Borosilicate Glass Recycling and Environmental Impact

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Borosilicate Glass Recycling Background and Objectives

Borosilicate glass, renowned for its exceptional thermal and chemical resistance, has been a cornerstone in various industries for over a century. Its development can be traced back to the late 19th century when German glassmaker Otto Schott pioneered its creation. Since then, borosilicate glass has found widespread applications in laboratory equipment, cookware, lighting, and even aerospace technology.

The evolution of borosilicate glass technology has been driven by the increasing demand for materials that can withstand extreme conditions while maintaining transparency and durability. Over the years, manufacturers have refined the composition and production processes to enhance its properties, leading to improved heat resistance, chemical inertness, and mechanical strength.

However, the recycling of borosilicate glass presents unique challenges due to its distinct chemical composition, which differs significantly from common soda-lime glass. The presence of boron oxide in borosilicate glass requires specialized recycling processes to ensure proper material recovery and environmental sustainability.

The primary objective of researching borosilicate glass recycling is to develop efficient and cost-effective methods for reclaiming this valuable material. This involves exploring innovative techniques for separating borosilicate glass from other glass types, as well as investigating potential applications for recycled borosilicate glass in various industries.

Another crucial aspect of this research is to assess and mitigate the environmental impact of borosilicate glass production and disposal. This includes analyzing the energy consumption and greenhouse gas emissions associated with its manufacturing process, as well as evaluating the long-term effects of borosilicate glass waste in landfills.

By focusing on these objectives, researchers aim to create a more sustainable lifecycle for borosilicate glass products. This not only addresses the growing concerns about waste management and resource conservation but also aligns with global efforts to reduce the environmental footprint of industrial materials.

The research on borosilicate glass recycling is expected to yield valuable insights into circular economy principles and contribute to the development of more sustainable practices in the glass industry. As environmental regulations become increasingly stringent, the outcomes of this research will play a crucial role in shaping future policies and industrial standards for glass recycling and waste management.

The evolution of borosilicate glass technology has been driven by the increasing demand for materials that can withstand extreme conditions while maintaining transparency and durability. Over the years, manufacturers have refined the composition and production processes to enhance its properties, leading to improved heat resistance, chemical inertness, and mechanical strength.

However, the recycling of borosilicate glass presents unique challenges due to its distinct chemical composition, which differs significantly from common soda-lime glass. The presence of boron oxide in borosilicate glass requires specialized recycling processes to ensure proper material recovery and environmental sustainability.

The primary objective of researching borosilicate glass recycling is to develop efficient and cost-effective methods for reclaiming this valuable material. This involves exploring innovative techniques for separating borosilicate glass from other glass types, as well as investigating potential applications for recycled borosilicate glass in various industries.

Another crucial aspect of this research is to assess and mitigate the environmental impact of borosilicate glass production and disposal. This includes analyzing the energy consumption and greenhouse gas emissions associated with its manufacturing process, as well as evaluating the long-term effects of borosilicate glass waste in landfills.

By focusing on these objectives, researchers aim to create a more sustainable lifecycle for borosilicate glass products. This not only addresses the growing concerns about waste management and resource conservation but also aligns with global efforts to reduce the environmental footprint of industrial materials.

The research on borosilicate glass recycling is expected to yield valuable insights into circular economy principles and contribute to the development of more sustainable practices in the glass industry. As environmental regulations become increasingly stringent, the outcomes of this research will play a crucial role in shaping future policies and industrial standards for glass recycling and waste management.

Market Analysis for Recycled Borosilicate Glass

The market for recycled borosilicate glass is experiencing significant growth, driven by increasing environmental awareness and the push for sustainable practices in various industries. Borosilicate glass, known for its durability and resistance to thermal shock, finds extensive applications in laboratory equipment, pharmaceutical packaging, and high-end kitchenware. As the demand for these products continues to rise, so does the need for efficient recycling solutions.

The global borosilicate glass market was valued at approximately $1.8 billion in 2020 and is projected to reach $2.5 billion by 2027, growing at a CAGR of around 5%. This growth is partly attributed to the increasing adoption of recycled borosilicate glass in various applications. The recycled borosilicate glass market, while smaller, is showing promising growth potential, with an estimated market size of $200 million in 2021 and expected to grow at a CAGR of 6-7% over the next five years.

