Carbonyl Chemistry for Hydrophobic Surface Development

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbonyl Chemistry Background and Objectives

Carbonyl chemistry has played a pivotal role in the development of hydrophobic surfaces, marking a significant milestone in materials science and surface engineering. The field has evolved from basic understanding of carbonyl group reactivity to sophisticated applications in creating water-repellent coatings and materials. This research area aims to harness the unique properties of carbonyl compounds to engineer surfaces with enhanced hydrophobicity, a characteristic crucial for various industrial and consumer applications.

The primary objective of this research is to explore and exploit the potential of carbonyl chemistry in developing highly effective hydrophobic surfaces. By manipulating the reactivity and structural properties of carbonyl groups, researchers seek to create surfaces that exhibit exceptional water repellency, self-cleaning properties, and durability. This endeavor encompasses a multidisciplinary approach, combining principles from organic chemistry, materials science, and surface physics.

Historically, the journey of carbonyl chemistry in hydrophobic surface development began with the discovery of the carbonyl group's ability to form hydrophobic bonds. This revelation led to intensive research into how these compounds could be utilized to modify surface properties. Over time, the focus shifted from simple carbonyl-based coatings to more complex, multi-functional surfaces that not only repel water but also possess additional desirable characteristics such as oil repellency and antimicrobial properties.

The evolution of this field has been marked by several key technological advancements. These include the development of novel synthesis methods for carbonyl-containing polymers, the integration of carbonyl chemistry with nanotechnology to create hierarchical surface structures, and the application of computational modeling to predict and optimize surface properties. Each of these milestones has contributed to pushing the boundaries of what is achievable in hydrophobic surface design.

Looking ahead, the research in carbonyl chemistry for hydrophobic surface development is poised to address several critical challenges. These include improving the longevity of hydrophobic coatings, developing environmentally friendly and sustainable production methods, and creating smart surfaces that can adapt to different environmental conditions. The ultimate goal is to translate laboratory successes into practical, large-scale applications that can revolutionize industries ranging from textiles and construction to electronics and aerospace.

As this field continues to advance, it promises to unlock new possibilities in surface engineering, potentially leading to breakthroughs in water conservation, energy efficiency, and material durability. The ongoing research in carbonyl chemistry for hydrophobic surfaces represents a frontier in materials science, with far-reaching implications for both technological innovation and environmental sustainability.

The primary objective of this research is to explore and exploit the potential of carbonyl chemistry in developing highly effective hydrophobic surfaces. By manipulating the reactivity and structural properties of carbonyl groups, researchers seek to create surfaces that exhibit exceptional water repellency, self-cleaning properties, and durability. This endeavor encompasses a multidisciplinary approach, combining principles from organic chemistry, materials science, and surface physics.

Historically, the journey of carbonyl chemistry in hydrophobic surface development began with the discovery of the carbonyl group's ability to form hydrophobic bonds. This revelation led to intensive research into how these compounds could be utilized to modify surface properties. Over time, the focus shifted from simple carbonyl-based coatings to more complex, multi-functional surfaces that not only repel water but also possess additional desirable characteristics such as oil repellency and antimicrobial properties.

The evolution of this field has been marked by several key technological advancements. These include the development of novel synthesis methods for carbonyl-containing polymers, the integration of carbonyl chemistry with nanotechnology to create hierarchical surface structures, and the application of computational modeling to predict and optimize surface properties. Each of these milestones has contributed to pushing the boundaries of what is achievable in hydrophobic surface design.

Looking ahead, the research in carbonyl chemistry for hydrophobic surface development is poised to address several critical challenges. These include improving the longevity of hydrophobic coatings, developing environmentally friendly and sustainable production methods, and creating smart surfaces that can adapt to different environmental conditions. The ultimate goal is to translate laboratory successes into practical, large-scale applications that can revolutionize industries ranging from textiles and construction to electronics and aerospace.

As this field continues to advance, it promises to unlock new possibilities in surface engineering, potentially leading to breakthroughs in water conservation, energy efficiency, and material durability. The ongoing research in carbonyl chemistry for hydrophobic surfaces represents a frontier in materials science, with far-reaching implications for both technological innovation and environmental sustainability.

