Antifreeze and Its Function in Future Cooling Scenarios

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antifreeze Evolution and Future Cooling Objectives

Antifreeze technology has undergone significant evolution since its inception, driven by the need for more efficient and environmentally friendly cooling solutions. The journey began with simple salt-based mixtures and has progressed to advanced synthetic formulations. Today, the focus is on developing next-generation antifreeze solutions that can meet the demands of emerging technologies and address environmental concerns.

The primary objective of antifreeze research is to enhance thermal management capabilities across various industries. In the automotive sector, the goal is to improve engine efficiency and extend the lifespan of cooling systems. For electronics and data centers, the aim is to develop more effective cooling solutions to handle increasing heat loads from high-performance computing systems.

Another crucial objective is to reduce the environmental impact of antifreeze products. This includes developing biodegradable formulations and minimizing toxicity to wildlife and ecosystems. Researchers are exploring plant-based alternatives and investigating ways to recycle and reuse antifreeze materials to promote sustainability.

In the context of future cooling scenarios, antifreeze technology is expected to play a pivotal role in enabling more efficient and compact cooling systems. This is particularly relevant for electric vehicles, where thermal management of batteries is critical for performance and longevity. The development of smart antifreeze solutions that can adapt to varying conditions and provide real-time feedback is also a key objective.

Nanotechnology is emerging as a promising avenue for antifreeze innovation. Researchers are exploring the use of nanoparticles to enhance heat transfer properties and improve overall cooling efficiency. This could lead to the development of ultra-efficient cooling fluids capable of managing heat in extreme environments.

As global warming continues to impact climate patterns, antifreeze technology is also being adapted to address new challenges. This includes developing formulations that can withstand wider temperature ranges and more frequent freeze-thaw cycles. The goal is to create robust cooling solutions that can maintain performance under increasingly unpredictable weather conditions.

In conclusion, the evolution of antifreeze technology is driven by the need for more efficient, sustainable, and adaptable cooling solutions. Future objectives focus on enhancing performance, reducing environmental impact, and addressing the thermal management challenges posed by emerging technologies and changing climate conditions.

The primary objective of antifreeze research is to enhance thermal management capabilities across various industries. In the automotive sector, the goal is to improve engine efficiency and extend the lifespan of cooling systems. For electronics and data centers, the aim is to develop more effective cooling solutions to handle increasing heat loads from high-performance computing systems.

Another crucial objective is to reduce the environmental impact of antifreeze products. This includes developing biodegradable formulations and minimizing toxicity to wildlife and ecosystems. Researchers are exploring plant-based alternatives and investigating ways to recycle and reuse antifreeze materials to promote sustainability.

In the context of future cooling scenarios, antifreeze technology is expected to play a pivotal role in enabling more efficient and compact cooling systems. This is particularly relevant for electric vehicles, where thermal management of batteries is critical for performance and longevity. The development of smart antifreeze solutions that can adapt to varying conditions and provide real-time feedback is also a key objective.

Nanotechnology is emerging as a promising avenue for antifreeze innovation. Researchers are exploring the use of nanoparticles to enhance heat transfer properties and improve overall cooling efficiency. This could lead to the development of ultra-efficient cooling fluids capable of managing heat in extreme environments.

As global warming continues to impact climate patterns, antifreeze technology is also being adapted to address new challenges. This includes developing formulations that can withstand wider temperature ranges and more frequent freeze-thaw cycles. The goal is to create robust cooling solutions that can maintain performance under increasingly unpredictable weather conditions.

In conclusion, the evolution of antifreeze technology is driven by the need for more efficient, sustainable, and adaptable cooling solutions. Future objectives focus on enhancing performance, reducing environmental impact, and addressing the thermal management challenges posed by emerging technologies and changing climate conditions.

Market Analysis for Advanced Cooling Solutions

The market for advanced cooling solutions is experiencing significant growth, driven by increasing demand across various industries. As global temperatures rise and energy efficiency becomes a paramount concern, the need for innovative cooling technologies has never been more pressing. The automotive sector, in particular, is witnessing a surge in demand for advanced cooling solutions, especially with the rapid adoption of electric vehicles (EVs) and the development of autonomous driving systems.

In the EV market, thermal management is crucial for battery performance and longevity. Traditional cooling methods are often inadequate for the high-power density batteries used in EVs, creating a substantial market opportunity for advanced cooling solutions. The data center industry is another key driver, with the exponential growth of cloud computing and big data necessitating more efficient cooling systems to manage the heat generated by high-performance servers.

