PMMA's Function as an Insulator in Electronics

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMMA Insulation Background

Polymethyl methacrylate (PMMA), commonly known as acrylic or plexiglass, has emerged as a versatile material in the electronics industry, particularly for its insulating properties. The use of PMMA as an insulator in electronics dates back to the mid-20th century when the demand for lightweight, durable, and efficient insulating materials began to rise with the rapid advancement of electronic technologies.

PMMA's journey as an insulator began in the 1930s when it was first synthesized by German chemists. However, its potential in electronics wasn't fully realized until the 1960s and 1970s, coinciding with the miniaturization of electronic components and the increasing need for reliable insulation in compact devices. The material's excellent dielectric properties, coupled with its optical clarity and ease of processing, made it an attractive option for various electronic applications.

In the realm of electronics, insulation plays a crucial role in preventing current leakage, protecting components from environmental factors, and ensuring the overall efficiency and safety of devices. PMMA's unique molecular structure, consisting of long polymer chains, contributes to its exceptional insulating capabilities. The material exhibits a high electrical resistivity and low dielectric loss, making it ideal for applications where minimal energy dissipation is essential.

The evolution of PMMA's use in electronics has been driven by several factors, including advancements in polymer science, increasing demands for miniaturization, and the need for materials that can withstand harsh environmental conditions. Over the years, researchers and engineers have developed various formulations and processing techniques to enhance PMMA's insulating properties, tailoring them to specific electronic applications.

One of the key advantages of PMMA as an insulator is its versatility. It can be molded, extruded, or cast into various shapes and forms, allowing for seamless integration into complex electronic designs. This flexibility has led to its widespread adoption in diverse sectors, ranging from consumer electronics to aerospace and medical devices.

As the electronics industry continues to evolve, with trends like the Internet of Things (IoT) and wearable technologies gaining prominence, the role of PMMA as an insulator is expected to expand further. The material's ability to combine insulating properties with other desirable characteristics, such as transparency and biocompatibility, positions it as a valuable component in next-generation electronic devices.

PMMA's journey as an insulator began in the 1930s when it was first synthesized by German chemists. However, its potential in electronics wasn't fully realized until the 1960s and 1970s, coinciding with the miniaturization of electronic components and the increasing need for reliable insulation in compact devices. The material's excellent dielectric properties, coupled with its optical clarity and ease of processing, made it an attractive option for various electronic applications.

In the realm of electronics, insulation plays a crucial role in preventing current leakage, protecting components from environmental factors, and ensuring the overall efficiency and safety of devices. PMMA's unique molecular structure, consisting of long polymer chains, contributes to its exceptional insulating capabilities. The material exhibits a high electrical resistivity and low dielectric loss, making it ideal for applications where minimal energy dissipation is essential.

The evolution of PMMA's use in electronics has been driven by several factors, including advancements in polymer science, increasing demands for miniaturization, and the need for materials that can withstand harsh environmental conditions. Over the years, researchers and engineers have developed various formulations and processing techniques to enhance PMMA's insulating properties, tailoring them to specific electronic applications.

One of the key advantages of PMMA as an insulator is its versatility. It can be molded, extruded, or cast into various shapes and forms, allowing for seamless integration into complex electronic designs. This flexibility has led to its widespread adoption in diverse sectors, ranging from consumer electronics to aerospace and medical devices.

As the electronics industry continues to evolve, with trends like the Internet of Things (IoT) and wearable technologies gaining prominence, the role of PMMA as an insulator is expected to expand further. The material's ability to combine insulating properties with other desirable characteristics, such as transparency and biocompatibility, positions it as a valuable component in next-generation electronic devices.

Market Demand Analysis

The market demand for PMMA as an insulator in electronics has been steadily growing due to its unique properties and versatile applications. PMMA, also known as acrylic or plexiglass, offers excellent electrical insulation properties, making it a valuable material in various electronic components and devices.

In the consumer electronics sector, PMMA is widely used in display screens, touchscreens, and protective covers for smartphones, tablets, and laptops. The increasing demand for these devices, coupled with the trend towards larger and more durable screens, has driven the growth of PMMA usage in this segment. The automotive industry has also become a significant consumer of PMMA insulators, particularly in the production of electric and hybrid vehicles, where high-performance insulation materials are crucial for battery systems and power electronics.

