Borosilicate Glass as Catalyst Support in Chemical Reactions

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Borosilicate Glass Catalysis Background

Borosilicate glass has emerged as a promising catalyst support material in chemical reactions, offering a unique combination of properties that make it suitable for various catalytic applications. The development of borosilicate glass as a catalyst support can be traced back to the early 20th century when its exceptional thermal and chemical resistance properties were first recognized.

Initially, borosilicate glass was primarily used in laboratory glassware and industrial applications due to its low thermal expansion coefficient and high resistance to chemical corrosion. However, researchers soon began to explore its potential as a catalyst support, recognizing its ability to withstand harsh reaction conditions and maintain structural integrity.

The evolution of borosilicate glass as a catalyst support has been driven by the increasing demand for more efficient and selective catalytic processes in various industries, including petrochemicals, fine chemicals, and environmental remediation. Its amorphous structure and high surface area make it an ideal substrate for dispersing catalytic active sites, enhancing the overall catalytic performance.

One of the key advantages of borosilicate glass as a catalyst support is its transparency, which allows for in-situ spectroscopic studies of catalytic reactions. This feature has greatly facilitated the understanding of reaction mechanisms and the development of more efficient catalytic systems.

Over the years, significant advancements have been made in the synthesis and modification of borosilicate glass to tailor its properties for specific catalytic applications. These include the development of porous borosilicate glasses with controlled pore sizes and distributions, as well as the incorporation of various functional groups on the glass surface to enhance catalyst-support interactions.

The use of borosilicate glass as a catalyst support has also been extended to the field of photocatalysis, where its optical properties play a crucial role in light-driven reactions. This has opened up new avenues for applications in environmental remediation and renewable energy production.

Recent research has focused on the development of composite materials that combine borosilicate glass with other support materials, such as metal oxides or carbon-based materials, to create synergistic effects and enhance catalytic performance. These hybrid systems have shown promising results in various catalytic reactions, including oxidation, hydrogenation, and C-C coupling reactions.

As the field of catalysis continues to evolve, borosilicate glass remains an important material in the development of novel catalyst support systems. Its versatility, stability, and unique properties make it a valuable tool for researchers and industry professionals seeking to improve the efficiency and selectivity of chemical reactions.

Initially, borosilicate glass was primarily used in laboratory glassware and industrial applications due to its low thermal expansion coefficient and high resistance to chemical corrosion. However, researchers soon began to explore its potential as a catalyst support, recognizing its ability to withstand harsh reaction conditions and maintain structural integrity.

The evolution of borosilicate glass as a catalyst support has been driven by the increasing demand for more efficient and selective catalytic processes in various industries, including petrochemicals, fine chemicals, and environmental remediation. Its amorphous structure and high surface area make it an ideal substrate for dispersing catalytic active sites, enhancing the overall catalytic performance.

One of the key advantages of borosilicate glass as a catalyst support is its transparency, which allows for in-situ spectroscopic studies of catalytic reactions. This feature has greatly facilitated the understanding of reaction mechanisms and the development of more efficient catalytic systems.

Over the years, significant advancements have been made in the synthesis and modification of borosilicate glass to tailor its properties for specific catalytic applications. These include the development of porous borosilicate glasses with controlled pore sizes and distributions, as well as the incorporation of various functional groups on the glass surface to enhance catalyst-support interactions.

The use of borosilicate glass as a catalyst support has also been extended to the field of photocatalysis, where its optical properties play a crucial role in light-driven reactions. This has opened up new avenues for applications in environmental remediation and renewable energy production.

Recent research has focused on the development of composite materials that combine borosilicate glass with other support materials, such as metal oxides or carbon-based materials, to create synergistic effects and enhance catalytic performance. These hybrid systems have shown promising results in various catalytic reactions, including oxidation, hydrogenation, and C-C coupling reactions.

As the field of catalysis continues to evolve, borosilicate glass remains an important material in the development of novel catalyst support systems. Its versatility, stability, and unique properties make it a valuable tool for researchers and industry professionals seeking to improve the efficiency and selectivity of chemical reactions.

Market Analysis for Catalytic Supports

The market for catalytic supports, particularly borosilicate glass, is experiencing significant growth driven by increasing demand in various chemical industries. The global catalyst market, which includes supports, is projected to reach $34.3 billion by 2024, with a compound annual growth rate (CAGR) of 4.4%. Within this market, the demand for borosilicate glass as a catalyst support is gaining traction due to its unique properties and versatility in chemical reactions.