The aerospace and defense sectors are also significant contributors to the market demand for advanced cooling solutions. As aircraft and military equipment become more sophisticated, the need for effective thermal management systems increases. Additionally, the growing focus on space exploration and satellite technology is opening new avenues for specialized cooling solutions capable of functioning in extreme environments.

In the consumer electronics market, the trend towards more powerful and compact devices is driving the need for innovative cooling technologies. Smartphones, laptops, and gaming consoles are pushing the boundaries of performance, requiring advanced thermal management to prevent overheating and maintain optimal functionality.

The industrial sector presents another substantial market for advanced cooling solutions. As manufacturing processes become more automated and energy-intensive, the demand for efficient cooling systems to maintain equipment performance and longevity is rising. This is particularly evident in industries such as chemical processing, metallurgy, and semiconductor manufacturing, where precise temperature control is critical.

The global push for sustainability and energy efficiency is also shaping the market landscape. Governments and organizations worldwide are implementing stricter regulations on energy consumption and emissions, driving the adoption of eco-friendly cooling solutions. This trend is creating opportunities for technologies that not only provide effective cooling but also minimize environmental impact.

As the market for advanced cooling solutions continues to expand, competition among key players is intensifying. Established companies are investing heavily in research and development to maintain their market position, while innovative startups are entering the space with disruptive technologies. This competitive landscape is fostering rapid technological advancements and driving down costs, making advanced cooling solutions more accessible across various industries.

In the EV market, thermal management is crucial for battery performance and longevity. Traditional cooling methods are often inadequate for the high-power density batteries used in EVs, creating a substantial market opportunity for advanced cooling solutions. The data center industry is another key driver, with the exponential growth of cloud computing and big data necessitating more efficient cooling systems to manage the heat generated by high-performance servers.

The aerospace and defense sectors are also significant contributors to the market demand for advanced cooling solutions. As aircraft and military equipment become more sophisticated, the need for effective thermal management systems increases. Additionally, the growing focus on space exploration and satellite technology is opening new avenues for specialized cooling solutions capable of functioning in extreme environments.

In the consumer electronics market, the trend towards more powerful and compact devices is driving the need for innovative cooling technologies. Smartphones, laptops, and gaming consoles are pushing the boundaries of performance, requiring advanced thermal management to prevent overheating and maintain optimal functionality.

The industrial sector presents another substantial market for advanced cooling solutions. As manufacturing processes become more automated and energy-intensive, the demand for efficient cooling systems to maintain equipment performance and longevity is rising. This is particularly evident in industries such as chemical processing, metallurgy, and semiconductor manufacturing, where precise temperature control is critical.

The global push for sustainability and energy efficiency is also shaping the market landscape. Governments and organizations worldwide are implementing stricter regulations on energy consumption and emissions, driving the adoption of eco-friendly cooling solutions. This trend is creating opportunities for technologies that not only provide effective cooling but also minimize environmental impact.

As the market for advanced cooling solutions continues to expand, competition among key players is intensifying. Established companies are investing heavily in research and development to maintain their market position, while innovative startups are entering the space with disruptive technologies. This competitive landscape is fostering rapid technological advancements and driving down costs, making advanced cooling solutions more accessible across various industries.

Current Antifreeze Technology Challenges

The current challenges in antifreeze technology primarily revolve around environmental concerns, performance limitations, and adaptability to future cooling scenarios. Traditional antifreeze solutions, such as ethylene glycol and propylene glycol, have been widely used for decades but are facing increasing scrutiny due to their environmental impact and toxicity.

One of the main challenges is the development of more environmentally friendly alternatives that maintain or improve upon the performance of conventional antifreeze solutions. While some bio-based options have been introduced, they often struggle to match the efficiency and cost-effectiveness of traditional products. The search for sustainable, non-toxic formulations that can withstand extreme temperature ranges remains a significant hurdle.

Another critical challenge is the need for antifreeze solutions that can adapt to the evolving requirements of future cooling systems, particularly in electric vehicles (EVs) and advanced industrial applications. As EV batteries require precise temperature management for optimal performance and longevity, antifreeze formulations must be tailored to meet these specific needs while also being compatible with new materials used in EV cooling systems.

The increasing demand for data centers and high-performance computing facilities also presents unique challenges for antifreeze technology. These applications require cooling solutions that can efficiently dissipate heat while maintaining system reliability under continuous operation. Current antifreeze formulations may not be optimized for these intensive cooling scenarios, necessitating further research and development.

