Potential Role of Phenolphthalein in Synthesis of Hybrid Nanomaterials

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Phenolphthalein-Nanomaterial Synthesis Background

Phenolphthalein, a widely recognized pH indicator, has recently emerged as a potential key component in the synthesis of hybrid nanomaterials. This development marks a significant shift in the application of this organic compound, traditionally used in analytical chemistry and medical diagnostics. The journey of phenolphthalein from a simple acid-base indicator to a crucial element in advanced materials science exemplifies the evolving nature of chemical applications in nanotechnology.

The exploration of phenolphthalein's role in nanomaterial synthesis stems from its unique molecular structure and responsive properties. Its ability to undergo structural changes in response to environmental stimuli, particularly pH variations, has piqued the interest of researchers in the field of smart and responsive nanomaterials. This characteristic opens up new avenues for creating hybrid nanomaterials with tunable properties, potentially revolutionizing areas such as drug delivery, sensing technologies, and environmental remediation.

The integration of phenolphthalein into nanomaterial synthesis represents a convergence of organic chemistry and materials science. This interdisciplinary approach has been driven by the growing demand for multifunctional nanomaterials that can respond to specific environmental cues. The incorporation of phenolphthalein into nanostructures offers the possibility of creating materials that change their properties or behavior based on pH levels, a feature highly desirable in various applications.

Recent advancements in synthetic methodologies have facilitated the incorporation of phenolphthalein into diverse nanomaterial platforms. These include but are not limited to nanoparticles, nanofibers, and nanocomposites. The synthesis techniques range from simple physical blending to more complex chemical modifications, allowing for the tailored integration of phenolphthalein into nanoscale structures.

The potential of phenolphthalein in hybrid nanomaterial synthesis extends beyond its pH-responsive properties. Researchers are exploring its interactions with various inorganic components, such as metal oxides and quantum dots, to create novel hybrid materials with enhanced optical, electrical, and chemical properties. This exploration is opening up new possibilities in fields like optoelectronics, catalysis, and biomedical imaging.

As research in this area progresses, the focus is shifting towards understanding the fundamental mechanisms of phenolphthalein's interaction with nanomaterials at the molecular level. This knowledge is crucial for optimizing synthesis protocols and tailoring the properties of the resulting hybrid materials. The ongoing investigations aim to unlock the full potential of phenolphthalein in nanomaterial synthesis, paving the way for innovative applications across multiple technological domains.

The exploration of phenolphthalein's role in nanomaterial synthesis stems from its unique molecular structure and responsive properties. Its ability to undergo structural changes in response to environmental stimuli, particularly pH variations, has piqued the interest of researchers in the field of smart and responsive nanomaterials. This characteristic opens up new avenues for creating hybrid nanomaterials with tunable properties, potentially revolutionizing areas such as drug delivery, sensing technologies, and environmental remediation.

The integration of phenolphthalein into nanomaterial synthesis represents a convergence of organic chemistry and materials science. This interdisciplinary approach has been driven by the growing demand for multifunctional nanomaterials that can respond to specific environmental cues. The incorporation of phenolphthalein into nanostructures offers the possibility of creating materials that change their properties or behavior based on pH levels, a feature highly desirable in various applications.

Recent advancements in synthetic methodologies have facilitated the incorporation of phenolphthalein into diverse nanomaterial platforms. These include but are not limited to nanoparticles, nanofibers, and nanocomposites. The synthesis techniques range from simple physical blending to more complex chemical modifications, allowing for the tailored integration of phenolphthalein into nanoscale structures.

The potential of phenolphthalein in hybrid nanomaterial synthesis extends beyond its pH-responsive properties. Researchers are exploring its interactions with various inorganic components, such as metal oxides and quantum dots, to create novel hybrid materials with enhanced optical, electrical, and chemical properties. This exploration is opening up new possibilities in fields like optoelectronics, catalysis, and biomedical imaging.

As research in this area progresses, the focus is shifting towards understanding the fundamental mechanisms of phenolphthalein's interaction with nanomaterials at the molecular level. This knowledge is crucial for optimizing synthesis protocols and tailoring the properties of the resulting hybrid materials. The ongoing investigations aim to unlock the full potential of phenolphthalein in nanomaterial synthesis, paving the way for innovative applications across multiple technological domains.