The telecommunications industry represents another major market for PMMA insulators. With the ongoing expansion of 5G networks and fiber-optic infrastructure, there is a growing need for reliable insulation materials in transmission equipment and cable systems. PMMA's transparency and weather resistance make it an ideal choice for outdoor applications in this sector.

In the industrial electronics market, PMMA insulators are increasingly used in control panels, switchgear, and other high-voltage applications. The material's ability to withstand harsh environmental conditions and maintain its insulating properties over time has led to its adoption in various industrial settings, including manufacturing plants and power distribution systems.

The medical electronics sector has also shown significant demand for PMMA insulators. The material's biocompatibility and sterilization resistance make it suitable for use in medical devices, diagnostic equipment, and implantable electronics. As the healthcare industry continues to advance towards more sophisticated electronic medical devices, the demand for high-quality insulation materials like PMMA is expected to rise.

The global market for PMMA in electronic applications is projected to experience substantial growth in the coming years. Factors driving this growth include the increasing miniaturization of electronic devices, the need for more efficient and reliable insulation materials, and the expanding applications of electronics in various industries. Additionally, the push towards more sustainable and recyclable materials in electronics manufacturing is likely to benefit PMMA, as it can be easily recycled and repurposed.

However, the market also faces challenges, such as competition from alternative insulation materials and fluctuations in raw material prices. Despite these challenges, the overall trend indicates a positive outlook for PMMA as an insulator in the electronics industry, with opportunities for innovation and market expansion in emerging technologies such as flexible electronics and wearable devices.

In the consumer electronics sector, PMMA is widely used in display screens, touchscreens, and protective covers for smartphones, tablets, and laptops. The increasing demand for these devices, coupled with the trend towards larger and more durable screens, has driven the growth of PMMA usage in this segment. The automotive industry has also become a significant consumer of PMMA insulators, particularly in the production of electric and hybrid vehicles, where high-performance insulation materials are crucial for battery systems and power electronics.

The telecommunications industry represents another major market for PMMA insulators. With the ongoing expansion of 5G networks and fiber-optic infrastructure, there is a growing need for reliable insulation materials in transmission equipment and cable systems. PMMA's transparency and weather resistance make it an ideal choice for outdoor applications in this sector.

In the industrial electronics market, PMMA insulators are increasingly used in control panels, switchgear, and other high-voltage applications. The material's ability to withstand harsh environmental conditions and maintain its insulating properties over time has led to its adoption in various industrial settings, including manufacturing plants and power distribution systems.

The medical electronics sector has also shown significant demand for PMMA insulators. The material's biocompatibility and sterilization resistance make it suitable for use in medical devices, diagnostic equipment, and implantable electronics. As the healthcare industry continues to advance towards more sophisticated electronic medical devices, the demand for high-quality insulation materials like PMMA is expected to rise.

The global market for PMMA in electronic applications is projected to experience substantial growth in the coming years. Factors driving this growth include the increasing miniaturization of electronic devices, the need for more efficient and reliable insulation materials, and the expanding applications of electronics in various industries. Additionally, the push towards more sustainable and recyclable materials in electronics manufacturing is likely to benefit PMMA, as it can be easily recycled and repurposed.

However, the market also faces challenges, such as competition from alternative insulation materials and fluctuations in raw material prices. Despite these challenges, the overall trend indicates a positive outlook for PMMA as an insulator in the electronics industry, with opportunities for innovation and market expansion in emerging technologies such as flexible electronics and wearable devices.

Technical Challenges

PMMA (Polymethyl methacrylate) has gained significant attention in the electronics industry as an insulator due to its unique properties. However, its application as an insulator in electronics faces several technical challenges that need to be addressed for optimal performance and reliability.

One of the primary challenges is PMMA's thermal stability at high temperatures. While PMMA exhibits excellent insulating properties at room temperature, its performance can degrade when exposed to elevated temperatures commonly encountered in electronic devices. This thermal instability can lead to changes in the material's physical and electrical properties, potentially compromising its insulating effectiveness and overall device reliability.

Another significant challenge is PMMA's moisture absorption tendency. As a hygroscopic material, PMMA can absorb moisture from the environment, which can affect its dielectric properties and potentially lead to electrical leakage or short circuits in electronic components. This moisture sensitivity necessitates careful consideration in design and manufacturing processes to ensure long-term reliability in various operating conditions.