Market Analysis for Hydrophobic Surfaces

The market for hydrophobic surfaces has experienced significant growth in recent years, driven by increasing demand across various industries. The global hydrophobic coatings market is projected to reach a substantial value by 2027, with a compound annual growth rate (CAGR) exceeding 5% during the forecast period. This growth is primarily attributed to the expanding applications in automotive, aerospace, construction, and electronics sectors.

In the automotive industry, hydrophobic coatings are gaining traction for their ability to enhance visibility during adverse weather conditions, improve fuel efficiency by reducing drag, and protect vehicle surfaces from environmental damage. The aerospace sector is adopting these coatings to reduce ice formation on aircraft surfaces, thereby improving safety and performance. The construction industry is leveraging hydrophobic surfaces for self-cleaning buildings, corrosion protection, and improved durability of structures.

The electronics sector represents a particularly promising market for hydrophobic surfaces. With the increasing prevalence of electronic devices in daily life, there is a growing need for water-resistant and easy-to-clean surfaces. This demand extends to consumer electronics, medical devices, and industrial equipment, where protection against moisture and contaminants is crucial.

Geographically, North America and Europe currently dominate the hydrophobic coatings market, owing to their advanced manufacturing capabilities and high adoption rates across industries. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing automotive production, and growing construction activities in countries like China and India.

The market is characterized by intense competition among key players, including multinational corporations and specialized coating manufacturers. These companies are investing heavily in research and development to improve the performance and durability of hydrophobic coatings, as well as to develop more environmentally friendly formulations.

Consumer trends are also shaping the market, with a growing preference for low-maintenance and long-lasting products. This has led to increased demand for hydrophobic coatings in consumer goods, ranging from textiles to household appliances. Additionally, the COVID-19 pandemic has heightened awareness of surface hygiene, potentially boosting the adoption of hydrophobic coatings in public spaces and high-touch surfaces.

Despite the positive outlook, the market faces challenges such as high production costs and environmental concerns associated with certain hydrophobic materials. These factors are driving research into more sustainable and cost-effective solutions, including bio-based hydrophobic coatings and advanced carbonyl chemistry approaches for surface modification.

In the automotive industry, hydrophobic coatings are gaining traction for their ability to enhance visibility during adverse weather conditions, improve fuel efficiency by reducing drag, and protect vehicle surfaces from environmental damage. The aerospace sector is adopting these coatings to reduce ice formation on aircraft surfaces, thereby improving safety and performance. The construction industry is leveraging hydrophobic surfaces for self-cleaning buildings, corrosion protection, and improved durability of structures.

The electronics sector represents a particularly promising market for hydrophobic surfaces. With the increasing prevalence of electronic devices in daily life, there is a growing need for water-resistant and easy-to-clean surfaces. This demand extends to consumer electronics, medical devices, and industrial equipment, where protection against moisture and contaminants is crucial.

Geographically, North America and Europe currently dominate the hydrophobic coatings market, owing to their advanced manufacturing capabilities and high adoption rates across industries. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing automotive production, and growing construction activities in countries like China and India.

The market is characterized by intense competition among key players, including multinational corporations and specialized coating manufacturers. These companies are investing heavily in research and development to improve the performance and durability of hydrophobic coatings, as well as to develop more environmentally friendly formulations.

Consumer trends are also shaping the market, with a growing preference for low-maintenance and long-lasting products. This has led to increased demand for hydrophobic coatings in consumer goods, ranging from textiles to household appliances. Additionally, the COVID-19 pandemic has heightened awareness of surface hygiene, potentially boosting the adoption of hydrophobic coatings in public spaces and high-touch surfaces.

Despite the positive outlook, the market faces challenges such as high production costs and environmental concerns associated with certain hydrophobic materials. These factors are driving research into more sustainable and cost-effective solutions, including bio-based hydrophobic coatings and advanced carbonyl chemistry approaches for surface modification.