Market Demand Analysis

The market demand for hybrid nanomaterials incorporating phenolphthalein is experiencing significant growth, driven by the unique properties and potential applications of these innovative materials. The synthesis of hybrid nanomaterials using phenolphthalein as a key component has garnered attention across various industries, particularly in the fields of environmental monitoring, chemical sensing, and biomedical applications.

In the environmental sector, there is a growing need for advanced materials capable of detecting and removing pollutants from water and air. Hybrid nanomaterials synthesized with phenolphthalein show promise in this area due to their high sensitivity to pH changes and potential for selective adsorption of contaminants. This has led to increased interest from water treatment companies and environmental monitoring agencies seeking to improve their detection and remediation capabilities.

The chemical sensing industry is another key driver of market demand for phenolphthalein-based hybrid nanomaterials. These materials offer enhanced sensitivity and selectivity compared to traditional sensing methods, making them attractive for applications in food safety, industrial process monitoring, and quality control. The ability to tailor the properties of hybrid nanomaterials through the incorporation of phenolphthalein opens up new possibilities for developing highly specific and responsive sensors.

In the biomedical field, the potential applications of phenolphthalein-hybrid nanomaterials are diverse and promising. There is growing interest in using these materials for drug delivery systems, diagnostic tools, and tissue engineering scaffolds. The pH-responsive nature of phenolphthalein, combined with the unique properties of nanomaterials, offers opportunities for creating smart drug delivery vehicles and biosensors with improved performance.

The market for hybrid nanomaterials is expected to continue expanding as research and development efforts intensify. Academic institutions and industrial research centers are investing in exploring new synthesis methods and applications for phenolphthalein-based hybrid nanomaterials. This increased focus on research is likely to drive innovation and create new market opportunities in the coming years.

However, challenges remain in scaling up production and ensuring consistent quality of these advanced materials. The complexity of synthesizing hybrid nanomaterials with precise control over their properties presents technical hurdles that need to be overcome to meet growing market demand. Additionally, regulatory considerations and safety assessments for novel nanomaterials may impact the rate of market adoption in certain sectors.

Despite these challenges, the overall market outlook for phenolphthalein-based hybrid nanomaterials remains positive. The unique combination of properties offered by these materials addresses unmet needs in various industries, driving continued investment and research efforts. As synthesis techniques improve and new applications are discovered, the market demand for these innovative materials is expected to grow, creating opportunities for both established companies and startups in the nanotechnology sector.

In the environmental sector, there is a growing need for advanced materials capable of detecting and removing pollutants from water and air. Hybrid nanomaterials synthesized with phenolphthalein show promise in this area due to their high sensitivity to pH changes and potential for selective adsorption of contaminants. This has led to increased interest from water treatment companies and environmental monitoring agencies seeking to improve their detection and remediation capabilities.

The chemical sensing industry is another key driver of market demand for phenolphthalein-based hybrid nanomaterials. These materials offer enhanced sensitivity and selectivity compared to traditional sensing methods, making them attractive for applications in food safety, industrial process monitoring, and quality control. The ability to tailor the properties of hybrid nanomaterials through the incorporation of phenolphthalein opens up new possibilities for developing highly specific and responsive sensors.

In the biomedical field, the potential applications of phenolphthalein-hybrid nanomaterials are diverse and promising. There is growing interest in using these materials for drug delivery systems, diagnostic tools, and tissue engineering scaffolds. The pH-responsive nature of phenolphthalein, combined with the unique properties of nanomaterials, offers opportunities for creating smart drug delivery vehicles and biosensors with improved performance.

The market for hybrid nanomaterials is expected to continue expanding as research and development efforts intensify. Academic institutions and industrial research centers are investing in exploring new synthesis methods and applications for phenolphthalein-based hybrid nanomaterials. This increased focus on research is likely to drive innovation and create new market opportunities in the coming years.

However, challenges remain in scaling up production and ensuring consistent quality of these advanced materials. The complexity of synthesizing hybrid nanomaterials with precise control over their properties presents technical hurdles that need to be overcome to meet growing market demand. Additionally, regulatory considerations and safety assessments for novel nanomaterials may impact the rate of market adoption in certain sectors.

Despite these challenges, the overall market outlook for phenolphthalein-based hybrid nanomaterials remains positive. The unique combination of properties offered by these materials addresses unmet needs in various industries, driving continued investment and research efforts. As synthesis techniques improve and new applications are discovered, the market demand for these innovative materials is expected to grow, creating opportunities for both established companies and startups in the nanotechnology sector.

