QLED vs. OLED: Understanding the Key Differences

JUN 19, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Display Tech Evolution

The evolution of display technology has been a remarkable journey, spanning several decades and encompassing numerous breakthroughs. From the early cathode ray tubes (CRTs) to the latest quantum dot and organic light-emitting diode (OLED) displays, each iteration has brought significant improvements in image quality, energy efficiency, and form factor.

The 1960s saw the introduction of liquid crystal displays (LCDs), which marked a significant departure from the bulky CRTs. LCDs offered thinner profiles and lower power consumption, paving the way for portable electronic devices. However, it wasn't until the 1990s that LCDs began to dominate the market, driven by advancements in thin-film transistor (TFT) technology.

The turn of the millennium heralded the era of plasma displays, which offered superior contrast ratios and wider viewing angles compared to LCDs. Although plasma technology eventually lost ground to LCDs in most consumer applications, it played a crucial role in pushing the boundaries of display quality and size.

OLED technology emerged in the early 2000s, promising even better picture quality, faster response times, and the possibility of flexible displays. OLEDs operate by emitting light directly from each pixel, eliminating the need for backlighting and allowing for true blacks and infinite contrast ratios.

In recent years, quantum dot technology has gained prominence, particularly in the form of QLED displays. Quantum dots are semiconductor nanocrystals that can produce highly saturated colors when excited by light. When applied to LCD panels, they significantly enhance color accuracy and brightness, rivaling the performance of OLEDs in many aspects.

The ongoing competition between QLED and OLED technologies represents the current pinnacle of display evolution. Both offer distinct advantages: QLEDs excel in brightness and color volume, while OLEDs provide superior contrast and viewing angles. This rivalry has spurred continuous innovation, with each technology pushing the other to new heights of performance.

Looking ahead, emerging technologies such as microLED and holographic displays promise to further revolutionize the field. MicroLEDs offer the potential for modular, scalable displays with exceptional brightness and efficiency, while holographic displays could bring true 3D viewing experiences without the need for special glasses.

The 1960s saw the introduction of liquid crystal displays (LCDs), which marked a significant departure from the bulky CRTs. LCDs offered thinner profiles and lower power consumption, paving the way for portable electronic devices. However, it wasn't until the 1990s that LCDs began to dominate the market, driven by advancements in thin-film transistor (TFT) technology.

The turn of the millennium heralded the era of plasma displays, which offered superior contrast ratios and wider viewing angles compared to LCDs. Although plasma technology eventually lost ground to LCDs in most consumer applications, it played a crucial role in pushing the boundaries of display quality and size.

OLED technology emerged in the early 2000s, promising even better picture quality, faster response times, and the possibility of flexible displays. OLEDs operate by emitting light directly from each pixel, eliminating the need for backlighting and allowing for true blacks and infinite contrast ratios.

In recent years, quantum dot technology has gained prominence, particularly in the form of QLED displays. Quantum dots are semiconductor nanocrystals that can produce highly saturated colors when excited by light. When applied to LCD panels, they significantly enhance color accuracy and brightness, rivaling the performance of OLEDs in many aspects.

The ongoing competition between QLED and OLED technologies represents the current pinnacle of display evolution. Both offer distinct advantages: QLEDs excel in brightness and color volume, while OLEDs provide superior contrast and viewing angles. This rivalry has spurred continuous innovation, with each technology pushing the other to new heights of performance.

Looking ahead, emerging technologies such as microLED and holographic displays promise to further revolutionize the field. MicroLEDs offer the potential for modular, scalable displays with exceptional brightness and efficiency, while holographic displays could bring true 3D viewing experiences without the need for special glasses.

Market Demand Analysis

The market demand for display technologies has been evolving rapidly, with QLED and OLED emerging as two dominant players in the high-end segment. Both technologies cater to consumers seeking superior picture quality, but their market positioning and growth trajectories differ significantly.

OLED displays have gained substantial traction in the premium smartphone and high-end TV markets. The technology's ability to produce perfect blacks, wide viewing angles, and thin form factors has made it a preferred choice for flagship devices. Major smartphone manufacturers have increasingly adopted OLED panels, driving demand in the mobile sector. In the TV market, OLED has established itself as a premium option, with steady growth in large-screen sizes.

