Dimethyl Ether Integration Across Global Infrastructure Masterplans

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Background and Objectives

Dimethyl ether (DME) has emerged as a promising alternative fuel and chemical feedstock, garnering significant attention in recent years due to its potential to address global energy and environmental challenges. The evolution of DME technology can be traced back to the early 20th century, with its initial synthesis and characterization. However, it wasn't until the late 1990s that DME began to gain traction as a viable energy solution, driven by the growing need for cleaner and more sustainable fuel options.

The development of DME technology has been marked by several key milestones, including advancements in production methods, improvements in storage and transportation infrastructure, and the expansion of its applications across various industries. From its early use as an aerosol propellant to its current status as a potential replacement for diesel fuel and liquefied petroleum gas (LPG), DME has demonstrated remarkable versatility and adaptability.

As global efforts to reduce greenhouse gas emissions and dependence on fossil fuels intensify, DME has positioned itself as a compelling alternative. Its clean-burning properties, high cetane number, and compatibility with existing infrastructure make it an attractive option for both developed and developing economies seeking to transition towards more sustainable energy systems.

The primary objective of researching DME integration across global infrastructure masterplans is to assess the feasibility and potential impact of widespread DME adoption on a global scale. This involves evaluating the technical, economic, and environmental aspects of incorporating DME into existing energy infrastructures, as well as identifying the necessary modifications and investments required to support its large-scale implementation.

Key areas of focus in this research include the optimization of DME production processes, the development of efficient distribution networks, and the adaptation of end-use technologies to accommodate DME as a fuel or chemical feedstock. Additionally, the study aims to explore the potential synergies between DME and other renewable energy sources, such as biomass and waste-to-energy systems, to create integrated and sustainable energy solutions.

By examining the integration of DME across global infrastructure masterplans, researchers and policymakers seek to unlock the full potential of this versatile compound and pave the way for a more sustainable and resilient energy future. The outcomes of this research are expected to inform strategic decisions regarding energy policy, infrastructure development, and technological innovation in the coming decades.

The development of DME technology has been marked by several key milestones, including advancements in production methods, improvements in storage and transportation infrastructure, and the expansion of its applications across various industries. From its early use as an aerosol propellant to its current status as a potential replacement for diesel fuel and liquefied petroleum gas (LPG), DME has demonstrated remarkable versatility and adaptability.

As global efforts to reduce greenhouse gas emissions and dependence on fossil fuels intensify, DME has positioned itself as a compelling alternative. Its clean-burning properties, high cetane number, and compatibility with existing infrastructure make it an attractive option for both developed and developing economies seeking to transition towards more sustainable energy systems.

The primary objective of researching DME integration across global infrastructure masterplans is to assess the feasibility and potential impact of widespread DME adoption on a global scale. This involves evaluating the technical, economic, and environmental aspects of incorporating DME into existing energy infrastructures, as well as identifying the necessary modifications and investments required to support its large-scale implementation.

Key areas of focus in this research include the optimization of DME production processes, the development of efficient distribution networks, and the adaptation of end-use technologies to accommodate DME as a fuel or chemical feedstock. Additionally, the study aims to explore the potential synergies between DME and other renewable energy sources, such as biomass and waste-to-energy systems, to create integrated and sustainable energy solutions.

By examining the integration of DME across global infrastructure masterplans, researchers and policymakers seek to unlock the full potential of this versatile compound and pave the way for a more sustainable and resilient energy future. The outcomes of this research are expected to inform strategic decisions regarding energy policy, infrastructure development, and technological innovation in the coming decades.

Global DME Market Analysis

The global Dimethyl Ether (DME) market has been experiencing significant growth in recent years, driven by increasing demand for clean and alternative fuels across various industries. DME, a colorless gas at ambient conditions, is gaining traction as a versatile energy carrier and chemical feedstock due to its environmental benefits and wide range of applications.

The market for DME is primarily segmented into two main categories: fuel applications and industrial applications. In the fuel sector, DME is being increasingly adopted as a substitute for diesel in transportation and power generation. Its low emissions profile and high cetane number make it an attractive option for reducing greenhouse gas emissions and improving air quality in urban areas.

Industrial applications of DME include its use as a propellant in aerosol products, a refrigerant in cooling systems, and a precursor in the production of various chemicals. The growing emphasis on sustainable manufacturing processes has further boosted the demand for DME in these sectors.

Geographically, the Asia-Pacific region dominates the global DME market, with China leading in both production and consumption. The region's rapid industrialization, coupled with stringent environmental regulations, has been a key driver for DME adoption. Europe and North America are also witnessing increased interest in DME, particularly in the transportation and energy sectors.