Current Challenges in Hybrid Nanomaterial Synthesis

The synthesis of hybrid nanomaterials presents several significant challenges that researchers and industry professionals are actively working to overcome. One of the primary obstacles is achieving precise control over the composition and structure of these materials at the nanoscale. The integration of organic and inorganic components in a single nanostructure requires meticulous control over reaction conditions, which can be difficult to maintain consistently across large-scale production.

Another major challenge lies in the interface between the organic and inorganic components. Ensuring strong and stable bonding between these disparate materials is crucial for the overall performance and longevity of hybrid nanomaterials. Weak interfaces can lead to phase separation or degradation of the material over time, compromising its intended functionality.

Reproducibility and scalability remain significant hurdles in the synthesis of hybrid nanomaterials. Laboratory-scale successes often face difficulties when translated to industrial-scale production. Maintaining uniform quality and properties across large batches is a complex task that requires sophisticated process control and quality assurance measures.

The characterization of hybrid nanomaterials poses its own set of challenges. Traditional analytical techniques may not be sufficient to fully elucidate the complex structures and interactions within these materials. Developing new and improved characterization methods is essential for advancing the field and optimizing synthesis processes.

Environmental and health concerns also present challenges in the synthesis of hybrid nanomaterials. Many synthesis methods involve the use of toxic precursors or generate hazardous byproducts. Developing green synthesis routes that minimize environmental impact and ensure worker safety is a priority for sustainable development in this field.

Cost-effectiveness is another critical challenge, particularly for commercial applications. The synthesis of hybrid nanomaterials often involves expensive precursors and complex processing steps. Finding ways to reduce production costs while maintaining material quality is crucial for widespread adoption of these materials in various industries.

Lastly, the integration of phenolphthalein into hybrid nanomaterials introduces specific challenges related to its chemical properties. Controlling the pH-sensitive behavior of phenolphthalein within the nanostructure, ensuring its stability, and optimizing its interaction with other components are areas that require focused research and development efforts.

Another major challenge lies in the interface between the organic and inorganic components. Ensuring strong and stable bonding between these disparate materials is crucial for the overall performance and longevity of hybrid nanomaterials. Weak interfaces can lead to phase separation or degradation of the material over time, compromising its intended functionality.

Reproducibility and scalability remain significant hurdles in the synthesis of hybrid nanomaterials. Laboratory-scale successes often face difficulties when translated to industrial-scale production. Maintaining uniform quality and properties across large batches is a complex task that requires sophisticated process control and quality assurance measures.

The characterization of hybrid nanomaterials poses its own set of challenges. Traditional analytical techniques may not be sufficient to fully elucidate the complex structures and interactions within these materials. Developing new and improved characterization methods is essential for advancing the field and optimizing synthesis processes.

Environmental and health concerns also present challenges in the synthesis of hybrid nanomaterials. Many synthesis methods involve the use of toxic precursors or generate hazardous byproducts. Developing green synthesis routes that minimize environmental impact and ensure worker safety is a priority for sustainable development in this field.

Cost-effectiveness is another critical challenge, particularly for commercial applications. The synthesis of hybrid nanomaterials often involves expensive precursors and complex processing steps. Finding ways to reduce production costs while maintaining material quality is crucial for widespread adoption of these materials in various industries.

Lastly, the integration of phenolphthalein into hybrid nanomaterials introduces specific challenges related to its chemical properties. Controlling the pH-sensitive behavior of phenolphthalein within the nanostructure, ensuring its stability, and optimizing its interaction with other components are areas that require focused research and development efforts.

Existing Phenolphthalein-Based Synthesis Methods

01 Synthesis and production methods of phenolphthalein

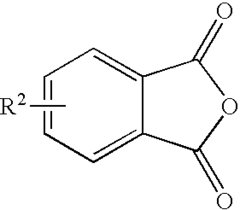

Various methods for synthesizing and producing phenolphthalein are described, including different reaction conditions, catalysts, and purification techniques. These methods aim to improve yield, purity, and efficiency in the manufacturing process of phenolphthalein.- Synthesis and preparation of phenolphthalein: Various methods for synthesizing and preparing phenolphthalein are described. These processes involve different chemical reactions and conditions to produce phenolphthalein efficiently and with high purity. The synthesis typically involves the condensation of phthalic anhydride with phenol in the presence of catalysts or specific reaction conditions.