Corrosion prevention remains a persistent challenge in antifreeze technology. As cooling systems become more complex and incorporate a wider range of materials, including advanced alloys and composites, antifreeze solutions must provide comprehensive corrosion protection without compromising heat transfer efficiency or system longevity.

Furthermore, the global push towards reducing water consumption in industrial processes has created a need for antifreeze solutions that can function effectively in low-water or waterless cooling systems. This shift requires innovative approaches to heat transfer and thermal management that go beyond traditional water-based antifreeze formulations.

Lastly, the challenge of improving the overall efficiency of antifreeze solutions in terms of heat transfer capabilities and thermal conductivity remains paramount. As cooling demands increase across various sectors, from automotive to renewable energy systems, there is a pressing need for antifreeze technologies that can deliver superior thermal performance while meeting stringent environmental and safety standards.

One of the main challenges is the development of more environmentally friendly alternatives that maintain or improve upon the performance of conventional antifreeze solutions. While some bio-based options have been introduced, they often struggle to match the efficiency and cost-effectiveness of traditional products. The search for sustainable, non-toxic formulations that can withstand extreme temperature ranges remains a significant hurdle.

Another critical challenge is the need for antifreeze solutions that can adapt to the evolving requirements of future cooling systems, particularly in electric vehicles (EVs) and advanced industrial applications. As EV batteries require precise temperature management for optimal performance and longevity, antifreeze formulations must be tailored to meet these specific needs while also being compatible with new materials used in EV cooling systems.

The increasing demand for data centers and high-performance computing facilities also presents unique challenges for antifreeze technology. These applications require cooling solutions that can efficiently dissipate heat while maintaining system reliability under continuous operation. Current antifreeze formulations may not be optimized for these intensive cooling scenarios, necessitating further research and development.

Corrosion prevention remains a persistent challenge in antifreeze technology. As cooling systems become more complex and incorporate a wider range of materials, including advanced alloys and composites, antifreeze solutions must provide comprehensive corrosion protection without compromising heat transfer efficiency or system longevity.

Furthermore, the global push towards reducing water consumption in industrial processes has created a need for antifreeze solutions that can function effectively in low-water or waterless cooling systems. This shift requires innovative approaches to heat transfer and thermal management that go beyond traditional water-based antifreeze formulations.

Lastly, the challenge of improving the overall efficiency of antifreeze solutions in terms of heat transfer capabilities and thermal conductivity remains paramount. As cooling demands increase across various sectors, from automotive to renewable energy systems, there is a pressing need for antifreeze technologies that can deliver superior thermal performance while meeting stringent environmental and safety standards.

Existing Antifreeze Formulations

01 Composition of antifreeze coolants

Antifreeze coolants are typically composed of a mixture of water and chemical additives. These additives, such as ethylene glycol or propylene glycol, lower the freezing point and raise the boiling point of the solution, enhancing its cooling efficiency. The composition may also include corrosion inhibitors and other performance-enhancing agents to protect the cooling system and improve heat transfer.- Composition of antifreeze coolants: Antifreeze coolants are typically composed of a mixture of water and chemical additives. These additives, such as ethylene glycol or propylene glycol, lower the freezing point and raise the boiling point of the solution, improving its cooling efficiency across a wide temperature range. The composition may also include corrosion inhibitors and other performance-enhancing agents to protect the cooling system and maintain optimal heat transfer properties.

- Nanofluid-based antifreeze solutions: Incorporating nanoparticles into antifreeze solutions can significantly enhance their thermal conductivity and heat transfer capabilities. These nanofluids typically consist of a base fluid (such as traditional antifreeze) with suspended nanoparticles of materials like metals, oxides, or carbon nanotubes. The increased surface area of nanoparticles leads to improved heat exchange efficiency, potentially allowing for more compact and effective cooling systems.

- Advanced heat exchange systems: Innovative heat exchange systems can improve the cooling efficiency of antifreeze solutions. These may include specially designed radiators, heat sinks, or microchannel heat exchangers that maximize the contact area between the coolant and the heat source. Some systems incorporate phase change materials or thermoelectric devices to enhance heat dissipation. The optimization of flow patterns and the use of turbulence-inducing structures can also contribute to improved heat transfer rates.