The mechanical properties of PMMA also present challenges in certain electronic applications. While PMMA offers good rigidity and impact resistance, it may not provide sufficient flexibility for some flexible electronic devices or applications requiring bendable insulation. This limitation can restrict its use in emerging fields such as wearable electronics or flexible displays.

PMMA's chemical resistance is another area of concern. Although it demonstrates good resistance to many common chemicals, it can be susceptible to degradation when exposed to certain organic solvents or aggressive chemicals used in electronic manufacturing processes. This vulnerability may limit its applicability in harsh chemical environments or require additional protective measures.

The processing and integration of PMMA into complex electronic structures pose technical challenges as well. Achieving uniform and defect-free PMMA layers, especially in miniaturized electronic components, requires precise control over deposition techniques and curing processes. Additionally, ensuring strong adhesion between PMMA and other materials used in electronic assemblies can be challenging and may require surface treatments or specialized bonding techniques.

Electrostatic discharge (ESD) protection is another critical consideration when using PMMA as an insulator in electronics. While PMMA provides good electrical insulation, it may not offer sufficient protection against ESD events, which can damage sensitive electronic components. Developing effective ESD mitigation strategies while maintaining PMMA's insulating properties presents a significant technical challenge.

Lastly, the long-term stability and aging characteristics of PMMA in electronic applications require careful evaluation. Factors such as UV exposure, thermal cycling, and mechanical stress can potentially degrade PMMA's properties over time, affecting its insulating performance and overall reliability. Understanding and mitigating these aging effects are crucial for ensuring the longevity of electronic devices utilizing PMMA as an insulator.

One of the primary challenges is PMMA's thermal stability at high temperatures. While PMMA exhibits excellent insulating properties at room temperature, its performance can degrade when exposed to elevated temperatures commonly encountered in electronic devices. This thermal instability can lead to changes in the material's physical and electrical properties, potentially compromising its insulating effectiveness and overall device reliability.

Another significant challenge is PMMA's moisture absorption tendency. As a hygroscopic material, PMMA can absorb moisture from the environment, which can affect its dielectric properties and potentially lead to electrical leakage or short circuits in electronic components. This moisture sensitivity necessitates careful consideration in design and manufacturing processes to ensure long-term reliability in various operating conditions.

The mechanical properties of PMMA also present challenges in certain electronic applications. While PMMA offers good rigidity and impact resistance, it may not provide sufficient flexibility for some flexible electronic devices or applications requiring bendable insulation. This limitation can restrict its use in emerging fields such as wearable electronics or flexible displays.

PMMA's chemical resistance is another area of concern. Although it demonstrates good resistance to many common chemicals, it can be susceptible to degradation when exposed to certain organic solvents or aggressive chemicals used in electronic manufacturing processes. This vulnerability may limit its applicability in harsh chemical environments or require additional protective measures.

The processing and integration of PMMA into complex electronic structures pose technical challenges as well. Achieving uniform and defect-free PMMA layers, especially in miniaturized electronic components, requires precise control over deposition techniques and curing processes. Additionally, ensuring strong adhesion between PMMA and other materials used in electronic assemblies can be challenging and may require surface treatments or specialized bonding techniques.

Electrostatic discharge (ESD) protection is another critical consideration when using PMMA as an insulator in electronics. While PMMA provides good electrical insulation, it may not offer sufficient protection against ESD events, which can damage sensitive electronic components. Developing effective ESD mitigation strategies while maintaining PMMA's insulating properties presents a significant technical challenge.

Lastly, the long-term stability and aging characteristics of PMMA in electronic applications require careful evaluation. Factors such as UV exposure, thermal cycling, and mechanical stress can potentially degrade PMMA's properties over time, affecting its insulating performance and overall reliability. Understanding and mitigating these aging effects are crucial for ensuring the longevity of electronic devices utilizing PMMA as an insulator.

Current PMMA Solutions

01 PMMA-based insulation composites

PMMA is used as a base material for creating insulation composites. These composites often incorporate other materials to enhance thermal insulation properties, improve mechanical strength, or add flame retardancy. The combination of PMMA with various additives results in versatile insulation materials suitable for different applications.- PMMA-based insulation composites: PMMA is used as a base material in insulation composites, often combined with other materials to enhance thermal insulation properties. These composites can be used in various applications, including building insulation and electronic devices.