QLED, on the other hand, has seen strong demand in the mid to high-end TV segment. The technology's ability to deliver high brightness levels and vibrant colors at a more competitive price point has resonated with consumers. QLED TVs have particularly excelled in well-lit environments, making them popular for living room setups. The technology has also found applications in gaming monitors, where high refresh rates and brightness are valued.

Market research indicates that both QLED and OLED technologies are experiencing growth, albeit at different rates and in different segments. OLED has shown robust growth in smaller displays for mobile devices and wearables, while QLED has gained momentum in larger displays for TVs and monitors. The global OLED market is projected to grow at a higher CAGR compared to QLED, driven by increasing adoption in smartphones and expansion in the TV sector.

Consumer preferences play a crucial role in shaping demand. OLED's superior contrast and color accuracy appeal to cinephiles and content creators, while QLED's brightness and affordability attract a broader consumer base. The gaming community has shown interest in both technologies, with OLED's fast response times competing against QLED's high brightness and reduced risk of burn-in.

Environmental considerations are increasingly influencing consumer choices. OLED's potential for lower power consumption in dark scenes aligns with energy efficiency trends. However, concerns about OLED's lifespan and burn-in risk persist, potentially affecting long-term demand in certain segments.

The commercial display market presents growth opportunities for both technologies. QLED's high brightness makes it suitable for digital signage in bright environments, while OLED's flexibility and transparency open up innovative applications in retail and automotive industries.

As the display market continues to evolve, the demand for QLED and OLED technologies is expected to remain strong, with each carving out its niche based on specific performance characteristics and price points. The ongoing competition between these technologies is likely to drive further innovations, potentially leading to hybrid solutions that combine the strengths of both QLED and OLED.

OLED displays have gained substantial traction in the premium smartphone and high-end TV markets. The technology's ability to produce perfect blacks, wide viewing angles, and thin form factors has made it a preferred choice for flagship devices. Major smartphone manufacturers have increasingly adopted OLED panels, driving demand in the mobile sector. In the TV market, OLED has established itself as a premium option, with steady growth in large-screen sizes.

QLED, on the other hand, has seen strong demand in the mid to high-end TV segment. The technology's ability to deliver high brightness levels and vibrant colors at a more competitive price point has resonated with consumers. QLED TVs have particularly excelled in well-lit environments, making them popular for living room setups. The technology has also found applications in gaming monitors, where high refresh rates and brightness are valued.

Market research indicates that both QLED and OLED technologies are experiencing growth, albeit at different rates and in different segments. OLED has shown robust growth in smaller displays for mobile devices and wearables, while QLED has gained momentum in larger displays for TVs and monitors. The global OLED market is projected to grow at a higher CAGR compared to QLED, driven by increasing adoption in smartphones and expansion in the TV sector.

Consumer preferences play a crucial role in shaping demand. OLED's superior contrast and color accuracy appeal to cinephiles and content creators, while QLED's brightness and affordability attract a broader consumer base. The gaming community has shown interest in both technologies, with OLED's fast response times competing against QLED's high brightness and reduced risk of burn-in.

Environmental considerations are increasingly influencing consumer choices. OLED's potential for lower power consumption in dark scenes aligns with energy efficiency trends. However, concerns about OLED's lifespan and burn-in risk persist, potentially affecting long-term demand in certain segments.

The commercial display market presents growth opportunities for both technologies. QLED's high brightness makes it suitable for digital signage in bright environments, while OLED's flexibility and transparency open up innovative applications in retail and automotive industries.

As the display market continues to evolve, the demand for QLED and OLED technologies is expected to remain strong, with each carving out its niche based on specific performance characteristics and price points. The ongoing competition between these technologies is likely to drive further innovations, potentially leading to hybrid solutions that combine the strengths of both QLED and OLED.

QLED vs OLED Challenges

QLED and OLED technologies, while both offering high-quality display solutions, face distinct challenges in their development and market adoption. QLED, or Quantum Dot Light Emitting Diode, technology struggles with achieving true black levels and wide viewing angles. The backlight used in QLED displays can lead to light bleed, reducing contrast in dark scenes. Additionally, off-angle viewing can result in color shift and reduced picture quality.

OLED, or Organic Light Emitting Diode, technology encounters difficulties with longevity and burn-in issues. The organic compounds used in OLED displays degrade over time, potentially leading to reduced brightness and color accuracy. Burn-in, where static images can leave permanent marks on the screen, remains a concern for OLED users, particularly in applications with static elements like news tickers or gaming HUDs.

