Efficient Light Transmission through Borosilicate Glass

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Borosilicate Glass Light Transmission Background

Borosilicate glass has been a cornerstone material in various industries for over a century, renowned for its exceptional thermal and chemical resistance properties. The study of efficient light transmission through this versatile material has gained significant attention in recent years, driven by the increasing demand for high-performance optical components in fields such as photonics, solar energy, and advanced imaging systems.

The journey of borosilicate glass began in the late 19th century when German glassmaker Otto Schott developed this revolutionary material. Initially prized for its low thermal expansion coefficient, which made it ideal for laboratory glassware and cookware, borosilicate glass soon found applications in optics due to its excellent transparency and durability.

As technology progressed, the need for materials capable of efficiently transmitting light across a wide spectrum became paramount. Borosilicate glass, with its unique composition of silica and boron trioxide, emerged as a promising candidate for such applications. Its inherent properties, including high transmittance in the visible and near-infrared regions, coupled with its resistance to thermal shock and chemical corrosion, made it an attractive option for researchers and engineers alike.

The evolution of light transmission research in borosilicate glass has been closely tied to advancements in manufacturing processes and surface treatment technologies. Early studies focused primarily on understanding the fundamental optical properties of the material, such as its refractive index and dispersion characteristics. As the field progressed, attention shifted towards enhancing transmission efficiency through innovative approaches like anti-reflective coatings and precision polishing techniques.

In recent years, the quest for efficient light transmission through borosilicate glass has been driven by the growing demands of cutting-edge technologies. The photonics industry, in particular, has been a significant driver of research in this area, as it seeks to develop high-performance optical components for applications ranging from fiber optics to laser systems. Similarly, the renewable energy sector has shown keen interest in optimizing light transmission through borosilicate glass for solar collectors and photovoltaic modules.

The current landscape of research on efficient light transmission through borosilicate glass is characterized by a multidisciplinary approach, combining expertise from materials science, optics, and nanotechnology. Scientists and engineers are exploring novel methods to manipulate the glass structure at the molecular level, aiming to enhance its light transmission properties while maintaining its other desirable characteristics.

As we look towards the future, the study of efficient light transmission through borosilicate glass continues to evolve, promising exciting developments in fields such as quantum optics, biomedical imaging, and advanced sensing technologies. The ongoing research in this area not only pushes the boundaries of what is possible with this versatile material but also opens up new avenues for innovation across a wide range of industries.

The journey of borosilicate glass began in the late 19th century when German glassmaker Otto Schott developed this revolutionary material. Initially prized for its low thermal expansion coefficient, which made it ideal for laboratory glassware and cookware, borosilicate glass soon found applications in optics due to its excellent transparency and durability.

As technology progressed, the need for materials capable of efficiently transmitting light across a wide spectrum became paramount. Borosilicate glass, with its unique composition of silica and boron trioxide, emerged as a promising candidate for such applications. Its inherent properties, including high transmittance in the visible and near-infrared regions, coupled with its resistance to thermal shock and chemical corrosion, made it an attractive option for researchers and engineers alike.

The evolution of light transmission research in borosilicate glass has been closely tied to advancements in manufacturing processes and surface treatment technologies. Early studies focused primarily on understanding the fundamental optical properties of the material, such as its refractive index and dispersion characteristics. As the field progressed, attention shifted towards enhancing transmission efficiency through innovative approaches like anti-reflective coatings and precision polishing techniques.

In recent years, the quest for efficient light transmission through borosilicate glass has been driven by the growing demands of cutting-edge technologies. The photonics industry, in particular, has been a significant driver of research in this area, as it seeks to develop high-performance optical components for applications ranging from fiber optics to laser systems. Similarly, the renewable energy sector has shown keen interest in optimizing light transmission through borosilicate glass for solar collectors and photovoltaic modules.

The current landscape of research on efficient light transmission through borosilicate glass is characterized by a multidisciplinary approach, combining expertise from materials science, optics, and nanotechnology. Scientists and engineers are exploring novel methods to manipulate the glass structure at the molecular level, aiming to enhance its light transmission properties while maintaining its other desirable characteristics.

As we look towards the future, the study of efficient light transmission through borosilicate glass continues to evolve, promising exciting developments in fields such as quantum optics, biomedical imaging, and advanced sensing technologies. The ongoing research in this area not only pushes the boundaries of what is possible with this versatile material but also opens up new avenues for innovation across a wide range of industries.