- PMMA foam insulation: PMMA can be processed into foam structures, which significantly improve its insulation capabilities. The foam structure creates air pockets that reduce heat transfer, making it an effective insulating material for construction and industrial applications.

- PMMA insulation in electronic devices: PMMA is utilized as an insulating material in various electronic components and devices. Its electrical insulation properties, combined with its thermal characteristics, make it suitable for protecting sensitive electronic parts and improving overall device performance.

- PMMA-based thermal insulation coatings: PMMA is incorporated into thermal insulation coatings, which can be applied to various surfaces to improve their insulation properties. These coatings are used in buildings, industrial equipment, and other applications where thermal management is crucial.

- PMMA insulation in optical applications: PMMA's optical properties, combined with its insulation capabilities, make it suitable for use in optical applications. It can be used to create insulating layers in optical devices, helping to maintain temperature stability and protect sensitive components.

02 PMMA foam insulation

PMMA can be processed into foam structures for insulation purposes. The foam form of PMMA offers improved thermal insulation properties due to its low density and trapped air pockets. Various techniques are employed to create PMMA foams with controlled cell structures and densities, optimizing their insulation performance.Expand Specific Solutions03 PMMA insulation in electronic devices

PMMA insulation is utilized in electronic devices and components. Its electrical insulation properties, combined with thermal management capabilities, make it suitable for applications in circuit boards, connectors, and other electronic parts. PMMA-based insulation materials can be tailored to meet specific requirements of electronic devices.Expand Specific Solutions04 PMMA insulation coatings

PMMA is used to develop insulation coatings for various surfaces. These coatings can provide thermal insulation, moisture resistance, and protection against environmental factors. The application of PMMA-based insulation coatings can enhance the energy efficiency of buildings, vehicles, and industrial equipment.Expand Specific Solutions05 PMMA insulation in construction materials

PMMA is incorporated into construction materials to improve their insulation properties. It can be used in the production of insulating panels, windows, and other building components. The integration of PMMA in construction materials contributes to better energy efficiency and thermal comfort in buildings.Expand Specific Solutions

Key Industry Players

The PMMA insulator market in electronics is in a mature growth stage, with a steady global market size driven by increasing demand for electronic devices and advancements in technology. The market is characterized by established players like LG Chem, DuPont, and Wanhua Chemical Group, who have developed sophisticated PMMA formulations for various electronic applications. The technology's maturity is evident in its widespread adoption, but ongoing research by companies and institutions like Zhejiang University of Technology and the Japan Science & Technology Agency continues to improve PMMA's insulating properties and explore new applications. Competition is intense, with companies focusing on product differentiation and cost-effective manufacturing processes to maintain their market positions.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has made significant strides in PMMA insulation technology for electronics. They have developed a high-performance PMMA grade with enhanced dielectric properties through molecular weight optimization and the incorporation of specialized additives[2]. Wanhua's PMMA insulators exhibit excellent resistance to electrical tracking and erosion, crucial for long-term reliability in electronic applications[4]. The company has also focused on improving the processability of their PMMA formulations, allowing for easier integration into complex electronic manufacturing processes[6]. Wanhua's PMMA materials demonstrate superior dimensional stability under varying temperature and humidity conditions, ensuring consistent insulation performance in diverse operating environments[8].

Strengths: High dielectric strength, excellent processability, and dimensional stability. Weaknesses: May have limited customization options compared to some competitors.

LG Chem Ltd.

Technical Solution: LG Chem has innovated in PMMA insulation technology for electronics by developing a proprietary blend of PMMA with other polymers to enhance its insulating capabilities. Their approach involves creating a multi-layered PMMA structure that provides improved electrical resistance and breakdown strength[2]. LG Chem's PMMA insulators incorporate flame-retardant additives without compromising the material's transparency or insulation properties[4]. The company has also focused on reducing the thickness of PMMA insulation layers while maintaining performance, enabling more compact electronic designs[6]. Their PMMA formulations show exceptional resistance to UV radiation, making them suitable for outdoor electronic applications[8].

Strengths: Enhanced insulation performance, flame-retardant properties, and UV resistance. Weaknesses: Complexity in manufacturing multi-layered structures may increase production costs.