Market analysts project a compound annual growth rate (CAGR) of over 9% for the global DME market in the coming years. This growth is attributed to several factors, including the rising focus on reducing carbon emissions, government initiatives promoting clean energy, and the increasing cost-competitiveness of DME compared to traditional fuels.

The market landscape is characterized by a mix of established players and new entrants, with ongoing research and development efforts aimed at improving production efficiency and expanding applications. Major companies in the DME market are investing in capacity expansion and strategic partnerships to strengthen their market position and meet the growing demand.

However, challenges such as the need for infrastructure development, particularly in the transportation sector, and competition from other alternative fuels continue to impact market growth. Despite these challenges, the long-term outlook for the global DME market remains positive, driven by its potential to contribute significantly to the transition towards a more sustainable energy future.

The market for DME is primarily segmented into two main categories: fuel applications and industrial applications. In the fuel sector, DME is being increasingly adopted as a substitute for diesel in transportation and power generation. Its low emissions profile and high cetane number make it an attractive option for reducing greenhouse gas emissions and improving air quality in urban areas.

Industrial applications of DME include its use as a propellant in aerosol products, a refrigerant in cooling systems, and a precursor in the production of various chemicals. The growing emphasis on sustainable manufacturing processes has further boosted the demand for DME in these sectors.

Geographically, the Asia-Pacific region dominates the global DME market, with China leading in both production and consumption. The region's rapid industrialization, coupled with stringent environmental regulations, has been a key driver for DME adoption. Europe and North America are also witnessing increased interest in DME, particularly in the transportation and energy sectors.

Market analysts project a compound annual growth rate (CAGR) of over 9% for the global DME market in the coming years. This growth is attributed to several factors, including the rising focus on reducing carbon emissions, government initiatives promoting clean energy, and the increasing cost-competitiveness of DME compared to traditional fuels.

The market landscape is characterized by a mix of established players and new entrants, with ongoing research and development efforts aimed at improving production efficiency and expanding applications. Major companies in the DME market are investing in capacity expansion and strategic partnerships to strengthen their market position and meet the growing demand.

However, challenges such as the need for infrastructure development, particularly in the transportation sector, and competition from other alternative fuels continue to impact market growth. Despite these challenges, the long-term outlook for the global DME market remains positive, driven by its potential to contribute significantly to the transition towards a more sustainable energy future.

DME Tech Status and Hurdles

Dimethyl ether (DME) has emerged as a promising alternative fuel and chemical feedstock, garnering significant attention in global infrastructure planning. However, the current technological landscape presents both advancements and challenges that need to be addressed for widespread DME integration.