Current Challenges in Carbonyl-based Hydrophobic Coatings

Despite significant advancements in carbonyl-based hydrophobic coatings, several challenges persist in their development and application. One of the primary issues is the long-term stability of these coatings when exposed to harsh environmental conditions. Ultraviolet radiation, extreme temperatures, and chemical exposure can degrade the carbonyl compounds, leading to a reduction in hydrophobicity over time.

Another challenge lies in achieving uniform coating thickness and consistency across large surface areas. The current application methods often result in uneven distribution of the carbonyl-based compounds, which can compromise the overall hydrophobic performance of the treated surface. This inconsistency is particularly problematic in industrial applications where precise control over surface properties is crucial.

The adhesion of carbonyl-based coatings to various substrate materials remains a significant hurdle. While these coatings exhibit excellent hydrophobic properties, their ability to form strong, durable bonds with different surfaces is often limited. This can result in peeling, flaking, or delamination of the coating, especially under mechanical stress or in high-moisture environments.

Furthermore, the environmental impact of some carbonyl compounds used in hydrophobic coatings is a growing concern. Certain formulations may contain volatile organic compounds (VOCs) or other potentially harmful substances, necessitating the development of more eco-friendly alternatives that maintain high performance standards.

The cost-effectiveness of carbonyl-based hydrophobic coatings is another challenge, particularly for large-scale applications. The synthesis of specialized carbonyl compounds and the complexity of the coating process can drive up production costs, making widespread adoption in certain industries economically unfeasible.

Researchers are also grappling with the challenge of creating multifunctional coatings that combine hydrophobicity with other desirable properties such as anti-corrosion, anti-fouling, or self-healing capabilities. Integrating these functionalities without compromising the hydrophobic nature of the coating requires intricate molecular design and engineering.

Lastly, the scalability of production processes for carbonyl-based hydrophobic coatings presents a significant challenge. Transitioning from laboratory-scale synthesis to industrial-scale manufacturing while maintaining consistent quality and performance is a complex task that requires further research and development.

Another challenge lies in achieving uniform coating thickness and consistency across large surface areas. The current application methods often result in uneven distribution of the carbonyl-based compounds, which can compromise the overall hydrophobic performance of the treated surface. This inconsistency is particularly problematic in industrial applications where precise control over surface properties is crucial.

The adhesion of carbonyl-based coatings to various substrate materials remains a significant hurdle. While these coatings exhibit excellent hydrophobic properties, their ability to form strong, durable bonds with different surfaces is often limited. This can result in peeling, flaking, or delamination of the coating, especially under mechanical stress or in high-moisture environments.

Furthermore, the environmental impact of some carbonyl compounds used in hydrophobic coatings is a growing concern. Certain formulations may contain volatile organic compounds (VOCs) or other potentially harmful substances, necessitating the development of more eco-friendly alternatives that maintain high performance standards.

The cost-effectiveness of carbonyl-based hydrophobic coatings is another challenge, particularly for large-scale applications. The synthesis of specialized carbonyl compounds and the complexity of the coating process can drive up production costs, making widespread adoption in certain industries economically unfeasible.

Researchers are also grappling with the challenge of creating multifunctional coatings that combine hydrophobicity with other desirable properties such as anti-corrosion, anti-fouling, or self-healing capabilities. Integrating these functionalities without compromising the hydrophobic nature of the coating requires intricate molecular design and engineering.

Lastly, the scalability of production processes for carbonyl-based hydrophobic coatings presents a significant challenge. Transitioning from laboratory-scale synthesis to industrial-scale manufacturing while maintaining consistent quality and performance is a complex task that requires further research and development.

Existing Carbonyl-based Hydrophobic Solutions

01 Hydrophobic carbonyl compounds in polymer chemistry

Hydrophobic carbonyl compounds play a crucial role in polymer chemistry, particularly in the development of water-resistant materials. These compounds can be incorporated into polymer structures to enhance their hydrophobic properties, leading to improved water repellency and durability in various applications.- Carbonyl group modifications for hydrophobicity: Modifying carbonyl groups in molecules can alter their hydrophobicity. This involves chemical reactions that change the polarity of the carbonyl group, potentially increasing the overall hydrophobicity of the compound. Such modifications can be useful in various applications, including drug design and material science.