PMMA Insulation Innovations

High-thermal-conductivity boron nitride/PMMA (polymethyl methacrylate) composite material and preparation method thereof

PatentPendingCN117736530A

Innovation

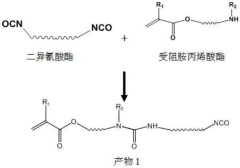

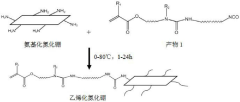

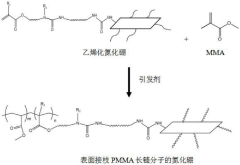

- By surface functionalizing boron nitride particles in MMA monomer and directly grafting them with PMMA monomer through in-situ polymerization, the uniform distribution of boron nitride in the PMMA system is achieved.

Environmental Impact

The environmental impact of PMMA (Polymethyl methacrylate) as an insulator in electronics is a crucial consideration in the context of sustainable technology development. PMMA, commonly known as acrylic or plexiglass, offers several environmental advantages over traditional insulating materials. Firstly, PMMA is recyclable, which significantly reduces its long-term environmental footprint. When electronic devices reach the end of their lifecycle, the PMMA components can be recovered and repurposed, minimizing waste and conserving resources.

Moreover, PMMA production processes are relatively energy-efficient compared to some alternative insulating materials. This lower energy requirement translates to reduced carbon emissions during manufacturing, aligning with global efforts to combat climate change. Additionally, PMMA does not contain harmful substances like chlorine or bromine, which are often found in other plastic insulators. This characteristic makes PMMA a safer option for both human health and the environment, particularly during disposal or recycling processes.

However, it is important to note that PMMA is derived from petrochemicals, which are non-renewable resources. This aspect raises concerns about long-term sustainability and the material's contribution to fossil fuel depletion. To address this issue, research is ongoing to develop bio-based alternatives that maintain PMMA's insulating properties while reducing reliance on petroleum-based raw materials.

In terms of durability, PMMA exhibits excellent resistance to weathering and UV radiation. This longevity reduces the frequency of replacement, thereby decreasing the overall environmental impact associated with manufacturing and disposal cycles. Furthermore, PMMA's transparency allows for the creation of more energy-efficient electronic devices by enabling better light transmission in displays, potentially reducing power consumption.

When considering the end-of-life phase, PMMA presents both advantages and challenges. While it is recyclable, the process requires specialized facilities, which may not be readily available in all regions. This limitation can lead to improper disposal if adequate recycling infrastructure is not in place. However, when properly recycled, PMMA can be transformed into new products, supporting a circular economy model and reducing the demand for virgin materials.

In conclusion, while PMMA as an insulator in electronics offers several environmental benefits, including recyclability, energy-efficient production, and durability, there are still areas for improvement. Ongoing research into bio-based alternatives and the development of more widespread recycling infrastructure will be key to enhancing PMMA's overall environmental profile in the electronics industry.

Moreover, PMMA production processes are relatively energy-efficient compared to some alternative insulating materials. This lower energy requirement translates to reduced carbon emissions during manufacturing, aligning with global efforts to combat climate change. Additionally, PMMA does not contain harmful substances like chlorine or bromine, which are often found in other plastic insulators. This characteristic makes PMMA a safer option for both human health and the environment, particularly during disposal or recycling processes.

However, it is important to note that PMMA is derived from petrochemicals, which are non-renewable resources. This aspect raises concerns about long-term sustainability and the material's contribution to fossil fuel depletion. To address this issue, research is ongoing to develop bio-based alternatives that maintain PMMA's insulating properties while reducing reliance on petroleum-based raw materials.

In terms of durability, PMMA exhibits excellent resistance to weathering and UV radiation. This longevity reduces the frequency of replacement, thereby decreasing the overall environmental impact associated with manufacturing and disposal cycles. Furthermore, PMMA's transparency allows for the creation of more energy-efficient electronic devices by enabling better light transmission in displays, potentially reducing power consumption.

When considering the end-of-life phase, PMMA presents both advantages and challenges. While it is recyclable, the process requires specialized facilities, which may not be readily available in all regions. This limitation can lead to improper disposal if adequate recycling infrastructure is not in place. However, when properly recycled, PMMA can be transformed into new products, supporting a circular economy model and reducing the demand for virgin materials.