Market Analysis for High-Efficiency Optical Glass

The market for high-efficiency optical glass, particularly borosilicate glass with enhanced light transmission properties, is experiencing significant growth driven by increasing demand across various industries. The global optical glass market, valued at $16.2 billion in 2020, is projected to reach $22.8 billion by 2026, with a compound annual growth rate (CAGR) of 5.8%. This growth is primarily fueled by the expanding applications in telecommunications, consumer electronics, and advanced optical systems.

Borosilicate glass, known for its excellent thermal and chemical resistance, is gaining traction in the high-efficiency optical glass segment. The market for borosilicate glass is expected to grow at a CAGR of 6.2% from 2021 to 2028, driven by its superior light transmission properties and durability. The increasing adoption of borosilicate glass in solar panels, fiber optics, and precision optics is a key factor contributing to this growth.

The telecommunications industry, particularly the fiber optic sector, is a major driver for the high-efficiency optical glass market. With the global fiber optic market projected to reach $9.1 billion by 2025, the demand for high-quality borosilicate glass with efficient light transmission capabilities is set to surge. This trend is further amplified by the ongoing 5G network deployments and the increasing need for high-speed data transmission.

In the consumer electronics sector, the demand for high-efficiency optical glass is being driven by the growing popularity of smartphones, tablets, and wearable devices. The global smartphone market, expected to reach 1.5 billion units by 2025, is creating a substantial demand for advanced display technologies that require high-quality optical glass with superior light transmission properties.

The automotive industry is emerging as a promising market for high-efficiency optical glass, particularly in the development of advanced driver-assistance systems (ADAS) and autonomous vehicles. The global automotive glass market is projected to grow at a CAGR of 4.5% from 2021 to 2028, with a significant portion attributed to the demand for high-performance optical glass in sensors and display systems.

Geographically, Asia-Pacific is expected to dominate the high-efficiency optical glass market, accounting for over 40% of the global market share. This is primarily due to the presence of major electronics manufacturers and the rapid adoption of advanced technologies in countries like China, Japan, and South Korea. North America and Europe are also significant markets, driven by innovations in telecommunications and automotive industries.

The market for high-efficiency optical glass, especially borosilicate glass with enhanced light transmission properties, is poised for substantial growth. As industries continue to demand advanced optical solutions, the development of more efficient light transmission technologies through borosilicate glass will play a crucial role in shaping the future of this market.

Borosilicate glass, known for its excellent thermal and chemical resistance, is gaining traction in the high-efficiency optical glass segment. The market for borosilicate glass is expected to grow at a CAGR of 6.2% from 2021 to 2028, driven by its superior light transmission properties and durability. The increasing adoption of borosilicate glass in solar panels, fiber optics, and precision optics is a key factor contributing to this growth.

The telecommunications industry, particularly the fiber optic sector, is a major driver for the high-efficiency optical glass market. With the global fiber optic market projected to reach $9.1 billion by 2025, the demand for high-quality borosilicate glass with efficient light transmission capabilities is set to surge. This trend is further amplified by the ongoing 5G network deployments and the increasing need for high-speed data transmission.

In the consumer electronics sector, the demand for high-efficiency optical glass is being driven by the growing popularity of smartphones, tablets, and wearable devices. The global smartphone market, expected to reach 1.5 billion units by 2025, is creating a substantial demand for advanced display technologies that require high-quality optical glass with superior light transmission properties.

The automotive industry is emerging as a promising market for high-efficiency optical glass, particularly in the development of advanced driver-assistance systems (ADAS) and autonomous vehicles. The global automotive glass market is projected to grow at a CAGR of 4.5% from 2021 to 2028, with a significant portion attributed to the demand for high-performance optical glass in sensors and display systems.

Geographically, Asia-Pacific is expected to dominate the high-efficiency optical glass market, accounting for over 40% of the global market share. This is primarily due to the presence of major electronics manufacturers and the rapid adoption of advanced technologies in countries like China, Japan, and South Korea. North America and Europe are also significant markets, driven by innovations in telecommunications and automotive industries.

The market for high-efficiency optical glass, especially borosilicate glass with enhanced light transmission properties, is poised for substantial growth. As industries continue to demand advanced optical solutions, the development of more efficient light transmission technologies through borosilicate glass will play a crucial role in shaping the future of this market.