- Use of phenolphthalein in analytical and indicator applications: Phenolphthalein is widely used as an acid-base indicator in analytical chemistry. It changes color from colorless to pink in alkaline solutions, making it useful for titrations and pH measurements. Various formulations and applications of phenolphthalein as an indicator in different fields are described.

- Phenolphthalein derivatives and their applications: Research on phenolphthalein derivatives, including modified structures and new compounds based on the phenolphthalein core. These derivatives may have improved properties or novel applications in fields such as medicine, materials science, or chemical analysis.

- Phenolphthalein in pharmaceutical and medical applications: The use of phenolphthalein and its derivatives in pharmaceutical formulations and medical applications. This includes its historical use as a laxative, as well as potential new medical applications based on its chemical properties or the properties of its derivatives.

- Environmental and safety considerations of phenolphthalein: Studies and regulations related to the environmental impact and safety of phenolphthalein. This includes research on its potential carcinogenicity, methods for its detection and removal from the environment, and alternative compounds to replace phenolphthalein in various applications due to safety concerns.

02 Applications of phenolphthalein in analytical chemistry

Phenolphthalein is widely used as an indicator in analytical chemistry, particularly in acid-base titrations. Its color-changing properties make it valuable for determining pH levels and endpoint detection in various chemical analyses.Expand Specific Solutions03 Phenolphthalein derivatives and their uses

Research on phenolphthalein derivatives focuses on modifying the molecule to enhance its properties or create new compounds with specific applications. These derivatives may have improved solubility, stability, or functionality in various fields such as medicine and materials science.Expand Specific Solutions04 Incorporation of phenolphthalein in polymers and materials

Phenolphthalein is used in the development of specialized polymers and materials. It can be incorporated into polymer structures to create materials with unique properties, such as pH-sensitive or color-changing characteristics, which find applications in smart materials and sensors.Expand Specific Solutions05 Environmental and safety considerations of phenolphthalein

Studies and regulations related to the environmental impact and safety of phenolphthalein are addressed. This includes research on its biodegradability, potential health effects, and development of safer alternatives or improved handling methods for industrial and laboratory use.Expand Specific Solutions

Key Players in Nanomaterial Industry

The development of hybrid nanomaterials incorporating phenolphthalein is in its early stages, with significant potential for growth. The market size is currently modest but expanding as research progresses. Technologically, the field is still evolving, with varying levels of maturity across different applications. Key players like Beijing University of Chemical Technology, Wuhan University of Technology, and Zhejiang Goodmin New Materials Co., Ltd. are advancing the technology through research and development. Established chemical companies such as China Petroleum & Chemical Corp. and CJ CheilJedang Corp. are also exploring this area, leveraging their expertise in materials science. The competitive landscape is characterized by a mix of academic institutions, specialized nanomaterial firms, and large chemical corporations, each contributing to the field's advancement.

Beijing University of Chemical Technology

Technical Solution: Beijing University of Chemical Technology has developed a novel approach for synthesizing hybrid nanomaterials using phenolphthalein as a key component. Their method involves incorporating phenolphthalein into metal-organic frameworks (MOFs) to create pH-responsive hybrid nanomaterials[1]. These materials exhibit enhanced catalytic activity and can be used for controlled drug delivery systems. The university has also explored the use of phenolphthalein-based hybrid nanomaterials in environmental remediation, particularly for the detection and removal of heavy metal ions from water[2].

Strengths: Expertise in MOF synthesis, pH-responsive materials, and environmental applications. Weaknesses: Limited large-scale production capabilities and potential cost constraints for industrial applications.

Wuhan University of Technology

Technical Solution: Wuhan University of Technology has made significant strides in the synthesis of phenolphthalein-based hybrid nanomaterials for energy storage applications. Their research focuses on developing high-performance supercapacitors using phenolphthalein-derived carbon nanomaterials[3]. The university has successfully created a hybrid nanocomposite by combining phenolphthalein-based carbon with metal oxides, resulting in enhanced electrical conductivity and specific capacitance. Additionally, they have explored the use of these hybrid nanomaterials in lithium-ion batteries, demonstrating improved cycling stability and rate capability[4].

Strengths: Strong focus on energy storage applications and expertise in carbon-based nanomaterials. Weaknesses: May face challenges in scaling up production and optimizing cost-effectiveness for commercial use.