In conclusion, while PMMA as an insulator in electronics offers several environmental benefits, including recyclability, energy-efficient production, and durability, there are still areas for improvement. Ongoing research into bio-based alternatives and the development of more widespread recycling infrastructure will be key to enhancing PMMA's overall environmental profile in the electronics industry.

Regulatory Compliance

Regulatory compliance plays a crucial role in the adoption and implementation of PMMA as an insulator in electronics. As the industry continues to evolve, manufacturers and designers must adhere to various standards and regulations to ensure the safety, reliability, and environmental sustainability of their products.

One of the primary regulatory bodies governing the use of materials in electronics is the Restriction of Hazardous Substances (RoHS) directive. PMMA, being a non-toxic and environmentally friendly material, generally complies with RoHS requirements. However, manufacturers must still ensure that any additives or processing agents used in PMMA production do not contain restricted substances such as lead, mercury, or cadmium.

The Waste Electrical and Electronic Equipment (WEEE) directive is another important regulation that impacts the use of PMMA in electronics. This directive aims to promote the recycling and proper disposal of electronic waste. PMMA's recyclability and durability align well with WEEE objectives, potentially reducing the environmental impact of electronic devices at the end of their lifecycle.

In terms of fire safety, PMMA must meet specific flammability standards set by organizations such as Underwriters Laboratories (UL) and the International Electrotechnical Commission (IEC). While PMMA is inherently flame-resistant, manufacturers may need to incorporate flame retardants to meet the most stringent requirements for certain applications.

Electromagnetic compatibility (EMC) regulations also apply to PMMA's use as an insulator. The material must not interfere with the device's electromagnetic emissions or susceptibility to external electromagnetic fields. Compliance with standards such as those set by the Federal Communications Commission (FCC) in the United States or the CE marking in Europe is essential for market access.

As the electronics industry increasingly focuses on sustainability, new regulations are emerging that emphasize the use of eco-friendly materials. The European Union's Ecodesign Directive, for instance, promotes the development of more energy-efficient and environmentally sustainable products. PMMA's recyclability and long lifespan position it favorably in this regulatory landscape.

Manufacturers must also consider regional variations in regulations. For example, California's Proposition 65 requires warnings for products containing certain chemicals, which may impact the formulation of PMMA used in electronics sold in that state. Similarly, countries like China and Japan have their own sets of regulations that may affect the use of PMMA in electronic devices.

One of the primary regulatory bodies governing the use of materials in electronics is the Restriction of Hazardous Substances (RoHS) directive. PMMA, being a non-toxic and environmentally friendly material, generally complies with RoHS requirements. However, manufacturers must still ensure that any additives or processing agents used in PMMA production do not contain restricted substances such as lead, mercury, or cadmium.

The Waste Electrical and Electronic Equipment (WEEE) directive is another important regulation that impacts the use of PMMA in electronics. This directive aims to promote the recycling and proper disposal of electronic waste. PMMA's recyclability and durability align well with WEEE objectives, potentially reducing the environmental impact of electronic devices at the end of their lifecycle.

In terms of fire safety, PMMA must meet specific flammability standards set by organizations such as Underwriters Laboratories (UL) and the International Electrotechnical Commission (IEC). While PMMA is inherently flame-resistant, manufacturers may need to incorporate flame retardants to meet the most stringent requirements for certain applications.

Electromagnetic compatibility (EMC) regulations also apply to PMMA's use as an insulator. The material must not interfere with the device's electromagnetic emissions or susceptibility to external electromagnetic fields. Compliance with standards such as those set by the Federal Communications Commission (FCC) in the United States or the CE marking in Europe is essential for market access.

As the electronics industry increasingly focuses on sustainability, new regulations are emerging that emphasize the use of eco-friendly materials. The European Union's Ecodesign Directive, for instance, promotes the development of more energy-efficient and environmentally sustainable products. PMMA's recyclability and long lifespan position it favorably in this regulatory landscape.

Manufacturers must also consider regional variations in regulations. For example, California's Proposition 65 requires warnings for products containing certain chemicals, which may impact the formulation of PMMA used in electronics sold in that state. Similarly, countries like China and Japan have their own sets of regulations that may affect the use of PMMA in electronic devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!