Borosilicate glass offers several advantages as a catalyst support, including high thermal and chemical stability, low thermal expansion, and excellent transparency. These properties make it particularly suitable for applications in petrochemicals, fine chemicals, and environmental catalysis. The petrochemical industry, in particular, is a major driver of demand for borosilicate glass catalyst supports, as it requires materials that can withstand harsh reaction conditions.

The market for borosilicate glass catalyst supports is also benefiting from the growing emphasis on green chemistry and sustainable production processes. As industries seek to reduce their environmental footprint, there is an increasing focus on developing more efficient and selective catalysts. Borosilicate glass supports can contribute to this goal by enhancing catalyst performance and enabling more environmentally friendly chemical processes.

Geographically, Asia-Pacific is expected to be the fastest-growing market for catalyst supports, including borosilicate glass. This growth is primarily driven by the rapid industrialization and increasing investments in chemical manufacturing in countries like China and India. North America and Europe remain significant markets, with a focus on advanced applications and research in catalysis.

The competitive landscape for borosilicate glass catalyst supports is characterized by a mix of established glass manufacturers and specialized catalyst support producers. Key players are investing in research and development to improve the properties of borosilicate glass supports and expand their application range. Collaborations between academic institutions and industry are also playing a crucial role in driving innovation in this field.

Despite the positive market outlook, challenges remain. The high cost of borosilicate glass compared to some alternative support materials may limit its adoption in certain applications. Additionally, the development of new support materials, such as advanced ceramics and structured materials, poses competition to borosilicate glass in specific market segments.

Borosilicate glass offers several advantages as a catalyst support, including high thermal and chemical stability, low thermal expansion, and excellent transparency. These properties make it particularly suitable for applications in petrochemicals, fine chemicals, and environmental catalysis. The petrochemical industry, in particular, is a major driver of demand for borosilicate glass catalyst supports, as it requires materials that can withstand harsh reaction conditions.

The market for borosilicate glass catalyst supports is also benefiting from the growing emphasis on green chemistry and sustainable production processes. As industries seek to reduce their environmental footprint, there is an increasing focus on developing more efficient and selective catalysts. Borosilicate glass supports can contribute to this goal by enhancing catalyst performance and enabling more environmentally friendly chemical processes.

Geographically, Asia-Pacific is expected to be the fastest-growing market for catalyst supports, including borosilicate glass. This growth is primarily driven by the rapid industrialization and increasing investments in chemical manufacturing in countries like China and India. North America and Europe remain significant markets, with a focus on advanced applications and research in catalysis.

The competitive landscape for borosilicate glass catalyst supports is characterized by a mix of established glass manufacturers and specialized catalyst support producers. Key players are investing in research and development to improve the properties of borosilicate glass supports and expand their application range. Collaborations between academic institutions and industry are also playing a crucial role in driving innovation in this field.

Despite the positive market outlook, challenges remain. The high cost of borosilicate glass compared to some alternative support materials may limit its adoption in certain applications. Additionally, the development of new support materials, such as advanced ceramics and structured materials, poses competition to borosilicate glass in specific market segments.

Current Challenges in Borosilicate Glass Catalysis

Despite the promising potential of borosilicate glass as a catalyst support in chemical reactions, several significant challenges currently hinder its widespread adoption and optimal performance. One of the primary obstacles is the limited surface area of borosilicate glass compared to traditional catalyst supports. This constraint reduces the number of active sites available for catalytic reactions, potentially decreasing overall efficiency and reaction rates.

Another challenge lies in the surface modification of borosilicate glass to enhance its catalytic properties. While various techniques have been developed to functionalize the glass surface, achieving uniform and stable modifications across large surface areas remains difficult. This inconsistency can lead to variations in catalytic activity and selectivity, impacting the reliability and reproducibility of chemical processes.

The thermal and chemical stability of borosilicate glass under harsh reaction conditions also presents a significant challenge. Although borosilicate glass is known for its resistance to thermal shock and chemical corrosion, prolonged exposure to extreme temperatures or highly reactive substances can still cause degradation. This deterioration may result in the loss of catalytic activity or the introduction of unwanted contaminants into the reaction system.