Both technologies face challenges in manufacturing scalability and cost reduction. QLED production requires precise control of quantum dot size and uniformity, which can be difficult to achieve at scale. OLED manufacturing, particularly for larger screens, involves complex processes that can result in lower yields and higher costs.

Energy efficiency is another area of concern for both technologies. While OLED can be more energy-efficient in displaying dark content due to its ability to turn off individual pixels, it can consume more power when displaying bright scenes. QLED, on the other hand, requires constant backlighting, which can lead to higher overall power consumption.

Color accuracy and gamut representation present ongoing challenges. QLED technology excels in producing vibrant colors but may struggle with color volume in darker scenes. OLED offers excellent color accuracy but can face issues with color shift at extreme viewing angles.

Durability and lifespan are critical factors for both technologies. QLED displays generally have longer lifespans due to their inorganic nature, but may suffer from degradation of the quantum dot layer over time. OLED displays are more susceptible to image retention and burn-in, particularly in high-usage scenarios.

As both technologies continue to evolve, addressing these challenges remains crucial for their widespread adoption and long-term success in the display market. Manufacturers are actively researching solutions to mitigate these issues, driving innovation in materials science, manufacturing processes, and display algorithms.

OLED, or Organic Light Emitting Diode, technology encounters difficulties with longevity and burn-in issues. The organic compounds used in OLED displays degrade over time, potentially leading to reduced brightness and color accuracy. Burn-in, where static images can leave permanent marks on the screen, remains a concern for OLED users, particularly in applications with static elements like news tickers or gaming HUDs.

Both technologies face challenges in manufacturing scalability and cost reduction. QLED production requires precise control of quantum dot size and uniformity, which can be difficult to achieve at scale. OLED manufacturing, particularly for larger screens, involves complex processes that can result in lower yields and higher costs.

Energy efficiency is another area of concern for both technologies. While OLED can be more energy-efficient in displaying dark content due to its ability to turn off individual pixels, it can consume more power when displaying bright scenes. QLED, on the other hand, requires constant backlighting, which can lead to higher overall power consumption.

Color accuracy and gamut representation present ongoing challenges. QLED technology excels in producing vibrant colors but may struggle with color volume in darker scenes. OLED offers excellent color accuracy but can face issues with color shift at extreme viewing angles.

Durability and lifespan are critical factors for both technologies. QLED displays generally have longer lifespans due to their inorganic nature, but may suffer from degradation of the quantum dot layer over time. OLED displays are more susceptible to image retention and burn-in, particularly in high-usage scenarios.

As both technologies continue to evolve, addressing these challenges remains crucial for their widespread adoption and long-term success in the display market. Manufacturers are actively researching solutions to mitigate these issues, driving innovation in materials science, manufacturing processes, and display algorithms.

Current QLED OLED Tech

01 QLED technology and color performance

QLED (Quantum Dot Light Emitting Diode) technology utilizes quantum dots to enhance color performance and brightness in displays. This results in a wider color gamut and improved color accuracy compared to traditional LED displays. QLED displays can achieve higher peak brightness levels, making them suitable for HDR content and viewing in bright environments.- QLED technology and color performance: QLED (Quantum Dot Light Emitting Diode) technology utilizes quantum dots to enhance color performance and brightness in displays. This technology offers a wider color gamut and improved color accuracy compared to traditional LED displays, resulting in more vibrant and lifelike images.

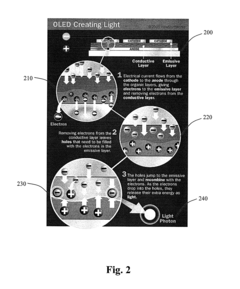

- OLED technology and display quality: OLED (Organic Light Emitting Diode) technology provides superior display quality with deep blacks, high contrast ratios, and wide viewing angles. Each pixel in an OLED display emits its own light, allowing for precise control over brightness and color, resulting in excellent image quality and energy efficiency.

- Comparison of QLED and OLED display technologies: Both QLED and OLED technologies offer distinct advantages in display quality. QLED excels in brightness and color volume, making it suitable for well-lit environments, while OLED provides superior contrast and black levels, ideal for dark room viewing. The choice between the two depends on specific use cases and viewing conditions.