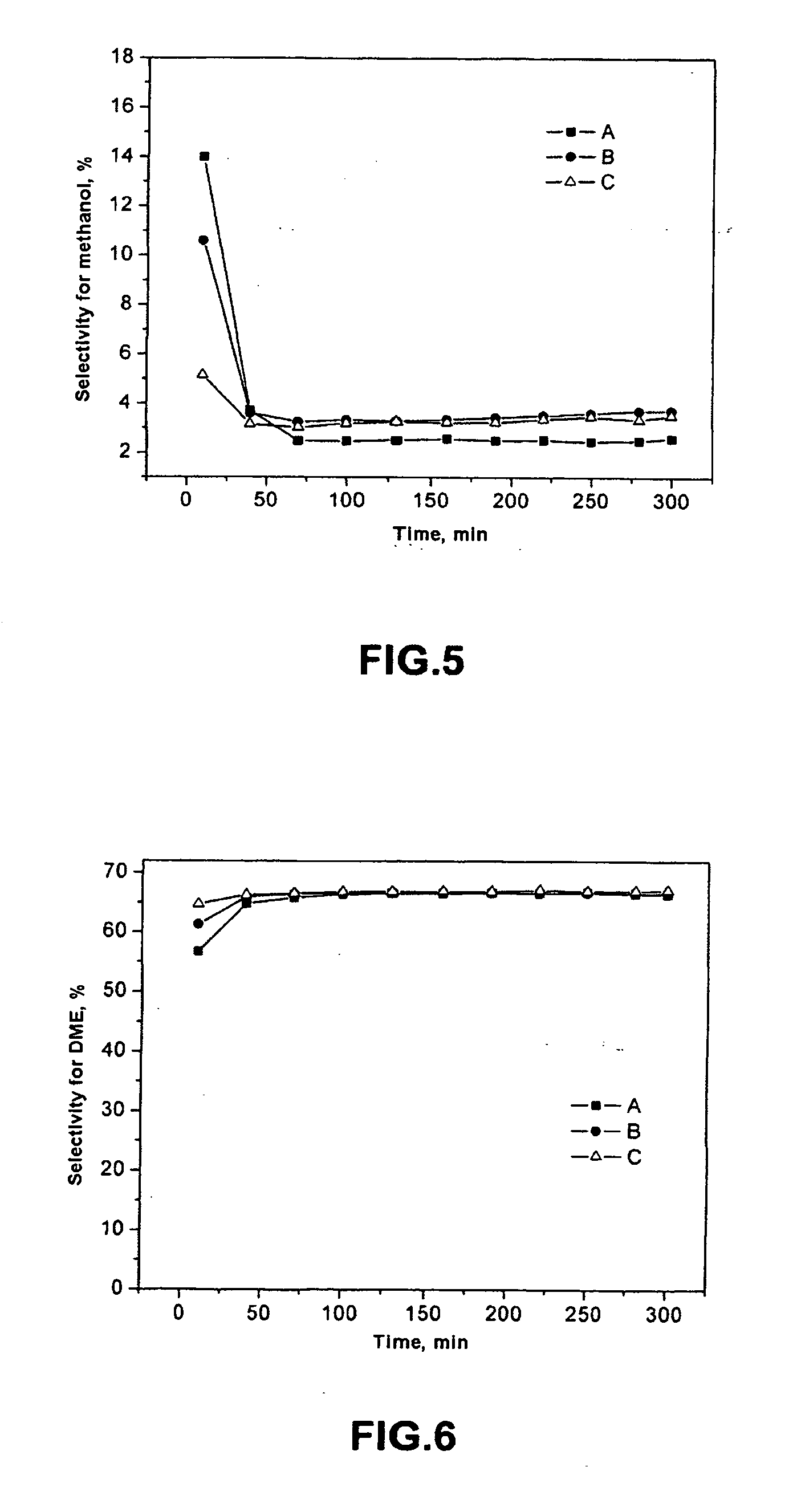

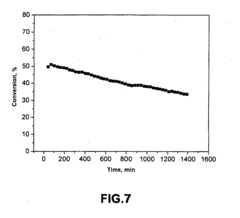

The production of DME has seen considerable progress, with two primary methods dominating the industry: direct synthesis from syngas and methanol dehydration. Direct synthesis offers higher efficiency and lower production costs, but faces challenges in catalyst stability and selectivity. Methanol dehydration, while more established, requires a two-step process that can be less economically viable for large-scale production.

One of the major hurdles in DME integration is the lack of dedicated infrastructure. Unlike conventional fuels, DME requires specialized storage, transportation, and distribution systems due to its unique physical properties. This necessitates significant investments in new infrastructure or modifications to existing systems, which can be a deterrent for widespread adoption.

The compatibility of DME with existing engines and equipment poses another challenge. While DME can be used in modified diesel engines, the extent of modifications required and the associated costs remain a concern for many potential users. Additionally, the lower energy density of DME compared to conventional diesel fuel necessitates larger fuel tanks or more frequent refueling, which can impact vehicle design and operational efficiency.

From a regulatory perspective, the integration of DME faces hurdles in standardization and policy support. The lack of uniform global standards for DME quality, handling, and use creates uncertainty for manufacturers and end-users alike. Furthermore, inconsistent policy frameworks across different regions hinder the development of a cohesive global DME market.

Environmental considerations also present both opportunities and challenges. While DME offers lower emissions compared to conventional fuels, concerns about potential methane slip during production and distribution need to be addressed. The lifecycle assessment of DME, particularly when produced from renewable sources, requires further research to fully establish its environmental credentials.

In terms of technological readiness, DME production at commercial scale has been demonstrated, but further optimization is needed to improve efficiency and reduce costs. Innovations in catalyst technology, process integration, and purification techniques are ongoing, with the potential to significantly enhance DME's economic viability.

The geographical distribution of DME technology development shows concentrations in Asia, particularly China and Japan, as well as in parts of Europe and North America. This uneven distribution presents challenges in technology transfer and global market development, potentially leading to disparities in DME adoption across different regions.

The production of DME has seen considerable progress, with two primary methods dominating the industry: direct synthesis from syngas and methanol dehydration. Direct synthesis offers higher efficiency and lower production costs, but faces challenges in catalyst stability and selectivity. Methanol dehydration, while more established, requires a two-step process that can be less economically viable for large-scale production.