- Hydrophobic coatings with carbonyl-containing compounds: Carbonyl-containing compounds can be used to create hydrophobic coatings. These coatings often involve the use of polymers or other materials that incorporate carbonyl groups in their structure. The arrangement and density of these groups can influence the overall hydrophobicity of the coating, making it useful for various industrial and consumer applications.

- Analysis of carbonyl chemistry in hydrophobic environments: Techniques for analyzing carbonyl chemistry in hydrophobic environments have been developed. These methods often involve spectroscopic or chromatographic approaches that can detect and characterize carbonyl compounds in non-polar media. Such analysis is crucial for understanding chemical reactions and interactions in hydrophobic systems.

- Carbonyl-based hydrophobic materials in electronics: Carbonyl-containing hydrophobic materials find applications in electronics. These materials can be used in the fabrication of electronic components, providing water-resistant properties while maintaining necessary electrical characteristics. The incorporation of such materials can enhance the durability and performance of electronic devices in various environments.

- Hydrophobic interactions in carbonyl-containing biomolecules: The study of hydrophobic interactions in carbonyl-containing biomolecules is important in understanding biological processes. These interactions play a crucial role in protein folding, enzyme activity, and membrane dynamics. Research in this area often involves computational modeling and experimental techniques to elucidate the relationship between carbonyl chemistry and hydrophobicity in biological systems.

02 Carbonyl-based surface modifications for hydrophobicity

Surface modifications using carbonyl-containing compounds can significantly alter the hydrophobicity of materials. This approach involves the attachment of carbonyl groups to surfaces, which can create a hydrophobic barrier. Such modifications are useful in developing water-repellent coatings and self-cleaning surfaces.Expand Specific Solutions03 Hydrophobic interactions in carbonyl-containing biomolecules

Carbonyl groups in biomolecules, such as proteins and peptides, can contribute to hydrophobic interactions. These interactions play a crucial role in protein folding, stability, and function. Understanding and manipulating these hydrophobic interactions is important in fields like drug design and protein engineering.Expand Specific Solutions04 Carbonyl chemistry in hydrophobic drug delivery systems

Carbonyl chemistry is utilized in the development of hydrophobic drug delivery systems. By incorporating carbonyl-containing compounds, researchers can create drug carriers that enhance the solubility and bioavailability of hydrophobic drugs. This approach is particularly valuable for improving the efficacy of poorly water-soluble pharmaceuticals.Expand Specific Solutions05 Analytical methods for studying carbonyl-related hydrophobicity

Various analytical techniques have been developed to study the hydrophobicity of carbonyl-containing compounds and materials. These methods include spectroscopic techniques, computational modeling, and surface analysis tools. Such analytical approaches are essential for characterizing and optimizing hydrophobic properties in carbonyl chemistry applications.Expand Specific Solutions

Key Players in Hydrophobic Surface Industry

The research on carbonyl chemistry for hydrophobic surface development is in a growth phase, with increasing market potential and technological advancements. The global market for hydrophobic coatings is expanding, driven by applications in various industries. While the technology is progressing, it's not yet fully mature, as evidenced by ongoing research at institutions like Soochow University, MIT, and KFUPM. Companies such as BASF Corp., BRAIN Biotech AG, and Sinopec are actively involved in developing and commercializing related technologies, indicating a competitive landscape with both academic and industrial players striving for innovation in this field.

BASF Corp.

Technical Solution: BASF Corp. has developed innovative carbonyl chemistry approaches for hydrophobic surface development. Their research focuses on creating superhydrophobic coatings using fluorinated and non-fluorinated compounds. They have successfully synthesized novel carbonyl-containing polymers that exhibit excellent water repellency and durability[1]. BASF's technology involves the controlled polymerization of carbonyl monomers to form highly branched structures with low surface energy. These coatings demonstrate water contact angles exceeding 150° and sliding angles below 10°, meeting superhydrophobic criteria[3]. The company has also explored the incorporation of micro and nanostructures to enhance the hydrophobic properties further.