- Advancements in QLED and OLED manufacturing: Ongoing research and development in QLED and OLED manufacturing processes aim to improve display quality, efficiency, and longevity. These advancements include new materials, enhanced production techniques, and innovative pixel structures to address challenges such as color shift, burn-in, and power consumption.

- Integration of QLED and OLED technologies in various applications: QLED and OLED display technologies are being integrated into a wide range of applications beyond traditional televisions and monitors. These include automotive displays, wearable devices, and flexible screens, each leveraging the unique strengths of the respective technologies to enhance user experience and display quality in diverse environments.

02 OLED technology and contrast ratio

OLED (Organic Light Emitting Diode) displays offer superior contrast ratios due to their ability to produce true blacks by turning off individual pixels. This technology allows for deeper blacks and more vibrant colors, resulting in improved image quality and better performance in low-light conditions. OLED displays also provide wider viewing angles compared to traditional LCD screens.Expand Specific Solutions03 Display panel structure and efficiency

Both QLED and OLED technologies employ unique panel structures to improve display efficiency and quality. QLED displays use a backlight and quantum dot layer to enhance color output, while OLED displays use self-emitting organic compounds. These structures affect factors such as power consumption, lifespan, and overall display performance.Expand Specific Solutions04 Color gamut and accuracy improvements

Advancements in both QLED and OLED technologies focus on expanding the color gamut and improving color accuracy. This includes developing new materials and refining manufacturing processes to achieve more precise color reproduction and a wider range of displayable colors, resulting in more lifelike and vibrant images.Expand Specific Solutions05 Display refresh rate and motion handling

Both QLED and OLED technologies are being developed to support higher refresh rates and improved motion handling. This results in smoother motion, reduced blur, and enhanced overall picture quality, particularly for fast-moving content such as sports and action scenes in movies or video games.Expand Specific Solutions

Key Industry Players

The QLED vs. OLED competition represents a mature stage in display technology, with both technologies vying for dominance in the high-end TV market. The global market for these advanced displays is substantial, projected to reach billions of dollars annually. Technologically, both QLED and OLED have achieved significant maturity, with companies like BOE Technology Group, TCL China Star Optoelectronics, and Sharp leading QLED development, while LG Display and Samsung Display are at the forefront of OLED technology. The competition has driven rapid advancements in picture quality, energy efficiency, and manufacturing processes, with each technology offering unique advantages in terms of brightness, color accuracy, and longevity.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced QLED technology using quantum dot materials to enhance color performance. Their QLED displays utilize a blue LED backlight combined with red and green quantum dots to produce a wide color gamut. BOE's QLED panels incorporate local dimming technology to improve contrast ratios and HDR performance. They have also made progress in reducing the blue light emission from QLED displays to protect eye health.

Strengths: Wide color gamut, high brightness, long lifespan. Weaknesses: Less perfect black levels compared to OLED, potential for image retention.

Sharp Corp.

Technical Solution: Sharp has been at the forefront of OLED development, particularly focusing on small and medium-sized OLED displays. Their OLED technology utilizes a unique IGZO (Indium Gallium Zinc Oxide) backplane for improved electron mobility and power efficiency. Sharp's OLED panels feature pixel-level light emission for true blacks and infinite contrast ratios. They have also developed flexible OLED displays that can be bent or folded without damaging the screen.

Strengths: Perfect blacks, wide viewing angles, potential for flexible displays. Weaknesses: Lower peak brightness compared to QLED, potential for burn-in.

Core Display Innovations

Optoelectronic device

PatentPendingUS20240107791A1

Innovation

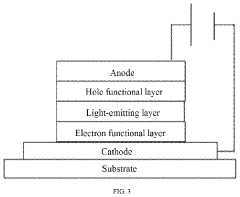

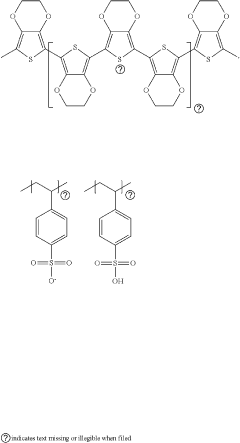

- An optoelectronic device with a quantum dot light-emitting layer in a core-shell structure, where the valence band top energy level difference between the shell layer material and the hole transport material is greater than or equal to 0.5 eV, and the electron transport layer comprises zinc oxide nanomaterials bound with amine/carboxyl ligands of 3-8 carbon atoms, optimizing hole and electron injection balance and reducing charge accumulation.