Key drivers for the recycled borosilicate glass market include stringent environmental regulations, growing consumer preference for eco-friendly products, and the cost-effectiveness of recycled materials. Industries such as pharmaceuticals and laboratories are increasingly adopting recycled borosilicate glass to reduce their environmental footprint and comply with sustainability goals.

Geographically, Europe leads the recycled borosilicate glass market, accounting for approximately 40% of the global share. This is primarily due to well-established recycling infrastructure and supportive government policies. North America follows closely, with a market share of around 30%, driven by increasing awareness and adoption of sustainable practices in the region. Asia-Pacific is emerging as a rapidly growing market, with countries like China and India showing significant potential for growth in recycled borosilicate glass adoption.

The market faces certain challenges, including the high cost of recycling borosilicate glass compared to other glass types and the limited availability of specialized recycling facilities. However, technological advancements in recycling processes and increasing investments in recycling infrastructure are expected to address these challenges in the coming years.

Key end-user industries for recycled borosilicate glass include pharmaceuticals, laboratories, and kitchenware manufacturers. The pharmaceutical industry, in particular, is showing a strong inclination towards using recycled borosilicate glass for packaging, driven by sustainability goals and the material's superior chemical resistance properties.

In conclusion, the market for recycled borosilicate glass presents significant opportunities for growth, driven by environmental concerns and the material's unique properties. As recycling technologies improve and awareness increases, the market is poised for substantial expansion in the coming years, offering potential for both environmental benefits and economic growth.

The global borosilicate glass market was valued at approximately $1.8 billion in 2020 and is projected to reach $2.5 billion by 2027, growing at a CAGR of around 5%. This growth is partly attributed to the increasing adoption of recycled borosilicate glass in various applications. The recycled borosilicate glass market, while smaller, is showing promising growth potential, with an estimated market size of $200 million in 2021 and expected to grow at a CAGR of 6-7% over the next five years.

Key drivers for the recycled borosilicate glass market include stringent environmental regulations, growing consumer preference for eco-friendly products, and the cost-effectiveness of recycled materials. Industries such as pharmaceuticals and laboratories are increasingly adopting recycled borosilicate glass to reduce their environmental footprint and comply with sustainability goals.

Geographically, Europe leads the recycled borosilicate glass market, accounting for approximately 40% of the global share. This is primarily due to well-established recycling infrastructure and supportive government policies. North America follows closely, with a market share of around 30%, driven by increasing awareness and adoption of sustainable practices in the region. Asia-Pacific is emerging as a rapidly growing market, with countries like China and India showing significant potential for growth in recycled borosilicate glass adoption.

The market faces certain challenges, including the high cost of recycling borosilicate glass compared to other glass types and the limited availability of specialized recycling facilities. However, technological advancements in recycling processes and increasing investments in recycling infrastructure are expected to address these challenges in the coming years.

Key end-user industries for recycled borosilicate glass include pharmaceuticals, laboratories, and kitchenware manufacturers. The pharmaceutical industry, in particular, is showing a strong inclination towards using recycled borosilicate glass for packaging, driven by sustainability goals and the material's superior chemical resistance properties.

In conclusion, the market for recycled borosilicate glass presents significant opportunities for growth, driven by environmental concerns and the material's unique properties. As recycling technologies improve and awareness increases, the market is poised for substantial expansion in the coming years, offering potential for both environmental benefits and economic growth.

Current Challenges in Borosilicate Glass Recycling

Borosilicate glass recycling faces several significant challenges that hinder its widespread implementation and efficiency. One of the primary obstacles is the lack of established collection and sorting systems specifically designed for borosilicate glass. Unlike common soda-lime glass, borosilicate glass requires separate processing due to its distinct chemical composition and higher melting point.

The contamination of borosilicate glass with other glass types during the collection process poses a major challenge. Even small amounts of borosilicate glass can compromise the quality of recycled soda-lime glass, leading to defects in the final products. This necessitates precise sorting techniques, which are often costly and time-consuming.

Another significant hurdle is the limited market demand for recycled borosilicate glass. The specialized nature of borosilicate glass products, primarily used in laboratory equipment and high-temperature applications, results in a smaller market compared to conventional glass. This economic factor often makes large-scale recycling initiatives less financially viable.