Current Challenges in Light Transmission

Despite significant advancements in glass technology, several challenges persist in achieving efficient light transmission through borosilicate glass. One of the primary obstacles is the inherent absorption and scattering of light within the glass matrix. Borosilicate glass, while known for its excellent thermal and chemical properties, still exhibits some level of light attenuation, particularly in the ultraviolet and infrared regions of the spectrum.

The presence of impurities and structural defects in the glass further complicates light transmission. These imperfections can act as scattering centers, leading to reduced transparency and increased optical losses. Minimizing these defects during the manufacturing process remains a significant challenge, especially when scaling up production for industrial applications.

Another critical issue is the reflection of light at the glass-air interface. While anti-reflective coatings have been developed to mitigate this problem, achieving uniform and durable coatings on complex glass shapes remains challenging. Moreover, these coatings often have limited spectral ranges, making it difficult to optimize light transmission across a broad spectrum.

The trade-off between mechanical strength and optical performance presents another hurdle. Increasing the thickness of borosilicate glass to improve its durability often comes at the cost of reduced light transmission. Conversely, thinner glass allows for better light transmission but may compromise structural integrity, limiting its applications in demanding environments.

Temperature-induced refractive index changes pose additional challenges, particularly in high-precision optical systems. As borosilicate glass experiences thermal expansion or contraction, its refractive index can vary, leading to optical distortions and reduced performance in applications requiring high stability.

The development of specialized borosilicate glass compositions for specific wavelength ranges or applications introduces further complexities. Tailoring the glass composition to enhance transmission in certain spectral regions often involves intricate balancing acts between various dopants and modifiers, which can be challenging to optimize and reproduce consistently.

Lastly, the integration of borosilicate glass with other optical components in complex systems presents its own set of challenges. Ensuring seamless interfaces between glass elements and other materials, while maintaining optimal light transmission and minimizing losses at junctions, requires advanced design and manufacturing techniques that are still being refined.

The presence of impurities and structural defects in the glass further complicates light transmission. These imperfections can act as scattering centers, leading to reduced transparency and increased optical losses. Minimizing these defects during the manufacturing process remains a significant challenge, especially when scaling up production for industrial applications.

Another critical issue is the reflection of light at the glass-air interface. While anti-reflective coatings have been developed to mitigate this problem, achieving uniform and durable coatings on complex glass shapes remains challenging. Moreover, these coatings often have limited spectral ranges, making it difficult to optimize light transmission across a broad spectrum.

The trade-off between mechanical strength and optical performance presents another hurdle. Increasing the thickness of borosilicate glass to improve its durability often comes at the cost of reduced light transmission. Conversely, thinner glass allows for better light transmission but may compromise structural integrity, limiting its applications in demanding environments.

Temperature-induced refractive index changes pose additional challenges, particularly in high-precision optical systems. As borosilicate glass experiences thermal expansion or contraction, its refractive index can vary, leading to optical distortions and reduced performance in applications requiring high stability.

The development of specialized borosilicate glass compositions for specific wavelength ranges or applications introduces further complexities. Tailoring the glass composition to enhance transmission in certain spectral regions often involves intricate balancing acts between various dopants and modifiers, which can be challenging to optimize and reproduce consistently.

Lastly, the integration of borosilicate glass with other optical components in complex systems presents its own set of challenges. Ensuring seamless interfaces between glass elements and other materials, while maintaining optimal light transmission and minimizing losses at junctions, requires advanced design and manufacturing techniques that are still being refined.

Existing Light Transmission Solutions

01 Composition and properties of borosilicate glass

Borosilicate glass is known for its high light transmission properties due to its unique composition. It typically contains boron trioxide and silica, which contribute to its excellent optical clarity and low refractive index. This composition allows for high transmittance across a wide range of wavelengths, making it suitable for various optical applications.- Composition optimization for light transmission: Borosilicate glass compositions can be optimized to enhance light transmission. This involves adjusting the ratios of key components such as silica, boron oxide, and other additives to achieve desired optical properties. The optimized composition can result in improved transparency and light transmission across various wavelengths.

- Surface treatment techniques: Various surface treatment methods can be applied to borosilicate glass to improve its light transmission properties. These techniques may include anti-reflective coatings, etching processes, or the application of specific films. Such treatments can reduce surface reflections and increase the overall light transmission through the glass.