Furthermore, the integration of borosilicate glass catalyst supports into existing industrial processes poses technical and economic challenges. Many current chemical production systems are optimized for traditional catalyst supports, and the transition to borosilicate glass-based catalysts may require significant modifications to equipment and processes. This adaptation can be costly and time-consuming, potentially deterring industry adoption.

The development of efficient methods for catalyst recovery and regeneration is another area of concern. Unlike some conventional catalyst supports, borosilicate glass may not be as amenable to standard regeneration techniques. This limitation could impact the long-term economic viability of borosilicate glass-based catalytic systems, particularly in large-scale industrial applications where catalyst longevity and recyclability are crucial factors.

Lastly, there is a need for more comprehensive understanding of the interaction between borosilicate glass surfaces and various catalytic species. The mechanisms by which different catalysts adhere to and function on borosilicate glass are not fully elucidated, making it challenging to optimize catalyst design and predict performance across a wide range of chemical reactions. Addressing these knowledge gaps requires extensive research and characterization efforts, which are ongoing but still incomplete.

Another challenge lies in the surface modification of borosilicate glass to enhance its catalytic properties. While various techniques have been developed to functionalize the glass surface, achieving uniform and stable modifications across large surface areas remains difficult. This inconsistency can lead to variations in catalytic activity and selectivity, impacting the reliability and reproducibility of chemical processes.

The thermal and chemical stability of borosilicate glass under harsh reaction conditions also presents a significant challenge. Although borosilicate glass is known for its resistance to thermal shock and chemical corrosion, prolonged exposure to extreme temperatures or highly reactive substances can still cause degradation. This deterioration may result in the loss of catalytic activity or the introduction of unwanted contaminants into the reaction system.

Furthermore, the integration of borosilicate glass catalyst supports into existing industrial processes poses technical and economic challenges. Many current chemical production systems are optimized for traditional catalyst supports, and the transition to borosilicate glass-based catalysts may require significant modifications to equipment and processes. This adaptation can be costly and time-consuming, potentially deterring industry adoption.

The development of efficient methods for catalyst recovery and regeneration is another area of concern. Unlike some conventional catalyst supports, borosilicate glass may not be as amenable to standard regeneration techniques. This limitation could impact the long-term economic viability of borosilicate glass-based catalytic systems, particularly in large-scale industrial applications where catalyst longevity and recyclability are crucial factors.

Lastly, there is a need for more comprehensive understanding of the interaction between borosilicate glass surfaces and various catalytic species. The mechanisms by which different catalysts adhere to and function on borosilicate glass are not fully elucidated, making it challenging to optimize catalyst design and predict performance across a wide range of chemical reactions. Addressing these knowledge gaps requires extensive research and characterization efforts, which are ongoing but still incomplete.

Existing Borosilicate Glass Catalyst Solutions

01 Composition and properties of borosilicate glass

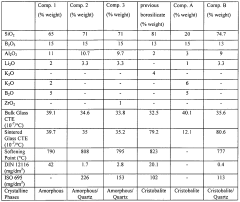

Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. It is known for its low thermal expansion coefficient, high chemical resistance, and excellent thermal shock resistance. These properties make it suitable for various applications in laboratory equipment, cookware, and industrial uses.- Composition and properties of borosilicate glass: Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. It is known for its low thermal expansion coefficient, high chemical resistance, and excellent thermal shock resistance. These properties make it suitable for various applications in laboratory equipment, cookware, and industrial uses.

- Manufacturing processes for borosilicate glass: Various manufacturing processes are employed to produce borosilicate glass, including melting, forming, and annealing. Advanced techniques such as float glass production and precision molding are used to create different forms of borosilicate glass products. The manufacturing process can be optimized to enhance specific properties of the glass.

- Applications of borosilicate glass in laboratory and industrial settings: Borosilicate glass is widely used in laboratory glassware, such as beakers, test tubes, and pipettes, due to its chemical resistance and thermal stability. It is also employed in industrial applications, including sight glasses, level gauges, and process vessels, where its durability and transparency are advantageous.

- Borosilicate glass in optical and lighting applications: The optical properties of borosilicate glass make it suitable for use in various lighting and optical applications. It is used in the production of lenses, mirrors, and other optical components. Borosilicate glass is also employed in the manufacturing of light bulbs, LED encapsulations, and other lighting products due to its heat resistance and light transmission characteristics.