Core Innovations in Hybrid Nanomaterial Synthesis

Catalytic method for producing phenolphthalein compounds

PatentInactiveUS20100081828A1

Innovation

- The use of heterogeneous metal oxide catalysts, such as molybdenum or tungsten oxides combined with porous supports like zirconium oxide, allows for easier separation and regeneration of the catalyst, reducing waste and improving the efficiency of phenolphthalein production while maintaining high purity.

Method for producing phenolphthalein compound using ionic liquid catalyst composition

PatentInactiveUS20100081831A1

Innovation

- The use of an ionic liquid catalyst composition, comprising a combination of an ionic liquid and a metal halide, facilitates the efficient separation and potential reuse of the catalyst, reducing waste and improving purity by reacting phenolic and phthalic anhydride compounds at controlled temperatures.

Environmental Impact Assessment

The synthesis of hybrid nanomaterials using phenolphthalein has potential environmental implications that require careful assessment. The production process may involve the use of various chemicals and solvents, which could lead to the generation of hazardous waste. Proper waste management and disposal protocols must be implemented to minimize environmental contamination.

One of the primary concerns is the potential release of nanoparticles into the environment during manufacturing or through the use of products containing these hybrid materials. Nanoparticles can have unique properties and behaviors in environmental systems, potentially affecting ecosystems and organisms in ways that are not yet fully understood. Long-term studies are needed to evaluate the persistence, bioaccumulation, and toxicity of these nanomaterials in different environmental compartments.

Water systems are particularly vulnerable to nanoparticle contamination. The small size of these particles allows them to remain suspended in water for extended periods, potentially impacting aquatic life and water quality. Filtration and water treatment systems may need to be adapted to effectively remove these nanomaterials from wastewater and drinking water sources.

Air quality is another area of concern, as the production of hybrid nanomaterials may release particulate matter into the atmosphere. Inhalation of nanoparticles can pose health risks to workers and nearby communities. Robust air filtration systems and personal protective equipment are essential to mitigate these risks.

The life cycle of products containing phenolphthalein-based hybrid nanomaterials must also be considered. As these products degrade or are disposed of, there is potential for the release of nanoparticles into the environment. Developing effective recycling and disposal methods for these materials is crucial to prevent environmental contamination and promote sustainability.

On the positive side, some hybrid nanomaterials may have applications in environmental remediation. For instance, they could be used in advanced water treatment technologies or as sensors for detecting environmental pollutants. These potential benefits should be weighed against the environmental risks associated with their production and use.

Regulatory frameworks may need to be updated to address the unique challenges posed by these novel materials. Environmental impact assessments should be conducted at various stages of development and implementation to ensure that potential risks are identified and mitigated. This may include toxicity testing, environmental fate studies, and long-term monitoring programs.

One of the primary concerns is the potential release of nanoparticles into the environment during manufacturing or through the use of products containing these hybrid materials. Nanoparticles can have unique properties and behaviors in environmental systems, potentially affecting ecosystems and organisms in ways that are not yet fully understood. Long-term studies are needed to evaluate the persistence, bioaccumulation, and toxicity of these nanomaterials in different environmental compartments.

Water systems are particularly vulnerable to nanoparticle contamination. The small size of these particles allows them to remain suspended in water for extended periods, potentially impacting aquatic life and water quality. Filtration and water treatment systems may need to be adapted to effectively remove these nanomaterials from wastewater and drinking water sources.

Air quality is another area of concern, as the production of hybrid nanomaterials may release particulate matter into the atmosphere. Inhalation of nanoparticles can pose health risks to workers and nearby communities. Robust air filtration systems and personal protective equipment are essential to mitigate these risks.

The life cycle of products containing phenolphthalein-based hybrid nanomaterials must also be considered. As these products degrade or are disposed of, there is potential for the release of nanoparticles into the environment. Developing effective recycling and disposal methods for these materials is crucial to prevent environmental contamination and promote sustainability.

On the positive side, some hybrid nanomaterials may have applications in environmental remediation. For instance, they could be used in advanced water treatment technologies or as sensors for detecting environmental pollutants. These potential benefits should be weighed against the environmental risks associated with their production and use.