The high melting point of borosilicate glass, typically around 1,640°C compared to 1,500°C for soda-lime glass, presents technical challenges in the recycling process. It requires more energy-intensive melting processes, which can increase both the environmental impact and the cost of recycling.

The complex chemical composition of borosilicate glass, containing significant amounts of boron oxide, also complicates the recycling process. The presence of boron can affect the properties of the recycled glass, making it challenging to maintain the high-quality standards required for specialized applications.

Furthermore, the durability of borosilicate glass, while beneficial for its primary uses, paradoxically contributes to recycling challenges. Its resistance to chemical and thermal stress means it degrades slowly in the environment, reducing the immediate pressure for recycling solutions compared to more rapidly degrading materials.

Lastly, there is a lack of standardized regulations and incentives specifically targeting borosilicate glass recycling. While many regions have well-established policies for general glass recycling, the unique properties of borosilicate glass often fall outside these standard frameworks, leading to inconsistent handling and disposal practices across different jurisdictions.

Addressing these challenges requires a multifaceted approach, involving technological innovations in sorting and processing, development of specialized recycling facilities, creation of targeted collection systems, and implementation of supportive policies and economic incentives. Overcoming these hurdles is crucial for improving the sustainability of borosilicate glass production and reducing its environmental impact.

The contamination of borosilicate glass with other glass types during the collection process poses a major challenge. Even small amounts of borosilicate glass can compromise the quality of recycled soda-lime glass, leading to defects in the final products. This necessitates precise sorting techniques, which are often costly and time-consuming.

Another significant hurdle is the limited market demand for recycled borosilicate glass. The specialized nature of borosilicate glass products, primarily used in laboratory equipment and high-temperature applications, results in a smaller market compared to conventional glass. This economic factor often makes large-scale recycling initiatives less financially viable.

The high melting point of borosilicate glass, typically around 1,640°C compared to 1,500°C for soda-lime glass, presents technical challenges in the recycling process. It requires more energy-intensive melting processes, which can increase both the environmental impact and the cost of recycling.

The complex chemical composition of borosilicate glass, containing significant amounts of boron oxide, also complicates the recycling process. The presence of boron can affect the properties of the recycled glass, making it challenging to maintain the high-quality standards required for specialized applications.

Furthermore, the durability of borosilicate glass, while beneficial for its primary uses, paradoxically contributes to recycling challenges. Its resistance to chemical and thermal stress means it degrades slowly in the environment, reducing the immediate pressure for recycling solutions compared to more rapidly degrading materials.

Lastly, there is a lack of standardized regulations and incentives specifically targeting borosilicate glass recycling. While many regions have well-established policies for general glass recycling, the unique properties of borosilicate glass often fall outside these standard frameworks, leading to inconsistent handling and disposal practices across different jurisdictions.

Addressing these challenges requires a multifaceted approach, involving technological innovations in sorting and processing, development of specialized recycling facilities, creation of targeted collection systems, and implementation of supportive policies and economic incentives. Overcoming these hurdles is crucial for improving the sustainability of borosilicate glass production and reducing its environmental impact.

Existing Borosilicate Glass Recycling Methods

01 Recycling and waste reduction

Borosilicate glass can be recycled, reducing environmental impact through waste reduction. Its durability allows for multiple uses, decreasing the need for frequent replacements. Recycling processes for borosilicate glass can be optimized to minimize energy consumption and emissions.- Recycling and waste reduction: Borosilicate glass can be recycled, reducing environmental impact through waste reduction. Its durability allows for multiple uses, decreasing the need for frequent replacements. Recycling processes for borosilicate glass can be optimized to minimize energy consumption and emissions.

- Energy-efficient production methods: Innovative production techniques for borosilicate glass aim to reduce energy consumption and greenhouse gas emissions. These methods include optimized furnace designs, improved melting processes, and the use of alternative energy sources in manufacturing.

- Chemical composition and environmental safety: The chemical composition of borosilicate glass can be modified to enhance its environmental safety. Research focuses on reducing or eliminating harmful components while maintaining desirable properties. This includes developing lead-free formulations and exploring eco-friendly alternatives to traditional raw materials.

- Applications in environmental protection: Borosilicate glass finds applications in environmental protection technologies. Its chemical resistance and thermal properties make it suitable for use in pollution control equipment, water treatment systems, and renewable energy technologies, contributing to overall environmental sustainability.