- Innovations and modifications in borosilicate glass technology: Ongoing research and development in borosilicate glass technology focus on improving its properties and expanding its applications. This includes the development of new compositions, surface treatments, and manufacturing techniques to enhance specific characteristics such as strength, transparency, or chemical resistance. Recent innovations also explore the integration of borosilicate glass with other materials for advanced applications.

02 Manufacturing processes for borosilicate glass

Various manufacturing processes are employed to produce borosilicate glass, including melting, forming, and annealing. Advanced techniques such as float glass production and precision molding are used to create high-quality borosilicate glass products with specific shapes and properties. The manufacturing process often involves careful control of temperature and composition to achieve desired characteristics.Expand Specific Solutions03 Applications of borosilicate glass in laboratory and industrial settings

Borosilicate glass is widely used in laboratory glassware, such as beakers, test tubes, and flasks, due to its chemical resistance and thermal stability. It is also employed in industrial applications, including chemical processing equipment, sight glasses, and high-temperature windows. The material's durability and transparency make it ideal for these demanding environments.Expand Specific Solutions04 Borosilicate glass in consumer products

Borosilicate glass is increasingly used in consumer products, particularly in kitchenware and household items. Its heat resistance and durability make it suitable for bakeware, storage containers, and coffee makers. The material's clarity and ability to withstand temperature changes also make it popular for artistic glassware and decorative objects.Expand Specific Solutions05 Innovations and modifications in borosilicate glass

Ongoing research and development in borosilicate glass focus on improving its properties and expanding its applications. This includes developing new compositions with enhanced characteristics, such as increased strength or improved optical properties. Innovations also involve surface treatments, coatings, and the incorporation of additional elements to create specialized borosilicate glass products for specific industries or applications.Expand Specific Solutions

Key Players in Catalytic Support Industry

The research on borosilicate glass as a catalyst support in chemical reactions is in a mature stage, with a well-established market and significant industry players. The global market for specialty glass, including borosilicate glass, is projected to reach $131 billion by 2025, driven by increasing demand in pharmaceuticals, electronics, and chemical industries. Leading companies like SCHOTT AG, Corning, Inc., and Nippon Electric Glass Co., Ltd. have extensive experience in developing and manufacturing high-quality borosilicate glass products. These firms, along with emerging players such as Hunan Kibing Pharmaceutical Material Technology Co., Ltd., are investing in R&D to enhance the performance and applications of borosilicate glass as catalyst supports, indicating a competitive and innovation-driven landscape.

SCHOTT AG

Technical Solution: SCHOTT AG has developed advanced borosilicate glass compositions specifically tailored for catalytic applications. Their NEXTREMA® glass-ceramic material exhibits high thermal shock resistance and chemical durability, making it ideal for catalyst support in high-temperature chemical reactions[1]. SCHOTT's borosilicate glass supports feature precisely controlled porosity and surface area, enhancing catalyst dispersion and activity. The company has also introduced innovative manufacturing processes to create complex glass structures, such as honeycomb monoliths, which provide increased surface area for catalyst loading while maintaining excellent mass transfer properties[2].

Strengths: High thermal and chemical stability, customizable porosity, and advanced manufacturing capabilities. Weaknesses: Higher cost compared to traditional ceramic supports, potential limitations in scaling up complex glass structures.

Corning, Inc.

Technical Solution: Corning has pioneered the use of borosilicate glass as a catalyst support through its Celcor® substrate technology. This honeycomb structure, made from thin-walled borosilicate glass, provides a high surface area-to-volume ratio, crucial for efficient catalytic reactions[3]. Corning's borosilicate glass supports are engineered with precise control over pore size distribution and wall thickness, optimizing catalyst loading and reaction efficiency. The company has also developed a proprietary coating process that enhances the adhesion of catalytic materials to the glass surface, improving durability and performance in harsh chemical environments[4]. Recent advancements include the integration of nanostructured borosilicate glass supports, which further increase surface area and catalytic activity[5].

Strengths: Extensive experience in glass technology, advanced manufacturing capabilities for complex structures, and proven performance in industrial applications. Weaknesses: Potential fragility of thin-walled structures, higher initial costs compared to traditional supports.