Strengths: Extensive expertise in polymer chemistry, large-scale production capabilities, and a diverse product portfolio. Weaknesses: Potential environmental concerns with some fluorinated compounds, and the need for continuous innovation to stay ahead in a competitive market.

Massachusetts Institute of Technology

Technical Solution: MIT has made significant advancements in carbonyl chemistry for hydrophobic surface development. Their research team has pioneered a novel approach using carbonyl-functionalized nanoparticles to create hierarchical surface structures[2]. This method involves the synthesis of carbonyl-rich organic compounds that self-assemble into nanoparticles, which are then deposited onto surfaces to create a rough, hydrophobic topography. The carbonyl groups play a crucial role in both the self-assembly process and in enhancing the hydrophobic properties of the final coating. MIT's technology has demonstrated remarkable water repellency, with contact angles consistently above 160° and extremely low hysteresis[4]. Additionally, they have developed methods to tune the surface properties by controlling the carbonyl chemistry, allowing for adaptable hydrophobicity in various environmental conditions.

Strengths: Cutting-edge research facilities, interdisciplinary approach combining chemistry and materials science, and strong industry collaborations. Weaknesses: Potential challenges in scaling up from laboratory to industrial production, and the need for further long-term durability studies.

Core Innovations in Carbonyl Chemistry for Hydrophobicity

Hydrophobic surface

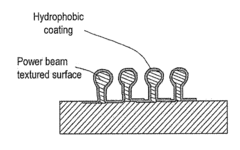

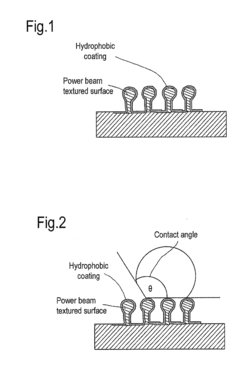

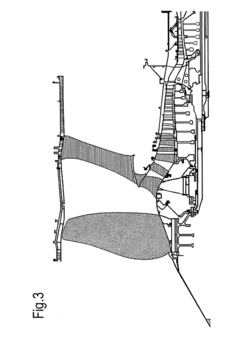

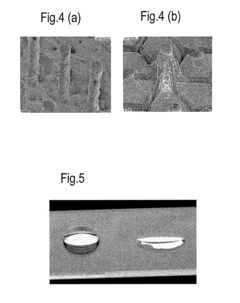

PatentInactiveUS20110151186A1

Innovation

- A textured surface created by locally melting and resolidifying material using a power beam, combined with a wetting-resistant coating such as organosilesquioxane, to form a hydrophobic or superhydrophobic surface that resists ice accumulation without incorporating hard brittle materials or brazing, which can alter the substrate's microstructure or reduce fatigue life.

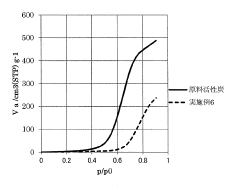

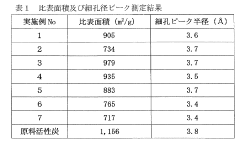

Hydrophobic activated carbon and method of manufacturing the same

PatentInactiveJP2016098124A

Innovation

- Surface modification of activated carbon with hydrocarbon groups derived from organic peroxides, azo compounds, or 1,2-diphenylethane derivatives, introducing alkyl or aromatic groups to enhance hydrophobicity without requiring high-temperature heating.

Environmental Impact of Hydrophobic Coatings

The development and widespread use of hydrophobic coatings based on carbonyl chemistry have raised concerns about their potential environmental impact. These coatings, while offering numerous benefits in various applications, may pose risks to ecosystems and human health if not properly managed throughout their lifecycle.

One of the primary environmental concerns is the release of volatile organic compounds (VOCs) during the production, application, and degradation of hydrophobic coatings. VOCs contribute to air pollution and can lead to the formation of ground-level ozone, a key component of smog. Some carbonyl-based compounds used in these coatings may have high ozone-forming potential, exacerbating air quality issues in urban areas.