- Life cycle assessment and sustainability: Life cycle assessments of borosilicate glass products evaluate their environmental impact from production to disposal. These studies consider factors such as raw material extraction, manufacturing processes, use phase, and end-of-life management to improve the overall sustainability of borosilicate glass products.

02 Energy-efficient production methods

Innovative manufacturing techniques for borosilicate glass aim to reduce energy consumption during production. These methods include optimized furnace designs, improved melting processes, and the use of alternative energy sources, contributing to a lower carbon footprint.Expand Specific Solutions03 Chemical resistance and environmental protection

Borosilicate glass's high chemical resistance makes it suitable for containing hazardous materials, preventing leaching and environmental contamination. This property also allows for its use in environmental monitoring and protection equipment.Expand Specific Solutions04 Thermal insulation properties

The thermal insulation properties of borosilicate glass contribute to energy efficiency in various applications. When used in buildings or industrial processes, it helps reduce heat loss and energy consumption, leading to lower environmental impact over time.Expand Specific Solutions05 Sustainable alternatives and modifications

Research into sustainable alternatives and modifications to borosilicate glass aims to further reduce its environmental impact. This includes exploring bio-based additives, reducing toxic components, and developing composites with enhanced environmental properties.Expand Specific Solutions

Key Players in Borosilicate Glass Recycling Industry

The borosilicate glass recycling and environmental impact sector is in a growth phase, with increasing market size driven by sustainability concerns and circular economy initiatives. The global market for specialty glass recycling, including borosilicate, is projected to expand significantly in the coming years. Technologically, the field is advancing, with companies like SCHOTT AG, Corning, Inc., and Nippon Electric Glass Co., Ltd. leading innovation in recycling processes and sustainable manufacturing. These industry leaders are investing in research and development to improve recycling efficiency and reduce environmental impact. However, the technology is not yet fully mature, with challenges remaining in separating borosilicate from other glass types and maintaining high-quality recycled products. Emerging players like Hunan Kibing Pharmaceutical Material Technology Co., Ltd. are also contributing to the sector's growth, particularly in specialized applications such as pharmaceutical packaging.

SCHOTT AG

Technical Solution: SCHOTT AG has developed an innovative approach to borosilicate glass recycling, focusing on closed-loop recycling within their production processes. They have implemented a system that allows for the collection and reprocessing of production scrap and end-of-life products. This recycled material is then reintegrated into the manufacturing process, reducing the need for raw materials and minimizing waste. SCHOTT's method involves precise sorting and cleaning of glass waste, followed by melting and refining processes that maintain the high quality standards required for borosilicate glass production[1][3]. The company has also invested in research to optimize the energy efficiency of the recycling process, aiming to reduce the overall environmental impact of glass production.

Strengths: Closed-loop system reduces raw material consumption and waste. High-quality recycled glass maintains product integrity. Weaknesses: Energy-intensive melting process may offset some environmental benefits. Limited to internal production waste, not addressing wider consumer recycling.

Corning, Inc.

Technical Solution: Corning has developed a comprehensive borosilicate glass recycling program that extends beyond internal production waste to include consumer products. Their approach involves a multi-step process of collection, sorting, and processing of borosilicate glass from various sources. Corning utilizes advanced optical sorting technology to separate borosilicate glass from other types, ensuring high purity in the recycled material[2]. The company has also invested in research to develop new formulations that incorporate higher percentages of recycled content without compromising the glass's performance characteristics. Additionally, Corning has implemented life cycle assessment tools to quantify the environmental benefits of their recycling efforts, showing significant reductions in energy consumption and CO2 emissions compared to virgin material production[4].

Strengths: Comprehensive approach including consumer recycling. Advanced sorting technology ensures high-quality recycled material. Quantifiable environmental benefits. Weaknesses: Requires extensive collection infrastructure. Higher initial costs for implementing advanced recycling technologies.

Innovative Approaches in Borosilicate Glass Recycling

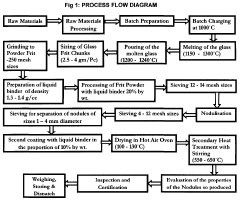

A process for the preparation of special glass beads for vitrification of nuclear waste

PatentInactiveIN3041DEL2012A

Innovation

- A process involving a five-component system of SiO2-B2O3-Na2O-Fe2O3-TiO2 with controlled impurity levels, involving mixing, preheating, melting, air quenching, and secondary heat treatment to produce glass beads with specific mechanical and physical properties, including compressive strength and low chloride/sulphate content.