One of the major hurdles in DME integration is the lack of dedicated infrastructure. Unlike conventional fuels, DME requires specialized storage, transportation, and distribution systems due to its unique physical properties. This necessitates significant investments in new infrastructure or modifications to existing systems, which can be a deterrent for widespread adoption.

The compatibility of DME with existing engines and equipment poses another challenge. While DME can be used in modified diesel engines, the extent of modifications required and the associated costs remain a concern for many potential users. Additionally, the lower energy density of DME compared to conventional diesel fuel necessitates larger fuel tanks or more frequent refueling, which can impact vehicle design and operational efficiency.

From a regulatory perspective, the integration of DME faces hurdles in standardization and policy support. The lack of uniform global standards for DME quality, handling, and use creates uncertainty for manufacturers and end-users alike. Furthermore, inconsistent policy frameworks across different regions hinder the development of a cohesive global DME market.

Environmental considerations also present both opportunities and challenges. While DME offers lower emissions compared to conventional fuels, concerns about potential methane slip during production and distribution need to be addressed. The lifecycle assessment of DME, particularly when produced from renewable sources, requires further research to fully establish its environmental credentials.

In terms of technological readiness, DME production at commercial scale has been demonstrated, but further optimization is needed to improve efficiency and reduce costs. Innovations in catalyst technology, process integration, and purification techniques are ongoing, with the potential to significantly enhance DME's economic viability.

The geographical distribution of DME technology development shows concentrations in Asia, particularly China and Japan, as well as in parts of Europe and North America. This uneven distribution presents challenges in technology transfer and global market development, potentially leading to disparities in DME adoption across different regions.

Current DME Integration Solutions

01 Production of dimethyl ether

Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.- Production of dimethyl ether: Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.