- Smart cooling management systems: Intelligent cooling management systems can optimize the performance of antifreeze coolants. These systems may use sensors to monitor temperature, pressure, and flow rates in real-time, adjusting coolant circulation and heat exchange parameters accordingly. Advanced control algorithms can predict cooling needs based on operating conditions, ensuring efficient use of the antifreeze solution. Some systems may also incorporate adaptive features that learn from past performance to continually improve cooling efficiency.

- Environmentally friendly antifreeze formulations: Development of eco-friendly antifreeze solutions focuses on improving cooling efficiency while reducing environmental impact. These formulations may use biodegradable base fluids, such as propylene glycol or glycerin, instead of more toxic ethylene glycol. Some solutions incorporate natural additives or renewable resources to enhance performance. Advanced filtration and recycling techniques can also be employed to extend the life of the antifreeze and minimize waste, contributing to overall system efficiency and sustainability.

02 Nanofluid-based antifreeze solutions

Incorporating nanoparticles into antifreeze solutions can significantly improve their thermal conductivity and heat transfer properties. These nanofluids can enhance the overall cooling efficiency of the system by increasing the rate of heat dissipation. The size, type, and concentration of nanoparticles can be optimized to achieve the best cooling performance.Expand Specific Solutions03 Advanced heat exchange systems

Innovative heat exchange systems can improve the cooling efficiency of antifreeze solutions. These may include specially designed radiators, heat sinks, or cooling channels that maximize the surface area for heat transfer. Some systems may also incorporate phase change materials or thermoelectric devices to enhance cooling performance.Expand Specific Solutions04 Intelligent cooling management

Smart cooling systems that utilize sensors, controllers, and algorithms can optimize the use of antifreeze coolants. These systems can adjust coolant flow rates, monitor temperatures, and regulate cooling cycles based on real-time data, leading to improved overall cooling efficiency and energy savings.Expand Specific Solutions05 Environmentally friendly antifreeze formulations

Development of eco-friendly antifreeze solutions that maintain high cooling efficiency while reducing environmental impact. These formulations may use biodegradable materials, natural additives, or recycled components. They aim to provide effective cooling performance while addressing concerns about toxicity and disposal of traditional antifreeze coolants.Expand Specific Solutions

Key Antifreeze Industry Players

The research on antifreeze and its function in future cooling scenarios is in a mature stage, with a competitive landscape shaped by established players and ongoing innovation. The market size is substantial, driven by the automotive and industrial sectors' demand for advanced cooling solutions. Technologically, the field is evolving, with companies like BASF Corp., Honda Motor Co., Ltd., and Adeka Corp. leading in developing eco-friendly and high-performance antifreeze formulations. The industry is transitioning towards more sustainable and efficient cooling technologies, with a focus on electric vehicle applications and environmentally friendly alternatives. Major automotive manufacturers such as Audi AG and Hyundai Motor Co., Ltd. are actively investing in research to optimize antifreeze performance for next-generation vehicles.

BASF Corp.

Technical Solution: BASF Corp. has developed advanced antifreeze solutions for future cooling scenarios, focusing on environmentally friendly and high-performance products. Their research includes the development of propylene glycol-based antifreeze, which offers improved biodegradability and reduced toxicity compared to traditional ethylene glycol-based products[1]. BASF has also introduced innovative additives to enhance the thermal conductivity and heat transfer properties of their antifreeze formulations, potentially improving the efficiency of cooling systems in various applications[2]. The company is exploring the use of nanoparticles in antifreeze solutions to further enhance heat transfer capabilities and reduce pumping power requirements in cooling systems[3].

Strengths: Extensive R&D capabilities, focus on eco-friendly solutions, and a wide range of applications. Weaknesses: Higher production costs for advanced formulations and potential regulatory challenges for new additives.

Honda Motor Co., Ltd.

Technical Solution: Honda Motor Co., Ltd. has been researching advanced cooling technologies for their vehicles, including innovative antifreeze solutions. They have developed a new type of antifreeze that incorporates organic acid technology (OAT), which provides extended service life and improved corrosion protection for engine cooling systems[1]. Honda's research also focuses on optimizing the antifreeze concentration and flow rates in their cooling systems to enhance overall thermal management efficiency[2]. The company is exploring the integration of smart sensors and control systems to dynamically adjust antifreeze properties based on real-time operating conditions, potentially improving fuel efficiency and reducing emissions[3].

Strengths: Extensive automotive expertise, integration of cooling systems with vehicle design, and focus on long-term durability. Weaknesses: Limited application outside the automotive sector and potential higher costs for advanced systems.