Method for producing borosilicate glasses

PatentInactiveEP1266872A1

Innovation

- The method involves adding sulfates as refining agents between 0.01% and 0.8% by weight as SO3 to initiate gas bubble formation and growth in the glass melt, allowing effective refining without the need for additional reducing agents, and can be combined with fluoride and chloride for enhanced refining.

Environmental Impact Assessment of Recycling Processes

The recycling of borosilicate glass presents both environmental benefits and potential impacts that require careful assessment. On the positive side, recycling reduces the need for raw material extraction and energy consumption associated with primary glass production. Studies have shown that recycling borosilicate glass can save up to 30% of the energy required for manufacturing new glass, resulting in reduced greenhouse gas emissions and air pollutants.

However, the recycling process itself is not without environmental considerations. The collection and transportation of glass waste contribute to vehicle emissions and fuel consumption. The sorting and cleaning stages may involve water usage and generate wastewater that requires treatment. Crushing and melting processes consume energy and can produce particulate matter emissions if not properly controlled.

One significant challenge in borosilicate glass recycling is the potential for contamination. Unlike common soda-lime glass, borosilicate glass has a different chemical composition that can affect the quality of recycled products if mixed with other glass types. This necessitates more stringent sorting procedures, which may increase the energy and resource inputs of the recycling process.

Life cycle assessments (LCAs) have been conducted to quantify the environmental impacts of borosilicate glass recycling compared to landfill disposal or incineration. These studies typically consider factors such as global warming potential, acidification, eutrophication, and resource depletion. Results generally indicate that recycling offers net environmental benefits, particularly when optimized collection and processing systems are in place.

The environmental impact of recycling also depends on the end-use of the recycled material. When borosilicate glass is recycled into new glass products, it maintains its high-value properties and can offset the production of virgin materials. However, in some cases, recycled borosilicate glass may be downcycled into lower-value applications, which may reduce the overall environmental benefits.

To minimize negative environmental impacts, best practices in borosilicate glass recycling include implementing efficient collection systems, using renewable energy sources in processing facilities, optimizing water usage and treatment, and ensuring proper air pollution control measures. Additionally, developing technologies for improved sorting and contaminant removal can enhance the quality of recycled borosilicate glass, expanding its potential applications and environmental benefits.

However, the recycling process itself is not without environmental considerations. The collection and transportation of glass waste contribute to vehicle emissions and fuel consumption. The sorting and cleaning stages may involve water usage and generate wastewater that requires treatment. Crushing and melting processes consume energy and can produce particulate matter emissions if not properly controlled.

One significant challenge in borosilicate glass recycling is the potential for contamination. Unlike common soda-lime glass, borosilicate glass has a different chemical composition that can affect the quality of recycled products if mixed with other glass types. This necessitates more stringent sorting procedures, which may increase the energy and resource inputs of the recycling process.

Life cycle assessments (LCAs) have been conducted to quantify the environmental impacts of borosilicate glass recycling compared to landfill disposal or incineration. These studies typically consider factors such as global warming potential, acidification, eutrophication, and resource depletion. Results generally indicate that recycling offers net environmental benefits, particularly when optimized collection and processing systems are in place.

The environmental impact of recycling also depends on the end-use of the recycled material. When borosilicate glass is recycled into new glass products, it maintains its high-value properties and can offset the production of virgin materials. However, in some cases, recycled borosilicate glass may be downcycled into lower-value applications, which may reduce the overall environmental benefits.

To minimize negative environmental impacts, best practices in borosilicate glass recycling include implementing efficient collection systems, using renewable energy sources in processing facilities, optimizing water usage and treatment, and ensuring proper air pollution control measures. Additionally, developing technologies for improved sorting and contaminant removal can enhance the quality of recycled borosilicate glass, expanding its potential applications and environmental benefits.