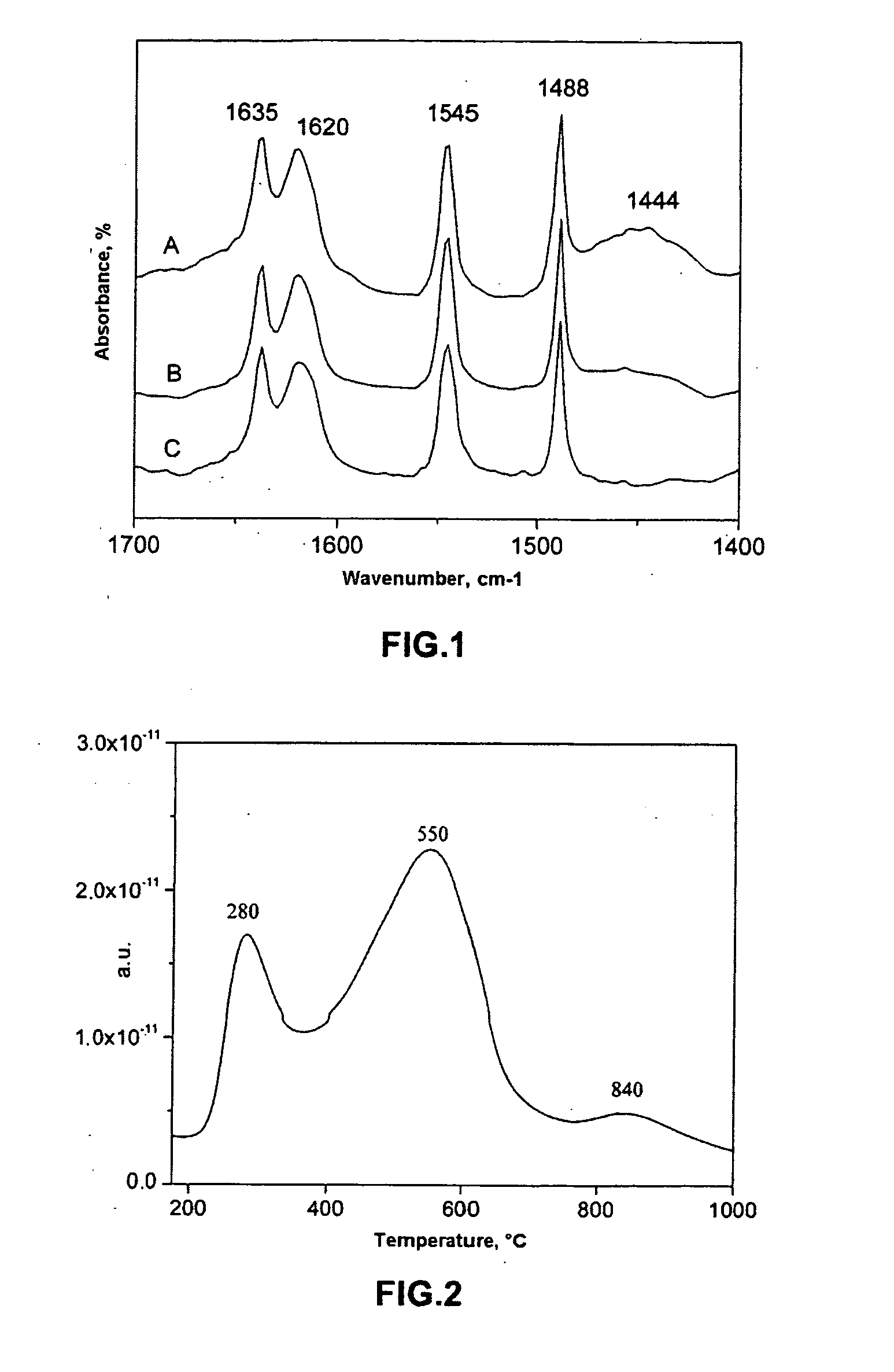

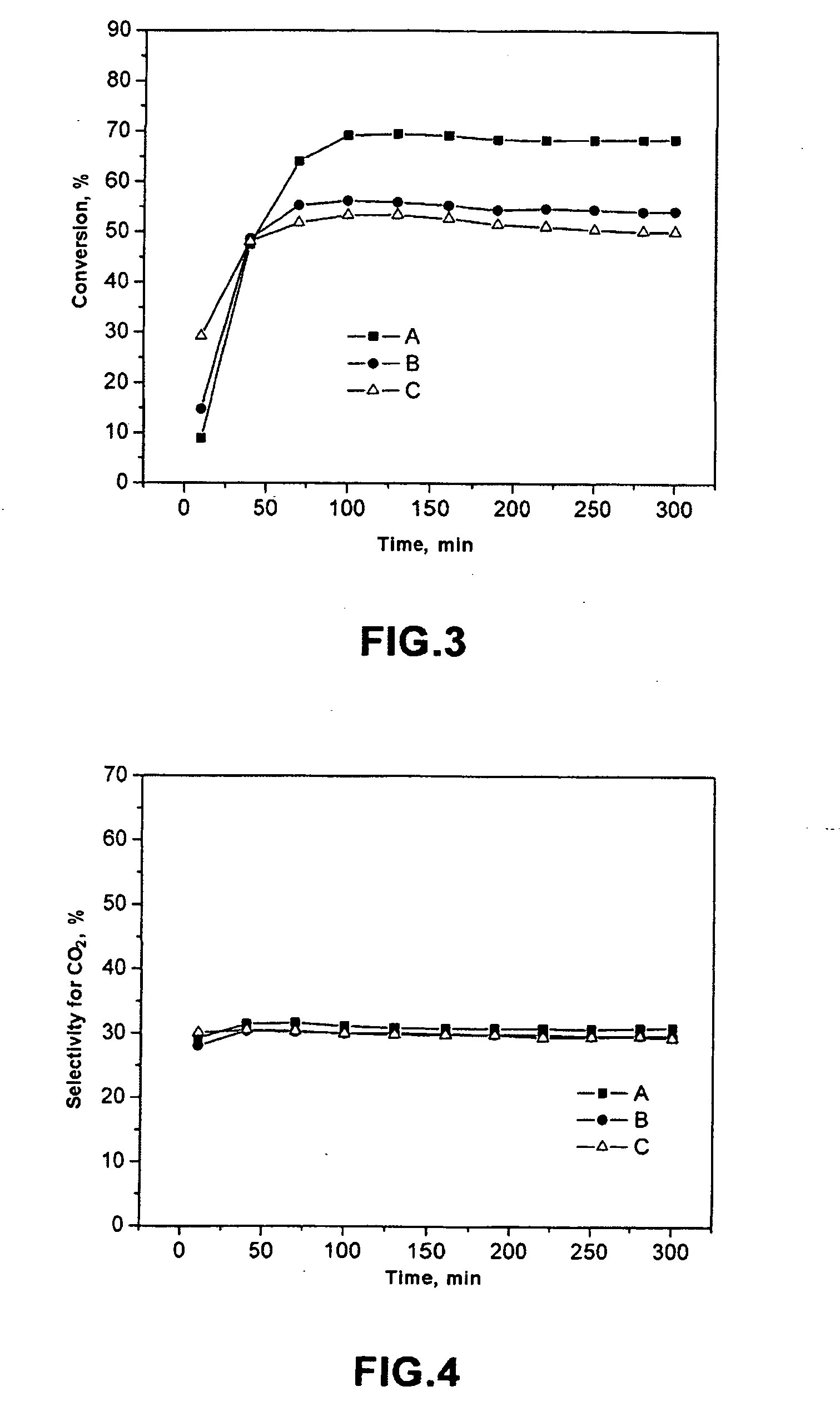

- Catalysts for dimethyl ether synthesis: Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice of catalyst can significantly affect the reaction efficiency, product selectivity, and overall process economics.