- Nanostructure incorporation: Incorporating nanostructures into borosilicate glass can significantly enhance its light transmission capabilities. This may involve the addition of nanoparticles or the creation of nanoscale surface patterns. These nanostructures can manipulate light at the subwavelength level, leading to improved transmission and reduced reflection.

- Heat treatment and annealing processes: Specific heat treatment and annealing processes can be employed to improve the light transmission properties of borosilicate glass. These thermal processes can help reduce internal stresses, minimize defects, and optimize the glass structure, resulting in enhanced optical clarity and light transmission.

- Doping with rare earth elements: Doping borosilicate glass with rare earth elements can modify its optical properties, including light transmission. The addition of specific rare earth ions can influence the glass's interaction with light, potentially enhancing transmission in certain wavelength ranges or creating unique optical effects that can be beneficial for specific applications.

02 Surface treatments to enhance light transmission

Various surface treatments can be applied to borosilicate glass to further improve its light transmission. These treatments may include anti-reflective coatings, etching processes, or the application of specific films. Such treatments can reduce surface reflections and increase the overall light transmission through the glass.Expand Specific Solutions03 Borosilicate glass in optical devices

Borosilicate glass is widely used in optical devices due to its high light transmission properties. It is commonly employed in lenses, prisms, and other optical components where clarity and minimal light loss are crucial. The glass's ability to maintain its optical properties under various environmental conditions makes it ideal for precision optical instruments.Expand Specific Solutions04 Thermal and chemical resistance affecting light transmission

The thermal and chemical resistance of borosilicate glass contributes to its stable light transmission properties. Its low coefficient of thermal expansion and high resistance to chemical corrosion help maintain optical clarity and light transmission even under harsh conditions or prolonged use, making it suitable for applications in extreme environments.Expand Specific Solutions05 Modifications for specific light transmission characteristics

Borosilicate glass can be modified to achieve specific light transmission characteristics. This may involve doping with certain elements, adjusting the glass composition, or applying specialized coatings. These modifications can enhance or selectively filter certain wavelengths of light, allowing for customized optical properties tailored to specific applications.Expand Specific Solutions

Key Players in Optical Glass Industry

The research on efficient light transmission through borosilicate glass is in a mature stage, with significant market potential and ongoing innovation. The global borosilicate glass market is experiencing steady growth, driven by increasing demand in pharmaceuticals, electronics, and laboratory equipment. Key players like SCHOTT AG, Corning, Inc., and AGC, Inc. are leading the field with advanced technologies and extensive product portfolios. These companies, along with others such as Nippon Electric Glass and LG Chem, are investing heavily in R&D to improve light transmission efficiency and develop new applications. The competitive landscape is characterized by a mix of established multinational corporations and specialized regional manufacturers, all striving to enhance product performance and expand market share in this technologically advanced sector.

SCHOTT AG

Technical Solution: SCHOTT AG has developed advanced borosilicate glass compositions with optimized light transmission properties. Their BOROFLOAT® glass offers excellent optical quality with up to 92% light transmission in the visible spectrum[1]. They have implemented nano-scale surface treatments to reduce reflection and enhance light throughput. SCHOTT has also pioneered the use of ion exchange processes to create chemically strengthened borosilicate glass that maintains high light transmission while improving durability[2]. Their research focuses on tailoring the glass composition and structure at the molecular level to maximize light transmission across specific wavelength ranges.

Strengths: Industry-leading expertise in specialized glass formulations, advanced manufacturing capabilities. Weaknesses: Higher production costs compared to standard glass, limited flexibility in large-scale production.

Corning, Inc.

Technical Solution: Corning has developed proprietary fusion draw process for manufacturing ultra-thin, high-quality borosilicate glass sheets with exceptional optical clarity. Their Gorilla® Glass technology, while primarily known for durability, also incorporates light transmission enhancements. Corning's research includes the development of anti-reflective coatings that can increase light transmission by up to 99% in specific wavelength ranges[3]. They have also explored the use of nanostructured surfaces to reduce reflection and improve light transmission at various angles of incidence. Corning's approach combines material science innovations with precision manufacturing to achieve optimal light transmission properties.

Strengths: Strong R&D capabilities, established manufacturing infrastructure. Weaknesses: Focus on consumer electronics may limit specialized optical applications.

Innovations in Borosilicate Glass Optics

UV transmitting glasses

PatentWO2007001881A3

Innovation

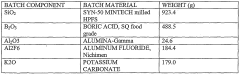

- High UV transmission: The glass exhibits excellent UV transmission, with greater than 80%/mm at 300 nm.

