Advanced Flow Control And Optimization For Check Valves

Technology Background And Goals

By analyzing the technological progression, this section will shed light on the critical stages and advancements that have contributed to the current state of the art. It will also highlight the geographical distribution of expertise and research efforts in this field, providing insights into the major players and their contributions. Ultimately, this background analysis will serve as a foundation for understanding the current landscape and informing future strategies for advancing check valve flow control and optimization technologies.

Check Valve Market Demand Analysis

- Market Size and Growth

Analyze the current market size for check valve products and services, including global and regional breakdowns. Estimate the projected growth rate and future market potential based on industry trends and economic factors. - Application Sectors

Identify key application sectors driving demand for check valves, such as oil and gas, power generation, chemical processing, and water treatment. Assess the specific requirements and demand patterns within each sector. - Demand Drivers

Examine the primary factors fueling the demand for advanced check valve solutions, including regulatory compliance, operational efficiency, safety concerns, and environmental considerations. - Customer Segmentation

Segment the customer base for check valve products and services based on factors like industry, company size, and geographic location. Analyze the unique needs and preferences of each customer segment. - Competitive Landscape

Evaluate the competitive landscape, including major players, their market shares, and product offerings. Identify emerging competitors and potential disruptors in the check valve market.

Technology Status And Challenges

- Valve Design Challenges

Intricate geometries and complex flow patterns pose significant challenges in optimizing valve designs for efficient flow control. - Material Limitations

Existing valve materials may not withstand extreme operating conditions, leading to erosion, corrosion, and premature failure. - Cavitation and Noise Issues

Cavitation and excessive noise generation can occur due to high-velocity fluid flow, impacting valve performance and lifespan. - Computational Modeling Limitations

Accurate computational fluid dynamics (CFD) modeling of complex valve geometries and transient flow conditions remains a challenge. - Scaling and Prototyping Difficulties

Scaling up from small-scale prototypes to full-size valves can introduce unforeseen flow behavior and performance issues.

Technology Evolution Path

Current Technical Solutions

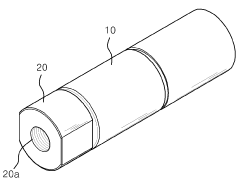

01 Check Valve Structure and Design

Various designs and structures of check valves are disclosed, including valve bodies, valve seats, valve discs, and biasing mechanisms. These designs aim to improve sealing performance, flow efficiency, and reliability.- Check Valve Structure and Design: Various designs and structures of check valves are disclosed, including valve bodies, valve seats, valve members, and biasing mechanisms. These designs aim to improve sealing performance, flow efficiency, and reliability.

- Check Valve Applications and Systems: Check valves are used in various applications and systems, such as fluid flow control, pressure regulation, and backflow prevention. The patents cover the integration of check valves in different systems and their specific applications.

- Check Valve Materials and Manufacturing: The patents disclose the use of different materials and manufacturing processes for check valves, aiming to improve durability, corrosion resistance, and cost-effectiveness.

- Check Valve Control and Monitoring: Methods and systems for controlling and monitoring the operation of check valves are described, including valve position sensing, flow monitoring, and feedback control mechanisms.

- Check Valve Maintenance and Repair: The patents cover techniques and methods for maintaining and repairing check valves, such as valve disassembly, cleaning, and replacement of components.

02 Check Valve Applications and Systems

Check valves are used in various applications and systems, such as fluid flow control, pressure regulation, and backflow prevention. The patents cover the integration of check valves into different systems and their specific applications.03 Check Valve Materials and Manufacturing

The patents disclose the use of different materials and manufacturing processes for check valves, including metals, plastics, and composites. The materials and processes aim to improve durability, corrosion resistance, and cost-effectiveness.04 Check Valve Control and Monitoring

Some patents cover the control and monitoring of check valves, including methods for detecting valve position, monitoring flow conditions, and adjusting valve operation based on feedback or external signals.05 Check Valve Maintenance and Repair

The patents address the maintenance and repair of check valves, including methods for disassembly, cleaning, and replacement of valve components, as well as techniques for extending the service life of check valves.

Technology Main Player Analysis

DENSO Corp.

Ford Global Technologies LLC

Key Technology Interpretation

- The check valve uses a seal ring equipped with an expandable wing that can improve the blocking ability using high-pressure fluid.

- The check valve simplifies the configuration by utilizing the high-pressure fluid to improve sealing ability and prevent deterioration in durability.

- The check valve reliably controls the flow direction of high-pressure fluid while improving sealing ability and durability.

Check Valve Potential Innovation Direction

- Check Valves with Advanced Flow Control and Optimization

- Check Valves with Additive Manufacturing and Topology Optimization

- Check Valves with Integrated Condition Monitoring and Predictive Maintenance