- Applications of dimethyl ether: Dimethyl ether has various applications, including use as a fuel additive, aerosol propellant, and refrigerant. It is also being explored as a potential alternative fuel for diesel engines due to its clean-burning properties and high cetane number.

- Purification and separation of dimethyl ether: Methods for purifying and separating dimethyl ether from reaction mixtures or other compounds are described. These processes may involve distillation, adsorption, or membrane separation techniques to achieve high-purity dimethyl ether for various applications.

- Environmental and safety considerations: Research on the environmental impact and safety aspects of dimethyl ether production and use is ongoing. This includes studies on emissions reduction, handling procedures, and storage requirements to ensure safe and sustainable utilization of dimethyl ether in various applications.

02 Catalysts for dimethyl ether synthesis

Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice and preparation of catalysts significantly affect the efficiency and selectivity of the dimethyl ether synthesis process.Expand Specific Solutions03 Applications of dimethyl ether

Dimethyl ether has various applications, including use as a fuel substitute, propellant, refrigerant, and chemical intermediate. Its properties make it suitable for use in diesel engines, aerosol sprays, and as a building block for other chemical compounds.Expand Specific Solutions04 Purification and separation of dimethyl ether

Methods for purifying and separating dimethyl ether from reaction mixtures or other compounds are described. These processes often involve distillation, adsorption, or membrane separation techniques to obtain high-purity dimethyl ether.Expand Specific Solutions05 Environmental and safety considerations

Research on the environmental impact and safety aspects of dimethyl ether production and use is conducted. This includes studies on emissions reduction, handling procedures, and risk assessments associated with its use as a fuel or chemical intermediate.Expand Specific Solutions

Key DME Industry Players

The research on Dimethyl Ether (DME) integration across global infrastructure masterplans is in a nascent stage, with the market still developing. The global DME market size is projected to grow significantly in the coming years, driven by increasing demand for clean alternative fuels. Technologically, DME production and utilization are relatively mature, but infrastructure integration remains challenging. Key players like China Petroleum & Chemical Corp., DuPont, and BASF are investing in DME research and development, focusing on production efficiency, storage, and distribution technologies. Universities and research institutions, such as the University of Southern California and Tianjin University, are also contributing to advancing DME integration strategies, indicating a collaborative approach to overcome implementation hurdles.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has been at the forefront of dimethyl ether (DME) integration research. They have developed a proprietary technology for large-scale DME production from syngas, with a capacity of up to 1 million tons per year[1]. Their process involves a single-step synthesis method, which significantly reduces production costs and improves energy efficiency. Sinopec has also been working on DME as a clean alternative fuel for vehicles and household cooking, with pilot projects demonstrating a reduction in particulate matter emissions by up to 90% compared to traditional diesel fuel[2]. The company has invested in DME infrastructure development, including dedicated storage facilities and distribution networks, to support the widespread adoption of DME as an energy source[3].

Strengths: Established large-scale production capability, integrated supply chain, and extensive R&D resources. Weaknesses: Dependence on fossil fuel feedstock for DME production, which may face challenges in a carbon-constrained future.

BP Corporation North America, Inc.

Technical Solution: BP Corporation North America, Inc. has been actively researching DME as part of its alternative energy portfolio. Their approach focuses on integrating DME production with existing natural gas infrastructure to leverage their global gas assets. BP has developed a novel process for direct DME synthesis from natural gas, which reduces capital costs by up to 30% compared to traditional two-step processes[10]. The company has also been exploring the use of DME in marine applications, conducting successful trials of DME-powered ships that demonstrated a 95% reduction in sulfur oxide emissions compared to conventional marine fuels[11]. BP's research extends to the use of carbon capture and storage (CCS) technologies in DME production, aiming to create a carbon-neutral or even carbon-negative fuel option. They have piloted a DME production facility that captures over 90% of CO2 emissions, significantly enhancing the environmental profile of DME as an energy carrier[12].