- Unique composition: Alkali fluorine-doped boroaluminosilicate glass with specific molar ratios of R/Al and F/O.

- Balanced oxide composition: Carefully controlled percentages of SiO2, Al2(O, F2)3, B2O3, and R2O to achieve desired properties.

UV transmitting glasses

PatentWO2007001881A2

Innovation

- Development of an alkali fluorine-doped boroaluminosilicate glass with a composition of 30-80% SiO2, 1-20% Al2(O, F2)3, 5-35% B2O3, and 5-20% R2O, where R is Li, Na, K, or Cs, with specific molar ratios and transition metal content, allowing for excellent UV transmission and stability, enabling continuous manufacturing and conventional forming methods.

Manufacturing Processes and Quality Control

The manufacturing processes and quality control measures for borosilicate glass play a crucial role in ensuring efficient light transmission. The production of high-quality borosilicate glass begins with carefully selecting and mixing raw materials, including silica sand, boric oxide, and other additives. These materials are melted in furnaces at temperatures exceeding 1500°C to create a homogeneous molten glass.

The molten glass then undergoes a forming process, which can include methods such as float glass production, pressing, or drawing, depending on the desired final product shape. During this stage, precise temperature control and uniform cooling rates are essential to prevent stress-induced defects that could affect light transmission properties.

After forming, the glass undergoes an annealing process to relieve internal stresses. This step is critical for maintaining optical clarity and preventing distortions that could impair light transmission. The annealing temperature and cooling rate must be carefully controlled to achieve optimal results.

Surface finishing techniques, such as polishing or fire polishing, are employed to enhance the glass surface's smoothness and reduce light scattering. Advanced polishing methods, including chemical mechanical polishing, can achieve surface roughness levels below 1 nanometer, significantly improving light transmission efficiency.

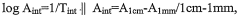

Quality control measures are implemented throughout the manufacturing process to ensure consistent optical properties. These include real-time monitoring of glass composition, thickness uniformity, and refractive index. Optical testing equipment, such as spectrophotometers and interferometers, is used to measure light transmission, reflection, and wavefront distortion.

Defect detection systems, including automated visual inspection and laser scanning, are employed to identify imperfections like bubbles, inclusions, or surface irregularities that could affect light transmission. Statistical process control techniques are applied to maintain tight tolerances and minimize variations in optical performance.

Advanced coating technologies, such as anti-reflective coatings, may be applied to further enhance light transmission. These coatings are carefully controlled for thickness and uniformity to achieve optimal performance across the desired wavelength range.

Stringent environmental controls, including clean room conditions for certain processes, are maintained to prevent contamination that could impact optical quality. Packaging and handling procedures are designed to protect the glass surfaces from damage during transportation and installation.

The molten glass then undergoes a forming process, which can include methods such as float glass production, pressing, or drawing, depending on the desired final product shape. During this stage, precise temperature control and uniform cooling rates are essential to prevent stress-induced defects that could affect light transmission properties.

After forming, the glass undergoes an annealing process to relieve internal stresses. This step is critical for maintaining optical clarity and preventing distortions that could impair light transmission. The annealing temperature and cooling rate must be carefully controlled to achieve optimal results.

Surface finishing techniques, such as polishing or fire polishing, are employed to enhance the glass surface's smoothness and reduce light scattering. Advanced polishing methods, including chemical mechanical polishing, can achieve surface roughness levels below 1 nanometer, significantly improving light transmission efficiency.

Quality control measures are implemented throughout the manufacturing process to ensure consistent optical properties. These include real-time monitoring of glass composition, thickness uniformity, and refractive index. Optical testing equipment, such as spectrophotometers and interferometers, is used to measure light transmission, reflection, and wavefront distortion.

Defect detection systems, including automated visual inspection and laser scanning, are employed to identify imperfections like bubbles, inclusions, or surface irregularities that could affect light transmission. Statistical process control techniques are applied to maintain tight tolerances and minimize variations in optical performance.

Advanced coating technologies, such as anti-reflective coatings, may be applied to further enhance light transmission. These coatings are carefully controlled for thickness and uniformity to achieve optimal performance across the desired wavelength range.

Stringent environmental controls, including clean room conditions for certain processes, are maintained to prevent contamination that could impact optical quality. Packaging and handling procedures are designed to protect the glass surfaces from damage during transportation and installation.