Water pollution is another significant consideration. As hydrophobic coatings wear off or degrade over time, they can release microparticles and chemical components into aquatic environments. These substances may accumulate in water bodies, potentially affecting aquatic life and entering the food chain. The long-term effects of these particles on marine ecosystems are still being studied, but there are concerns about their bioaccumulation and potential toxicity to various organisms.

The persistence of hydrophobic coatings in the environment is a double-edged sword. While their durability is a desirable feature for many applications, it also means that these materials can remain in the environment for extended periods. This persistence raises questions about their long-term impact on soil quality, groundwater, and biodiversity.

Furthermore, the production of carbonyl-based hydrophobic coatings often involves energy-intensive processes and the use of petrochemical feedstocks. This reliance on non-renewable resources contributes to carbon emissions and resource depletion, aligning with broader concerns about industrial sustainability and climate change.

Disposal and end-of-life management of products treated with hydrophobic coatings present additional challenges. These coatings can complicate recycling processes and may require special handling to prevent environmental contamination. Improper disposal can lead to the release of harmful substances into landfills or incineration facilities, potentially causing soil and air pollution.

However, it's important to note that ongoing research and development efforts are focused on mitigating these environmental concerns. Innovations in green chemistry are leading to the development of more environmentally friendly hydrophobic coatings, including bio-based alternatives and formulations with reduced VOC content. Additionally, advancements in coating technology are improving durability and reducing the frequency of reapplication, which can help minimize overall environmental impact.

As the use of hydrophobic coatings continues to expand, there is a growing emphasis on lifecycle assessments to comprehensively evaluate their environmental footprint. These assessments consider factors such as raw material sourcing, production processes, use-phase impacts, and end-of-life scenarios. By understanding the full environmental implications, researchers and industry professionals can work towards optimizing coating formulations and application methods to minimize negative impacts while maximizing performance benefits.

One of the primary environmental concerns is the release of volatile organic compounds (VOCs) during the production, application, and degradation of hydrophobic coatings. VOCs contribute to air pollution and can lead to the formation of ground-level ozone, a key component of smog. Some carbonyl-based compounds used in these coatings may have high ozone-forming potential, exacerbating air quality issues in urban areas.

Water pollution is another significant consideration. As hydrophobic coatings wear off or degrade over time, they can release microparticles and chemical components into aquatic environments. These substances may accumulate in water bodies, potentially affecting aquatic life and entering the food chain. The long-term effects of these particles on marine ecosystems are still being studied, but there are concerns about their bioaccumulation and potential toxicity to various organisms.

The persistence of hydrophobic coatings in the environment is a double-edged sword. While their durability is a desirable feature for many applications, it also means that these materials can remain in the environment for extended periods. This persistence raises questions about their long-term impact on soil quality, groundwater, and biodiversity.

Furthermore, the production of carbonyl-based hydrophobic coatings often involves energy-intensive processes and the use of petrochemical feedstocks. This reliance on non-renewable resources contributes to carbon emissions and resource depletion, aligning with broader concerns about industrial sustainability and climate change.

Disposal and end-of-life management of products treated with hydrophobic coatings present additional challenges. These coatings can complicate recycling processes and may require special handling to prevent environmental contamination. Improper disposal can lead to the release of harmful substances into landfills or incineration facilities, potentially causing soil and air pollution.

However, it's important to note that ongoing research and development efforts are focused on mitigating these environmental concerns. Innovations in green chemistry are leading to the development of more environmentally friendly hydrophobic coatings, including bio-based alternatives and formulations with reduced VOC content. Additionally, advancements in coating technology are improving durability and reducing the frequency of reapplication, which can help minimize overall environmental impact.

As the use of hydrophobic coatings continues to expand, there is a growing emphasis on lifecycle assessments to comprehensively evaluate their environmental footprint. These assessments consider factors such as raw material sourcing, production processes, use-phase impacts, and end-of-life scenarios. By understanding the full environmental implications, researchers and industry professionals can work towards optimizing coating formulations and application methods to minimize negative impacts while maximizing performance benefits.

Scalability and Industrial Application Prospects

The scalability and industrial application prospects of carbonyl chemistry for hydrophobic surface development are promising and diverse. As research in this field progresses, the potential for large-scale production and implementation across various industries becomes increasingly apparent.