Regulatory frameworks may need to be updated to address the unique challenges posed by these novel materials. Environmental impact assessments should be conducted at various stages of development and implementation to ensure that potential risks are identified and mitigated. This may include toxicity testing, environmental fate studies, and long-term monitoring programs.

Scalability and Commercialization Potential

The scalability and commercialization potential of phenolphthalein in the synthesis of hybrid nanomaterials presents both promising opportunities and significant challenges. The unique properties of phenolphthalein, particularly its pH-sensitive color-changing ability, make it an attractive component for various applications in nanomaterial synthesis.

From a scalability perspective, the integration of phenolphthalein into hybrid nanomaterials can be achieved through relatively straightforward chemical processes. These processes, such as sol-gel methods or self-assembly techniques, are generally amenable to large-scale production. However, maintaining consistent quality and uniformity of the hybrid nanomaterials at industrial scales remains a key challenge that requires further research and development.

The commercialization potential of phenolphthalein-based hybrid nanomaterials spans several industries. In the field of sensors and diagnostics, these materials could be utilized for developing highly sensitive and specific pH sensors or colorimetric assays. The healthcare sector might benefit from smart drug delivery systems that leverage the pH-responsive nature of phenolphthalein to release therapeutic agents at targeted locations within the body.

Environmental applications present another avenue for commercialization. Hybrid nanomaterials incorporating phenolphthalein could be employed in water treatment processes, offering visual indicators of pH changes or contaminant presence. Additionally, the materials could find use in smart packaging for food and beverages, providing consumers with easy-to-read freshness or safety indicators.

To realize the full commercial potential, several hurdles must be addressed. Cost-effective production methods need to be developed to compete with existing technologies. The long-term stability and performance of these hybrid nanomaterials in various environmental conditions must be thoroughly evaluated and optimized. Regulatory approval processes, particularly for applications in healthcare and food industries, will require extensive safety and efficacy studies.

Market acceptance and consumer education will play crucial roles in the successful commercialization of phenolphthalein-based hybrid nanomaterials. Clear communication of the benefits and proper usage of products incorporating these materials will be essential for widespread adoption. Collaborations between academic institutions, research laboratories, and industry partners could accelerate the transition from laboratory-scale synthesis to commercial production.

In conclusion, while the scalability and commercialization potential of phenolphthalein in hybrid nanomaterial synthesis is significant, realizing this potential will require a concerted effort to overcome technical, regulatory, and market-related challenges. With continued research and development, these innovative materials could lead to transformative products across multiple sectors in the coming years.

From a scalability perspective, the integration of phenolphthalein into hybrid nanomaterials can be achieved through relatively straightforward chemical processes. These processes, such as sol-gel methods or self-assembly techniques, are generally amenable to large-scale production. However, maintaining consistent quality and uniformity of the hybrid nanomaterials at industrial scales remains a key challenge that requires further research and development.

The commercialization potential of phenolphthalein-based hybrid nanomaterials spans several industries. In the field of sensors and diagnostics, these materials could be utilized for developing highly sensitive and specific pH sensors or colorimetric assays. The healthcare sector might benefit from smart drug delivery systems that leverage the pH-responsive nature of phenolphthalein to release therapeutic agents at targeted locations within the body.

Environmental applications present another avenue for commercialization. Hybrid nanomaterials incorporating phenolphthalein could be employed in water treatment processes, offering visual indicators of pH changes or contaminant presence. Additionally, the materials could find use in smart packaging for food and beverages, providing consumers with easy-to-read freshness or safety indicators.

To realize the full commercial potential, several hurdles must be addressed. Cost-effective production methods need to be developed to compete with existing technologies. The long-term stability and performance of these hybrid nanomaterials in various environmental conditions must be thoroughly evaluated and optimized. Regulatory approval processes, particularly for applications in healthcare and food industries, will require extensive safety and efficacy studies.

Market acceptance and consumer education will play crucial roles in the successful commercialization of phenolphthalein-based hybrid nanomaterials. Clear communication of the benefits and proper usage of products incorporating these materials will be essential for widespread adoption. Collaborations between academic institutions, research laboratories, and industry partners could accelerate the transition from laboratory-scale synthesis to commercial production.

In conclusion, while the scalability and commercialization potential of phenolphthalein in hybrid nanomaterial synthesis is significant, realizing this potential will require a concerted effort to overcome technical, regulatory, and market-related challenges. With continued research and development, these innovative materials could lead to transformative products across multiple sectors in the coming years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!