespan and reducing waste generation.

Recycling and end-of-life management of enhanced PMMA products present both challenges and opportunities. The additives used to improve impact resistance may complicate traditional recycling processes, potentially requiring the development of new recycling technologies. However, the increased durability of these materials may lead to longer product lifespans, reducing the overall waste generated and the frequency of replacement.

The potential for biodegradability and compostability of enhanced PMMA should also be explored. While traditional PMMA is not biodegradable, research into bio-based additives or modifications that improve impact resistance while maintaining or enhancing biodegradability could offer significant environmental benefits.

Life Cycle Assessment (LCA) studies are essential to quantify the environmental impacts of enhanced PMMA compared to traditional PMMA and alternative materials. These assessments should consider factors such as raw material extraction, energy consumption during production, transportation, use phase, and end-of-life scenarios. The results can guide decision-making processes for manufacturers and consumers alike.

The potential for enhanced PMMA to contribute to energy efficiency in various applications should not be overlooked. For instance, in automotive and aerospace industries, the use of lighter, more impact-resistant PMMA could lead to improved fuel efficiency and reduced emissions during the use phase of vehicles and aircraft.

Regulatory compliance and environmental standards play a significant role in the development and adoption of enhanced PMMA. Manufacturers must ensure that their products meet or exceed environmental regulations in different markets, which may include restrictions on certain additives or requirements for recyclability and waste management.

As the focus on circular economy principles intensifies, the design of enhanced PMMA products should incorporate considerations for disassembly, repair, and reuse. This approach can significantly extend the useful life of products and reduce the overall environmental footprint of PMMA applications.

Regulatory Framework

The regulatory framework surrounding PMMA (Polymethyl Methacrylate) and its impact-resistant enhancements is complex and multifaceted, involving various international and regional standards. These regulations primarily focus on ensuring product safety, environmental protection, and quality control throughout the manufacturing and application processes.

In the United States, the Food and Drug Administration (FDA) regulates PMMA used in medical devices and food contact applications. The FDA's 21 CFR 177.1010 specifically addresses the use of acrylic and modified acrylic plastics in food-contact applications, setting forth requirements for composition, manufacturing processes, and testing. For impact-resistant PMMA applications in automotive and construction industries, standards set by the American Society for Testing and Materials (ASTM) are crucial, particularly ASTM D256 for impact resistance testing.

The European Union has established comprehensive regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. REACH requires manufacturers and importers to register substances, including PMMA and its additives, with the European Chemicals Agency (ECHA). The EU's Restriction of Hazardous Substances (RoHS) Directive also impacts PMMA production, especially when electronic components are involved.

In Asia, Japan's Ministry of Health, Labour and Welfare regulates PMMA in food contact materials under the Food Sanitation Act. China's GB standards, particularly GB 4806.1-2016 for food contact materials, set requirements for PMMA used in food packaging and utensils. These standards often align with international norms but may have specific local requirements.

Globally, the International Organization for Standardization (ISO) provides several relevant standards, including ISO 179 for determining Charpy impact properties of plastics and ISO 180 for Izod impact strength testing. These standards are widely recognized and often incorporated into national regulations.

Environmental regulations also play a significant role in PMMA production and disposal. Many countries have implemented Extended Producer Responsibility (EPR) programs, requiring manufacturers to consider the entire lifecycle of their products, including end-of-life management and recycling. The EU's Waste Electrical and Electronic Equipment (WEEE) Directive is a prime example, affecting PMMA used in electronic devices.

As research into enhancing PMMA's impact resistance progresses, regulatory bodies are likely to update their frameworks to address new additives, manufacturing processes, and potential environmental impacts. Manufacturers and researchers must stay abreast of these evolving regulations to ensure compliance and market access for their enhanced PMMA products.

In the United States, the Food and Drug Administration (FDA) regulates PMMA used in medical devices and food contact applications. The FDA's 21 CFR 177.1010 specifically addresses the use of acrylic and modified acrylic plastics in food-contact applications, setting forth requirements for composition, manufacturing processes, and testing. For impact-resistant PMMA applications in automotive and construction industries, standards set by the American Society for Testing and Materials (ASTM) are crucial, particularly ASTM D256 for impact resistance testing.

The European Union has established comprehensive regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. REACH requires manufacturers and importers to register substances, including PMMA and its additives, with the European Chemicals Agency (ECHA). The EU's Restriction of Hazardous Substances (RoHS) Directive also impacts PMMA production, especially when electronic components are involved.

In Asia, Japan's Ministry of Health, Labour and Welfare regulates PMMA in food contact materials under the Food Sanitation Act. China's GB standards, particularly GB 4806.1-2016 for food contact materials, set requirements for PMMA used in food packaging and utensils. These standards often align with international norms but may have specific local requirements.

Globally, the International Organization for Standardization (ISO) provides several relevant standards, including ISO 179 for determining Charpy impact properties of plastics and ISO 180 for Izod impact strength testing. These standards are widely recognized and often incorporated into national regulations.

Environmental regulations also play a significant role in PMMA production and disposal. Many countries have implemented Extended Producer Responsibility (EPR) programs, requiring manufacturers to consider the entire lifecycle of their products, including end-of-life management and recycling. The EU's Waste Electrical and Electronic Equipment (WEEE) Directive is a prime example, affecting PMMA used in electronic devices.

As research into enhancing PMMA's impact resistance progresses, regulatory bodies are likely to update their frameworks to address new additives, manufacturing processes, and potential environmental impacts. Manufacturers and researchers must stay abreast of these evolving regulations to ensure compliance and market access for their enhanced PMMA products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!