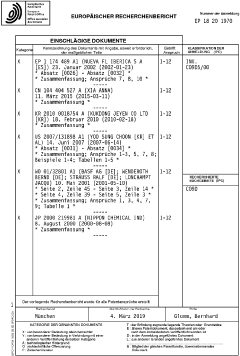

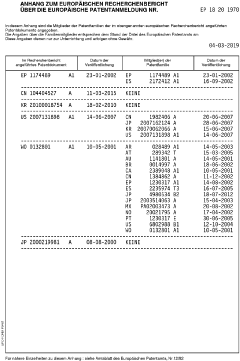

Innovative Antifreeze Patents

Antifreeze

PatentInactiveEP3476903A1

Innovation

- A combination of succinic acid, benzotriazole, and potassium hydroxide (KOH) with a pH range of 10.4 to 10.8, or succinic acid, cinnamic acid, benzotriazole, and KOH with a pH range of 8.5 to 10.8, which synergistically provides excellent frost protection and corrosion protection for all common metals, including solder, while reducing the need for high benzotriazole concentrations.

Antifreeze/liquid coolant composition and method of use

PatentInactiveUS20070090324A1

Innovation

- A non-hazardous antifreeze coolant composition comprising glycerine, anti-oxidants, and boron-based film formers, with optional water addition, that enhances temperature stability, prevents corrosion and scale formation, and ensures effective heat transfer across a wide temperature range.

Environmental Impact of Antifreeze

The environmental impact of antifreeze is a critical consideration in the research and development of cooling technologies. Traditional antifreeze solutions, primarily based on ethylene glycol or propylene glycol, have raised significant environmental concerns due to their toxicity and persistence in ecosystems.

When antifreeze leaks or is improperly disposed of, it can contaminate soil and water sources, posing serious risks to wildlife and aquatic organisms. The sweet taste of ethylene glycol-based antifreeze can attract animals, leading to poisoning and potential fatalities. Furthermore, the biodegradation of these substances can deplete oxygen levels in water bodies, adversely affecting aquatic life.

In response to these environmental challenges, researchers are exploring more eco-friendly alternatives. Bio-based antifreeze solutions derived from renewable resources, such as glycerol from biodiesel production or propanediol from corn sugar fermentation, are gaining attention. These alternatives offer reduced toxicity and improved biodegradability, minimizing their environmental footprint.

Another avenue of research focuses on developing antifreeze formulations with enhanced thermal properties, allowing for smaller quantities to be used while maintaining effective cooling performance. This approach not only reduces the volume of potentially harmful substances but also contributes to resource conservation and waste reduction.

Nanotechnology is emerging as a promising field for environmentally friendly antifreeze solutions. Nanofluids, which incorporate nanoparticles into base fluids, have shown potential for improving heat transfer efficiency and reducing the required concentration of antifreeze compounds. This could lead to more sustainable cooling systems with minimal environmental impact.

The development of closed-loop cooling systems and improved recycling technologies for antifreeze solutions is also crucial in mitigating environmental risks. By implementing efficient recovery and purification processes, the lifecycle of antifreeze can be extended, reducing the need for new production and minimizing waste.

As regulations become more stringent regarding the use and disposal of antifreeze, there is a growing emphasis on developing products that meet both performance requirements and environmental standards. This has led to increased collaboration between chemical engineers, environmental scientists, and regulatory bodies to create innovative solutions that balance cooling efficiency with ecological responsibility.

When antifreeze leaks or is improperly disposed of, it can contaminate soil and water sources, posing serious risks to wildlife and aquatic organisms. The sweet taste of ethylene glycol-based antifreeze can attract animals, leading to poisoning and potential fatalities. Furthermore, the biodegradation of these substances can deplete oxygen levels in water bodies, adversely affecting aquatic life.

In response to these environmental challenges, researchers are exploring more eco-friendly alternatives. Bio-based antifreeze solutions derived from renewable resources, such as glycerol from biodiesel production or propanediol from corn sugar fermentation, are gaining attention. These alternatives offer reduced toxicity and improved biodegradability, minimizing their environmental footprint.

Another avenue of research focuses on developing antifreeze formulations with enhanced thermal properties, allowing for smaller quantities to be used while maintaining effective cooling performance. This approach not only reduces the volume of potentially harmful substances but also contributes to resource conservation and waste reduction.

Nanotechnology is emerging as a promising field for environmentally friendly antifreeze solutions. Nanofluids, which incorporate nanoparticles into base fluids, have shown potential for improving heat transfer efficiency and reducing the required concentration of antifreeze compounds. This could lead to more sustainable cooling systems with minimal environmental impact.