Innovations in Borosilicate Glass Surface Modification

Ceramic catalysts

PatentInactiveUS20080045409A1

Innovation

- A ceramic catalyst with interconnecting pores and particles of colloids or nanocrystals comprising noble metals, such as silver and gold, is created using a borosilicate glass substrate with specific compositions and manufacturing processes, including melting, phase separation, and leaching to ensure a high surface area and noble metal distribution.

Borosilicate glass compositions and uses thereof

PatentWO2004050575A1

Innovation

- A borosilicate glass composition with silicon dioxide, boric oxide, aluminum oxide, and at least one alkali oxide, which resists devitrification without the addition of inhibitor oxides, maintaining a suitable coefficient of thermal expansion and mechanical strength.

Environmental Impact of Borosilicate Catalysts

The environmental impact of borosilicate catalysts is a crucial consideration in their application for chemical reactions. Borosilicate glass, when used as a catalyst support, offers several environmental advantages over traditional materials. Its chemical inertness and thermal stability contribute to reduced contamination and longer catalyst lifespans, potentially decreasing the frequency of catalyst replacement and associated waste generation.

One of the primary environmental benefits of borosilicate catalysts is their potential for improved reaction efficiency. By providing a stable and high-surface-area support, these catalysts can enhance reaction rates and selectivity, leading to reduced energy consumption and fewer unwanted by-products. This efficiency can translate into lower overall environmental footprints for chemical processes utilizing borosilicate-supported catalysts.

The recyclability of borosilicate glass is another significant environmental advantage. Unlike some catalyst supports that degrade or become contaminated over time, borosilicate glass can often be cleaned and reused multiple times. This recyclability reduces the demand for raw materials and energy required for producing new catalyst supports, thereby minimizing the environmental impact associated with catalyst production and disposal.

In terms of waste management, borosilicate catalysts present both challenges and opportunities. While the glass itself is inert and non-toxic, the catalytic materials deposited on its surface may require special handling and disposal procedures. However, the stability of borosilicate glass can facilitate more effective separation and recovery of precious metals or other valuable catalytic components, potentially reducing the environmental burden of catalyst disposal and promoting the circular economy in catalyst management.

The production process of borosilicate glass catalysts also warrants environmental consideration. While glass manufacturing is energy-intensive, the durability and long lifespan of borosilicate catalysts may offset this initial energy investment over time. Additionally, advancements in glass production technologies, such as electric melting and improved furnace designs, are continually reducing the carbon footprint associated with borosilicate glass manufacturing.

When comparing borosilicate catalysts to alternatives, their environmental profile is generally favorable. They often exhibit lower leaching rates of toxic elements, reduced particulate emissions, and better resistance to thermal shock and chemical attack. These properties not only enhance the safety and reliability of chemical processes but also contribute to reduced environmental risks and potential contamination incidents.

One of the primary environmental benefits of borosilicate catalysts is their potential for improved reaction efficiency. By providing a stable and high-surface-area support, these catalysts can enhance reaction rates and selectivity, leading to reduced energy consumption and fewer unwanted by-products. This efficiency can translate into lower overall environmental footprints for chemical processes utilizing borosilicate-supported catalysts.

The recyclability of borosilicate glass is another significant environmental advantage. Unlike some catalyst supports that degrade or become contaminated over time, borosilicate glass can often be cleaned and reused multiple times. This recyclability reduces the demand for raw materials and energy required for producing new catalyst supports, thereby minimizing the environmental impact associated with catalyst production and disposal.

In terms of waste management, borosilicate catalysts present both challenges and opportunities. While the glass itself is inert and non-toxic, the catalytic materials deposited on its surface may require special handling and disposal procedures. However, the stability of borosilicate glass can facilitate more effective separation and recovery of precious metals or other valuable catalytic components, potentially reducing the environmental burden of catalyst disposal and promoting the circular economy in catalyst management.

The production process of borosilicate glass catalysts also warrants environmental consideration. While glass manufacturing is energy-intensive, the durability and long lifespan of borosilicate catalysts may offset this initial energy investment over time. Additionally, advancements in glass production technologies, such as electric melting and improved furnace designs, are continually reducing the carbon footprint associated with borosilicate glass manufacturing.

When comparing borosilicate catalysts to alternatives, their environmental profile is generally favorable. They often exhibit lower leaching rates of toxic elements, reduced particulate emissions, and better resistance to thermal shock and chemical attack. These properties not only enhance the safety and reliability of chemical processes but also contribute to reduced environmental risks and potential contamination incidents.