Environmental Impact and Sustainability

The environmental impact and sustainability aspects of research on efficient light transmission through borosilicate glass are significant considerations in the development and application of this technology. Borosilicate glass, known for its durability and resistance to thermal shock, has been widely used in various industries, including optics and photonics.

One of the primary environmental benefits of improving light transmission through borosilicate glass is the potential for energy conservation. Enhanced light transmission efficiency can lead to reduced energy consumption in lighting systems, particularly in applications such as solar panels, greenhouses, and architectural glazing. This reduction in energy usage contributes to lower greenhouse gas emissions and a decreased carbon footprint.

The production process of borosilicate glass itself has environmental implications. While it requires higher melting temperatures compared to soda-lime glass, resulting in increased energy consumption during manufacturing, the long lifespan and recyclability of borosilicate glass offset some of these initial environmental costs. Improved light transmission efficiency may also lead to the use of thinner glass sheets, potentially reducing raw material requirements and associated environmental impacts.

In terms of sustainability, the research on efficient light transmission through borosilicate glass aligns with several United Nations Sustainable Development Goals, particularly those related to affordable and clean energy, sustainable cities and communities, and responsible consumption and production. The technology's potential applications in solar energy harvesting and energy-efficient building designs contribute to these global sustainability objectives.

The recyclability of borosilicate glass is a crucial factor in its environmental profile. Unlike many other materials used in optical applications, borosilicate glass can be recycled multiple times without significant loss of quality. This characteristic supports circular economy principles and reduces the demand for virgin raw materials, thereby minimizing environmental impact over the long term.

However, it is important to note that the research and development process itself may have environmental implications. The use of specialized equipment, chemicals, and energy-intensive processes in the pursuit of improved light transmission efficiency should be carefully managed to minimize negative environmental impacts. Researchers and industry stakeholders should prioritize sustainable practices throughout the entire lifecycle of the technology, from initial research to final product implementation and eventual recycling.

As the technology advances, life cycle assessments (LCAs) will be crucial in quantifying the overall environmental impact of improved light transmission through borosilicate glass. These assessments should consider factors such as raw material extraction, manufacturing processes, use-phase energy savings, and end-of-life management. By conducting comprehensive LCAs, researchers and industry leaders can make informed decisions to optimize the environmental performance of this technology.

One of the primary environmental benefits of improving light transmission through borosilicate glass is the potential for energy conservation. Enhanced light transmission efficiency can lead to reduced energy consumption in lighting systems, particularly in applications such as solar panels, greenhouses, and architectural glazing. This reduction in energy usage contributes to lower greenhouse gas emissions and a decreased carbon footprint.

The production process of borosilicate glass itself has environmental implications. While it requires higher melting temperatures compared to soda-lime glass, resulting in increased energy consumption during manufacturing, the long lifespan and recyclability of borosilicate glass offset some of these initial environmental costs. Improved light transmission efficiency may also lead to the use of thinner glass sheets, potentially reducing raw material requirements and associated environmental impacts.

In terms of sustainability, the research on efficient light transmission through borosilicate glass aligns with several United Nations Sustainable Development Goals, particularly those related to affordable and clean energy, sustainable cities and communities, and responsible consumption and production. The technology's potential applications in solar energy harvesting and energy-efficient building designs contribute to these global sustainability objectives.

The recyclability of borosilicate glass is a crucial factor in its environmental profile. Unlike many other materials used in optical applications, borosilicate glass can be recycled multiple times without significant loss of quality. This characteristic supports circular economy principles and reduces the demand for virgin raw materials, thereby minimizing environmental impact over the long term.

However, it is important to note that the research and development process itself may have environmental implications. The use of specialized equipment, chemicals, and energy-intensive processes in the pursuit of improved light transmission efficiency should be carefully managed to minimize negative environmental impacts. Researchers and industry stakeholders should prioritize sustainable practices throughout the entire lifecycle of the technology, from initial research to final product implementation and eventual recycling.

As the technology advances, life cycle assessments (LCAs) will be crucial in quantifying the overall environmental impact of improved light transmission through borosilicate glass. These assessments should consider factors such as raw material extraction, manufacturing processes, use-phase energy savings, and end-of-life management. By conducting comprehensive LCAs, researchers and industry leaders can make informed decisions to optimize the environmental performance of this technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!