Regulatory Framework for Glass Recycling and Waste Management

The regulatory framework for glass recycling and waste management plays a crucial role in shaping the landscape of borosilicate glass recycling and its environmental impact. At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides guidelines for the management of hazardous waste, including certain types of glass waste. This convention influences national policies and encourages countries to develop environmentally sound management practices for waste materials.

In the European Union, the Waste Framework Directive (2008/98/EC) establishes the basic concepts and definitions related to waste management, including recycling targets for various materials. The directive sets a recycling target of 70% for glass by 2025, which has spurred innovation in glass recycling technologies and processes. Additionally, the EU's Circular Economy Action Plan emphasizes the importance of recycling and reusing materials, further supporting the development of glass recycling initiatives.

At the national level, countries have implemented various regulations to promote glass recycling and reduce environmental impact. For instance, Germany's Packaging Act (VerpackG) mandates that manufacturers and distributors of packaged goods participate in a dual system for collecting and recycling packaging materials, including glass. This legislation has led to high glass recycling rates in Germany, serving as a model for other countries.

In the United States, glass recycling regulations vary by state and municipality. The Resource Conservation and Recovery Act (RCRA) provides the framework for the management of hazardous and non-hazardous solid waste. Some states have implemented bottle deposit laws, which incentivize consumers to return glass containers for recycling. California's Beverage Container Recycling and Litter Reduction Act, for example, has significantly increased glass recycling rates in the state.

Specific to borosilicate glass, regulations often classify it as a special waste due to its unique composition and properties. In many jurisdictions, borosilicate glass is not accepted in standard glass recycling streams and requires specialized handling. For instance, the UK's Environmental Protection Act 1990 and subsequent regulations classify borosilicate glass as a controlled waste, necessitating specific disposal and recycling procedures.

The regulatory landscape also addresses the environmental impact of glass production and recycling. Environmental Impact Assessment (EIA) regulations in many countries require glass manufacturers and recycling facilities to evaluate and mitigate their environmental effects. These assessments often consider factors such as energy consumption, emissions, and waste generation throughout the glass lifecycle.

As awareness of the environmental benefits of glass recycling grows, many governments are implementing Extended Producer Responsibility (EPR) programs. These initiatives hold manufacturers responsible for the entire lifecycle of their products, including disposal and recycling. Such programs are particularly relevant for borosilicate glass products, given their specialized nature and potential environmental impact.

In the European Union, the Waste Framework Directive (2008/98/EC) establishes the basic concepts and definitions related to waste management, including recycling targets for various materials. The directive sets a recycling target of 70% for glass by 2025, which has spurred innovation in glass recycling technologies and processes. Additionally, the EU's Circular Economy Action Plan emphasizes the importance of recycling and reusing materials, further supporting the development of glass recycling initiatives.

At the national level, countries have implemented various regulations to promote glass recycling and reduce environmental impact. For instance, Germany's Packaging Act (VerpackG) mandates that manufacturers and distributors of packaged goods participate in a dual system for collecting and recycling packaging materials, including glass. This legislation has led to high glass recycling rates in Germany, serving as a model for other countries.

In the United States, glass recycling regulations vary by state and municipality. The Resource Conservation and Recovery Act (RCRA) provides the framework for the management of hazardous and non-hazardous solid waste. Some states have implemented bottle deposit laws, which incentivize consumers to return glass containers for recycling. California's Beverage Container Recycling and Litter Reduction Act, for example, has significantly increased glass recycling rates in the state.

Specific to borosilicate glass, regulations often classify it as a special waste due to its unique composition and properties. In many jurisdictions, borosilicate glass is not accepted in standard glass recycling streams and requires specialized handling. For instance, the UK's Environmental Protection Act 1990 and subsequent regulations classify borosilicate glass as a controlled waste, necessitating specific disposal and recycling procedures.

The regulatory landscape also addresses the environmental impact of glass production and recycling. Environmental Impact Assessment (EIA) regulations in many countries require glass manufacturers and recycling facilities to evaluate and mitigate their environmental effects. These assessments often consider factors such as energy consumption, emissions, and waste generation throughout the glass lifecycle.

As awareness of the environmental benefits of glass recycling grows, many governments are implementing Extended Producer Responsibility (EPR) programs. These initiatives hold manufacturers responsible for the entire lifecycle of their products, including disposal and recycling. Such programs are particularly relevant for borosilicate glass products, given their specialized nature and potential environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!