The development of closed-loop cooling systems and improved recycling technologies for antifreeze solutions is also crucial in mitigating environmental risks. By implementing efficient recovery and purification processes, the lifecycle of antifreeze can be extended, reducing the need for new production and minimizing waste.

As regulations become more stringent regarding the use and disposal of antifreeze, there is a growing emphasis on developing products that meet both performance requirements and environmental standards. This has led to increased collaboration between chemical engineers, environmental scientists, and regulatory bodies to create innovative solutions that balance cooling efficiency with ecological responsibility.

Regulatory Framework for Coolants

The regulatory framework for coolants, particularly antifreeze, is a critical aspect of ensuring safety and environmental protection in future cooling scenarios. As the automotive and industrial sectors continue to evolve, regulations governing the use of coolants have become increasingly stringent.

At the international level, organizations such as the United Nations Environment Programme (UNEP) have established guidelines for the production, use, and disposal of coolants. These guidelines aim to reduce the environmental impact of coolants, particularly those with high global warming potential (GWP) or ozone depletion potential (ODP).

In the United States, the Environmental Protection Agency (EPA) regulates coolants under the Significant New Alternatives Policy (SNAP) program. This program evaluates and regulates substitutes for ozone-depleting substances to reduce overall risk to human health and the environment. The EPA has also implemented regulations to prevent the release of coolants into the atmosphere during servicing, maintenance, and disposal of equipment.

The European Union has implemented the F-Gas Regulation, which aims to reduce emissions of fluorinated greenhouse gases, including many common coolants. This regulation sets quotas for the production and import of these gases and mandates regular leak checks for equipment containing significant quantities of coolants.

In the automotive sector, regulations such as the EU's End-of-Life Vehicles Directive require manufacturers to design vehicles with improved recyclability and to reduce the use of hazardous substances, including certain coolants. This has led to the development of more environmentally friendly antifreeze formulations.

Many countries have also implemented product stewardship programs for coolants, requiring manufacturers and importers to take responsibility for the entire lifecycle of their products. These programs often include requirements for proper labeling, handling, and disposal of coolants.

As research into new antifreeze technologies progresses, regulatory bodies are likely to update their frameworks to address emerging concerns and opportunities. This may include regulations promoting the use of bio-based or renewable coolants, as well as stricter controls on the disposal and recycling of used coolants.

The future regulatory landscape for coolants is expected to focus on further reducing environmental impact, improving energy efficiency, and ensuring the safe handling and disposal of these substances. As such, ongoing research into antifreeze and its function in future cooling scenarios must consider these regulatory trends to ensure compliance and market viability.

At the international level, organizations such as the United Nations Environment Programme (UNEP) have established guidelines for the production, use, and disposal of coolants. These guidelines aim to reduce the environmental impact of coolants, particularly those with high global warming potential (GWP) or ozone depletion potential (ODP).

In the United States, the Environmental Protection Agency (EPA) regulates coolants under the Significant New Alternatives Policy (SNAP) program. This program evaluates and regulates substitutes for ozone-depleting substances to reduce overall risk to human health and the environment. The EPA has also implemented regulations to prevent the release of coolants into the atmosphere during servicing, maintenance, and disposal of equipment.

The European Union has implemented the F-Gas Regulation, which aims to reduce emissions of fluorinated greenhouse gases, including many common coolants. This regulation sets quotas for the production and import of these gases and mandates regular leak checks for equipment containing significant quantities of coolants.

In the automotive sector, regulations such as the EU's End-of-Life Vehicles Directive require manufacturers to design vehicles with improved recyclability and to reduce the use of hazardous substances, including certain coolants. This has led to the development of more environmentally friendly antifreeze formulations.

Many countries have also implemented product stewardship programs for coolants, requiring manufacturers and importers to take responsibility for the entire lifecycle of their products. These programs often include requirements for proper labeling, handling, and disposal of coolants.

As research into new antifreeze technologies progresses, regulatory bodies are likely to update their frameworks to address emerging concerns and opportunities. This may include regulations promoting the use of bio-based or renewable coolants, as well as stricter controls on the disposal and recycling of used coolants.

The future regulatory landscape for coolants is expected to focus on further reducing environmental impact, improving energy efficiency, and ensuring the safe handling and disposal of these substances. As such, ongoing research into antifreeze and its function in future cooling scenarios must consider these regulatory trends to ensure compliance and market viability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!