Scalability and Industrial Applications

The scalability and industrial applications of borosilicate glass as a catalyst support in chemical reactions present significant opportunities for large-scale manufacturing and diverse industrial processes. Borosilicate glass offers several advantages that make it suitable for scaling up from laboratory experiments to industrial-scale production. Its high thermal stability, chemical resistance, and mechanical strength allow for the creation of robust catalyst support systems that can withstand harsh reaction conditions in industrial settings.

In terms of scalability, borosilicate glass can be manufactured in various shapes and sizes, enabling the design of customized reactor systems for different chemical processes. This flexibility allows for the optimization of reactor geometry, which is crucial for maximizing catalyst efficiency and product yield in large-scale operations. Additionally, the transparency of borosilicate glass facilitates real-time monitoring of reactions, a valuable feature for process control and quality assurance in industrial applications.

The industrial applications of borosilicate glass as a catalyst support extend across multiple sectors. In the petrochemical industry, it can be used in catalytic cracking processes for the production of high-value fuels and chemicals. The pharmaceutical sector can benefit from borosilicate glass-supported catalysts in the synthesis of complex drug molecules, where precise control of reaction conditions is essential. Environmental applications include the use of these catalysts in emission control systems and water treatment processes, leveraging the material's durability and resistance to corrosive environments.

Another promising area for industrial application is in the field of fine chemicals production. Borosilicate glass-supported catalysts can be employed in continuous flow reactors, enabling more efficient and sustainable manufacturing processes. This approach aligns with the principles of green chemistry, potentially reducing waste generation and energy consumption in industrial-scale chemical synthesis.

The scalability of borosilicate glass as a catalyst support also extends to its recyclability and regeneration potential. In industrial settings, the ability to recover and reuse catalyst supports is crucial for cost-effectiveness and sustainability. Borosilicate glass can be easily cleaned and regenerated, allowing for multiple reaction cycles and reducing the overall environmental impact of chemical processes.

However, challenges remain in fully realizing the industrial potential of borosilicate glass-supported catalysts. These include optimizing catalyst loading techniques for large-scale production, ensuring uniform distribution of catalytic sites across the glass surface, and developing efficient methods for catalyst recovery in continuous flow systems. Addressing these challenges will be key to expanding the use of borosilicate glass-supported catalysts in diverse industrial applications and enhancing their economic viability on a commercial scale.

In terms of scalability, borosilicate glass can be manufactured in various shapes and sizes, enabling the design of customized reactor systems for different chemical processes. This flexibility allows for the optimization of reactor geometry, which is crucial for maximizing catalyst efficiency and product yield in large-scale operations. Additionally, the transparency of borosilicate glass facilitates real-time monitoring of reactions, a valuable feature for process control and quality assurance in industrial applications.

The industrial applications of borosilicate glass as a catalyst support extend across multiple sectors. In the petrochemical industry, it can be used in catalytic cracking processes for the production of high-value fuels and chemicals. The pharmaceutical sector can benefit from borosilicate glass-supported catalysts in the synthesis of complex drug molecules, where precise control of reaction conditions is essential. Environmental applications include the use of these catalysts in emission control systems and water treatment processes, leveraging the material's durability and resistance to corrosive environments.

Another promising area for industrial application is in the field of fine chemicals production. Borosilicate glass-supported catalysts can be employed in continuous flow reactors, enabling more efficient and sustainable manufacturing processes. This approach aligns with the principles of green chemistry, potentially reducing waste generation and energy consumption in industrial-scale chemical synthesis.

The scalability of borosilicate glass as a catalyst support also extends to its recyclability and regeneration potential. In industrial settings, the ability to recover and reuse catalyst supports is crucial for cost-effectiveness and sustainability. Borosilicate glass can be easily cleaned and regenerated, allowing for multiple reaction cycles and reducing the overall environmental impact of chemical processes.

However, challenges remain in fully realizing the industrial potential of borosilicate glass-supported catalysts. These include optimizing catalyst loading techniques for large-scale production, ensuring uniform distribution of catalytic sites across the glass surface, and developing efficient methods for catalyst recovery in continuous flow systems. Addressing these challenges will be key to expanding the use of borosilicate glass-supported catalysts in diverse industrial applications and enhancing their economic viability on a commercial scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!