Method and system for an organic light emitting diode structure

PatentInactiveUS20150303396A1

Innovation

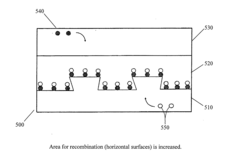

- Incorporating a plurality of spaced inverted non-cylindrical nano-pillars in the structure of OLEDs, specifically between the emissive and conductive layers, to broaden the carrier recombination space and reduce carrier accumulation, thereby enhancing light extraction and efficiency.

Environmental Impact

The environmental impact of display technologies is an increasingly important consideration in the consumer electronics industry. When comparing QLED (Quantum Dot Light Emitting Diode) and OLED (Organic Light Emitting Diode) technologies, several factors come into play regarding their ecological footprint.

QLED displays typically consume more energy than OLED panels, particularly when displaying bright content. This higher energy consumption translates to increased carbon emissions over the lifetime of the device. However, QLED technology has seen improvements in energy efficiency in recent years, narrowing the gap with OLED.

In terms of manufacturing, QLED displays generally have a lower environmental impact during production. The quantum dots used in QLED are inorganic materials that can be produced with less energy-intensive processes compared to the organic compounds used in OLED displays. Additionally, QLED manufacturing typically involves fewer toxic chemicals and solvents.

The lifespan of displays is another crucial factor in their environmental impact. QLED displays often have a longer lifespan than OLED panels, which can suffer from burn-in and degradation over time. This longevity means fewer replacements and less electronic waste generated over the long term.

Recycling and end-of-life considerations also differ between the two technologies. QLED displays, being based on traditional LCD technology with added quantum dots, can often be recycled using existing LCD recycling infrastructure. OLED displays, however, may require specialized recycling processes due to their unique organic materials.

Both technologies face challenges regarding the use of rare earth elements and other scarce resources. Quantum dots in QLED displays often contain cadmium, a toxic heavy metal, although cadmium-free alternatives are being developed. OLED technology relies on materials like indium, which is in limited supply globally.

Water usage in manufacturing is another environmental concern. QLED production typically requires less water compared to OLED manufacturing, which can be a water-intensive process. This difference becomes significant when considering large-scale production and its impact on local water resources.

In conclusion, while both QLED and OLED technologies have environmental implications, QLED currently holds some advantages in terms of manufacturing impact and device longevity. However, OLED's energy efficiency during use could offset some of these benefits over time. As both technologies continue to evolve, ongoing research and development efforts are focused on improving their overall environmental performance.

QLED displays typically consume more energy than OLED panels, particularly when displaying bright content. This higher energy consumption translates to increased carbon emissions over the lifetime of the device. However, QLED technology has seen improvements in energy efficiency in recent years, narrowing the gap with OLED.

In terms of manufacturing, QLED displays generally have a lower environmental impact during production. The quantum dots used in QLED are inorganic materials that can be produced with less energy-intensive processes compared to the organic compounds used in OLED displays. Additionally, QLED manufacturing typically involves fewer toxic chemicals and solvents.

The lifespan of displays is another crucial factor in their environmental impact. QLED displays often have a longer lifespan than OLED panels, which can suffer from burn-in and degradation over time. This longevity means fewer replacements and less electronic waste generated over the long term.

Recycling and end-of-life considerations also differ between the two technologies. QLED displays, being based on traditional LCD technology with added quantum dots, can often be recycled using existing LCD recycling infrastructure. OLED displays, however, may require specialized recycling processes due to their unique organic materials.

Both technologies face challenges regarding the use of rare earth elements and other scarce resources. Quantum dots in QLED displays often contain cadmium, a toxic heavy metal, although cadmium-free alternatives are being developed. OLED technology relies on materials like indium, which is in limited supply globally.

Water usage in manufacturing is another environmental concern. QLED production typically requires less water compared to OLED manufacturing, which can be a water-intensive process. This difference becomes significant when considering large-scale production and its impact on local water resources.

In conclusion, while both QLED and OLED technologies have environmental implications, QLED currently holds some advantages in terms of manufacturing impact and device longevity. However, OLED's energy efficiency during use could offset some of these benefits over time. As both technologies continue to evolve, ongoing research and development efforts are focused on improving their overall environmental performance.