Strengths: Extensive global energy infrastructure, significant R&D resources, and a strong focus on decarbonization technologies. Weaknesses: Potential conflicts with existing fossil fuel business models and the need for large-scale infrastructure investments.

DME Infrastructure Innovations

Energy supply method and system

PatentWO2006004140A1

Innovation

- The introduction of Dimethyl Ether (DME) as a versatile energy circulation medium, which can be derived from biomass, waste, and petroleum residues, and used for power generation, transportation, and heating, allowing for efficient energy storage and distribution without relying on pipelines, and enabling the conversion of waste heat into usable energy.

Catalytic system and process for direct synthesis of dimethyl ether from synthesis gas

PatentInactiveUS20090326281A1

Innovation

- A mixed-bed catalytic system comprising a catalyst for methanol synthesis and acid form zeolite ferrierite, with a silica/alumina ratio of 10 and specific potassium and sodium content, is physically mixed and activated, providing a high concentration of Brønsted acid sites for efficient dehydration without forming unwanted products.

DME Environmental Impact

The environmental impact of dimethyl ether (DME) integration across global infrastructure masterplans is a critical consideration for policymakers and industry stakeholders. DME, as a clean-burning fuel alternative, offers significant potential for reducing greenhouse gas emissions and improving air quality in various sectors, particularly in transportation and power generation.

One of the primary environmental benefits of DME is its lower carbon footprint compared to conventional fossil fuels. When produced from renewable sources such as biomass or captured CO2, DME can achieve near-zero or even negative carbon emissions. This characteristic aligns well with global efforts to mitigate climate change and transition towards a low-carbon economy.

In the transportation sector, DME can serve as a substitute for diesel fuel in heavy-duty vehicles, reducing particulate matter and NOx emissions. This shift could lead to improved air quality in urban areas, where vehicular emissions are a major contributor to pollution. Additionally, DME's compatibility with existing diesel engine technology allows for a smoother transition without requiring extensive infrastructure overhaul.

The integration of DME in power generation systems also presents environmental advantages. As a cleaner-burning fuel, DME can replace coal or heavy fuel oil in power plants, resulting in lower sulfur dioxide and mercury emissions. This transition could significantly improve air quality and reduce the environmental impact of electricity production, particularly in regions heavily reliant on coal-fired power plants.

However, the environmental impact of DME integration is not without challenges. The production process of DME, especially when derived from fossil fuels, can still contribute to greenhouse gas emissions. Therefore, the full life-cycle assessment of DME production and use must be considered to accurately evaluate its environmental benefits.

Water consumption is another environmental factor to consider in DME production. Depending on the production method, significant water resources may be required, potentially impacting local ecosystems and water availability in water-stressed regions.

Land use changes associated with large-scale DME production, particularly from biomass feedstocks, could have implications for biodiversity and food security. Careful planning and sustainable land management practices are essential to mitigate these potential negative impacts.

As global infrastructure masterplans incorporate DME, it is crucial to implement robust environmental monitoring and management systems. These systems should track emissions, water usage, and land-use changes associated with DME production and utilization to ensure that the intended environmental benefits are realized and any unforeseen negative impacts are promptly addressed.

One of the primary environmental benefits of DME is its lower carbon footprint compared to conventional fossil fuels. When produced from renewable sources such as biomass or captured CO2, DME can achieve near-zero or even negative carbon emissions. This characteristic aligns well with global efforts to mitigate climate change and transition towards a low-carbon economy.

In the transportation sector, DME can serve as a substitute for diesel fuel in heavy-duty vehicles, reducing particulate matter and NOx emissions. This shift could lead to improved air quality in urban areas, where vehicular emissions are a major contributor to pollution. Additionally, DME's compatibility with existing diesel engine technology allows for a smoother transition without requiring extensive infrastructure overhaul.

The integration of DME in power generation systems also presents environmental advantages. As a cleaner-burning fuel, DME can replace coal or heavy fuel oil in power plants, resulting in lower sulfur dioxide and mercury emissions. This transition could significantly improve air quality and reduce the environmental impact of electricity production, particularly in regions heavily reliant on coal-fired power plants.

However, the environmental impact of DME integration is not without challenges. The production process of DME, especially when derived from fossil fuels, can still contribute to greenhouse gas emissions. Therefore, the full life-cycle assessment of DME production and use must be considered to accurately evaluate its environmental benefits.

Water consumption is another environmental factor to consider in DME production. Depending on the production method, significant water resources may be required, potentially impacting local ecosystems and water availability in water-stressed regions.