One of the key advantages of carbonyl-based hydrophobic surface treatments is their versatility in application methods. These treatments can be applied through simple dip-coating, spray-coating, or even roll-to-roll processes, making them suitable for high-volume manufacturing. This scalability is particularly important for industries such as textiles, automotive, and construction, where large surface areas need to be treated efficiently.

The automotive industry stands to benefit significantly from these advancements. Hydrophobic coatings derived from carbonyl chemistry can be applied to windshields, side mirrors, and body panels to improve visibility during rainy conditions and reduce the need for frequent cleaning. The ability to integrate these treatments into existing production lines without major modifications enhances their industrial viability.

In the textile sector, the potential for mass production of water-repellent fabrics using carbonyl-based treatments is substantial. From outdoor apparel to home furnishings, the demand for durable, environmentally friendly hydrophobic textiles continues to grow. The scalability of these treatments allows for cost-effective production, potentially making high-performance fabrics more accessible to a broader market.

The construction industry also presents significant opportunities for large-scale application. Hydrophobic coatings can be applied to building materials such as concrete, wood, and glass to enhance durability and reduce maintenance costs. The ability to treat large surfaces quickly and efficiently makes these solutions attractive for both new construction and renovation projects.

Moreover, the electronics industry can leverage carbonyl-based hydrophobic treatments for water-resistant coatings on devices and components. As consumer electronics become increasingly integrated into daily life, the demand for water-resistant products continues to rise. The scalability of these treatments allows for application in high-volume manufacturing processes typical in electronics production.

The potential for customization and fine-tuning of carbonyl-based hydrophobic treatments further enhances their industrial prospects. By adjusting the chemical composition and application methods, researchers and manufacturers can tailor the treatments to meet specific industry requirements, opening up new markets and applications.

As environmental regulations become more stringent, the eco-friendly nature of many carbonyl-based hydrophobic treatments positions them favorably for widespread industrial adoption. Their potential to replace less sustainable alternatives could drive significant market growth and technological innovation in the coming years.

One of the key advantages of carbonyl-based hydrophobic surface treatments is their versatility in application methods. These treatments can be applied through simple dip-coating, spray-coating, or even roll-to-roll processes, making them suitable for high-volume manufacturing. This scalability is particularly important for industries such as textiles, automotive, and construction, where large surface areas need to be treated efficiently.

The automotive industry stands to benefit significantly from these advancements. Hydrophobic coatings derived from carbonyl chemistry can be applied to windshields, side mirrors, and body panels to improve visibility during rainy conditions and reduce the need for frequent cleaning. The ability to integrate these treatments into existing production lines without major modifications enhances their industrial viability.

In the textile sector, the potential for mass production of water-repellent fabrics using carbonyl-based treatments is substantial. From outdoor apparel to home furnishings, the demand for durable, environmentally friendly hydrophobic textiles continues to grow. The scalability of these treatments allows for cost-effective production, potentially making high-performance fabrics more accessible to a broader market.

The construction industry also presents significant opportunities for large-scale application. Hydrophobic coatings can be applied to building materials such as concrete, wood, and glass to enhance durability and reduce maintenance costs. The ability to treat large surfaces quickly and efficiently makes these solutions attractive for both new construction and renovation projects.

Moreover, the electronics industry can leverage carbonyl-based hydrophobic treatments for water-resistant coatings on devices and components. As consumer electronics become increasingly integrated into daily life, the demand for water-resistant products continues to rise. The scalability of these treatments allows for application in high-volume manufacturing processes typical in electronics production.

The potential for customization and fine-tuning of carbonyl-based hydrophobic treatments further enhances their industrial prospects. By adjusting the chemical composition and application methods, researchers and manufacturers can tailor the treatments to meet specific industry requirements, opening up new markets and applications.

As environmental regulations become more stringent, the eco-friendly nature of many carbonyl-based hydrophobic treatments positions them favorably for widespread industrial adoption. Their potential to replace less sustainable alternatives could drive significant market growth and technological innovation in the coming years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!