Manufacturing Processes

The manufacturing processes for QLED and OLED displays differ significantly, reflecting their distinct technological approaches. QLED (Quantum Dot Light Emitting Diode) displays are essentially enhanced LCD screens, while OLED (Organic Light Emitting Diode) displays represent a fundamentally different technology.

QLED manufacturing begins with the production of a traditional LCD panel. This involves creating a backlight unit, typically using LEDs, and assembling layers of liquid crystals and color filters. The quantum dot layer, which gives QLED its name and enhanced color capabilities, is then applied. This layer consists of nano-scale semiconductor particles that emit light of specific colors when excited by the backlight.

The quantum dots are usually suspended in a resin and applied as a film over the LCD panel. Precise control of quantum dot size and composition is crucial, as these factors determine the color of light emitted. The process requires clean room conditions and sophisticated deposition techniques to ensure uniform distribution of quantum dots.

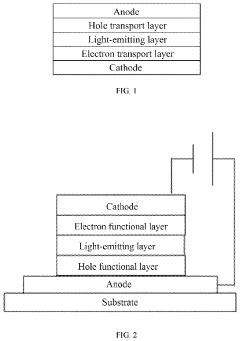

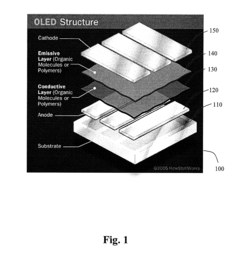

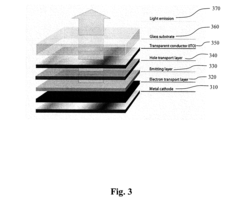

In contrast, OLED manufacturing is a more complex process that involves the deposition of organic materials onto a substrate. The process begins with a glass or plastic substrate, onto which a series of thin films are deposited. These include the anode, hole injection layer, hole transport layer, emissive layer, electron transport layer, and cathode.

Each layer in an OLED display is extremely thin, often just a few nanometers thick. The deposition of these layers requires highly specialized equipment, typically using vacuum thermal evaporation or organic vapor phase deposition. The emissive layer, which produces light, consists of organic compounds that emit different colors when electrically stimulated.

A key challenge in OLED manufacturing is achieving uniform deposition of the organic materials across large areas. This is particularly crucial for larger displays. Additionally, OLED materials are sensitive to moisture and oxygen, necessitating stringent environmental controls during production and robust encapsulation of the final product.

Both QLED and OLED manufacturing processes face challenges in scaling up to larger screen sizes while maintaining quality and yield. However, QLED manufacturing benefits from leveraging existing LCD production infrastructure, potentially offering cost advantages. OLED manufacturing, while more complex, allows for the creation of flexible and transparent displays, opening up new design possibilities.

QLED manufacturing begins with the production of a traditional LCD panel. This involves creating a backlight unit, typically using LEDs, and assembling layers of liquid crystals and color filters. The quantum dot layer, which gives QLED its name and enhanced color capabilities, is then applied. This layer consists of nano-scale semiconductor particles that emit light of specific colors when excited by the backlight.

The quantum dots are usually suspended in a resin and applied as a film over the LCD panel. Precise control of quantum dot size and composition is crucial, as these factors determine the color of light emitted. The process requires clean room conditions and sophisticated deposition techniques to ensure uniform distribution of quantum dots.

In contrast, OLED manufacturing is a more complex process that involves the deposition of organic materials onto a substrate. The process begins with a glass or plastic substrate, onto which a series of thin films are deposited. These include the anode, hole injection layer, hole transport layer, emissive layer, electron transport layer, and cathode.

Each layer in an OLED display is extremely thin, often just a few nanometers thick. The deposition of these layers requires highly specialized equipment, typically using vacuum thermal evaporation or organic vapor phase deposition. The emissive layer, which produces light, consists of organic compounds that emit different colors when electrically stimulated.

A key challenge in OLED manufacturing is achieving uniform deposition of the organic materials across large areas. This is particularly crucial for larger displays. Additionally, OLED materials are sensitive to moisture and oxygen, necessitating stringent environmental controls during production and robust encapsulation of the final product.

Both QLED and OLED manufacturing processes face challenges in scaling up to larger screen sizes while maintaining quality and yield. However, QLED manufacturing benefits from leveraging existing LCD production infrastructure, potentially offering cost advantages. OLED manufacturing, while more complex, allows for the creation of flexible and transparent displays, opening up new design possibilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!