Land use changes associated with large-scale DME production, particularly from biomass feedstocks, could have implications for biodiversity and food security. Careful planning and sustainable land management practices are essential to mitigate these potential negative impacts.

As global infrastructure masterplans incorporate DME, it is crucial to implement robust environmental monitoring and management systems. These systems should track emissions, water usage, and land-use changes associated with DME production and utilization to ensure that the intended environmental benefits are realized and any unforeseen negative impacts are promptly addressed.

DME Policy and Regulations

The integration of Dimethyl Ether (DME) into global infrastructure masterplans requires a comprehensive understanding of the existing policy and regulatory landscape. Governments worldwide are increasingly recognizing the potential of DME as a clean alternative fuel, leading to the development of supportive policies and regulations.

In the United States, the Environmental Protection Agency (EPA) has approved DME as a renewable fuel under the Renewable Fuel Standard program. This classification allows DME producers to generate Renewable Identification Numbers (RINs), providing economic incentives for production and use. Additionally, several states have implemented their own policies to promote DME adoption, such as California's Low Carbon Fuel Standard, which offers credits for low-carbon fuels including DME.

The European Union has also taken significant steps to support DME integration. The Renewable Energy Directive (RED II) includes DME as an eligible renewable fuel, setting targets for renewable energy use in transportation. This directive encourages member states to develop national policies that promote DME production and utilization. Countries like Sweden and Denmark have been at the forefront, implementing tax incentives and infrastructure support for DME projects.

In Asia, China has been a leader in DME policy development. The country's 13th Five-Year Plan (2016-2020) explicitly mentioned DME as a key alternative fuel, leading to supportive regulations for production and distribution. Japan has also shown interest, with the Ministry of Economy, Trade and Industry (METI) funding research and pilot projects to explore DME's potential in various applications.

Globally, international organizations are playing a crucial role in shaping DME policies. The International DME Association (IDA) works with policymakers to develop standards and regulations that facilitate DME adoption. The International Energy Agency (IEA) has recognized DME in its clean energy transition scenarios, influencing policy discussions in member countries.

However, challenges remain in harmonizing DME regulations across borders. Differences in fuel quality standards, safety regulations, and taxation policies can hinder the seamless integration of DME into global infrastructure. Efforts are underway to develop international standards, such as those by the International Organization for Standardization (ISO), to address these issues.

As DME gains traction, policymakers are increasingly focusing on lifecycle assessments to ensure its environmental benefits. Regulations are evolving to consider the entire production chain, from feedstock sourcing to end-use emissions. This holistic approach is crucial for maintaining DME's status as a sustainable alternative fuel and ensuring its long-term viability in global energy strategies.

In the United States, the Environmental Protection Agency (EPA) has approved DME as a renewable fuel under the Renewable Fuel Standard program. This classification allows DME producers to generate Renewable Identification Numbers (RINs), providing economic incentives for production and use. Additionally, several states have implemented their own policies to promote DME adoption, such as California's Low Carbon Fuel Standard, which offers credits for low-carbon fuels including DME.

The European Union has also taken significant steps to support DME integration. The Renewable Energy Directive (RED II) includes DME as an eligible renewable fuel, setting targets for renewable energy use in transportation. This directive encourages member states to develop national policies that promote DME production and utilization. Countries like Sweden and Denmark have been at the forefront, implementing tax incentives and infrastructure support for DME projects.

In Asia, China has been a leader in DME policy development. The country's 13th Five-Year Plan (2016-2020) explicitly mentioned DME as a key alternative fuel, leading to supportive regulations for production and distribution. Japan has also shown interest, with the Ministry of Economy, Trade and Industry (METI) funding research and pilot projects to explore DME's potential in various applications.

Globally, international organizations are playing a crucial role in shaping DME policies. The International DME Association (IDA) works with policymakers to develop standards and regulations that facilitate DME adoption. The International Energy Agency (IEA) has recognized DME in its clean energy transition scenarios, influencing policy discussions in member countries.

However, challenges remain in harmonizing DME regulations across borders. Differences in fuel quality standards, safety regulations, and taxation policies can hinder the seamless integration of DME into global infrastructure. Efforts are underway to develop international standards, such as those by the International Organization for Standardization (ISO), to address these issues.

As DME gains traction, policymakers are increasingly focusing on lifecycle assessments to ensure its environmental benefits. Regulations are evolving to consider the entire production chain, from feedstock sourcing to end-use emissions. This holistic approach is crucial for maintaining DME's status as a sustainable alternative fuel and ensuring its long-term viability in global energy strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!